1. GENERAL PRECAUTIONS

Before operating the balancing machine, read carefully the use and maintenance manual. The noncompliance with these

standards frees the constructor from any responsibility.

1.1. Warnings and cautions

- The machine is to be operated only by authorized personnel.

- Check that the use of the balancing machine does not trigger off hazardous situations to people or things.

- When irregularities or malfunctions occur, stop immediately and require the intervention of the specialized technical

assistance.

- Any maintenance operation is to be carried out by specialized personnel.

- It is absolutely forbidden to alter equipment and safety devices.

- Any utilization of spare parts whose features do not correspond to the following specifications, any modifications or even

any little alterations, free the constructor from any responsibility related to proper use and safety for people and/or things.

1.2. Technical data

–

3

–

Product Weight

165.35lbs(75kg)

2.

INTRODUCTION

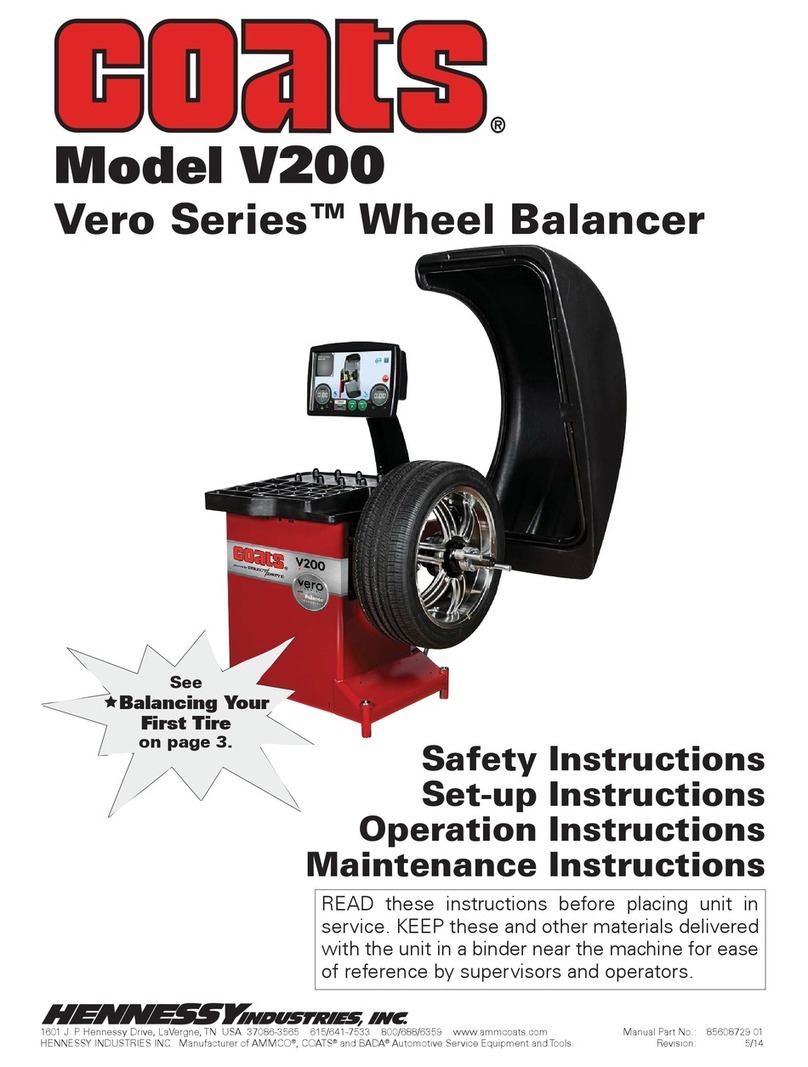

The

wheel

balancer

with

a

microprocessor,

capable

of

balancing

wheels

weighing

up

to

45

Kg.

The

control

elements

and

signals

are

all

contained

on

the

front

panel.

The

keyboard

calibration

system

also

provides

a

sufficient

adjustment

range

to

cope

with

unusual

wheels

(acing

motorcycles

and

cars).

Some

ALU

functions

are

available

for

specially

shaped

wheels

or

for

presetting

optional

balancing

machine

functions.

NOTE

:

Accessories for motorcycles need to be equipped by the customer himself.

Motor 110V,

60Hz,

1Ph,

0.34HP(

0.25kW

)

Cycle

Time 6

to

9

seconds

Data

Entry Keypad

Balancing

Modes Dynamic/Static/Alloy

Rim Diameter Capacity 11 31/32 - 24 1/64 in ( 304 - 610 mm )

Rim

Width Capacity 53 3/64 - 10 15/64 in ( 140 - 260 mm)

Max. Wheel Diameter 40 15/16 in ( 1040 mm )

Max. Wheel Weight 99.2 lbs ( 45 kg )

Shaft Size 36 mm

Max. Shaft Weight 48.5 - 50.7 lbs ( 22 - 23 kg )

Balancing Speed 250 RPM

Accuracy 0.035 ounces ( 1 gram )

Display Standard Or Metric

Self Calibration Yes

Power Cord Length 96 1/16 in ( 2440 mm )

Noise Level <70 dB

Product Dimensions L 40.55 x W 24.4 x H 38.19 in ( 1030 x 620 x 970 mm )