Wheel balancer 80-2000T. Operation Manual p.3

3

CONTENTS

1 WHEEL BALANCER APPLICATION ........................................................................... 5

2 TECHNICAL DATA ...................................................................................................... 6

3 ACCESSORIES ........................................................................................................... 7

4 STRUCTURE AND PREPARATION FOR OPERATION .............................................. 9

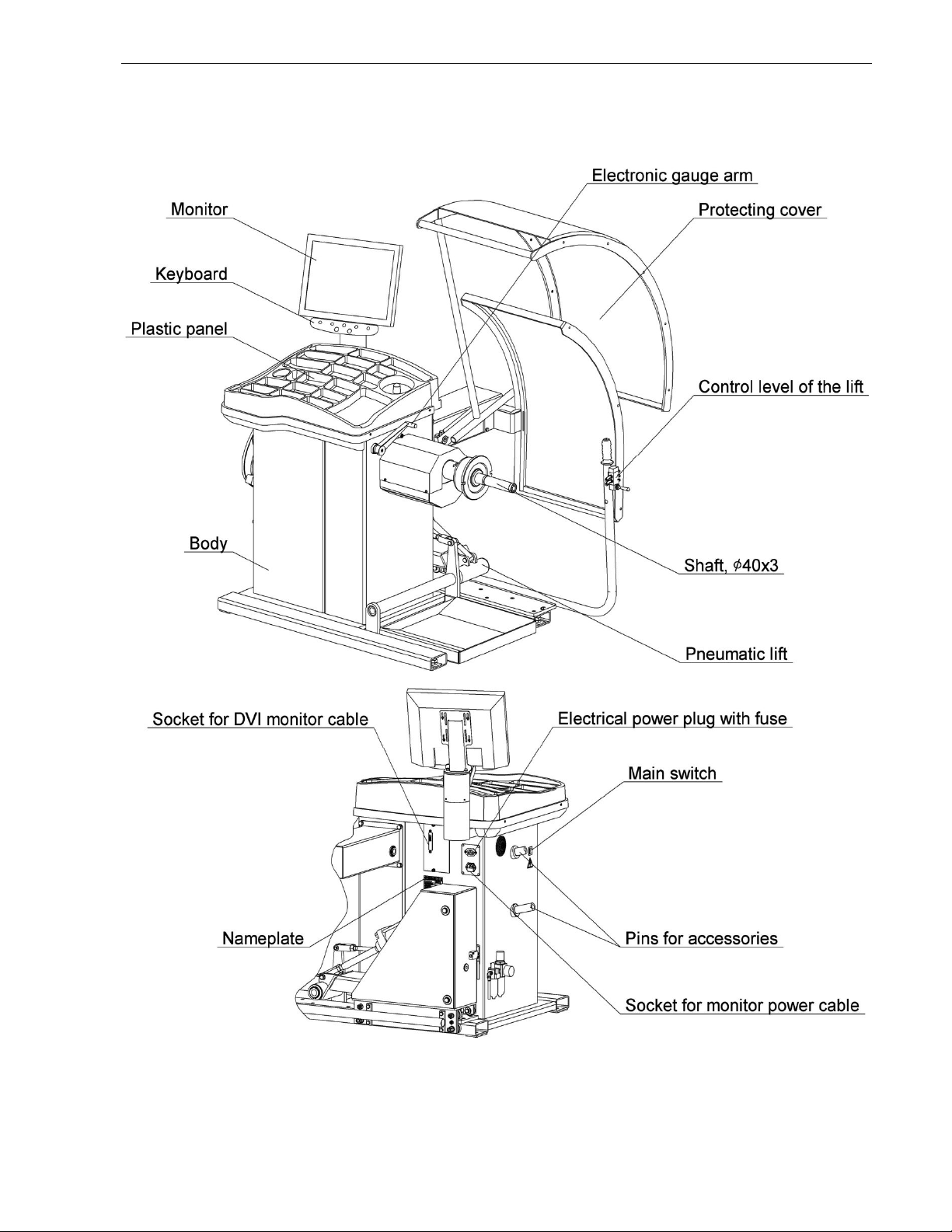

4.1 General machine structure................................................................................................ 9

4.2 Preparation of the machine for operation ..................................................................... 10

4.3 Control and display elements ......................................................................................... 13

4.4 Using the menu ................................................................................................................ 14

4.5 Switching the wheel balancer......................................................................................... 14

5 WHEEL BALANCING ................................................................................................ 16

5.1 Wheel balancing procedure ............................................................................................ 16

5.2 Wheel mounting ............................................................................................................... 16

5.2.1 Truck-car wheel mounting ........................................................................................... 16

5.2.2 Motor-car wheel mounting ........................................................................................... 17

5.3 Entering the type of the wheel: motor car or truck car................................................ 18

5.4 Wheel parameters input .................................................................................................. 18

5.5 Imbalance measurement ................................................................................................. 20

5.6 Weight setting................................................................................................................... 20

6 EXAMPLES OF WHEEL BALANCING ...................................................................... 22

6.1 Standard wheel balancing............................................................................................... 22

6.2 Alloy wheel (ALU) balancing........................................................................................... 23

7 ADDITIONAL POSSIBILITIES ................................................................................... 25

7.1 Effective alloy wheels balancing - SmartALU technology........................................... 25

7.2 Split – «hidden weight» ................................................................................................... 26

7.3 Effective work of three operators................................................................................... 27

7.4 Optimization...................................................................................................................... 27

7.5 Adaptor imbalance compensation ................................................................................. 28

7.6 Manual parameters setting.............................................................................................. 29

7.7 Report................................................................................................................................ 29

7.8 Wheel balancing recommendations............................................................................... 29

8 WHEEL BALANCER SETTING ................................................................................. 30

8.1 Parameters setting........................................................................................................... 30

8.1.1 Rounding: yes, no ........................................................................................................ 30

8.1.2 Null threshold (car): 0…15 ........................................................................................... 30

8.1.3 Null threshold (truck): 15…45 ...................................................................................... 31

8.1.4 Safety start: yes, no ..................................................................................................... 31

8.1.5 Stick-on weight setting: 6 h, 12 h ................................................................................ 31

8.1.6 SmartALU: yes, no ...................................................................................................... 31

8.1.7 Autoswitch to the «New wheel»: yes, no ..................................................................... 31

8.2 Shaft: Testing and calibration......................................................................................... 31

8.2.1 Shaft calibration testing ............................................................................................... 31

8.2.2 Shaft calibration ........................................................................................................... 32

8.3 Gauge arms: testing and calibration.............................................................................. 32