CASTLE, INC TSM-22 OWNERS MANUAL V1.0 Page 3 of 41

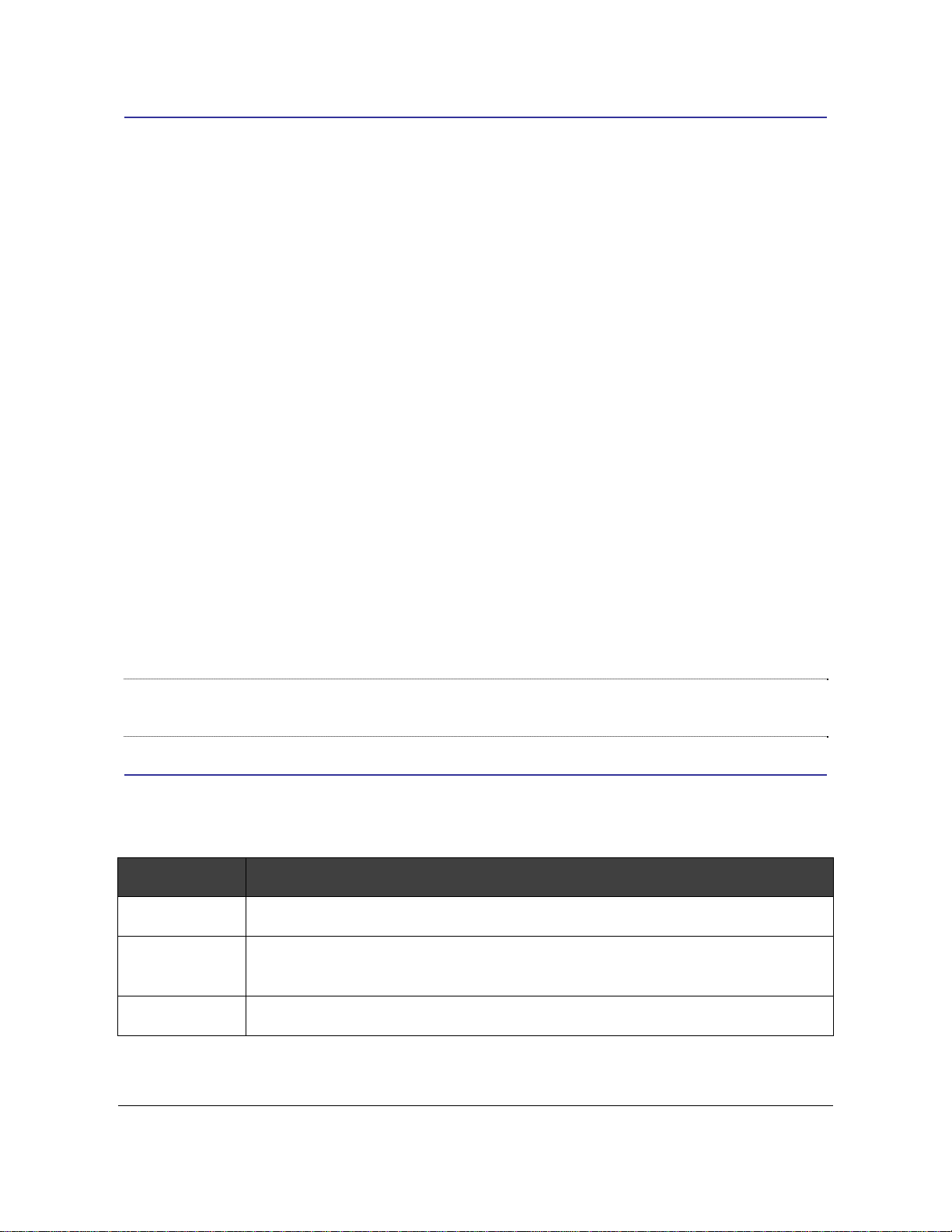

Table of Contents

1INTRODUCTION.............................................................................................................................5

1.1DEFINITION OF TERMS................................................................................................................5

1.2IDENTIFICATION OF OPERATING FEATURES AND CONTROLS .........................................................6

1.3MANUAL CONTENTS NOTICE.......................................................................................................8

2MACHINE SAFETY.........................................................................................................................9

2.1SAFETY RULES..........................................................................................................................9

