Rev.00 - 09.2018 | LDP1/LDP2 Single and Dual Loop Detector | © 2018 | CARLO GAVAZZI Industri

3

EN

Table of contents

1. Introduction .............................................................................................................. 4

1.1 Description ..........................................................................................................................4

1.2 Validity of documentation ......................................................................................................4

1.3 Who should use this documentation........................................................................................4

1.4 Use of the product ................................................................................................................4

1.5 Safety precautions................................................................................................................4

1.6 Other documents..................................................................................................................4

1.7 Acronyms............................................................................................................................5

2. Product ..................................................................................................................... 6

2.1 Main features.......................................................................................................................6

2.2 Identification number ............................................................................................................6

2.3 Operating modes .................................................................................................................7

2.3.1 SIO mode.........................................................................................................................7

2.3.2 IO-Link mode ....................................................................................................................7

2.4 Output Parameters................................................................................................................8

2.4.1 Sensor front ......................................................................................................................8

2.4.2 Input selector ..................................................................................................................11

2.4.3 Logic function block .........................................................................................................11

2.4.4 Timer (Can be set individually for Out1 and Out2) ..............................................................13

2.4.5 Output Inverter................................................................................................................16

2.4.6 Output stage mode..........................................................................................................16

2.5 Teach procedure ................................................................................................................17

2.5.1 External Teach (Teach-by-wire)...........................................................................................17

2.5.2 Teach from IO-Link Master ................................................................................................17

2.6 Sensor Specific adjustable parameters .................................................................................20

2.6.1 Selection of local or remote adjustment ..............................................................................20

2.6.2 Process data and variables...............................................................................................20

2.6.3 Sensor application setting.................................................................................................20

2.6.4 Temperature alarm threshold.............................................................................................20

2.6.5 Safe limits.......................................................................................................................21

2.6.6 Event configuration..........................................................................................................21

2.6.7 Quality of run QoR..........................................................................................................21

2.6.8 Quality of Teach QoT.......................................................................................................22

2.6.9 Detection Filter ................................................................................................................22

2.6.10 LED activation ...............................................................................................................22

2.7 Diagnostic parameters ........................................................................................................23

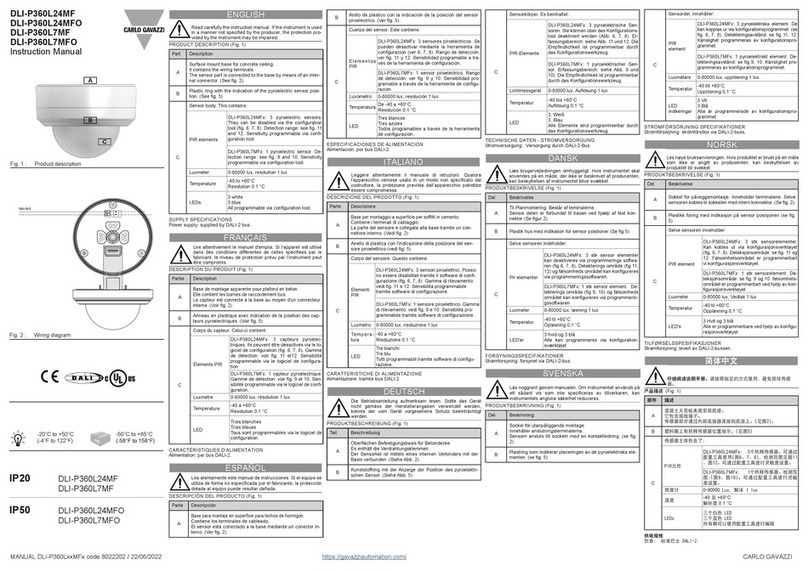

3. Wiring diagrams..................................................................................................... 24

4. Commissioning........................................................................................................ 24

5. Operation ............................................................................................................... 25

6. IODD file and factory setting ................................................................................... 26

6.1 IODD file of an IO-Link device..............................................................................................26

