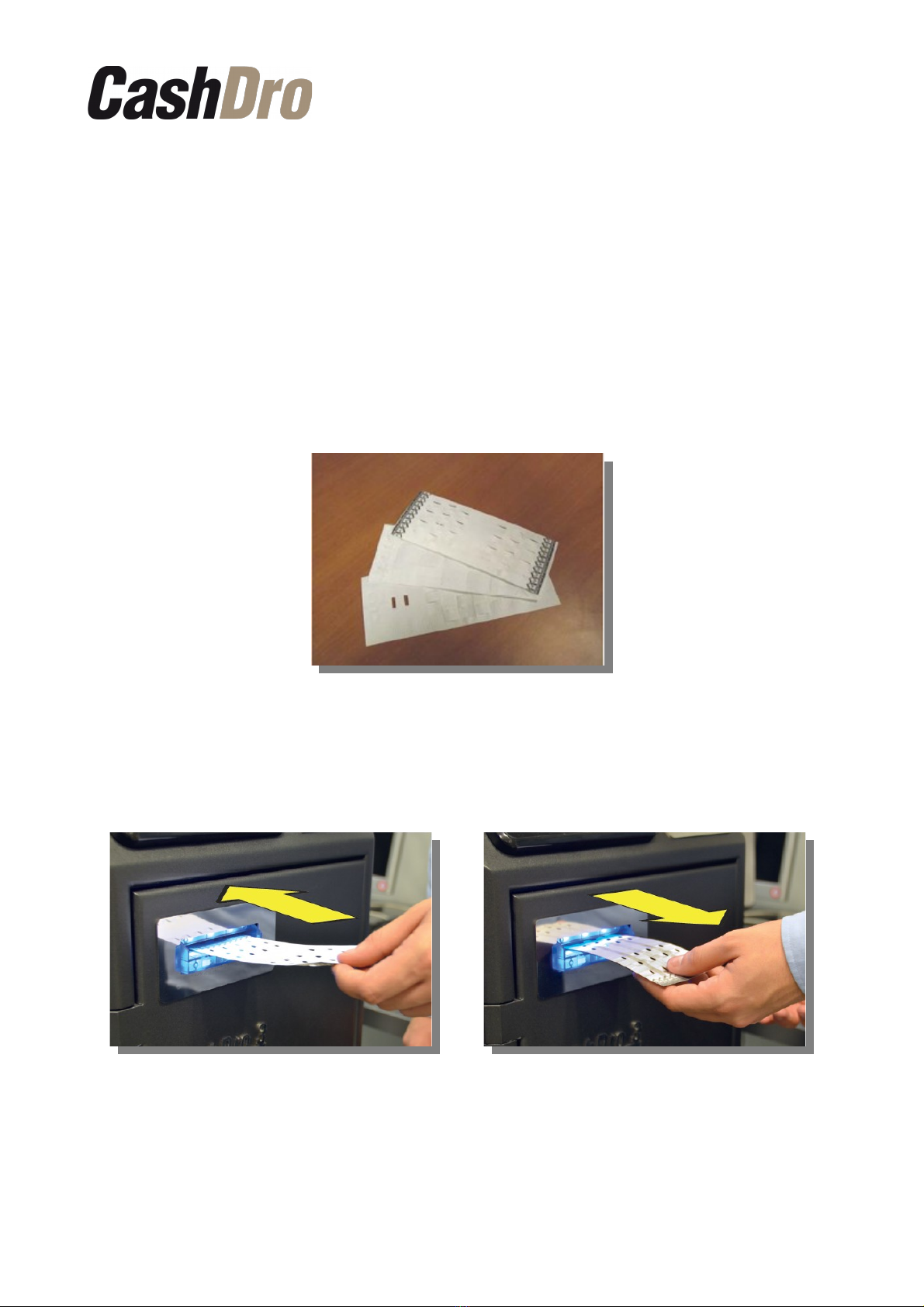

6.2 Cleaning

6.2.1 Bill Validator

Use specific cleaning cards for Bill Validator, his flexibility produces the desired cleaning

effect by increasing the pressure applied to the internal components when passing through

the mechanism. It also acts in the cavities of the surface cleaning the embedded sensors.

Moreover, the anterior and posterior surfaces of the optical rounded lenses obtained

effective cleaning. If you use a flat cleaning card not reach the sensor holes and in the

best case, only have contact with the convex rounded tip of the optical lens. When

introduced and dispensed the cleaning card by the mechanism, being cleaning all

surfaces.

The cleaning process of Bill Device must be realized with CashDro3 on and in the charge

screen. You must insert the cleaning card when the front of the validator is in blue, that is

to say, active. When entering clean the sensors and the alignment mechanism and does it

again on departure.

After entering the cleaning card, it will be ejected automatically.

The cleaning process should be performed several times to verify that the cleaning card

has been impregnated with all the dirt of Bill Validator.

Maintenance manual | 7