1

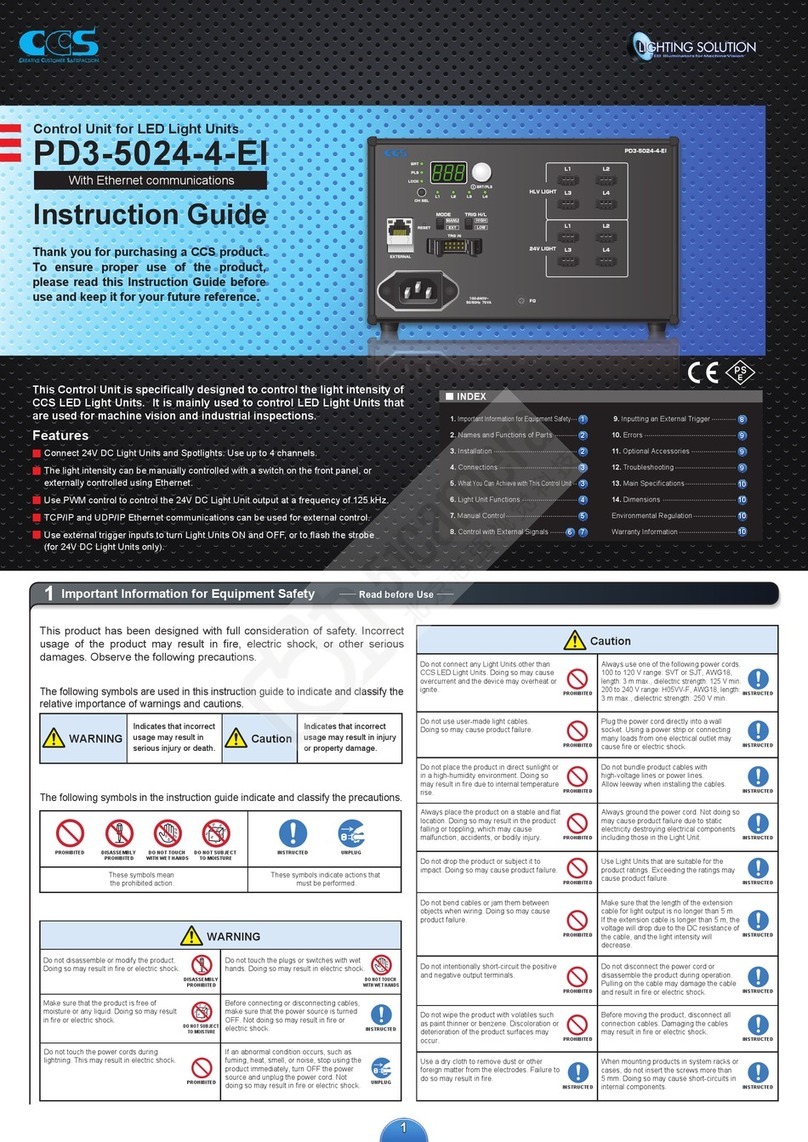

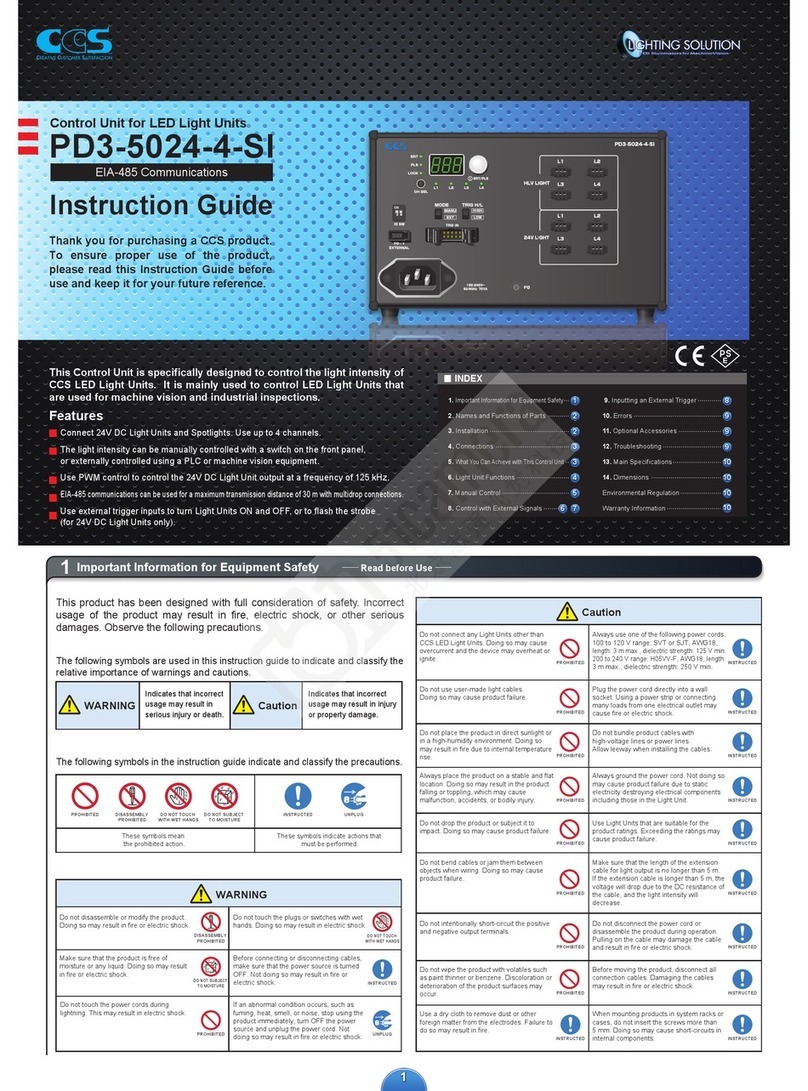

