•Securethepistonwithoutspringinthesameholeshownabove.

With the barrier open, the spring must NOT be

compressed.

•Installthebeamanditsfixingpocketusingtheprovidedscrews,

asshowninFig.17,ref.fromato h(therubberprofileofthe

beammustfacetheclosingdirection)

Do not grease the xing screw of the bar.

•Ifthe application requiresasegmented bar, oncethefirst

segment and fixing pocket have been assembled, close

theautomatic system, lock it andfollowthe instructions for

additionalsegmentassembly,asshowninFig.20,ref. from

ato d

•Adjusttheopeningandclosingmechanicalstopsasshownin

Fig.15,andtightenthelocknut.

•Ensure that the beam is balanced following the instructions

containedinparagraphs4.5and4.6.

The compartment should be fixed, as shown in the

sequence in Fig. 21, when all mechanical installations,

wiring and start-up have been completed.

4.5 Fixing the plunging pistons

Barrierbalancingisobtainedbycorrectlyadjustingthespringpreload

ringnut(seenextparagraph)butalsobysettingthetwoplunging

pistonsinthemostsuitableposition.Thispositionisdeterminedby

thelengthofthebeamandthepresenceofanyaccessoriesthat

maybeappliedtoit(seeparagraph11).

4.6 Balancing the barrier

WARNING: This procedure must be carried out as the barrier is

not internally balanced. The beam is balanced when, operating

manually (ref. paragraph 6) the beam remains stationary in the

45° position.

Tobalancethebarrier,proceedasfollows:

•Installthebarandallrelatedaccessoriesonthebarrierstructure,

asrequiredbythefinalconfigurationofthesystem.

• Ensurethattheoperatorisreleased:seeparagraph6.

• Ensurethattheplungingpistonsaresecuredontherockerarm

accordingtotheinstructionsinparagraph11inTable2orTable

3,dependingontheinstalledbeammodel(SorL,respectively)

• Manuallymovethebartothe45°positionandverifyitremains

stationary.Ifthebartendstoopen,turnthespringpreloadring

nutanti-clockwise(Fig.16ref.a);ifittendstoclose,turnthering

• nutclockwise(Fig.16ref.b).

5. START-UP

5.1 Connecting the control equipment

WARNING: Before carrying out any work on the control board

(connections, maintenance, etc.) always cut off the electrical

power.

For all automatic system connections and testing, refer

to the section dedicated to the electronic equipment,

paragraph 1 on page 6 and following.

5.2 Testing the automated system

Onceinstallationhasbeencompleted,applythe"danger"signsticker

(ref.Fig.29)tothetopoftheuprightprofile.Proceedtoensurecorrect

operationoftheautomatedsystemandalltheaccessories

connected to it.

Give the Customer the “User’s Manual”, the

documentation required by current law and show how

to correctly operate the barrier, pointing out the areas

of potential danger.

