Page 6

Stock type

Most photo paper has a resin coating on the back and should be run at a slightly lower

temperature. If the temperature is too high the heat will affect the resin coating. This will

cause the photo paper to stick to the roller and go under the stripper fingers. If you

experience this adjust the temperature knob from the 12 o’clock position to the 11 o’clock

position. You will then need to wait 25 minutes for the temperature to drop.

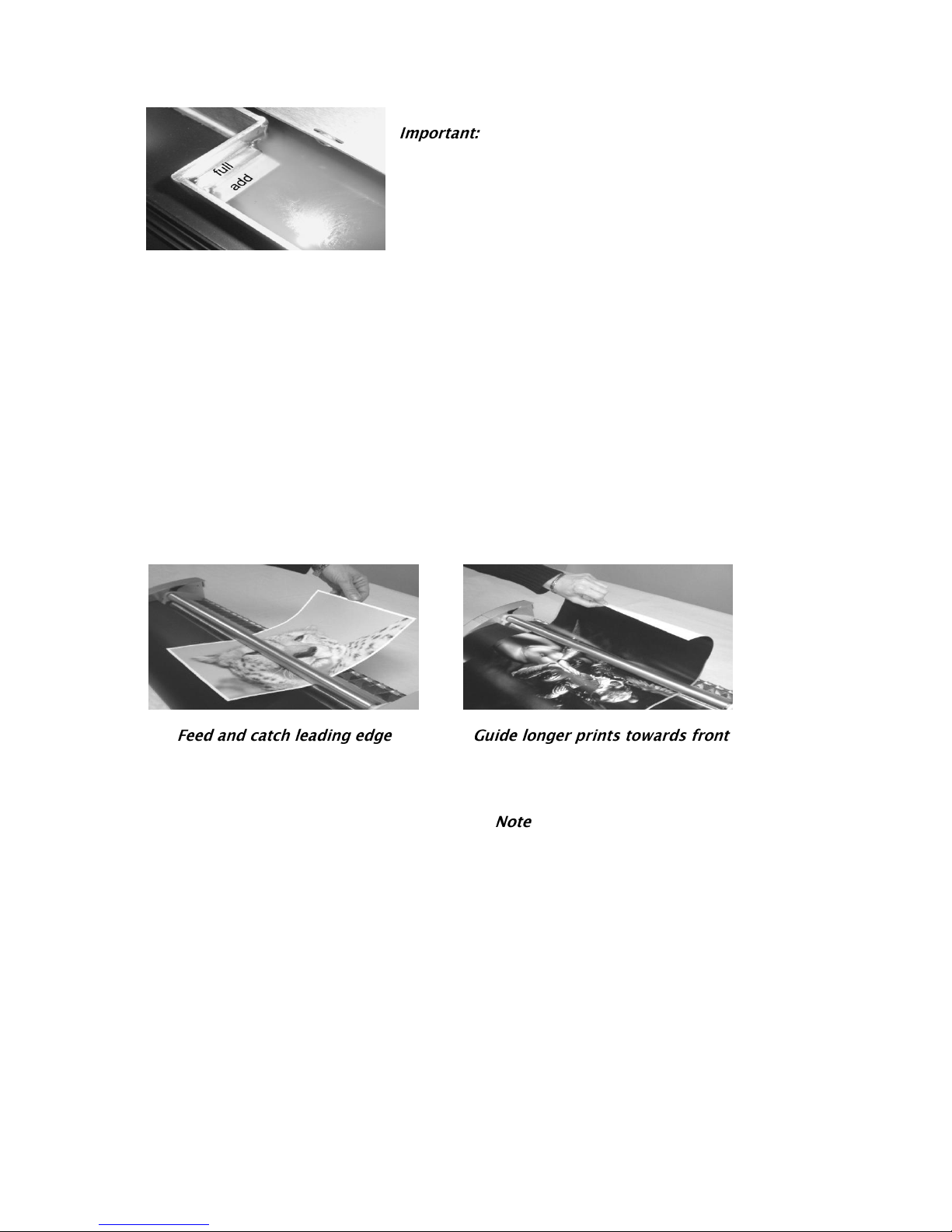

You should use a minimum stock of 60gsm and for thin papers should apply a thin coating

and set the temperature slightly higher. If the paper is too thin, it will receive cut marks from

the stripper fingers at the rear of the coating roller.

Mounting

After coating your print, MX wax will not dry out, so you can mount your print at any time.

However, with RP wax the substrate must be mounted within 2 minutes or adhesion may be

affected. The wax will stick to most surfaces including plastic, metal and wood. After rolling

down your print, you will immediately receive a permanent bond. Maximum adhesion will be

achieved after 24 hours.