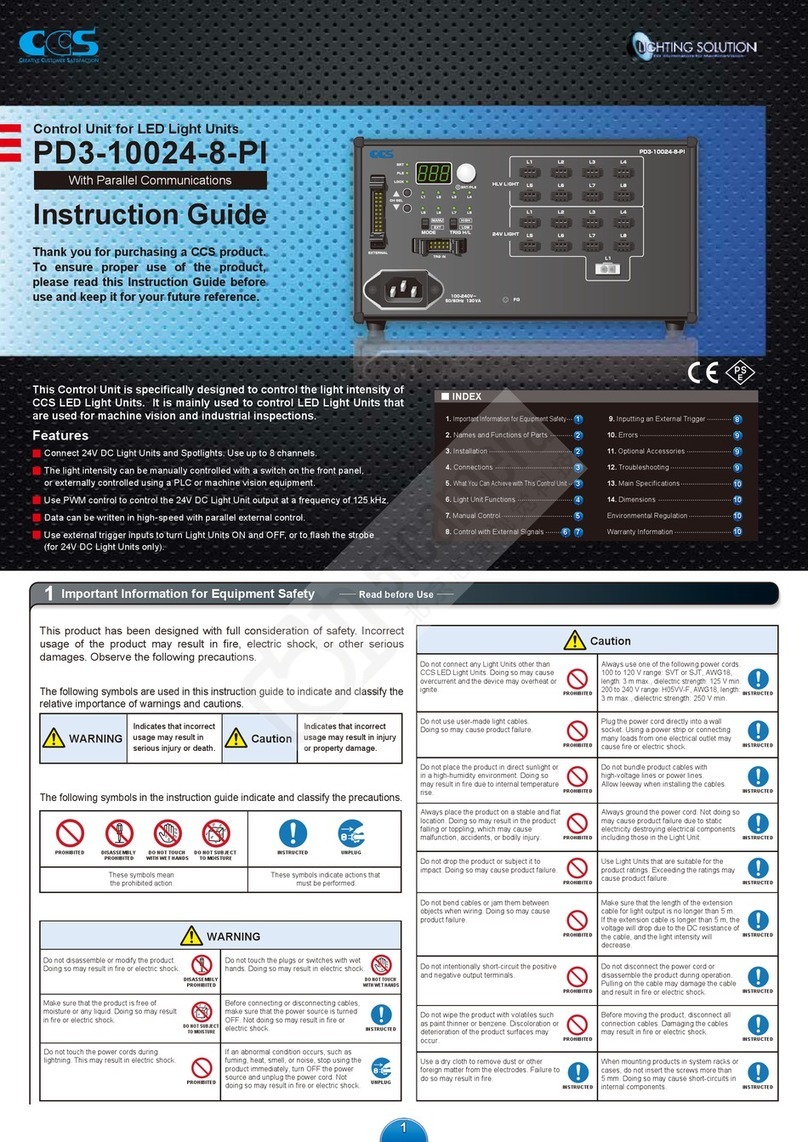

Connect 24V DC Light Units and Spotlights. Use up to 8 channels.

