Page 4

Requi ements

All G26 units are C A International certified to AN I

Z21.47 and C A 2.3 standards.

In the U A, installation of Lennox gas central furnaces must

conform with local building codes. In the absence of local

codes, units must be installed according to the current NaĆ

tional Fuel Gas Code (AN I-Z223.1) in the United tates.

The National Fuel Gas Code is available from the following

address:

American National tandards Institute, Inc.

11 West 42nd treet

New York, NY 10036

In Canada, installation must conform with current National

tandard of Canada CAN/CGA-B149.1 Installation Code

for Natural Gas Burning Appliances and Equipment" and

CAN/CGA-B149.2 Installation Code for Propane Gas

Burning Appliances and Equipment," local plumbing or

waste water codes and other applicable local codes.

Adequate clearance must be made around the air openĆ

ings into the vestibule area. Provisions must be made for

proper operation and for combustion air and ventilation air

supply according to the current National Fuel Gas Code or

CAN/CGA-B149 standards.

This furnace is C A International certified for installation

clearances to combustible material as listed on the unit rating

plate and in table 1.

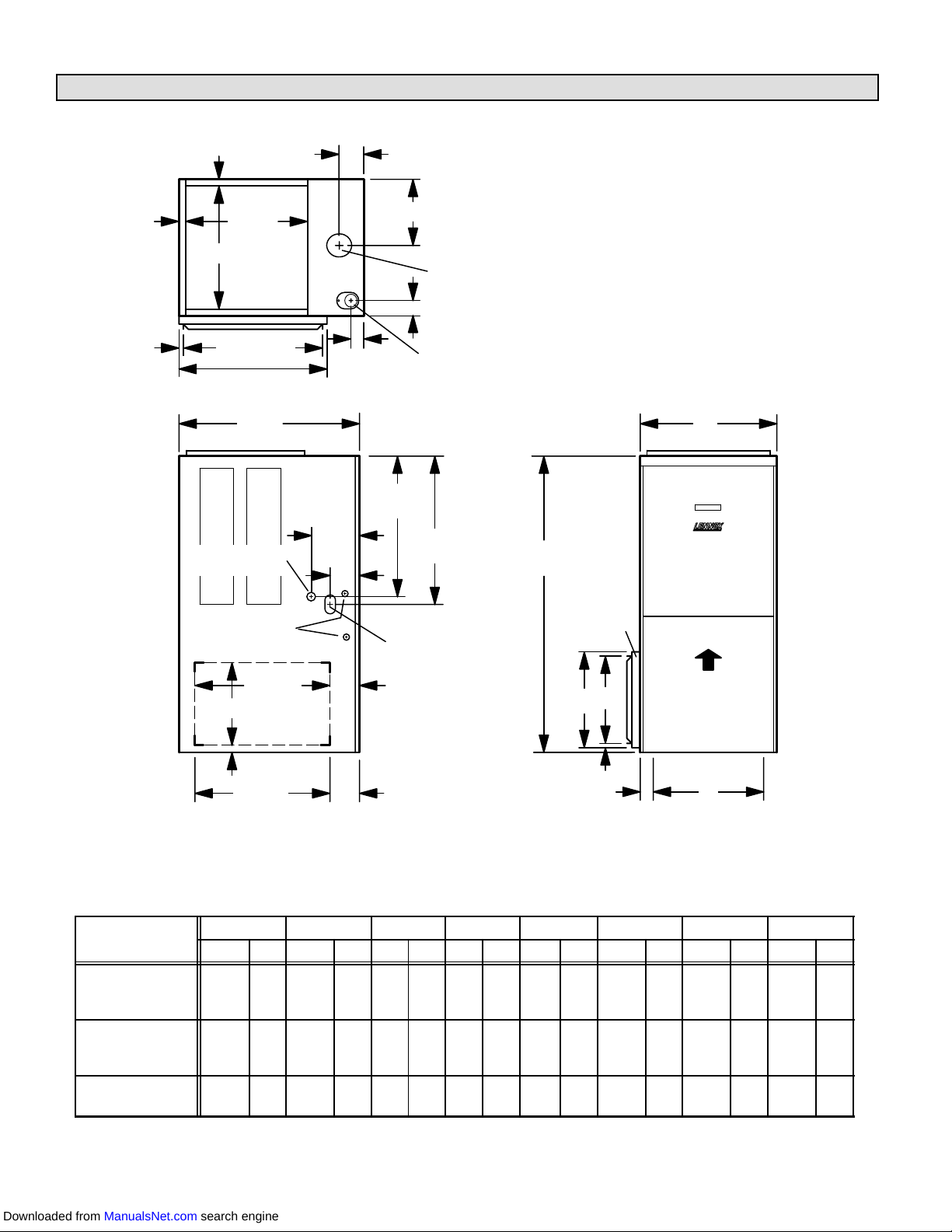

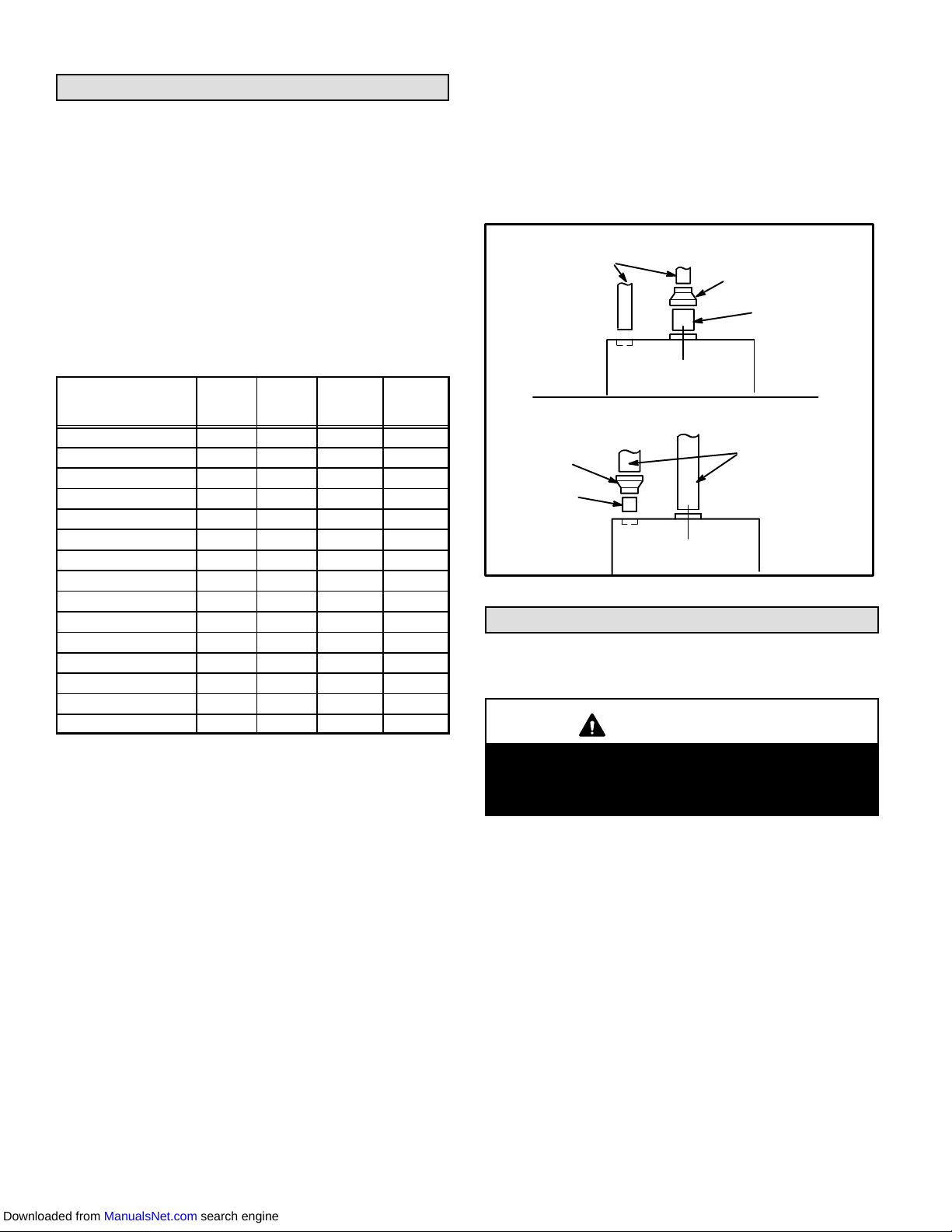

TABLE 1

Clea ances Location Inches (mm)

Front 24 (610)

ervice access Condensate side 3 (76)

(from side of unit)

Top 1 (25)

To combustible Exhaust 0

materials ide, rear, and front 0

Floor 0*

*Appliance shall not be installed directly on carpeting, tile or other combustible mateĆ

rial other than wood flooring.

NOTE- ervice access clearance must be maintained.

