Carlisle Binks 85-441 User manual

Other Carlisle Controllers manuals

Carlisle

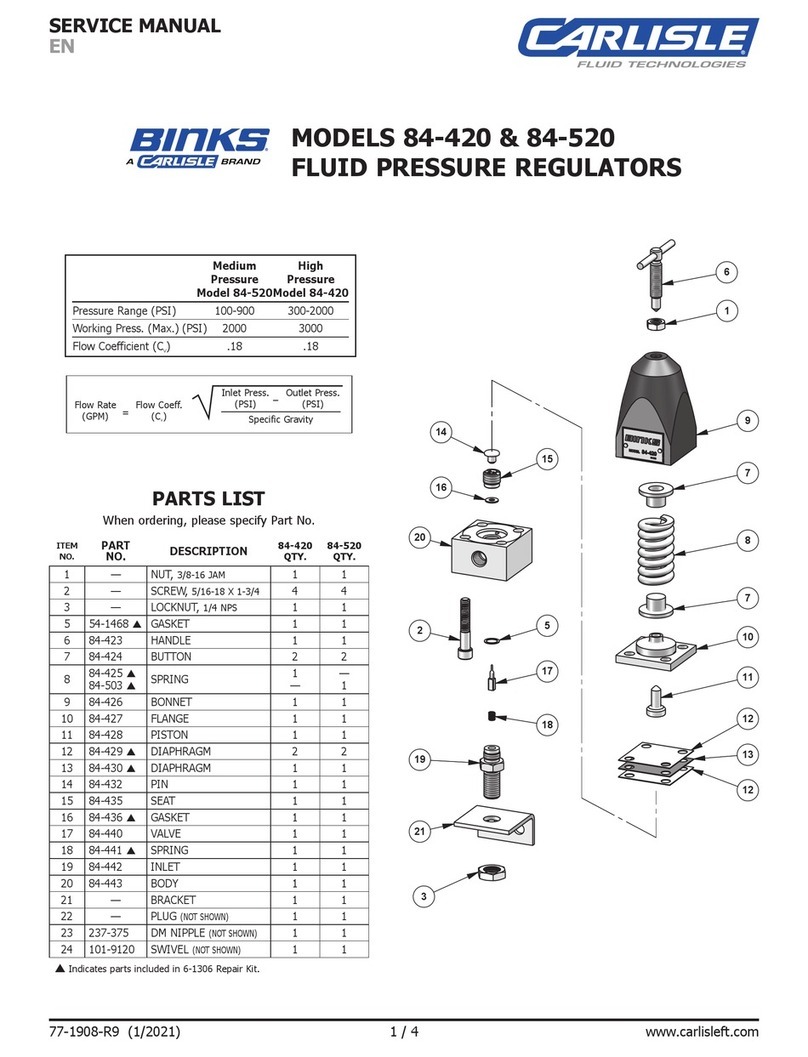

Carlisle BINKS 84-520 User manual

Carlisle

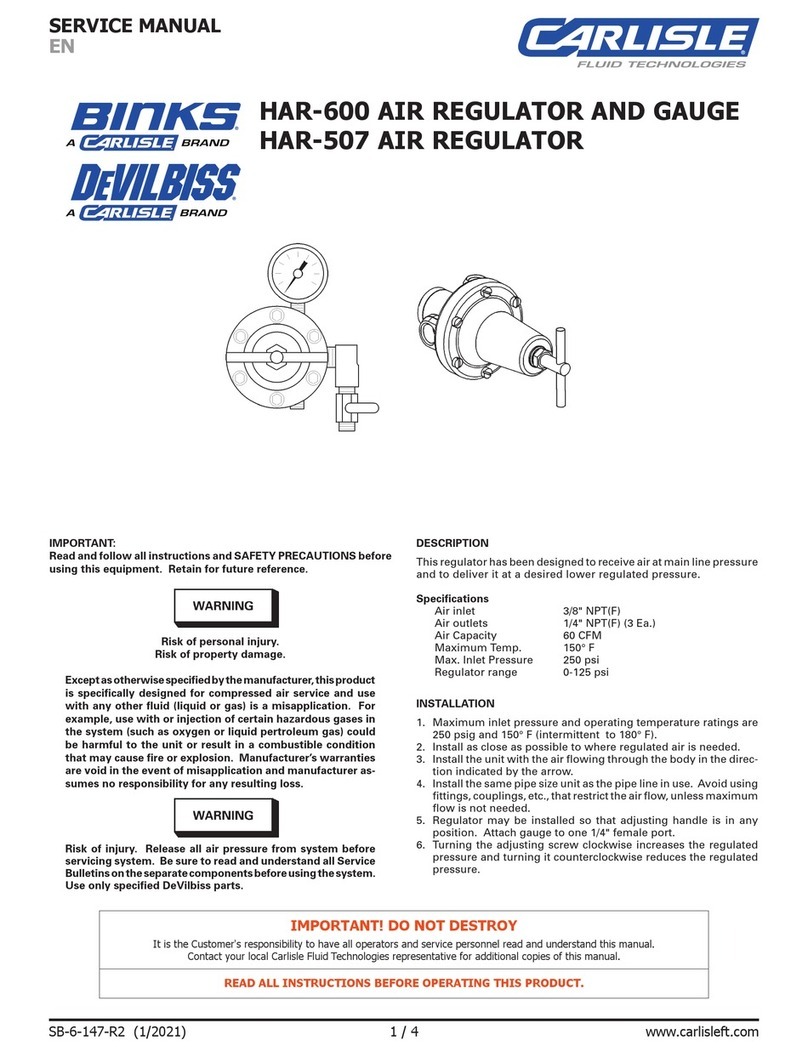

Carlisle BINKS DEVILBISS HAR-600 User manual