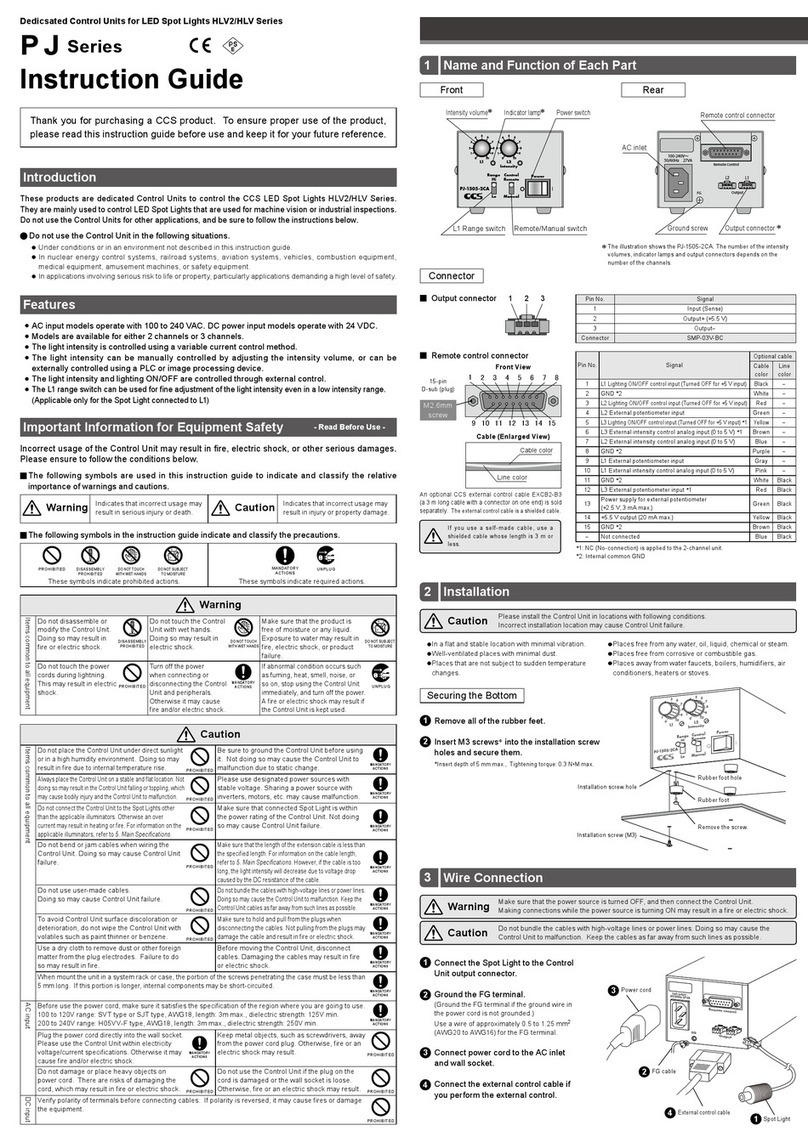

The light intensity can be manually controlled with a switch on the front panel,

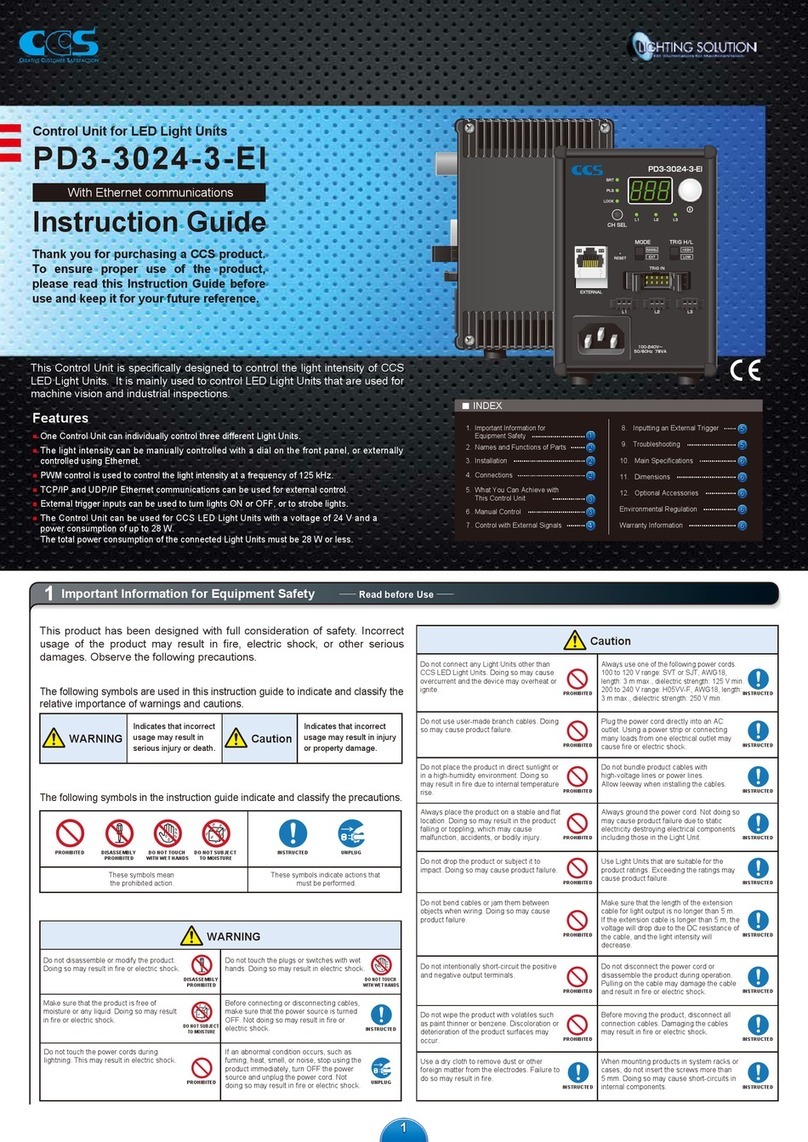

or externally controlled using Ethernet.

Use PWM control to control the 24V DC Light Unit output at a frequency of 125 kHz.

TCP/IP and UDP/IP Ethernet communications can be used for external control.

Use external trigger inputs to turn Light Units ON and OFF, or to flash the strobe

(for 24V DC Light Units only).

