IDEAL 60-1500 Wheel Aligner Manual

Table of Contents

———————————————————————————————————————-

I. Introduction...........................................................................................................3

1.1 Warning..................................................................................................................3

1.2 Safety warning.......................................................................................................3

II. Getting Started......................................................................................................5

2.1 Equipment transport conditions.............................................................................5

ncrating Instructions..................................................................................................5

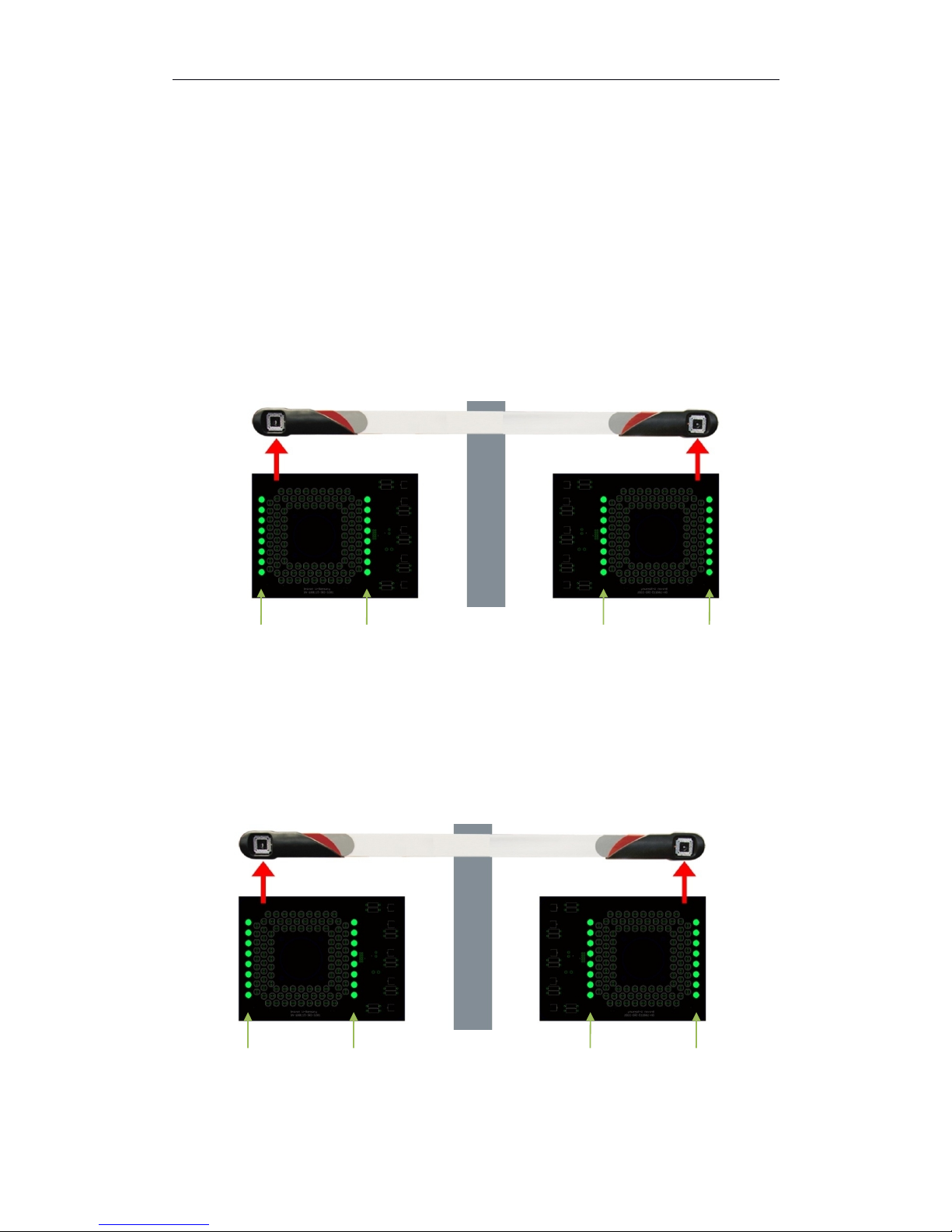

2.2 Smart LED board...................................................................................................6

2.3 Equipment and Servicing.......................................................................................8

1. Check List.........................................................................................................8

2. Camera Care....................................................................................................9

3. Target Care.......................................................................................................9

III. Installation Guide................................................................................................10

3.1 Installation Dimensions........................................................................................10

3.1.1 Camera Beam Position..............................................................................10

3.1.2 Level Lift.....................................................................................................11

3.2 Positioning............................................................................................................13

3.3 Installing wheel clamps and target.......................................................................14

3.3.1 Installing wheel clamps..............................................................................14

3.3.2 Fixing targets.............................................................................................14

3.4 Installing/Removing brake depressor..................................................................15

3.5 Installing/Removing steering wheel holder..........................................................15

IV. Software..............................................................................................................16

4.1 Opening/Closing Alignment software...................................................................16

4.2 Hot keys...............................................................................................................17

4.3 Visual Check........................................................................................................18

4.4 Standard Measurement.......................................................................................18

4.5 Quick Measurement.............................................................................................37

4.6 Aligner Management............................................................................................40

V.Technical data.............................................................................................................45

5.1 Measuring Range.................................................................................................45

5.2 Power supply unit.................................................................................................45

Appendix I . Troubleshooting.............................................................................................46

2