Proceedasfollowsto inspectthecombustionareaand

power-ventingsystemofyourunit.

•Turn off gas supply to your unit.

• Turn off electrical power to your unit; install lockout tag.

• Remove gas component access panel.

• Using a flashlight, carefully inspect the burner areas for

dirt, soot, or scale.

EQUIPMENT DAMAGE HAZARD

Failure to follow this caution may result in damage to

equipment.

If dirt, soot, rust or scale accumulations are found, call

your service technician and do not operate your

heating section.

• When you have completed your inspection, follow the

start-up procedures in this manual to restore your unit

to operation.

PERSONAL INJURY HAZARD

Failure to follow this warning could result in personal

injury.

Components in heat section may be hot after unit has

been started up. When observing flame, be careful not

to get close to or touch heating components.

•Observe unit heating operation. Watch the burner flame

to see if it is bright blue. If you observe a suspected

malfunction or that the burner flame is not bright blue,

shut down the unit and call your dealer.

• Replace gas component access panel.

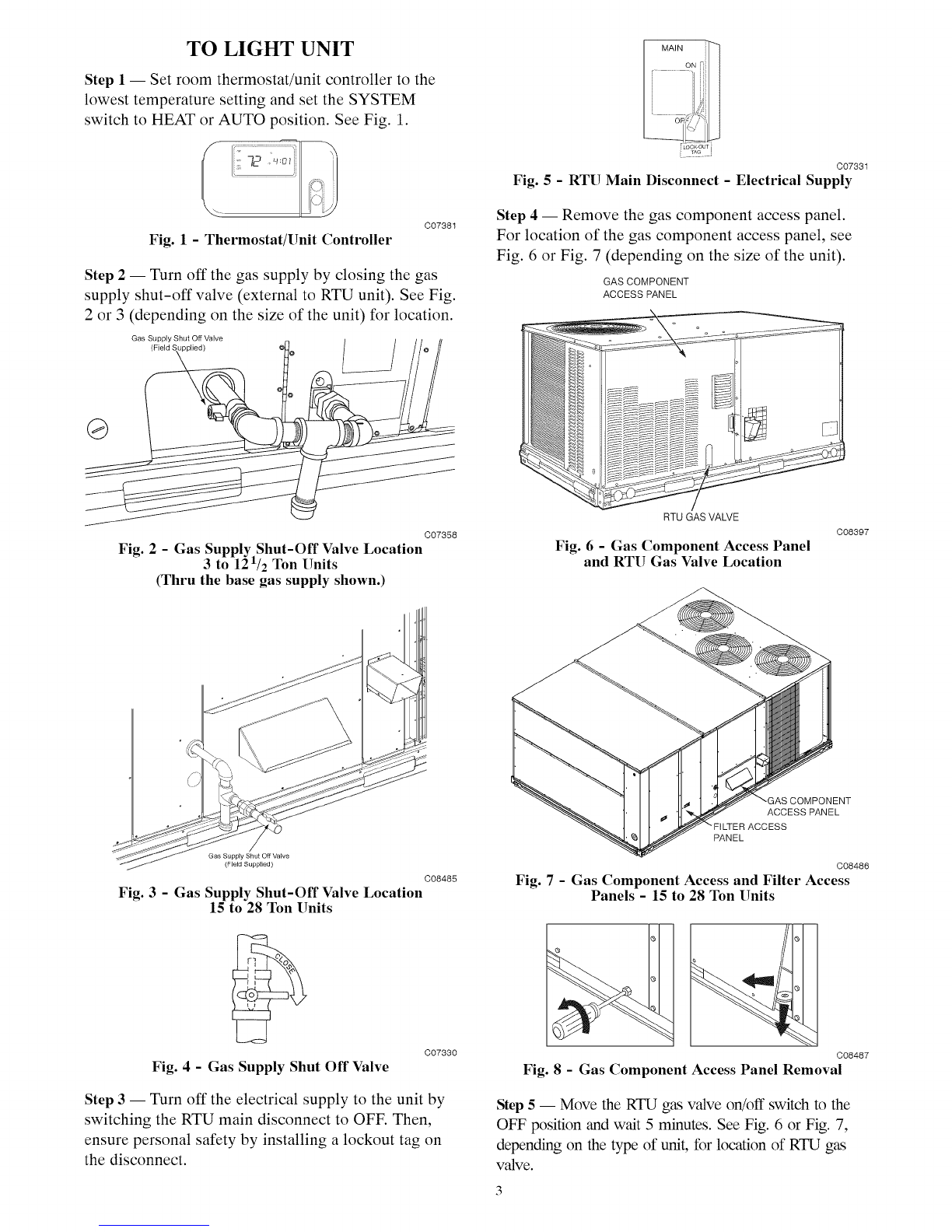

Integrated Gas Controller (IGC)

The IGC board incorporates an LED that emits a flashing

light to indicate an alarm code. If the furnace section will

not operate and the LED is flashing a code (1 to 9 flashes

in succession), contact your dealer and request service.

