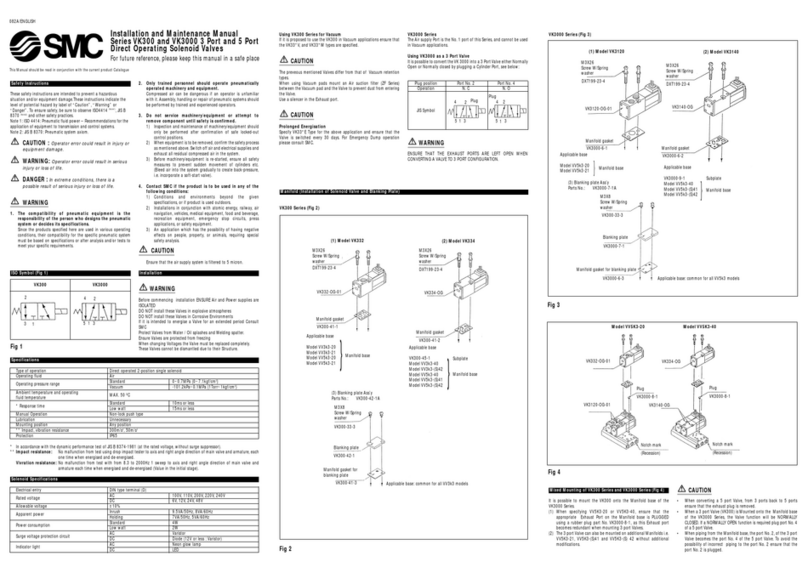

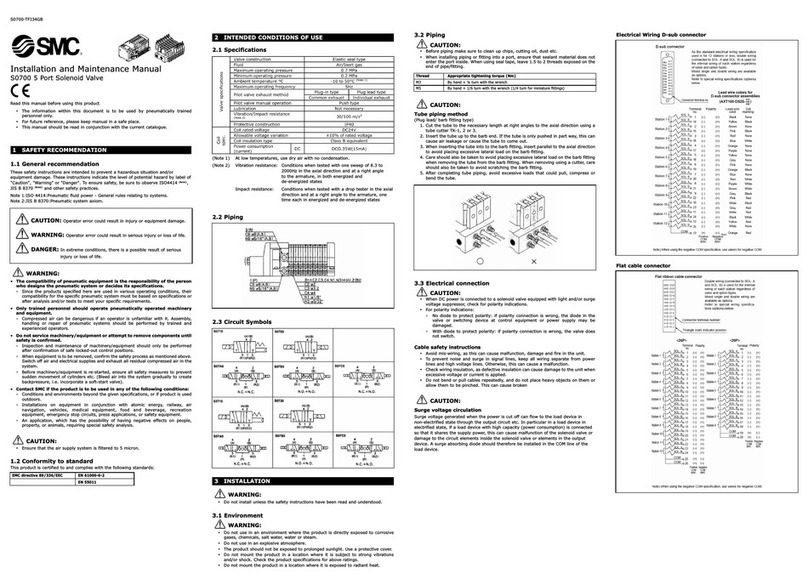

Table 7.

3.9 Countermeasure for surge voltage

Caution

•At times of sudden interruption of the power supply, the energy stored

in a large inductive device may cause non-polar type valves in a de-

energised state to switch.

•When installing a breaker circuit to isolate the power, consider a valve

with polarity (with polarity protection diode), or install a surge

absorption diode across the output of the breaker.

3.10 Extended periods of continuous energization

Caution

•When the product is continuously energized for a long period of time

(10 minutes or longer), select the low wattage type.

•Refer to ‘3, 4, 5 port solenoid valves precautions’ for more details.

•When solenoid valves are mounted in a control panel, employ

measures to radiate excess heat, so that temperatures remain within

the valve specification range. Use special caution when three or more

stations sequentially aligned on the manifold are continuously

energized since this will cause a drastic temperature rise.

3.11 Air supply Warning

•Use clean air. If the compressed air supply includes chemicals,

synthetic materials (including organic solvents), salinity, corrosive gas

etc., it can lead to damage or malfunction.

Caution

•Install an air filter upstream near the valve. Select an air filter with a

filtration size 5 μm or smaller.

3.12 Effect of back pressure when using a manifold

Warning

•Use caution whenvalves are usedon a manifold, because an actuator

may malfunction due to back-pressure.

•For a 3-position exhaust centre valve or single acting cylinder, take

appropriate measures to prevent malfunction by using it with an

individual EXH interface block.

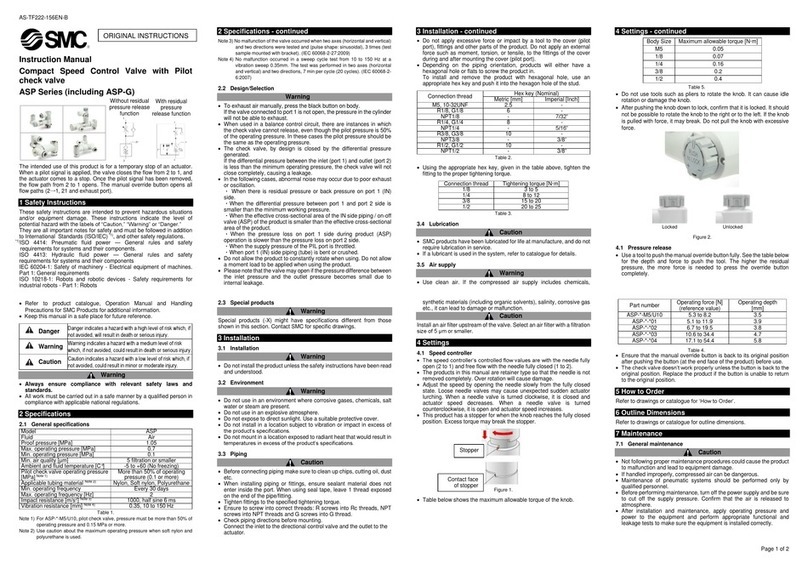

3 Installation - continued

3.13 Manual override Warning

•Regardless of an electric signal for the valve, the manual override is

used for switching the main valve. Since connected equipment will

operate when the manual override is activated, confirm that conditions

are safe prior to activation.