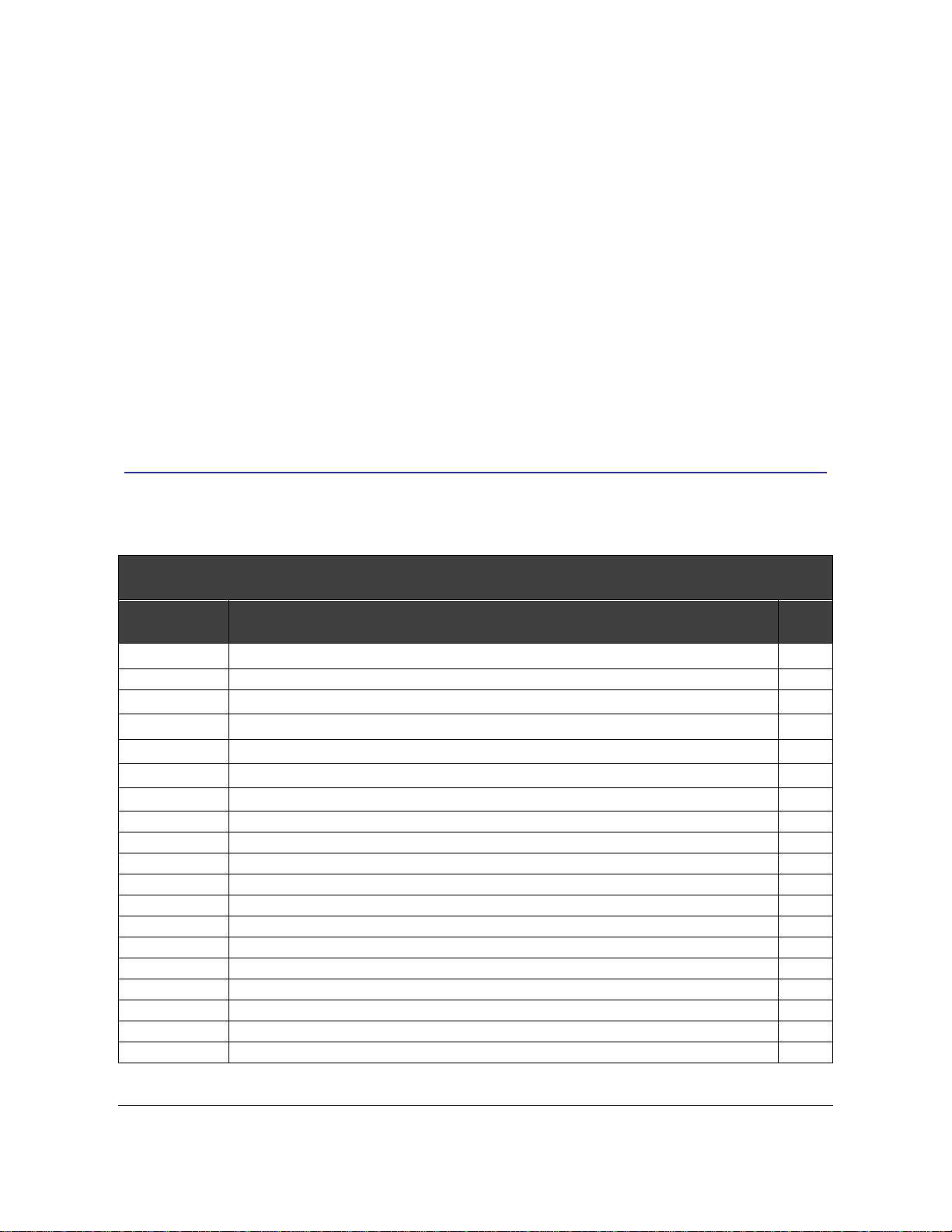

2.2INVENTORY..............................................................................................................................10

2.3MACHINE REQUIREMENTS ........................................................................................................11

3SETTING UP YOUR TSM-22 .......................................................................................................12

3.1INSTALLING THE WORK TOP .....................................................................................................14

3.2INSTALLING THE GAS SPRING ...................................................................................................15

3.3INITIAL CONFIGURATION ...........................................................................................................16

4ADJUSTMENTS............................................................................................................................19

4.1ROUTER FEED RATE ADJUSTMENT ...........................................................................................19

4.2POCKET WEB ADJUSTMENT......................................................................................................20

4.3POCKET DEPTH ADJUSTMENT...................................................................................................21

4.4DRILL FEED RATE ADJUSTMENT ...............................................................................................22

4.5PILOT DRILL DEPTH ADJUSTMENT ............................................................................................23

4.6PILOT DRILL HEIGHT ADJUSTMENT ...........................................................................................24

5OPERATION.................................................................................................................................25

6SERVICE AND MAINTENANCE ..................................................................................................27

6.1TOOL CHANGES.......................................................................................................................27

6.2ROUTER BIT ............................................................................................................................27

6.3PILOT DRILL BIT.......................................................................................................................28

6.4GENERAL MACHINE MAINTENANCE ...........................................................................................28

6.5MOTORS AND BITS...................................................................................................................29

7TROUBLESHOOTING..................................................................................................................31

7.1DRY CYCLE TEST.....................................................................................................................31

7.2SAFETY SWITCH (STOCK SENSE)..............................................................................................33

7.3FOOT SWITCH..........................................................................................................................34