6.2 Factory setting ...................................................................................................................26

7. Appendix................................................................................................................ 26

7.1 Acronyms..........................................................................................................................26

7.2 IO-Link Device Parameters for CA18CA.. and CA30CA..........................................................27

7.2.1 Device parameters...........................................................................................................27

7.2.2 SSC parameters ..............................................................................................................28

7.2.3 Output Parameters...........................................................................................................29

7.2.4 Sensor specific adjustable parameters................................................................................30

7.2.5 Diagnostic parameters .....................................................................................................31

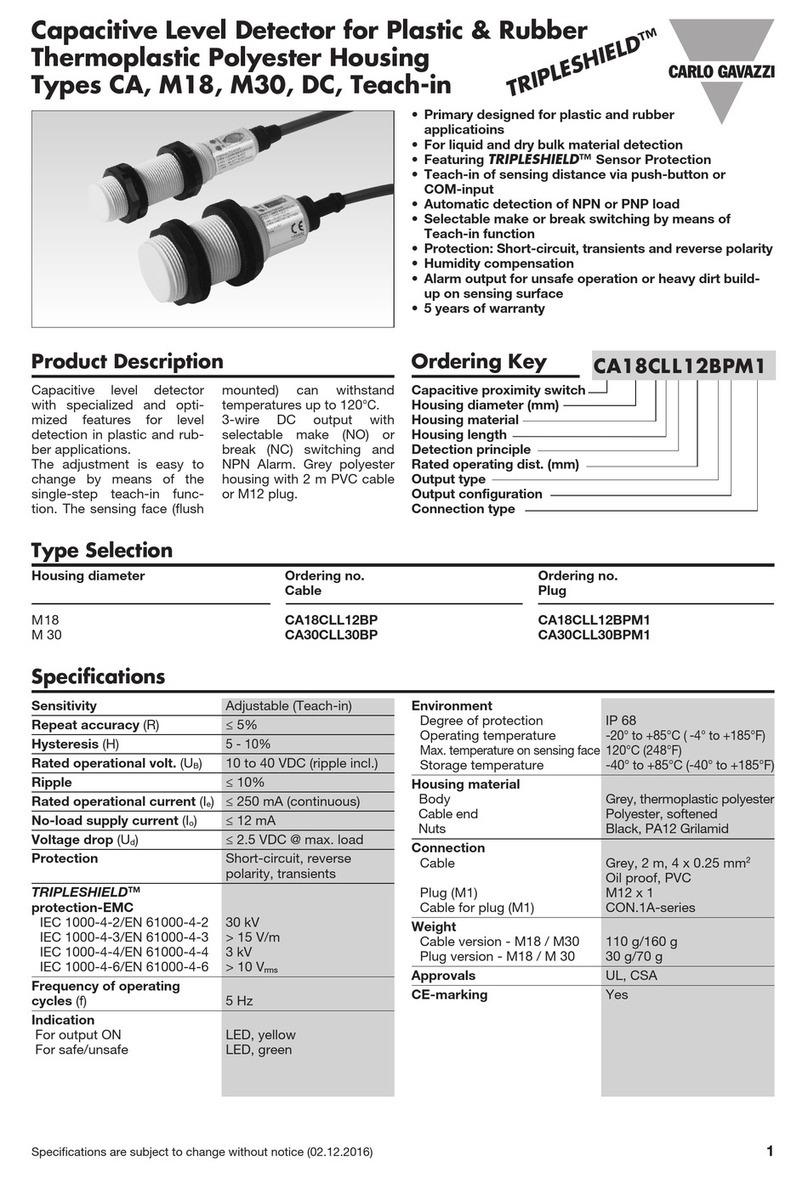

Dimensions ................................................................................................................. 212

Mounting .................................................................................................................... 212

Detection stability ....................................................................................................... 213

Installation hints ......................................................................................................... 214