Carlisle

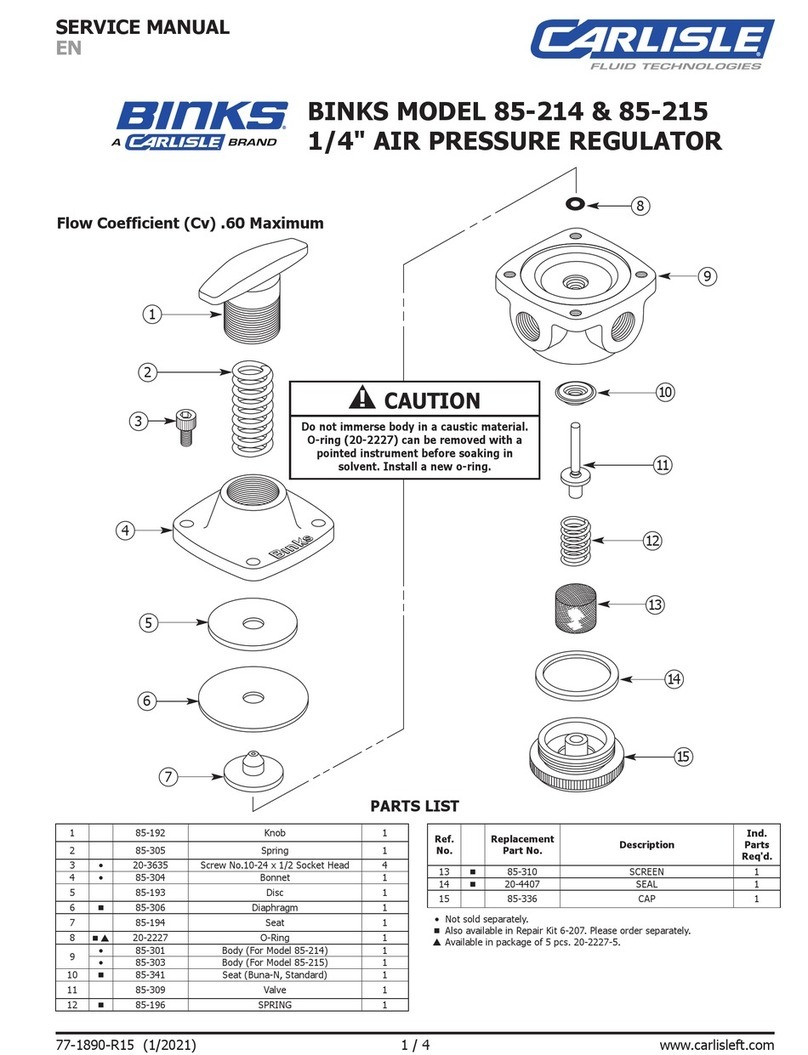

Carlisle BINKS 85-214 User manual

Carlisle

Carlisle 81-540 User manual

Carlisle

Carlisle DeVILBISS HGB Series User manual

Carlisle

Carlisle Ransburg DR-1 User manual