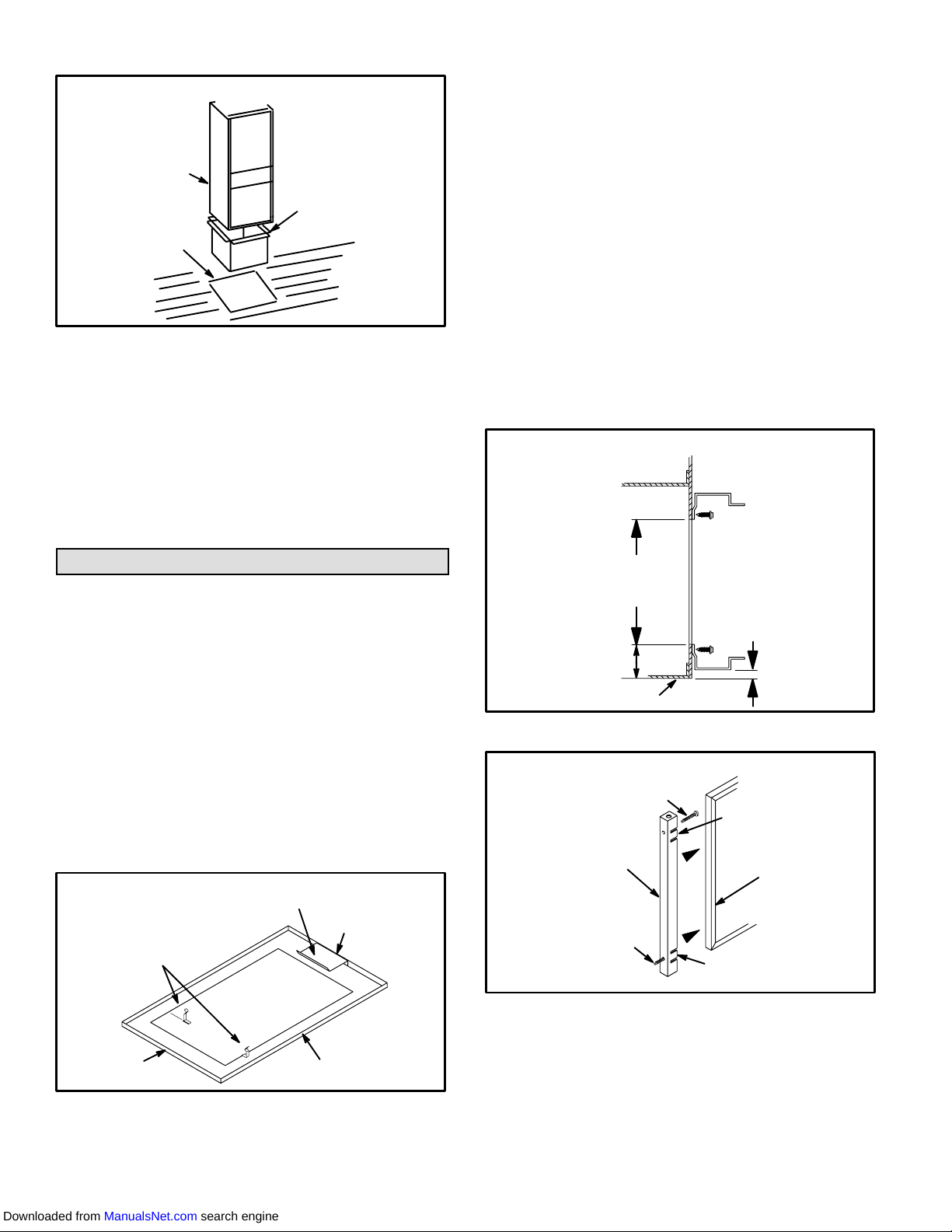

NOTE - For installation on combustible floors, the furnace shall

not be installed directly on carpeting, tile, or other combustible

material other than wood flooring.

Accessibility and service clearances must take preceĆ

dence over fire protection clearances.

For installation in a residential garage, the furnace must be

installed so that the burner(s) and the ignition source are loĆ

cated no less than 18 inches (457 mm) above the floor. The

furnace must be located or protected to avoid physical dam-

age by vehicles. When a furnace is installed in a public garage,

hangar, or other building that has a hazardous atmosphere,

the furnace must be installed according to recommended

good practice requirements and current National Fuel Gas

Code or CAN/CGA B149.1 and B149.2 standards.

The furnace must be adjusted to obtain a temperature rise

within the range specified on the unit rating plate.

When installed, the furnace must be electrically grounded

according to local codes. In addition, in the United tates,

installation must conform with the current National Electric

Code, AN I/NFPA No. 70. The National Electric Code

(AN I/NFPA No. 70) is available from the following ad-

dress:

National Fire Protection Association

1 Battery March Park

Quincy, MA 02269

Wiring to be done in the field, between the furnace and deĆ

vices not attached to the furnace or between separate deĆ

vices which are field-installed and located, shall conform

with the temperature limitation for type T wire [63°F (17°C)

rise] when installed in accordance with these instructions.

G26 unit must be installed so that electrical components

are protected from water.

When the furnace is installed so that supply ducts carry air

circulated by the furnace to areas outside of the space conĆ

taining the furnace, return air shall be handled by a duct(s)

sealed to the furnace casing and terminating out-side

space containing furnace.

WARNING

P oduct contains fibe glass wool.

Distu bing the insulation in this p oduct du ing

installation, maintenance, o epai will expose you

to fibe glass wool dust. B eathing this may cause

lung cance . (Fibe glass wool is known to the State

of Califo nia to cause cance .)

Fibe glass wool may also cause espi ato y, skin,

and eye i itation.

To educe exposu e to this substance o fo fu the

info mation, consult mate ial safety data sheets

available f om add ess shown below, o contact you

supe viso .

Lennox Indust ies Inc.

P.O. Box 799900

Dallas, TX 75379-9900

NOTE - G26 series units must not be used as a construcĆ

tion heater during any phase of construction. Very low re-

turn air temperatures, harmful vapors and misplacement of

the filters will damage the unit and lower its efficiency.

Gene al

These instructions are intended as a general guide and do not

supersede local codes in any way. Consult authorities having

jurisdiction before installation.

Downloaded from ManualsNet.com search engine