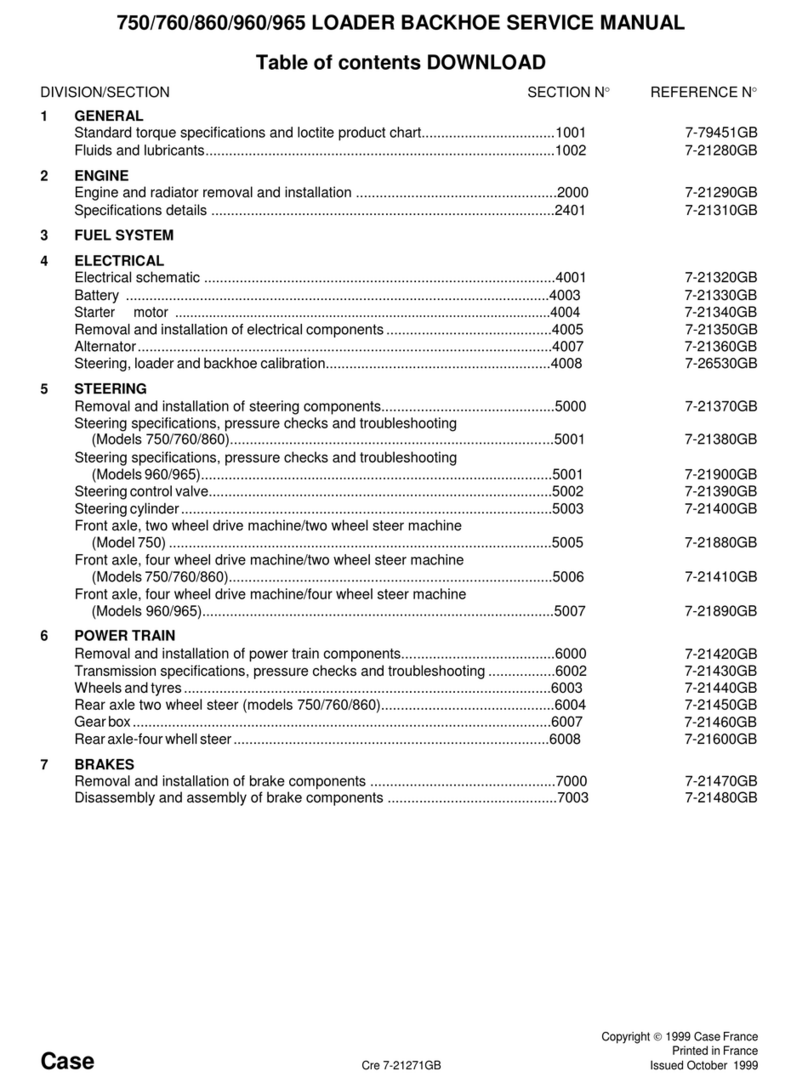

Contents

1GENERALINFORMATION

Intendeduse................................................................................1-1

CNHAmericaLLCtechnicalmanuals......................................................1-2

Electro-MagneticCompatibility(EMC).....................................................1-3

Notetotheowner...........................................................................1-3

ReadtheOperator'sManual...............................................................1-4

Manualstorage.............................................................................1-4

Right,left,frontandrearofthemachine...................................................1-5