Carlisle

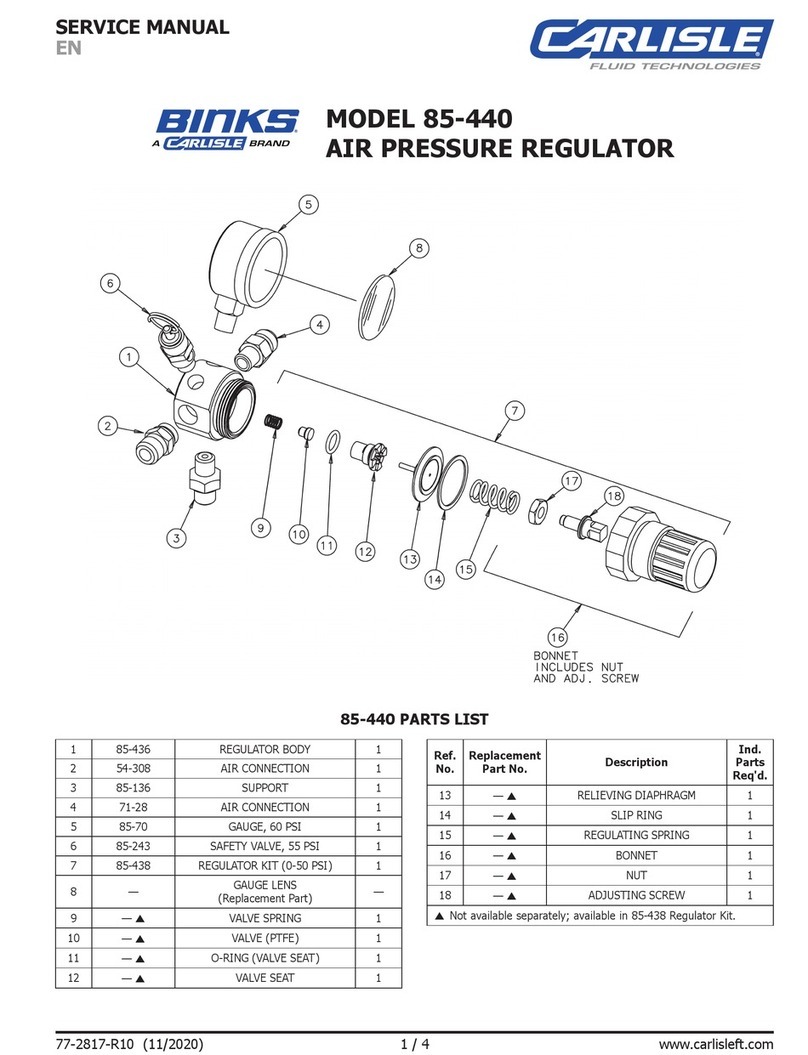

Carlisle Binks 85-440 User manual

Carlisle

Carlisle Binks 107757 User manual

Carlisle

Carlisle Ransburg 9060 User manual

Carlisle

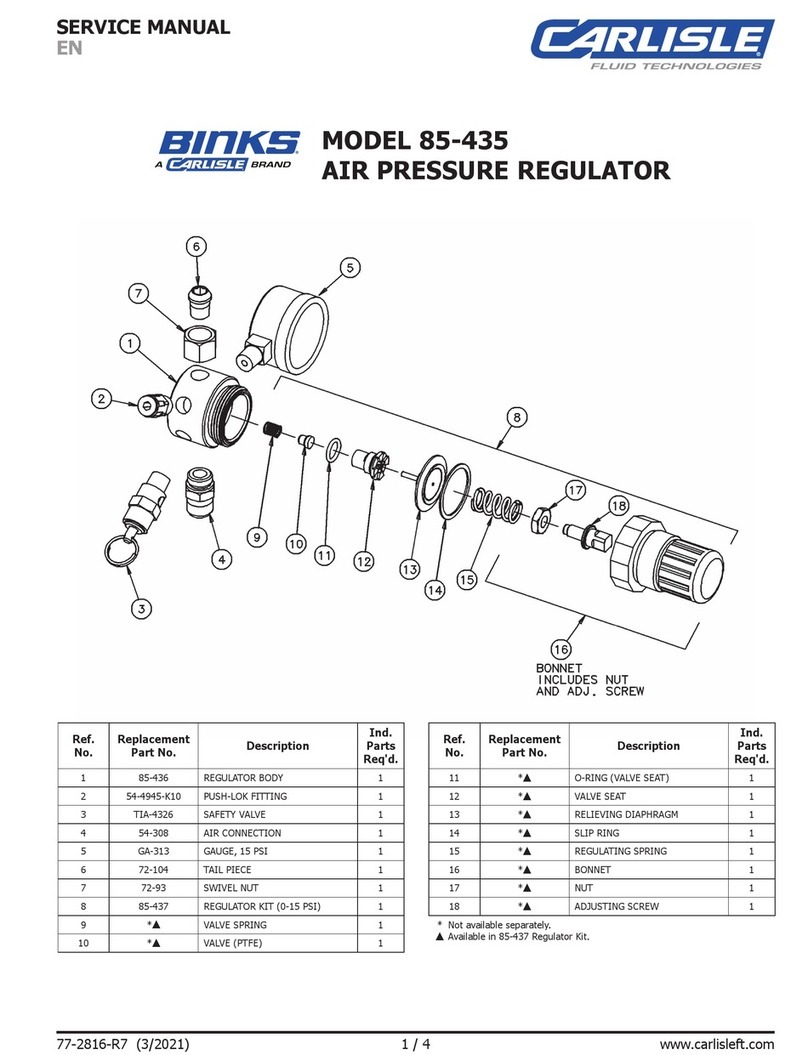