NOTE: Make note of the flash code before powering off

the unit. The alarm codes clear after power cycle.

Unit Panels

After performing any maintenance or service on the unit,

be sure all panels are securely fastened in place to prevent

rain from entering unit cabinet and to prevent disruption

of the correct unit airflow pattern.

BEFORE YOU CALL FOR SERVICE,

CHECK FOR PROBLEMS THAT

CAN BE EASILY SOLVED

If insufficient heating or cooling is suspected:

( ) Check for sufficient airflow. Check the air filter for dirt

Check for blocked return- or supply-air grilles. Be sure

they are open and unobstructed. If these checks do not

reveal the cause, call your servicing dealer.

If your unit is not operating at all, check the following list

for easy solutions:

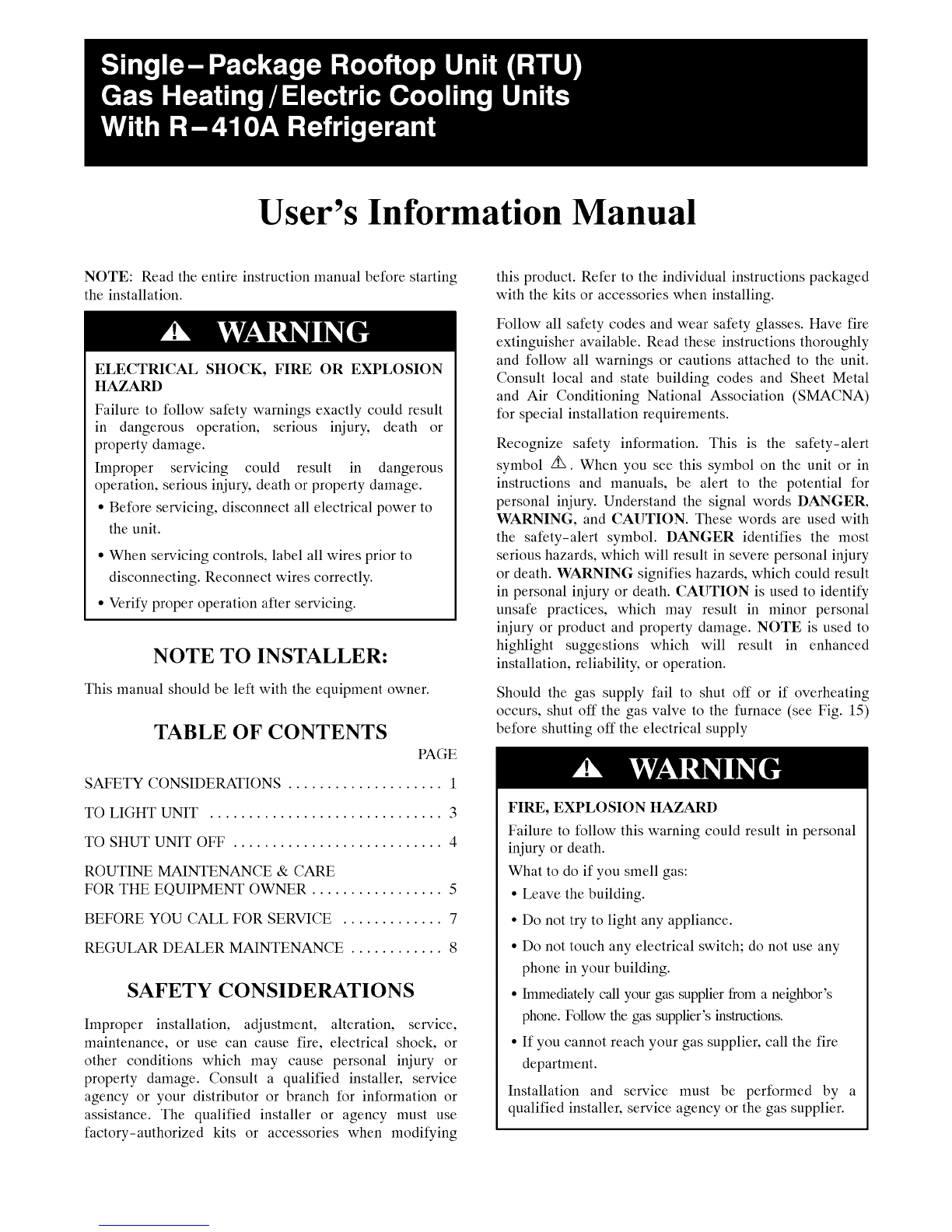

( ) Check to be sure that your thermostat/unit controller

temperature selector is set above the indoor temperature

during the heating season, or below the indoor

temperature during the cooling season. Be sure the

SYSTEM switch in the proper HEAT or COOL position

and not in the OFF position.

( ) Is the electrical supply switch ON'? Are any fuses

blown, or has the circuit breaker tripped'?