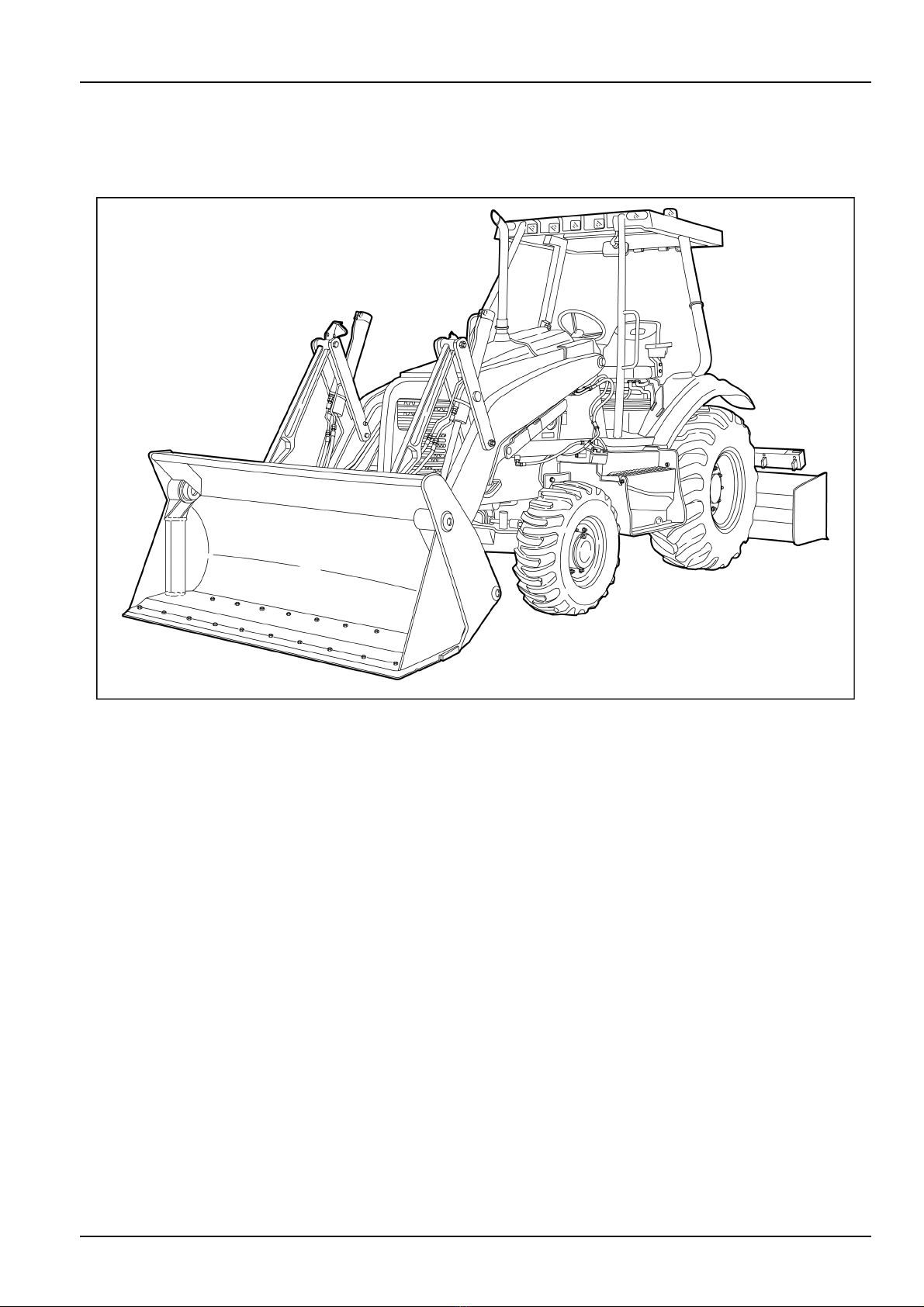

ComponentIdentication...................................................................1-6

ProductIdenticationNumber(PIN)........................................................1-9

ExhaustGasRecirculation(EGR)-DieselParticulateFilter(DPF)exhausttreatment-Product

overview...................................................................................1-12

2SAFETYINFORMATION

Safetyrules.................................................................................2-1

Safetyrules-CaliforniaProposition65Warning..........................................2-2

Safetyrules-General.....................................................................2-3

Safetyrules-Airconditioningsystem.....................................................2-3

Safetyrules-Basicoperating.............................................................2-4

Safetyrules-Battery......................................................................2-5

Safetyrules-Electricalstormsafety.......................................................2-6

Safetyrules-Fireorexplosionprevention................................................2-6

Safetyrules-Fuelhandlingprecautions...................................................2-7

Safetyrules-Hazardouschemicals.......................................................2-7

Safetyrules-Liftingandoverheadloads..................................................2-7

Safetyrules-Generalmaintenanceprecautions..........................................2-8

Safetyrules-Mountinganddismounting..................................................2-9

Safetyrules-Operatorprecautions.......................................................2-9

Safetyrules-Specicprecautionstothismachine.......................................2-10

Safetyrules-Transportingprecautions...................................................2-10

Safetyrules-Utilityprecautions..........................................................2-11

Safetyrules-Wheelsandtires...........................................................2-12

Safetyrules-Ductileiron.................................................................2-12

Safetyrules-RollOverProtectiveStructure(ROPS)....................................2-13

Safetyrules-Seatbelt....................................................................2-14

Safetysigns...............................................................................2-15

Handsignals...............................................................................2-34

DoNotOperatehangtag..................................................................2-36

3CONTROLS/INSTRUMENTS

ACCESSTOOPERATOR'SPLATFORM

Machineaccess........................................................................3-1