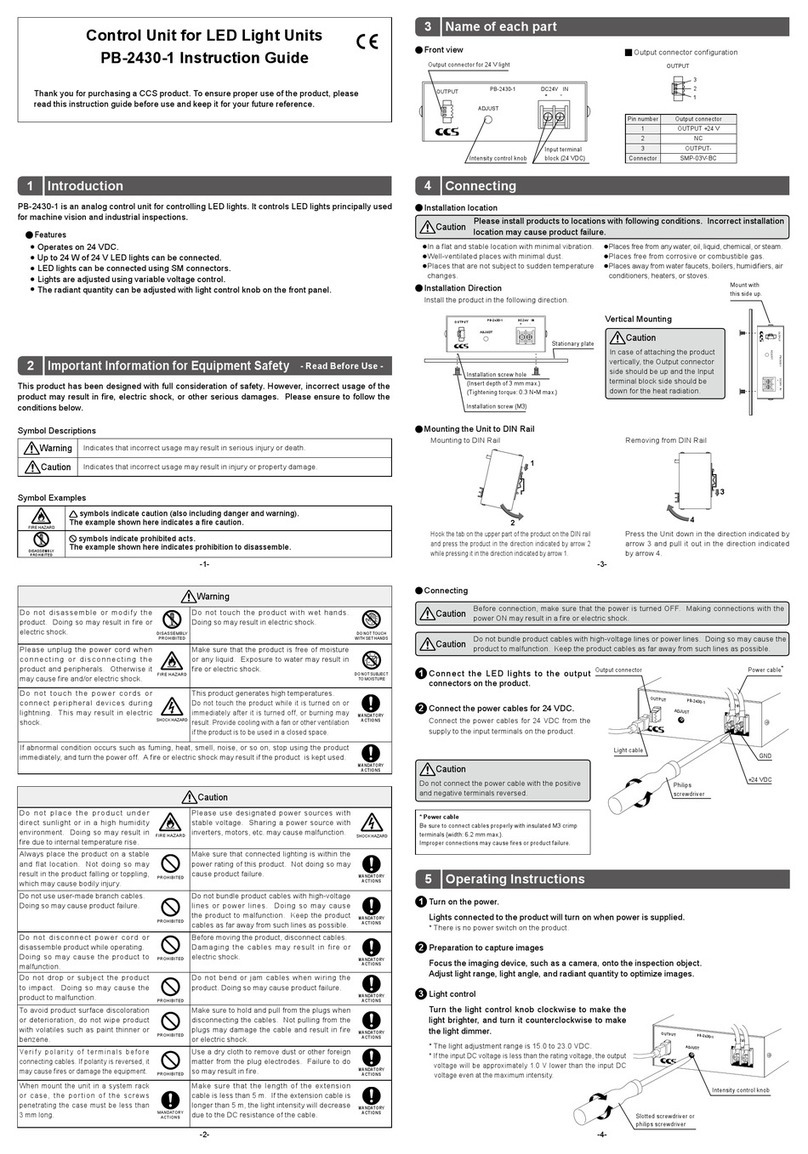

PD3-10024-8-EI(A)