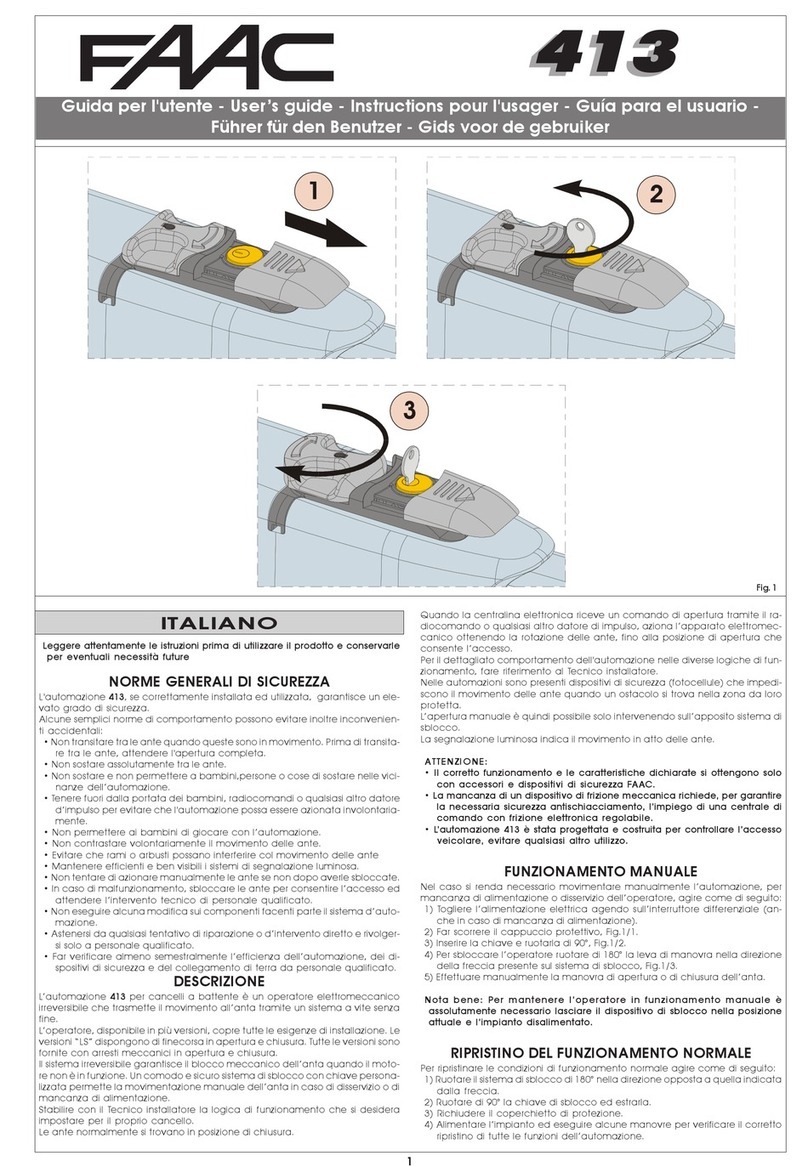

6. MANUAL OPERATION

Shouldmanualoperationofthebarrierberequiredduetoelectrical

power cut-offs or automated system inefficiency, use the release

devicewiththeprovidedkey.

Theprovidedunlockingkeyiseithertriangular(Fig.18ref.a) or

customised(Fig.18ref.boptional).

•Insert the unlocking key in the lock and turn the key

anticlockwiseuntilitclicksintoplace,asshowninFig.18

• Openorclosethebeammanually.

With the bar released, the motor may start for

approximately 3 seconds. This is normal and determined

by the parameter Hold Close / Hold Open

7. RESTORING NORMAL OPERATION

Toavoidanaccidentalpulseopeningthebarrierduringthisoperation,

beforeactivatingthelockingsystem,cutoffallpowertothesystem.

triangular unlocking key (standard):

- turnthekeyclockwiseuntilitstopsandthenremoveit(Fig.18

ref. a).

customised unlocking key (optional):

- turnthekeyclockwiseuntilitstopsandthenremoveit(Fig.18ref.

b).

8. MAINTENANCE

Whenperformingsix-monthmaintenance,alwayscheckthecorrect

balancing of the system and the correct operation of the safety

devices.

8.1 Topping up the oil

Checktheamountofoilinthetankevery6months.

Thelevelmustbeincludedbetweenthetwonotchesontheinspection

rod.

Totopup,unscrewthefillercap(Fig.12ref.a)andpouroilupto

the indicated level.

UseonlyFAACHPOIL.

8.2 Air bleeding

FAACproductsaredeliveredalreadybledofanyairinthehydraulic

circuit. Maintenance operations, replacing spare parts (e.g.

connectionpipes)orcarelesstransportcancauseentryofairinthe

hydrauliccircuit,whichinturncancauseoperatorirregularmovement

orreduceitstorque.Shouldbeammovementbeirregular,release

theairfromthehydraulicsystemfollowingtheinstructionsbelow:

• Electricallyoperatethebeam:

•When opening is completed, slightly loosen and tighten the

bleeder screw of the piston with the balance spring (Fig. 5

ref. d).

•Whenclosing is completed,slightlyloosen and tighten the

bleederscrewofthepistonwithoutthebalancespring(Fig.5

ref. l).

If necessary, repeat the operation until regular movement of the

beam is obtained.

Care needs to be taken at this stage as the pistons

contain oil under pressure which could leak out if the

screws are loosened too much.

If the parameters FO and FC in Advanced

Configuration have been changed and set to a value

lower than default, during bleeding we recommend

setting them to an equal or greater value, to facilitate

air bleeding