Carlisle BINKS 85-435 User manual

Carlisle

Carlisle MS Elite 461959 B Series User manual

Carlisle

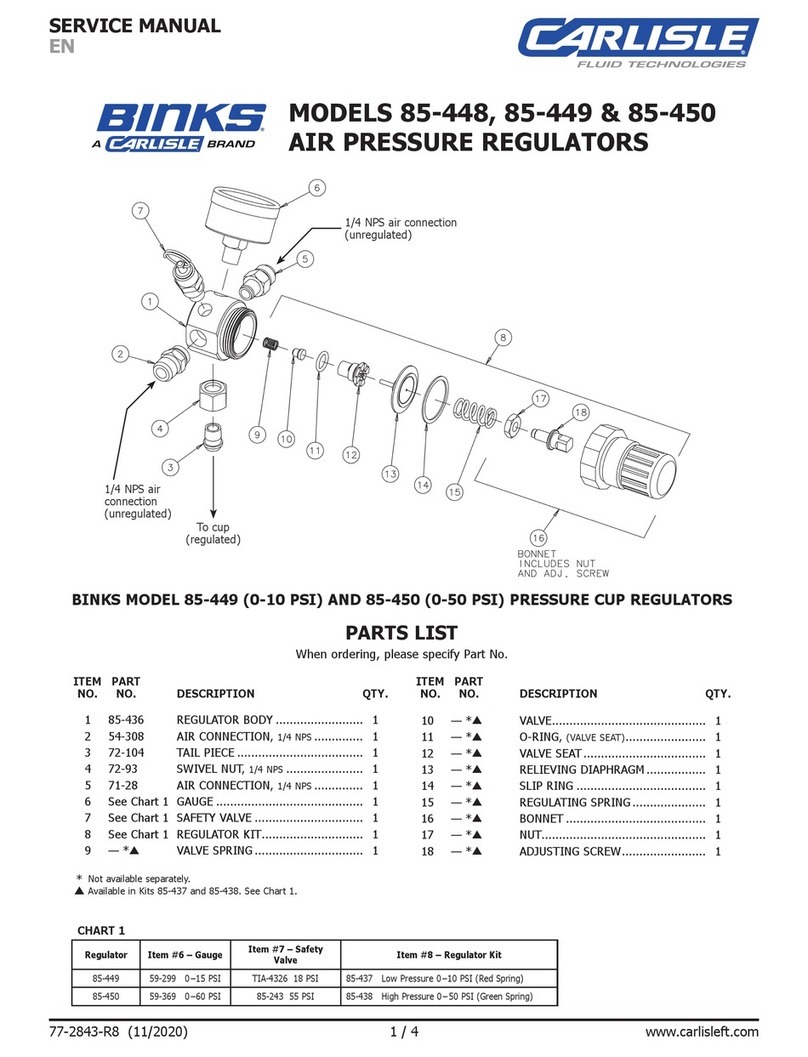

Carlisle BINKS 85-448 User manual

Carlisle

Carlisle Ransburg MicroPak 2e User manual