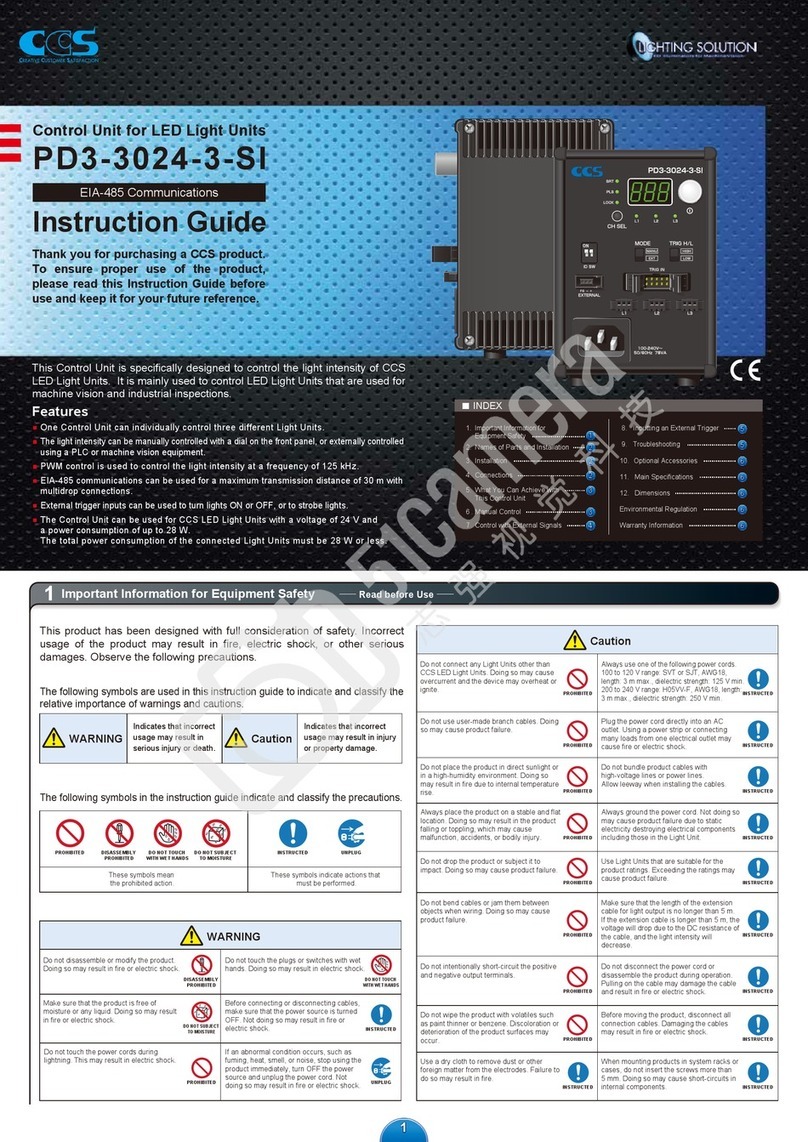

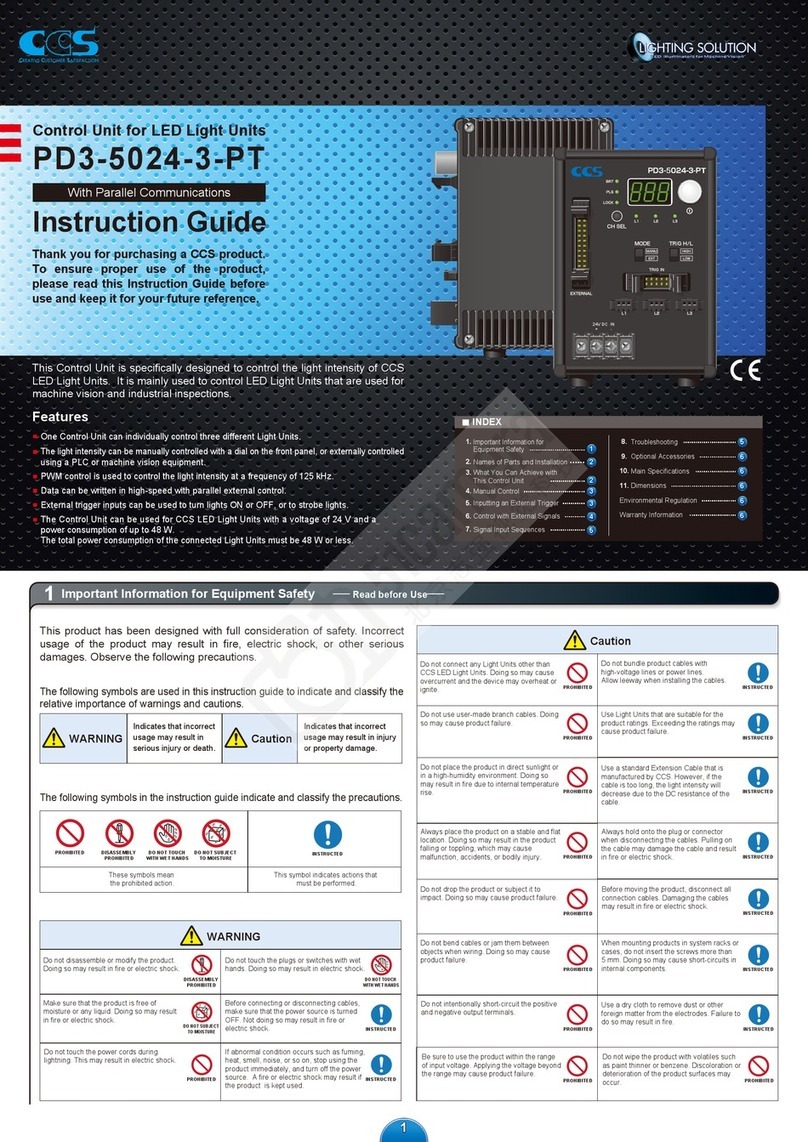

Features

This Control Unit is specifically designed to control the light intensity of

CCS LED Light Units. It is mainly used to control LED Light Units that

are used for machine vision and industrial inspections.

Control Unit for LED Light Units

With Ethernet communications

Thank you for purchasing a CCS product.

To ensure proper use of the product,

please read this Instruction Guide before

use and keep it for your future reference.

Instruction Guide

Caution

MANDATORY

ACTIONS

PROHIBITED

MANDATORY

ACTIONS

PROHIBITED

MANDATORY

ACTIONS

PROHIBITED

MANDATORY

ACTIONS

PROHIBITED

MANDATORY

ACTIONS

PROHIBITED

MANDATORY

ACTIONS

PROHIBITED

MANDATORY

ACTIONS

PROHIBITED

MANDATORY

ACTIONS

MANDATORY

ACTIONS

MANDATORY

ACTIONS

PROHIBITED

The following symbols are used in this instruction guide to indicate and classify the

relative importance of warnings and cautions.

The following symbols in the instruction guide indicate and classify the precautions.