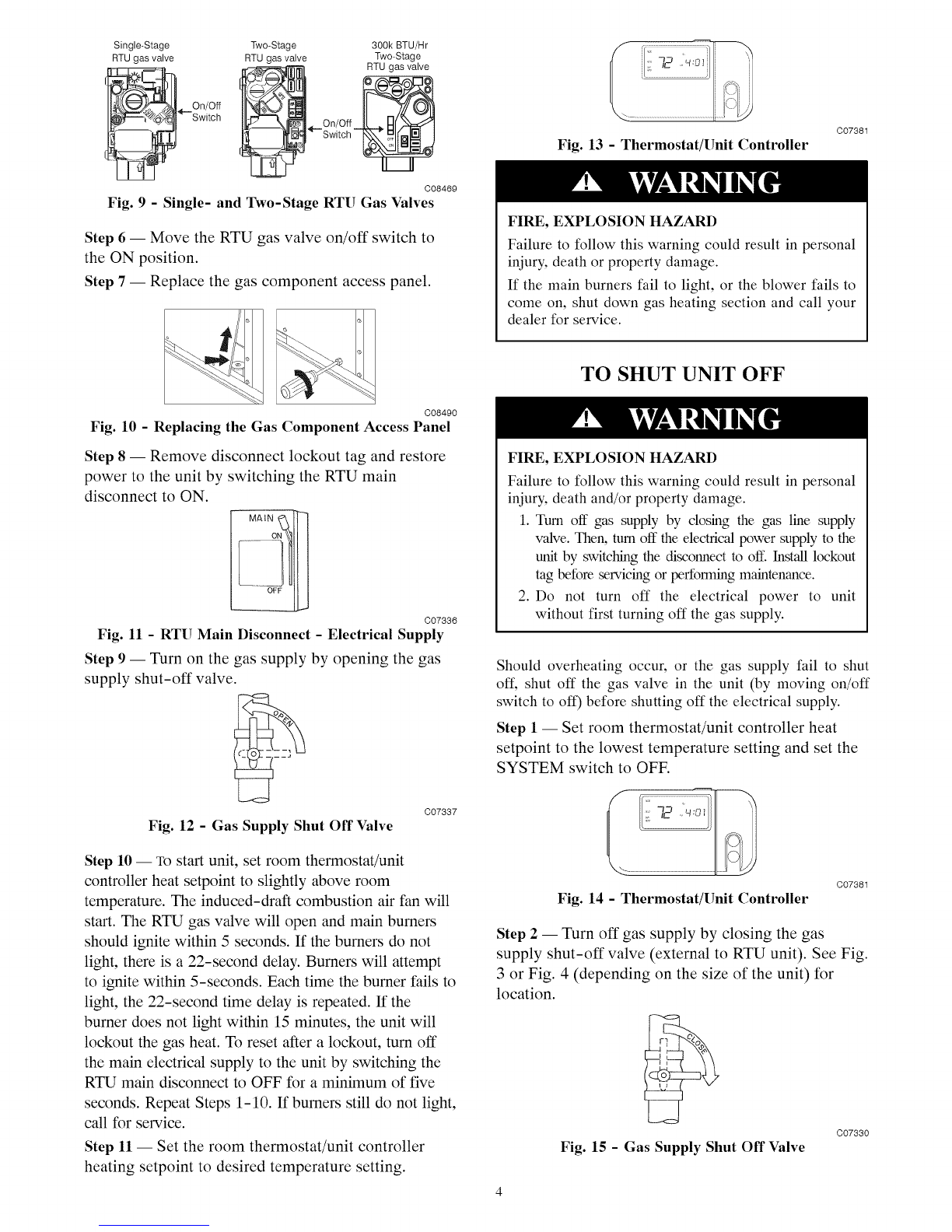

( ) During the heating season, check the external manual

shutoff valve. Is this lever parallel with the pipe,

indicating that the valve is open'? Or is the lever at the

right angle, indicating that the valve is closed'? If closed,

has the gas been shut off for safety reasons'? Otherwise,

you may open the valve and follow the start-up

procedures listed in this manual.

NOTE: Before proceeding with the next check, turn OFF

the electrical power supply to the unit. Remove the gas

component access panel.

( ) During the heating season, check the control switch on

the gas valve. Is it in the ON position'? If it is not, be sure

it has not been turned off for the purpose of safety. If no

safety hazards are present, follow the start-up procedures

in this manual.

( ) If your unit still fails to operate, call your servicing

dealer for troubleshooting and repairs. Specify the model

and serial numbers of your unit. (Record them in this

manual in the space provided.) If the dealer knows exactly

which unit you have, he may be able to offer suggestions

over the phone, or save valuable time through

knowledgeable preparation for the service call.

IN CASE OF TROUBLE

If, after performing the above checks, unit performance is

unsatisfactory, shut off the unit and call your dealer.

Dealer's Name

Telephone No.

Unit Model

Unit Serial Number