6 3LIOD2

EN

USE AND INSTALLING INSTRUCTIONS

Carefully read the following important information

regarding installation safety and maintenance.

Keep this information booklet accessible for further

consultations.

INSTALLING INSTRUCTIONS

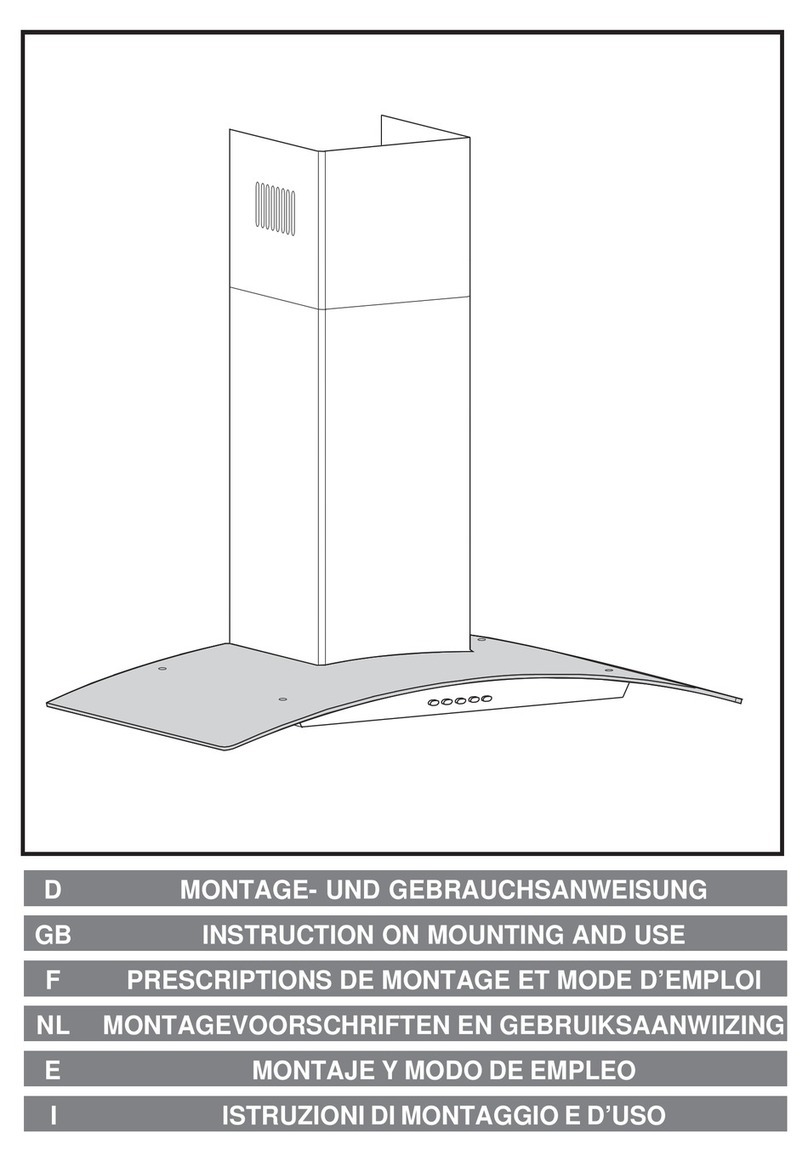

This hood has been arranged to be installed above

a cooktop. It can be used in 2 ways:

•EXHAUST MODE: the kitcken vapours are puried

by the metal anti-grease lters and carried outside

through a ducting system.

•RECIRCULATING MODE: the kitcken vapours

are puried by the metal anti-grease lters and

an activated carbon lter (sold separately), then

conveyed back into the kitchen.

We suggest to have installation carried out

by qualied personnel, in compliance with all

the current regulations and in particular with

the ones concerning air exhaust and electrical

connection.

The manufacturer cannot be held liable for

damages caused by improper installation or

if it has not been carried out according to the

state-of-the-art.

SAFETY

The appliance must be installed at a minimum

height of 65 cm from an electric cooker stove, or

75 cm from gas or combined cooker stoves (Fig.

8). If a connection tube composed of two parts is

used, the upper part must be placed outside the

lower part. Do not connect the cooker hood exhaust

to the same conductor used to circulate hot air or for

evacuating fumes from other appliances generated

by other than an electrical source.

Take care when the cooker hood is operating

simultaneously with an open replace or burner

that depend on the air in the environment and are

supplied by other than electrical energy, as the

cooker hood removes the air from the environment

which a burner or replace need for combustion.

The negative pressure in the environment must

not exceed 4 Pa (4x10 –5 bar). Provide adequate

ventilation in the environment for a safe operation of

the cooker hood. Follow the local laws applicable for

external air evacuation.

INSTALLATION

Components > see Fig.4

Use screws and screw anchors suitable for wall

(e.g. reinforced cement, plasterboard) for the

mounting of the cooker hood.

Where screws and screw anchors are supplied

ensure that they are suitable for the type of wall

where the cooker hood is to be mounted.

EXHAUST MODE INSTALLATION

• Drill the holes A-B-C for wall-xing according

to indications quoted in (Fig.3). Make the holes

that correspond with the centre of the hob and

so that the lower part of the hood, which is to be

assembled afterwards, is arranged at least 75 cm

from the cook top (Fig.8).

• Afx the support clamp Z (Fig.4) to the wall via

the drill holes C.

• Afx the support clamp D to the wall via the 4 drill

holesA.Ifthekitckenisprovidedwithawall ducting

system x the support clamp as shown on Fig.5.

If the kitcken is provided with a ceiling ducting

system x the support clamp in correspondence

to the ducting system hole as shown on Fig.6.

• Insert the connection block Eon the support

clamp D and x it using 4 screws (Fig.7).

• Cut the exhaust tube Ffollowing the indication

provided in gure 8.

• Insert the exhaust tube Fon the opening of the

hood body.

• Hang the hood on the support clamp Z and x it

using 4 screws (Fig.9).

• Fasten the cooker hood to the wall using the

security drill holes B (Fig.10).

RECIRCULATING MODE INSTALLATION

• Drill the holes A-B for wall-xing according to

indications quoted in (Fig.3). Make the holes

that correspond with the centre of the hob and

so that the lower part of the hood, which is to be

assembled afterwards, is arranged at least 75 cm

from the cook top (Fig.8).

• Afx the support clamp Z (Fig.4) to the wall via

the drill holes C.

• Hang the hood on the support clamp Z and x it

using 4 screws (Fig.9).

• Fasten the cooker hood to the wall using the

security drill holes B (Fig.10).

ELECTRICAL CONNECTION

The appliance has been manufactured as a class II,

therefore no earth cable is necessary.

The connection to the mains is carried out as

follows:

BROWN = L line BLUE = N neutral

If not provided, connect a plug for the electrical load

indicated on the description label. Where a plug is

provided, the cooker hood must be installed in order

that the plug is easily accessible.

An omnipolar switch with a minimum aperture of

3 mm between contacts, in line with the electrical

load and local standards, must be placed between

the appliance and the network in the case of direct

connection to the electrical network.

OPERATING CHECKS

Check lights and motor start-up on all speeds.

EN