•Locked manual overrides might prevent the valve responding to being

electrically de-energised or cause unexpected movement in the

equipment.

•Refer to the catalogue for details of manual override operation.

•Do not apply excessive torque when turning the locking type manual

override, (0.1 N∙m or less).

3.14 External pilot exhausts Caution

The external pilot variants use the exhaust port of the manifold. Ensure

that this connection is always vented to atmosphere and do not block the

exhaust port when arranging the piping.

3.15 Electrical wiring specification

Refer to catalogue for electrical wiring specifications.

4 How to Order

4.1 Standard products

Refer to catalogue for ‘How to Order’ or to product drawing for special

products.

5 Outline Dimensions

Refer to catalogue and special drawings for outline dimensions.

6 Maintenance

6.1 General maintenance Caution

•Not following proper maintenance procedures could cause the product

to malfunction and lead to equipment damage.

•If handled improperly, compressed air can be dangerous.

•Maintenance of pneumatic systems should be performed only by

qualified personnel.

•Before performing maintenance, turn off the power supply and be sure

to cut off the supply pressure. Confirm that the air is released to

atmosphere.

•After installation and maintenance, apply operating pressure and

power to the equipment and perform appropriate functional and

leakage tests to make sure the equipment is installed correctly.

•If any electricalconnections are disturbed duringmaintenance, ensure

they are reconnected correctly and safety checks are carried out as

required to ensure continued compliance with applicable national

regulations.

•Do not make any modification to the product.

•Do not disassemble the product, unless required by installation or

maintenance instructions.

•When the 3-position closed centre type is in its rest position, air can be

trapped between the valve and the cylinder. Exhaust this air pressure

before removing piping or performing any maintenance.

•When the equipment is operated after remounting or replacement, first

confirm that measures are in place to prevent lurching of actuators,

etc. Then, confirm that the equipment is operating normally.

•Operate thevalve according tothe minimum operating frequency given

in section 2.

•For maintenance purposes install a system for releasing residual

pressure. Especially in the case of 3-position closed centre valve or

double check valve type, ensure that the residual pressure between

the valve and the cylinder is released.

•Dust on sealing surfaces of the gasket of solenoid valve can cause air

leakage. Ensure gaskets are in place and parts are dust free.

6 Maintenance - continued

6.2 Replacement parts

6.2.1 Installation/removal of light cover

Caution

Refer to catalogue for additional information.

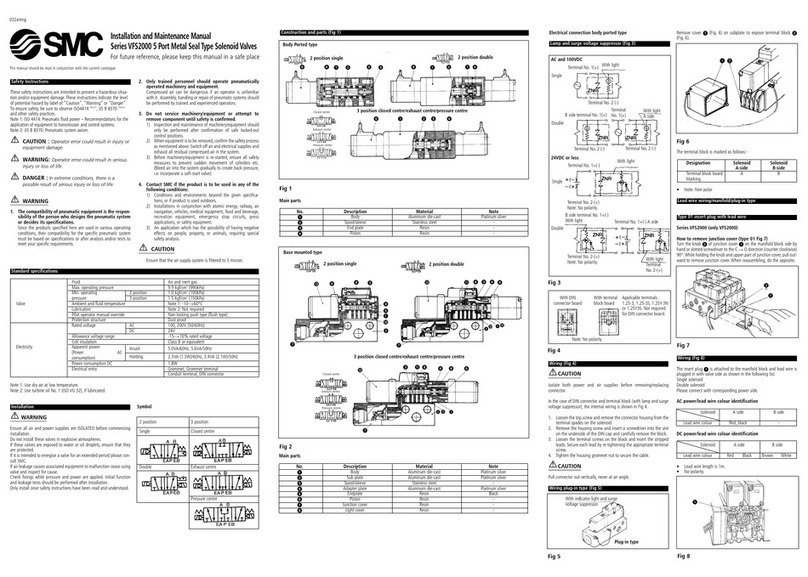

Figure 5. VQ(C)4000

Figure 6. VQ(C)5000

6.2.2 Replacement of the pilot valve

Caution

After confirming the gasket is correctly placed under the valve, securely

tighten the bolts with the proper torque shown in figure 7.

Figure 7.

Figure 8.

Note) The light circuit boards: A side is red and the B side is green. It must be

mounted on the pilot valve in accordance with the mounting indicators.

6 Maintenance - continued

6.2.3 Plug lead type Caution

Refer to catalogue for additional information.

Figure 9.

7 Limitations of Use Warning

System designer should determine the effect of the possible failure

modes of the product on the system.

7.1 Limited warranty and disclaimer/compliance requirements

Refer to Handling Precautions for SMC Products.

Warning

Do not exceed any of the specifications laid out in section 2 of this

document or the specific product catalogue.

7.2 Leakage voltage Caution

Ensure that any leakage current when the switching element is OFF

causes ≤3% of the rated voltage across the valve.

7.3 Low temperature operation

Caution

Unless otherwise indicated in the specifications for each valve, operation

is possible to -10˚C (-5˚C for VQC5000), but appropriate measures

should be taken to avoid solidification or freezing of drainage and

moisture, etc.

7.4 Mounting orientation Caution