After the stock has been coated, the wax will never dry out so the stock can be mounted at

any time. Lift and position the stock until you are happy with its location then roll it down

with a burnishing roller. The harder you roll, the stronger the adhesion. Rubbing the

substrate lightly with your fingers will not create adhesion!

Adding Wax

Speedcote wax comes in pellets which normally stick together in the bag. Either cut the

required amount with a knife or alternatively, refrigerate the product for approximately 2

hours. It is then easy to tear off the wax in the pieces you require.

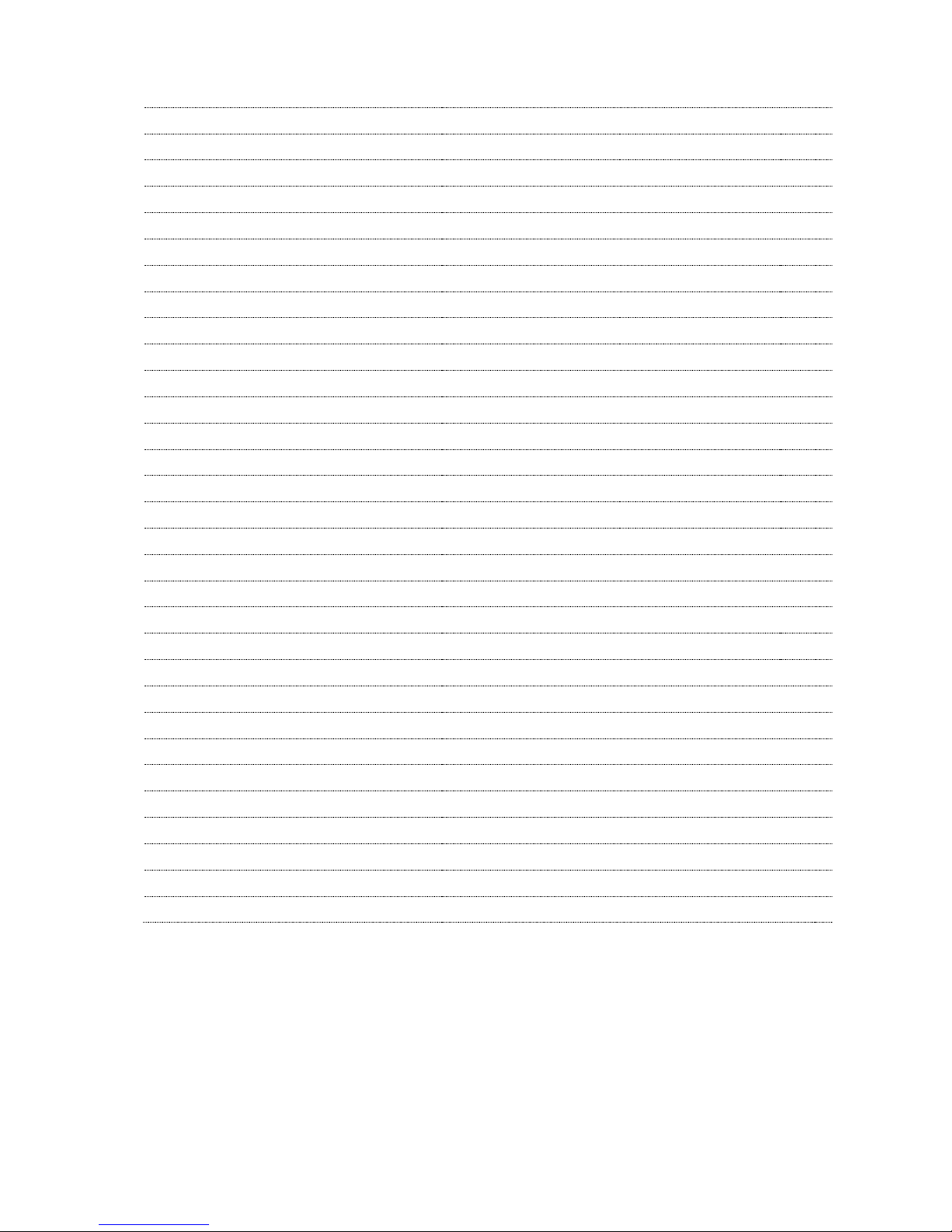

When the wax level drops to the ‘add level’add more wax. It is important to maintain the

wax level at, or above, the ‘full’ level. If not, you will not achieve the correct coating and it

will take longer to warm up in the morning.

Pull down the front cover. Place approximately half of

the wax pellets in the front of the tray. You do not

need to wait for the pellets to melt before using the

Speedcote. The bag is made from a special material

and is dissolvable in the hot wax.