Page 4 TSCH Slide-out Extractors.doc

INSTALLATION INSTRUCTIONS

INSTALLATION REQUIREMENTS

Please ensure that when the appliance is

installed it is easily accessible to an

engineer in the event of a breakdown.

All installations must comply with the local

authorities requirements for the discharge

of exhaust air.

Incorrect installation may affect the safety

of this cooker hood.

IMPORTANT: Before installation

check the wall to which the cooker

hood is to be fitted for electric

cables, water pipes or gas pipes

before drilling.

If it is necessary to fix the cooker hood to

a hollow construction plaster or partition

board structure then it must be sufficiently

reinforced to be quite rigid in the area of

the hood mounting brackets and special

screws and Rawlplugs may be required

which are suitable for hollow plaster or

partition board walls.

The installation work must be undertaken

by a qualified and competent person. The

manufacturer disclaims any responsibility

for damages due to incorrect installation

of the cooker hood or if the cooker hood

is not installed in compliance with the

relevant regulations controlling this type

of installation.

UNPACKING

Before unpacking the cooker hood

position the carton with the arrows

pointing upwards as illustrated on the

carton. Care should be taken when

unpacking the cooker hood to ensure that

the items supplied below are not thrown

away with the box.

1 No. Template

6 No. Fixing screws

1 No. 100mm dia. ducting spigot

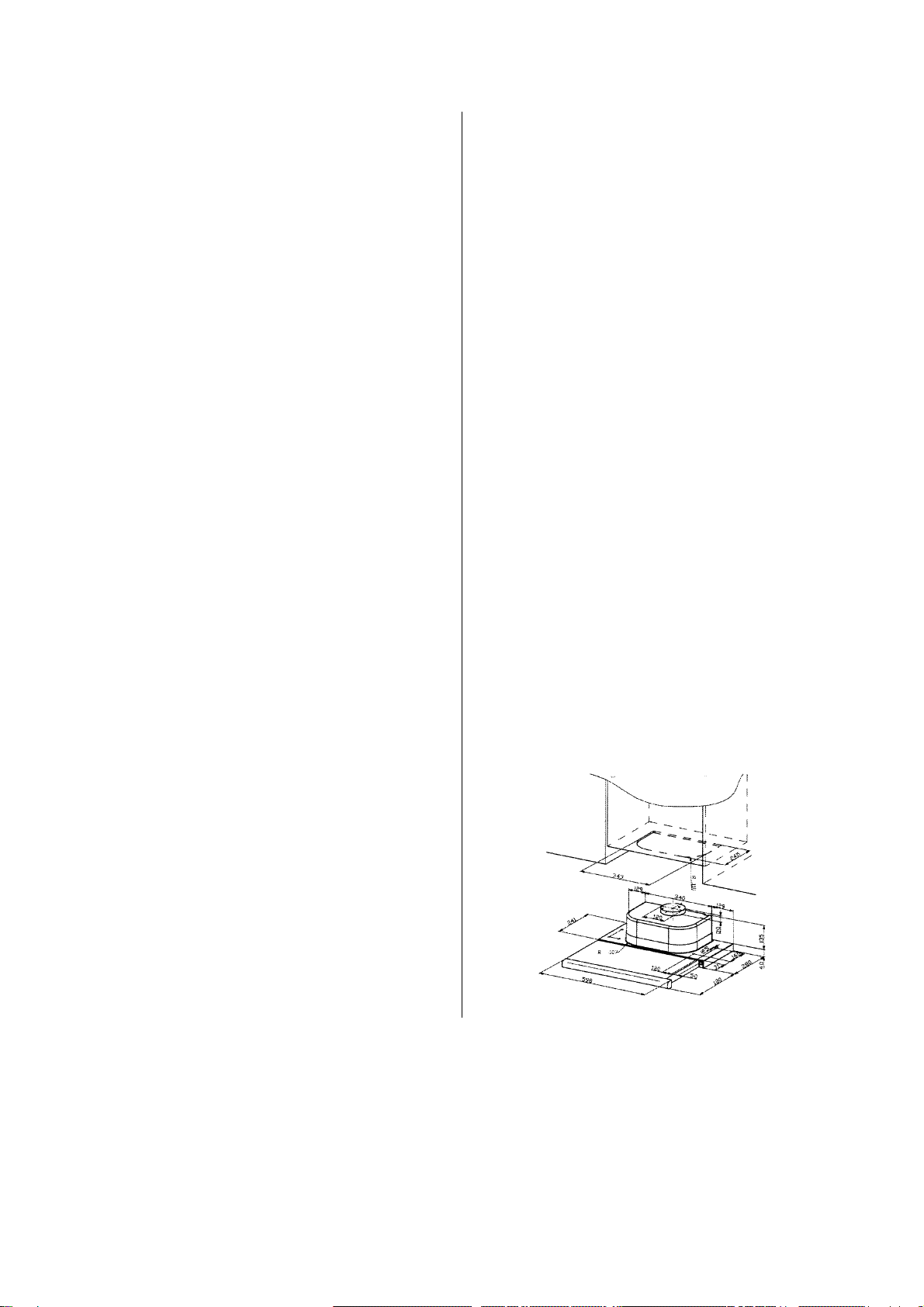

CLEARANCE HEIGHTS

The cooker hood is designed to be fitted

over a cooking appliance at the clearance

heights stated, provided the maximum

output of the hob beneath does not

exceed 7kw for electric and 10kw for gas.

If the output of the appliance below the

cooker hood exceeds the maximum

outputs quoted, please refer to the cooker

manufacturer's installation instructions.

A minimum height of 650mm is required

when installed above an electric hob, or

700mm when installed above a built-in

gas hob.

When installed between adjoining wall

cabinets, the wall cabinets must not

overhang the hob and the distance

between the underside of the cabinet and

the worktop must be 450mm. If the

height of the wall cabinet is less than

450mm a gap of 50mm must be

maintained either side of the hob.

Do not install above a cooker with a

high level grill.

FITTING INTO A WALL CABINET

To fit the cooker hood into the wall

cabinet, use the paper template provided

to mark the hole position on the underside

of the cabinet. When fitted the trim rail

along the front of the cooker hood must

align with the front of the cabinet door.

It is important to check the hole is

positioned correctly using a tape

measure before cutting the hole and

no metal fastenings obstruct the

cut-out.

Cut the hole in the base of the cabinet

using a pad saw or jig saw. Open the

metal grease filter tray and remove it.

Raise the hood into the cut-out ready for

fixing. Pilot drill the holes for the fixing

screws from inside the hood and fix the

hood using the screws in the bag of

fittings provided.