WARNING

WARNING

Indicates that incorrect

usage may result in

serious injury or death. Caution

Indicates that incorrect

usage may result in injury

or property damage.

PROHIBITED

PROHIBITED

DISASSEMBLY

PROHIBITED

DISASSEMBLY

PROHIBITED

DO NOT TOUCH

WITH WET HANDS

DO NOT TOUCH

WITH WET HANDS

These symbols indicate prohibited actions. These symbols indicate required actions.

DO NOT SUBJECT

TO MOISTURE

DO NOT SUBJECT

TO MOISTURE

MANDATORY

ACTIONS

MANDATORY

ACTIONS

UNPLUG

UNPLUG

This product has been designed with full consideration of safety. Incorrect

usage of the product may result in fire, electric shock, or other serious

damages. Observe the following precautions.

Do not touch the power cords during

lightning. This may result in electric shock.

Do not disassemble or modify the Control

Unit. Doing so may result in fire or electric

shock.

Do not touch the plugs or switches with wet

hands. Doing so may result in electric shock.

Make sure that the Control Unit is free of

moisture or any liquid. Doing so may result

in fire or electric shock.

Before connecting or disconnecting cables,

make sure that the power source is turned

OFF. Not doing so may result in fire or

electric shock.

If an abnormal condition occurs, such as

fuming, heat, smell, or noise, stop using the

Control Unit immediately, turn OFF the power

source and unplug the power cord. Not doing

so may result in fire or electric shock.

Do not use user-made light cables.

Doing so may cause Control Unit failure.

Do not place the Control Unit in direct

sunlight or in a high-humidity environment.

Doing so may result in fire due to internal

temperature rise.

Always place the Control Unit on a stable and

flat location. Not doing so may result in the

Control Unit falling or toppling, which may

cause malfunction, accidents, or bodily injury.

Do not intentionally short-circuit the positive

and negative output terminals.

Do not bend cables or jam them between

objects when wiring. Doing so may cause

Control Unit failure.

Do not wipe the Control Unit with volatiles

such as paint thinner or benzene.

Discoloration or deterioration of the Control

Unit surfaces may occur.

Do not drop the Control Unit or subject it to

impact. Doing so may cause Control Unit

failure.

Use a dry cloth to remove dust or other

foreign matter from the electrodes. Failure to

do so may result in fire.

Do not connect any Light Units other than

CCS LED Light Units. Doing so may cause

overcurrent and the device may overheat or

ignite.

Always use one of the following power cords.

100 to 120 V range: SVT or SJT, AWG18,

length: 3 m max., dielectric strength: 125 V min.

200 to 240 V range: H05VV-F, AWG18, length:

3 m max., dielectric strength: 250 V min.

Plug the power cord directly into a wall

socket. Using a power strip or connecting

many loads from one electrical outlet may

cause fire or electric shock.

Do not bundle Control Unit cables with

high-voltage lines or power lines.

Allow leeway when installing the cables.

Always ground the power cord. Not doing so

may cause Control Unit failure due to static

electricity destroying electrical components

including those in the Light Unit.

Use Light Units that are suitable for the

Control Unit ratings. Exceeding the ratings

may cause Control Unit failure.

Use a standard Extension Cable that is

manufactured by CCS. However, if the cable

is too long, the light intensity will decrease

due to voltage drop caused by the DC

resistance of the cable.

Do not disconnect the power cord or

disassemble the Control Unit during

operation. Pulling on the cable may damage

the cable and result in fire or electric shock.

Before moving the Control Unit, disconnect

all connection cables. Damaging the cables

may result in fire or electric shock.

When mounting the Control Units in system

racks or cases, do not insert the screws

more than 5 mm. Doing so may cause

short-circuits in internal components.

1Important Information for Equipment Safety Read before Use

8

9

9

9

10

10

1

2

2

3

3

4

5

6

INDEX

1.

Important Information for Equipment Safety

2. Names and Functions of Parts

3. Installation

4. Connections

5.

What You Can Achieve with This Control Unit

6. Light Unit Functions

7. Manual Control

8. Control with External Signals

9. Inputting an External Trigger

10. Errors

11. Optional Accessories

12. Troubleshooting

13. Main Specifications

14. Dimensions

7