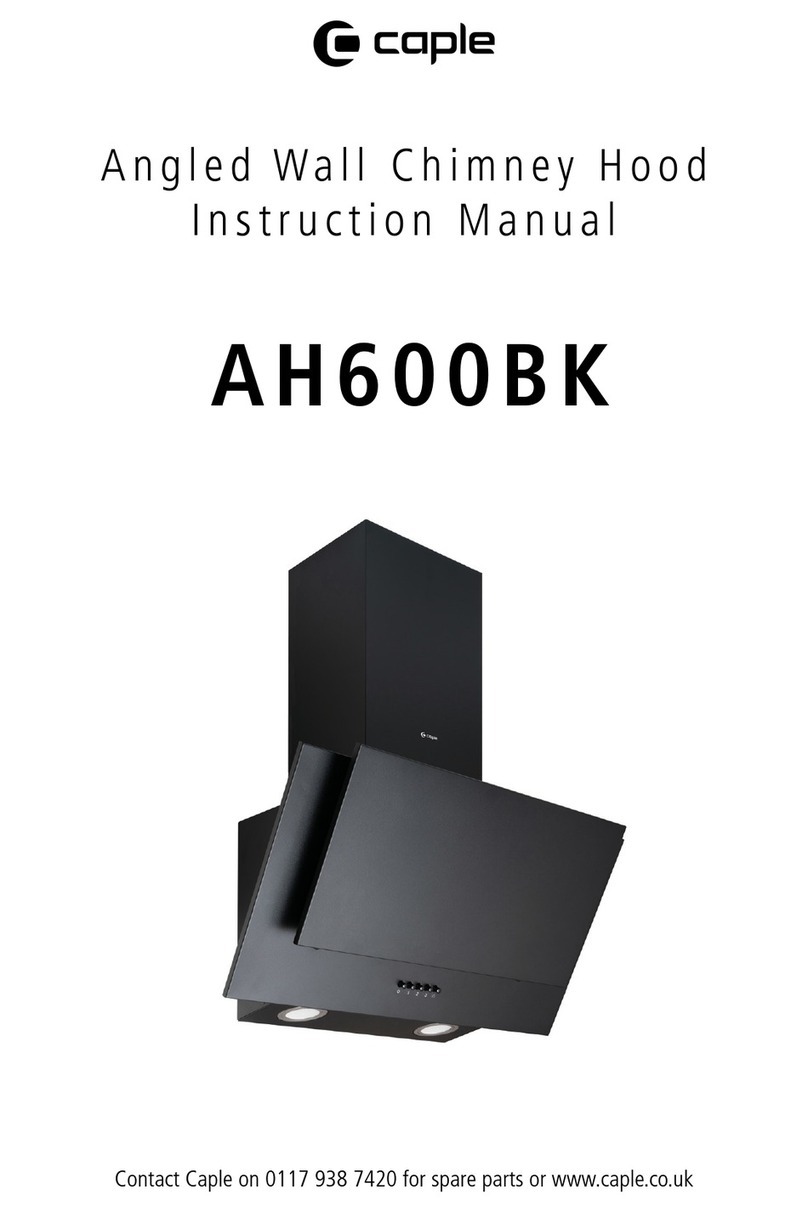

Instruction manual DD912BK 9

Please keep this instruction manual for future reference

INSTALLING THE EXTRACTOR

Before carrying out the appliance installation, please check that all components are not damaged,

in such a case contact your retailer and do not carry out any installation operation.

› Before the installation of the Downdraft, please remove the safety piece you can see in the

picture (Fig. 1). Furthermore, please read carefully all of the following

installation instructions.

› Use an air exhausting pipe whose maximum length

does not exceed 5 metres.

› Limit the number of elbows in the piping, since each

elbow reduces the air capacity of 1 linear metre. (eg.

if you use no. 2 x 90° elbows, the length of piping

should not exceed 3 metres).

› Avoid abrupt direction changes.

› Use a 150mm constant diametre rigid ducting pipe for

the whole length.

› Use piping approved by standards in force.

The manufacturer shall not be deemed responsible for air capacity or noise problems caused by

failure to comply with the above instructions and no warranty on the product shall be provided.

› Before making the hole, check that there are no

structural or other parts inside the cabinet, where

the appliance is to be placed, which could hinder a

proper installation. Check that the dimensions of the

Downdraft and the ones of the cook top are compatible

with the cabinet so that the installation can be carried

out properly.

› Make a rectangular opening, 842 x 100mm in size, in

the back of the cook top for the 90cm model, 1142 x

100mm for the 1200cm model and 542 x 100mm for

the 60cm model.

› Put the Downdraft in the opening, inserting it from above as shown in (Fig. 2).

1

2