Carlisle

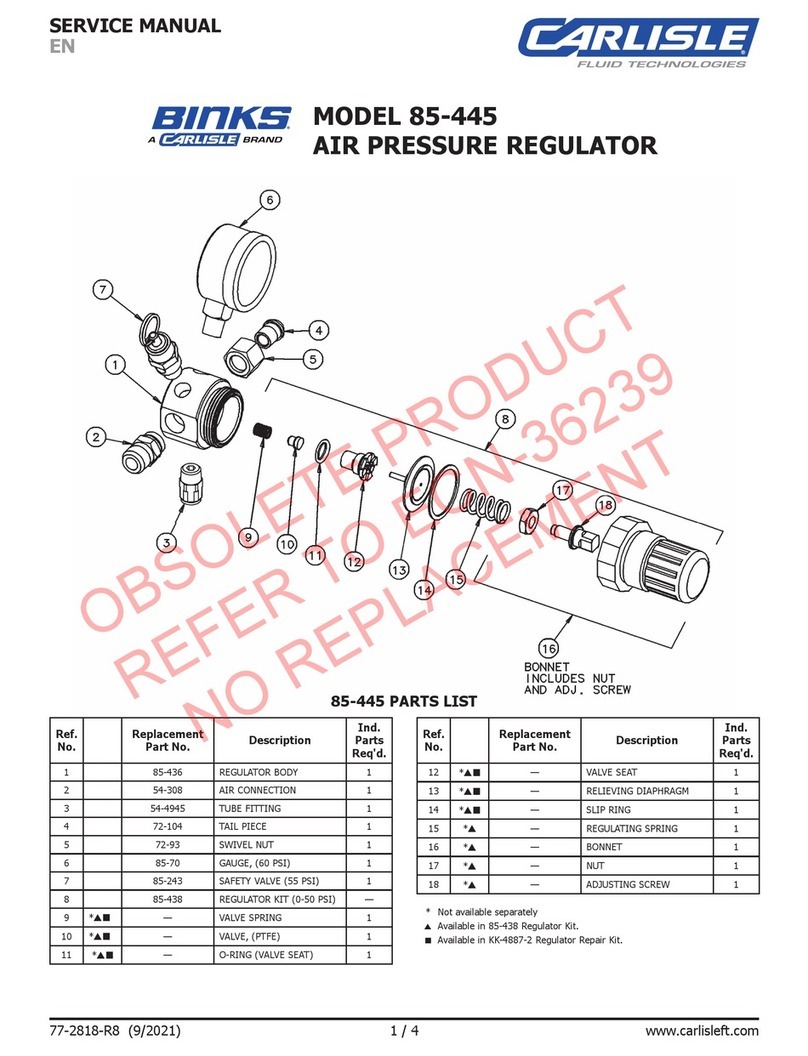

Carlisle BINKS 85-445 User manual

Carlisle

Carlisle Ransburg 9060 HV2 User manual

Carlisle

Carlisle BINKS 84-410 User manual

Carlisle

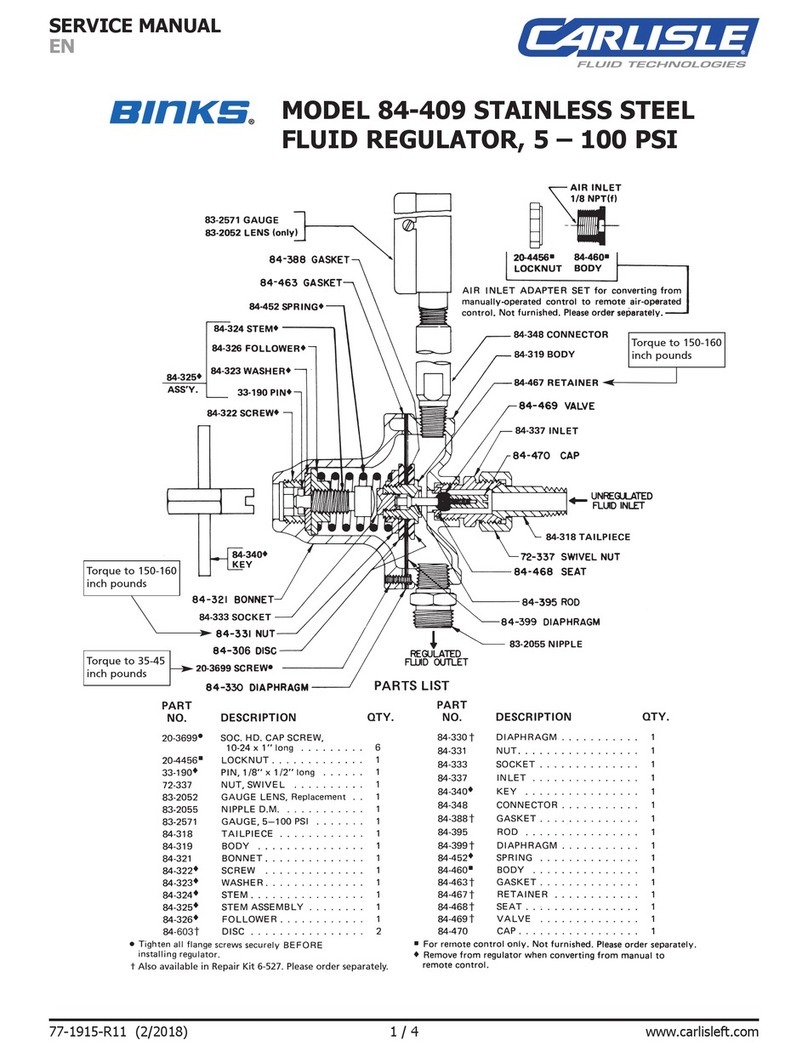

Carlisle Binks 84-407 User manual

Carlisle

Carlisle Binks 84-409 User manual

Carlisle

Carlisle Ransburg DynaFlow 77376 User manual

Carlisle

Carlisle Ransburg User manual

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions