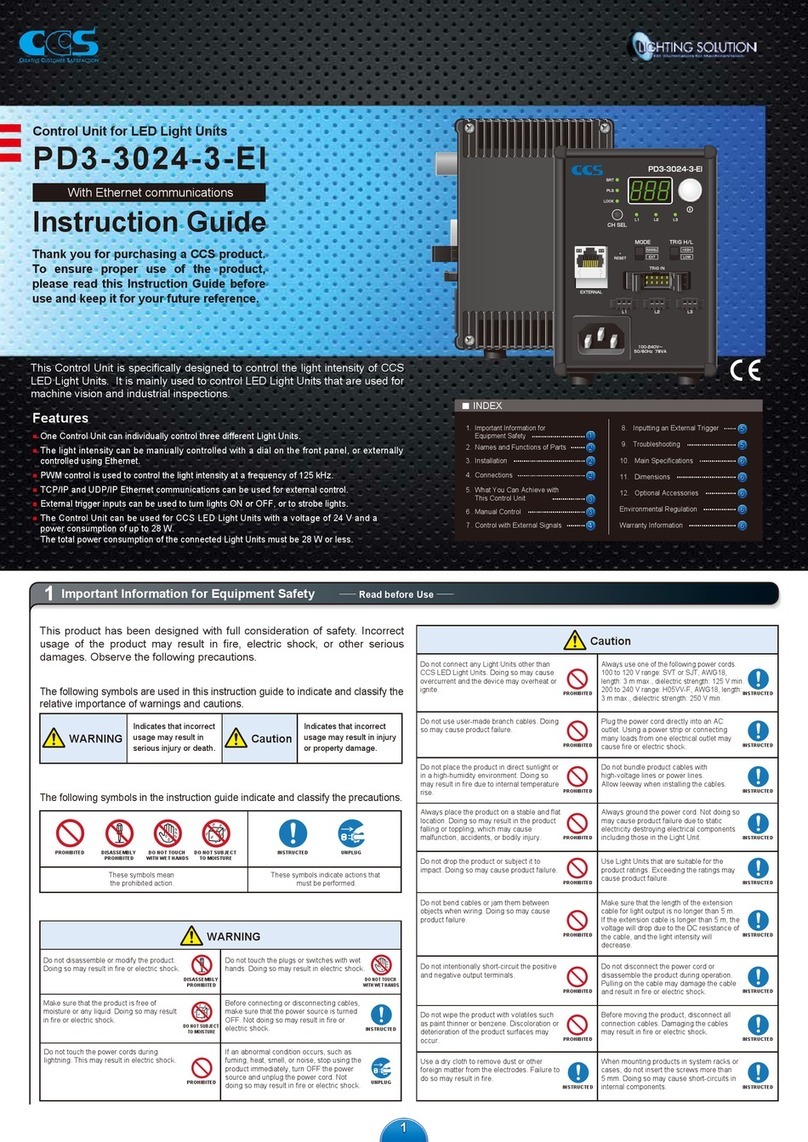

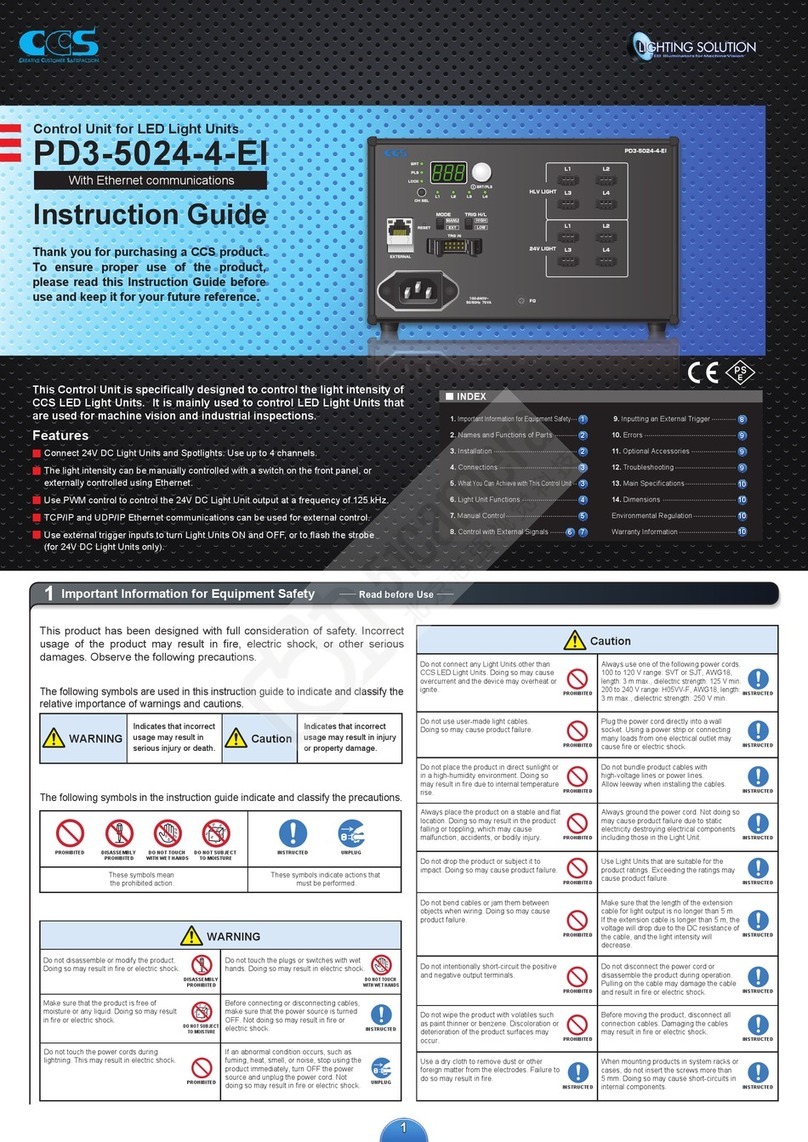

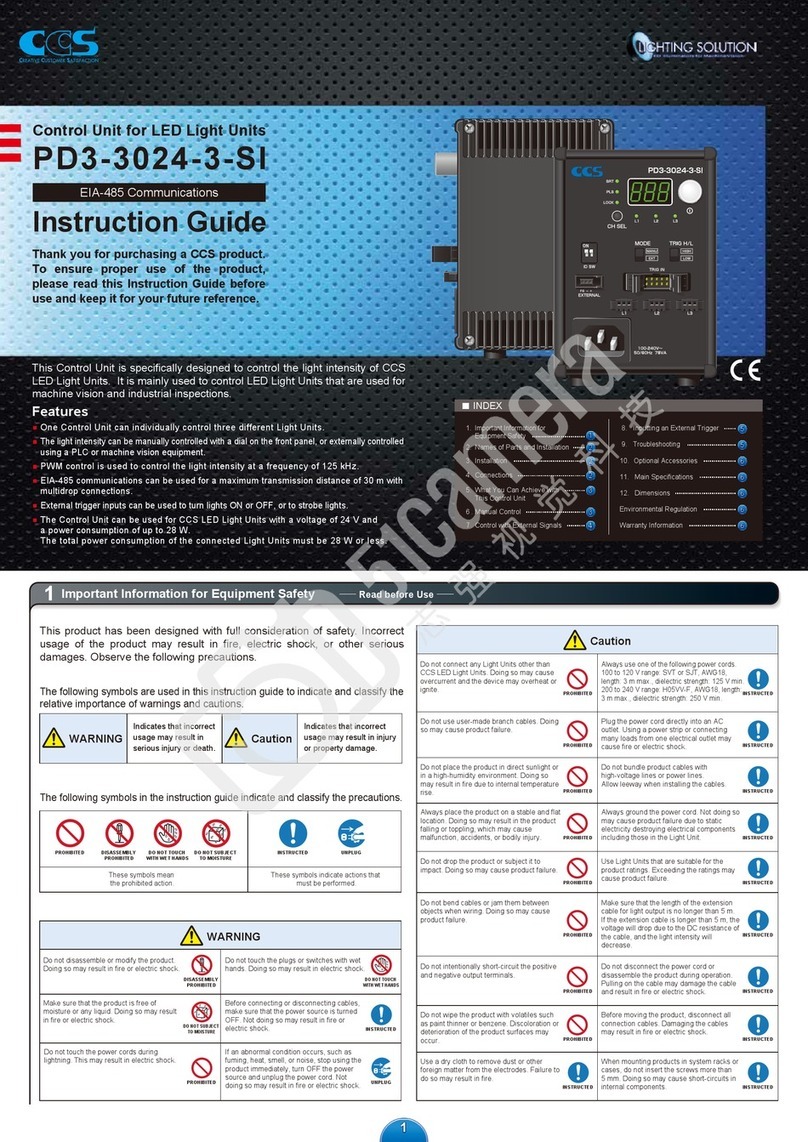

Using Models with an AC Input

Name and Function of Each Part

1

Wire Connection

3

Do not bundle the cables with high-voltage lines or power lines. Doing so may cause the

Control Unit to malfunction. Keep the cables as far away from such lines as possible.

Make sure that the power source is turned OFF, and then connect the Control Unit.

Making connections while the power source is turning ON may result in a re or electric shock.

Connect the Spot Light to the Control

Unit output connector.

Ground the FG terminal.

(Ground the FG terminal if the ground wire in

the power cord is not grounded.)

Use a wire of approximately 0.5 to 1.25 mm2

(AWG20 to AWG16) for the FG terminal.

Connect power cord to the AC inlet

and wall socket.

Connect the external control cable if

you perform the external control.

1

2

4

FG

Remote control

100-240V~

50/60Hz 27VA

Output

Spot Light

1

4

External control cable

2FG cable

3Power cord

3

Installation

2

・振動が少 な い 、水 平 で 安 定 し ている。

・埃 が 少 な い 、換 気 の よ い 。

・水、油、液、薬品、蒸気などが本製品にかからない。

・腐食性ガスや可燃性ガスがない。

・水道、湯沸かし器、加湿器、クーラー、ヒーター、

ストーブなどが近くにない。

・温度が急に変化しない。

・必ず接地できる。

※並べて設置する際は上方50mm以 上 、左 右

20mm以 上 の 間 隔 を あ け て 設 置 してく ださい 。

底面固定

Coarse

Fine

L1 L2

Power

1

2

3

4

5

67891011

12

13

14

15

16

1

2

3

4

5

67891011

12

13

14

15

16

1

2

3

4

5

67891011

12

13

14

15

16

1

2

3

4

5

67891011

12

13

14

15

16

ゴム足をはずして固定します。

※下図に示す方向以外では固定しないでください。

固定方法

本製品と接続するケーブル類は高圧線や動力線と束ねると誤動作の原因となり

ます。できるだ け 離して 配 線 してください 。

配 線 に あたっての 注 意

設置場所

4設置のしかた

Coarse

Fine

L1 L2

Power

1

2

3

4

5

67891011

12

13

14

15

16

1

2

3

4

5

67891011

12

13

14

15

16

1

2

3

4

5

67891011

12

13

14

15

16

1

2

3

4

5

67891011

12

13

14

15

16

50mm

20mm

縦置き

Coarse

Fine

L1 L2

Power

1

2

3

4

5

67891011

12

13

14

15

16

1

2

3

4

5

67891011

12

13

14

15

16

1

2

3

4

5

67891011

12

13

14

15

16

1

2

3

4

5

67891011

12

13

14

15

16

20mm

50mm

横置き

拡大図

固 定ネジ 穴

固定ネジ (M3)

(挿入深さ 5mm 以下 )

(締 付けトル ク 0.3N

・

m以下 )

ゴム足固定穴

これを 引き 抜くと

ゴム足が取れます

ゴム足

側面固定

Coarse

Fine

L1 L2

Power

1

2

3

4

5

67891011

12

13

14

15

16

1

2

3

4

5

67891011

12

13

14

15

16

1

2

3

4

5

67891011

12

13

14

15

16

1

2

3

4

5

67891011

12

13

14

15

16

横置き

この 面 を上にして 固 定

本体: 背面

固 定ネジ 穴

縦置き

固定板

(板厚 1.6t 以上 )

On/Off

100-240V~

1

2

L1

Light

L2

L1

(FAN)

EXT

GND

固定ネジ (M3)

(挿入深さ 5mm 以下 )

(締 付けトル ク 0.3N

・

m以下 )

以下の条件のところに設置してください。

設 置 場 所 に よっては 製 品 が 故 障 する恐 れ がありま す。

(P22 図面掲載)

注意

注意

Coarse

Fine

L1 L2

Power

1

2

3

4

5

67891011

12

13

14

15

16

1

2

3

4

5

67891011

12

13

14

15

16

1

2

3

4

5

67891011

12

13

14

15

16

1

2

3

4

5

67891011

12

13

14

15

16

ゴム足をはずして固定します。

拡大図

固 定ネジ 穴

固定ネジ (M3)

(挿入深さ 5mm 以下 )

(締 付けトル ク 0.3N

・

m以下 )

ゴム足固定穴

これを 引き 抜 くと

ゴム足が取れます

ゴム足

5

010

5

010

1

2

3467

8

91

2

346

9

7

8

L2

Control

Range

Remote

Hi

Lo Manual

Intensity

Power

L1

PJ-1505-2CA

Hi

5

010

5

010

1

2

3

46

7

8

91

3

46

9

7

8

L2

ControlRange Remote

Lo Manual

Intensit y

Power

L1

PJ-1505-2CA

2

Hi

5

010

5

010

1

2

3

46

7

8

91

3

46

9

7

8

L2

ControlRange Remote

Lo Manual

Intensit y

Power

L1

PJ-1505-2CA

2

5

5

3

46

73

46

Hi

0100 10

1

28

919

7

8

L2

Control

Range Remote

Lo Manual

Intensity

Power

L1

PJ-1505-2CA

2

Rubber foot

Rubber foot hole

Remove the screw.

Installation screw hole

Installation screw (M3)

Remove all of the rubber feet.

Insert M3 screws*into the installation screw

holes and secure them.

1

2

Securing the Bottom

In a at and stable location with minimal vibration.

Well-ventilated places with minimal dust.

Places that are not subject to sudden temperature

changes.

Places free from any water, oil, liquid, chemical or steam.

Places free from corrosive or combustible gas.

Places away from water faucets, boilers, humidiers, air

conditioners, heaters or stoves.

Please install the Control Unit in locations with following conditions.

Incorrect installation location may cause Control Unit failure.

*Insert depth of 5 mm max., Tightening torque: 0.3 N•M max.

Front Rear

The illustration shows the PJ-1505-2CA. The number of the intensity

volumes, indicator lamps and output connectors depends on the

number of the channels.

*

Remote Control

FG

100 -240V~

50/60Hz 27VA

Output

PJ-1505 -2 C A

Power

Control

Remote

Manual

Range

Hi

Lo

L2

Intensity

L1

5

010

1

2

3

46

7

8

9

5

010

1

2

3

46

7

8

9

Remote control connector

AC inlet

Ground screw Output connector

Remote/Manual switch

Intensity volume Power switch

L1 Range switch

Indicator lamp

* *

*

Pin No. Signal

1Input (Sense)

2 Output+ (+5.5 V)

3Output

-

Connector SMP-03V-BC

Pin No. Signal

Optional cable

Cable

color

Line

color

1

L1 Lighting ON/OFF control input (Turned OFF for +5 V input)

Black

-

2 GND *2White

-

3

L2 Lighting ON/OFF control input (Turned OFF for +5 V input)

Red

-

4L2 External potentiometer input Green

-

5

L3 Lighting ON/OFF control input (Turned OFF for +5 V input) *1

Yellow

-

6 L3 External intensity control analog input (0 to 5 V) *1Brown

-

7 L2 External intensity control analog input (0 to 5 V) Blue

-

8 GND *2Purple

-

9L1 External potentiometer input Gray

-

10 L1 External intensity control analog input (0 to 5 V) Pink

-

11 GND *2White Black

12 L3 External potentiometer input *1Red Black

13 Power supply for external potentiometer

(+2.5 V, 3 mA max.) Green Black

14 +5.5 V output (20 mA max.) Yellow Black

15 GND *2Brown Black

-

Not connected Blue Black

Connector

An optional CCS external control cable EXCB2-B3

(a 3 m long cable with a connector on one end) is sold

separately.

The external control cable is a shielded cable.

*1: NC (No-connection) is applied to the 2-channel unit.

*2: Internal common GND

Output connector

Remote control connector

11109 14 151312

32

16 7 854

Cable (Enlarged View)

Line color

Cable color

15-pin

D-sub (plug)

M2.6mm

screw

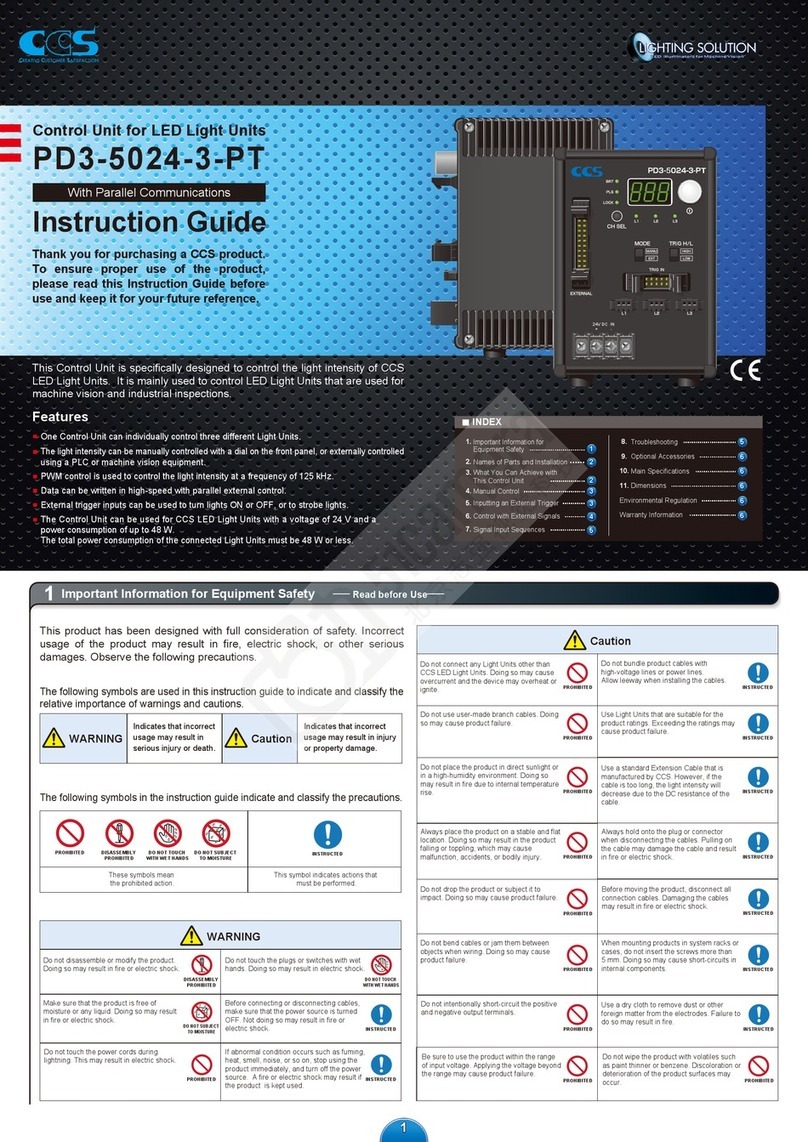

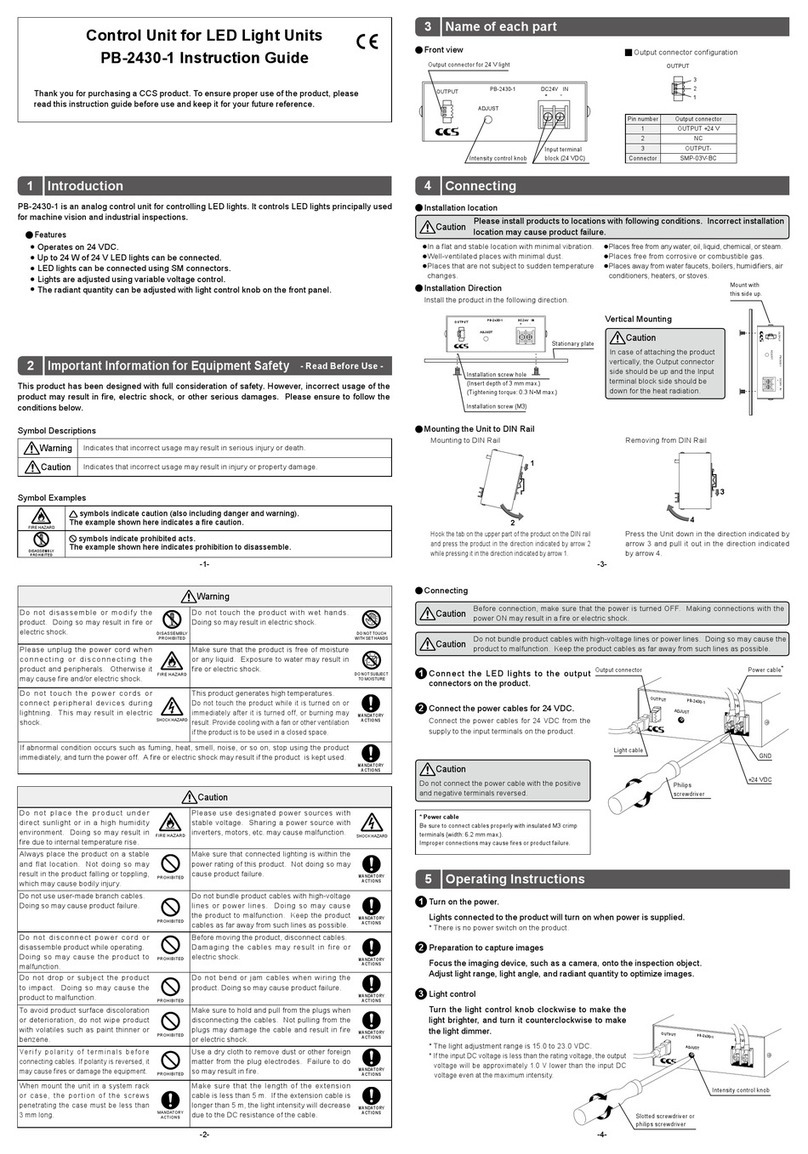

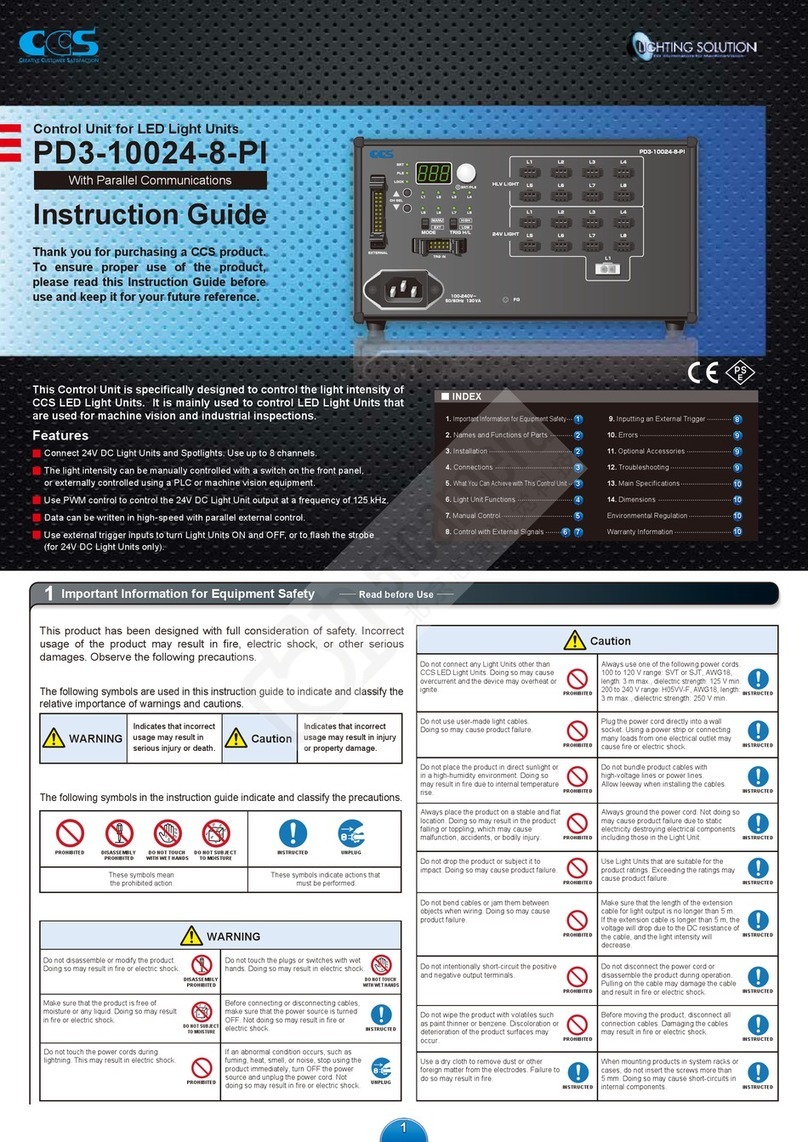

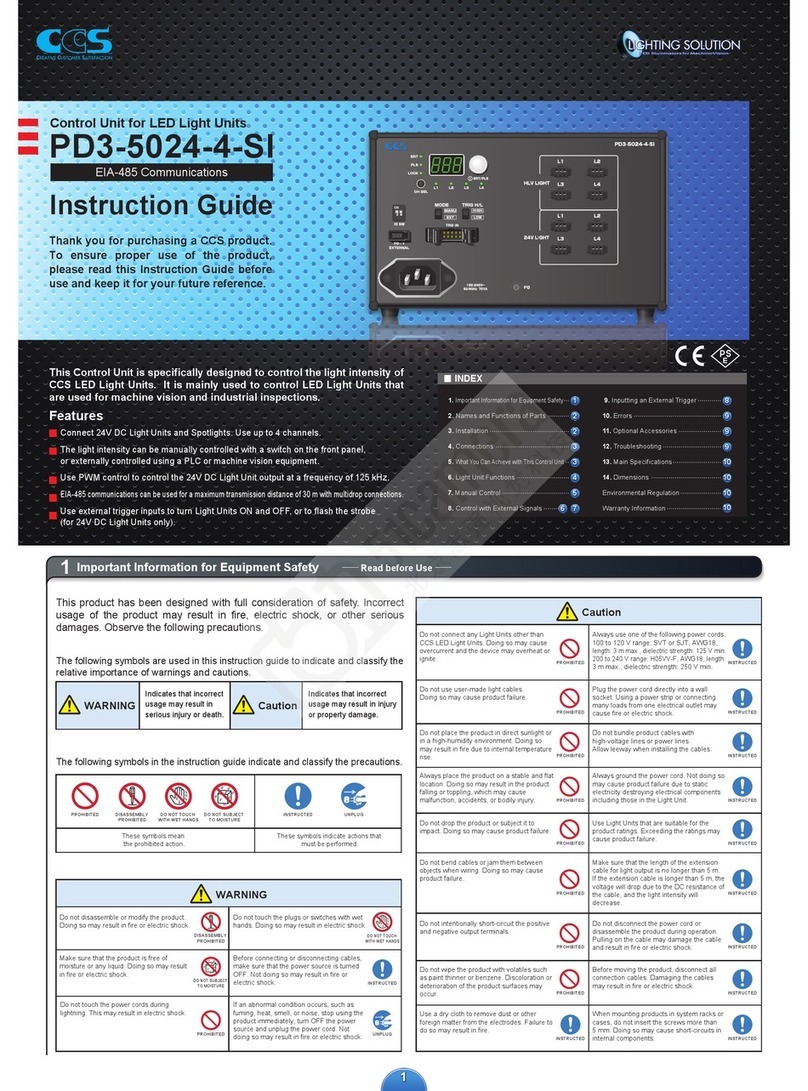

AC input models operate with 100 to 240 VAC. DC power input models operate with 24 VDC.

Models are available for either 2 channels or 3 channels.

The light intensity is controlled using a variable current control method.

The light intensity can be manually controlled by adjusting the intensity volume, or can be

externally controlled using a PLC or image processing device.

The light intensity and lighting ON/OFF are controlled through external control.

The L1 range switch can be used for ne adjustment of the light intensity even in a low intensity range.

(Applicable only for the Spot Light connected to L1)

Features

Introduction

These products are dedicated Control Units to control the CCS LED Spot Lights HLV2/HLV Series.

They are mainly used to control LED Spot Lights that are used for machine vision or industrial inspections.

Do not use the Control Units for other applications, and be sure to follow the instructions below.

Under conditions or in an environment not described in this instruction guide.

In nuclear energy control systems, railroad systems, aviation systems, vehicles, combustion equipment,

medical equipment, amusement machines, or safety equipment.

In applications involving serious risk to life or property, particularly applications demanding a high level of safety.

Do not use the Control Unit in the following situations.

Items common to all equipment

Do not place the Control Unit under direct sunlight

or in a high humidity environment. Doing so may

result in re due to internal temperature rise.

Be sure to ground the Control Unit before using

it. Not doing so may cause the Control Unit to

malfunction due to static change.

Always place the Control Unit on a stable and at location. Not

doing so may result in the Control Unit falling or toppling, which

may cause bodily injury and the Control Unit to malfunction.

Please use designated power sources with

stable voltage. Sharing a power source with

inverters, motors, etc. may cause malfunction.

Do not connect the Control Unit to the Spot Lights other

than the applicable illuminators. Otherwise an over

current may result in heating or re. For information on the

applicable illuminators, refer to 5. Main Specications.

Make sure that connected Spot Light is within

the power rating of the Control Unit. Not doing

so may cause Control Unit failure.

Do not bend or jam cables when wiring the

Control Unit. Doing so may cause Control Unit

failure.

Make sure that the length of the extension cable is less than

the specied length. For information on the cable length,

refer to 5. Main Specications. However, if the cable is too

long, the light intensity will decrease due to voltage drop

caused by the DC resistance of the cable.

Do not use user-made cables.

Doing so may cause Control Unit failure.

Do not bundle the cables with high-voltage lines or power lines.

Doing so may cause the Control Unit to malfunction. Keep the

Control Unit cables as far away from such lines as possible.

To avoid Control Unit surface discoloration or

deterioration, do not wipe the Control Unit with

volatiles such as paint thinner or benzene.

Make sure to hold and pull from the plugs when

disconnecting the cables. Not pulling from the plugs may

damage the cable and result in re or electric shock.

Use a dry cloth to remove dust or other foreign

matter from the plug electrodes. Failure to do

so may result in re.

Before moving the Control Unit, disconnect

cables. Damaging the cables may result in re

or electric shock.

When mount the unit in a system rack or case, the portion of the screws penetrating the case must be less than

5 mm long. If this portion is longer, internal components may be short-circuited.

AC input

Before use the power cord, make sure it satises the specication of the region where you are going to use.

100 to 120V range: SVT type or SJT type, AWG18, length: 3m max., dielectric strength: 125V min.

200 to 240V range: H05VV-F type, AWG18, length: 3m max., dielectric strength: 250V min.

Plug the power cord directly into the wall socket.

Please use the Control Unit within electricity

voltage/current specications. Otherwise it may

cause re and/or electric shock.

Keep metal objects, such as screwdrivers, away

from the power cord plug. Otherwise, re or an

electric shock may result.

Do not damage or place heavy objects on

power cord. There are risks of damaging the

cord, which may result in re or electric shock.

Do not use the Control Unit if the plug on the

cord is damaged or the wall socket is loose.

Otherwise, re or an electric shock may result.

DC input

Verify polarity of terminals before connecting cables. If polarity is reversed, it may cause res or damage

the equipment.

Items common to all equipment

Do not disassemble or

modify the Control Unit.

Doing so may result in

re or electric shock.

Do not touch the Control

Unit with wet hands.

Doing so may result in

electric shock.

DO NOT TOUCH

Make sure that the product is

free of moisture or any liquid.

Exposure to water may result in

re, electric shock, or product

failure.

DO NOT SUBJECT

TO MOISTURE

Do not touch the power

cords during lightning.

This may result in electric

shock.

Turn off the power

when connecting or

disconnecting the Control

Unit and peripherals.

Otherwise it may cause

re and/or electric shock.

If abnormal condition occurs such

as fuming, heat, smell, noise, or

so on, stop using the Control Unit

immediately, and turn off the power.

A re or electric shock may result if

the Control Unit is kept used.

Incorrect usage of the Control Unit may result in re, electric shock, or other serious damages.

Please ensure to follow the conditions below.

Indicates that incorrect usage may

result in serious injury or death.

Indicates that incorrect usage may

result in injury or property damage.

The following symbols are used in this instruction guide to indicate and classify the relative

importance of warnings and cautions.

These symbols indicate prohibited actions. These symbols indicate required actions.

DO NOT TOUCH

DO NOT SUBJECT

TO MOISTURE

The following symbols in the instruction guide indicate and classify the precautions.

Important Information for Equipment Safety - Read Before Use -

Instruction Guide

Thank you for purchasing a CCS product. To ensure proper use of the product,

please read this instruction guide before use and keep it for your future reference.

Dedicsated Control Units for LED Spot Lights HLV2/HLV Series

PJ

Series

Front View

If you use a self-made cable, use a

shielded cable whose length is 3 m or

less.