cegard/Pro CabSafe 2D Light Curtain English

© CEDES | V 1.0 CEDESAG reserves the right to modify or change technical data without prior notice. 2/14

Contents

1 About this manual .................................. 2

1.1 Measurements...................................2

1.2 Related documents ........................... 2

1.3 CEDES headquarters........................ 2

2 Safety information .................................. 2

2.1 Non-intended use..............................3

2.2 Intended use ..................................... 3

3 Symbols, safety messages .................... 3

3.1 Symbols ............................................ 3

3.2 Safety massage category..................3

4 Introduction............................................. 4

4.1 Light curtain system applications.......4

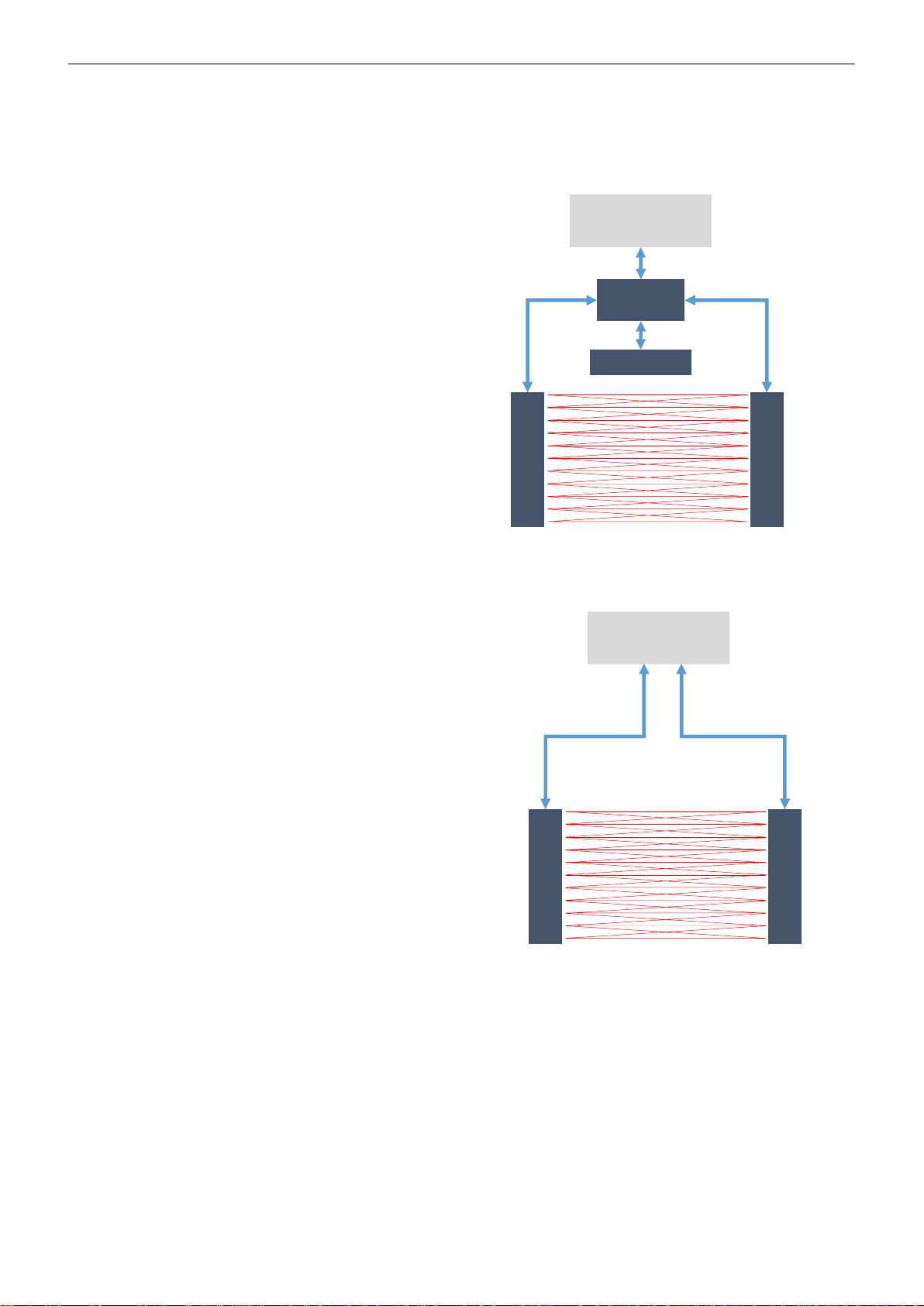

4.2 General operation..............................4

4.3 Features............................................ 5

4.4 General instructions and precautions 5

4.5 Integration.........................................6

4.6 Installation.........................................6

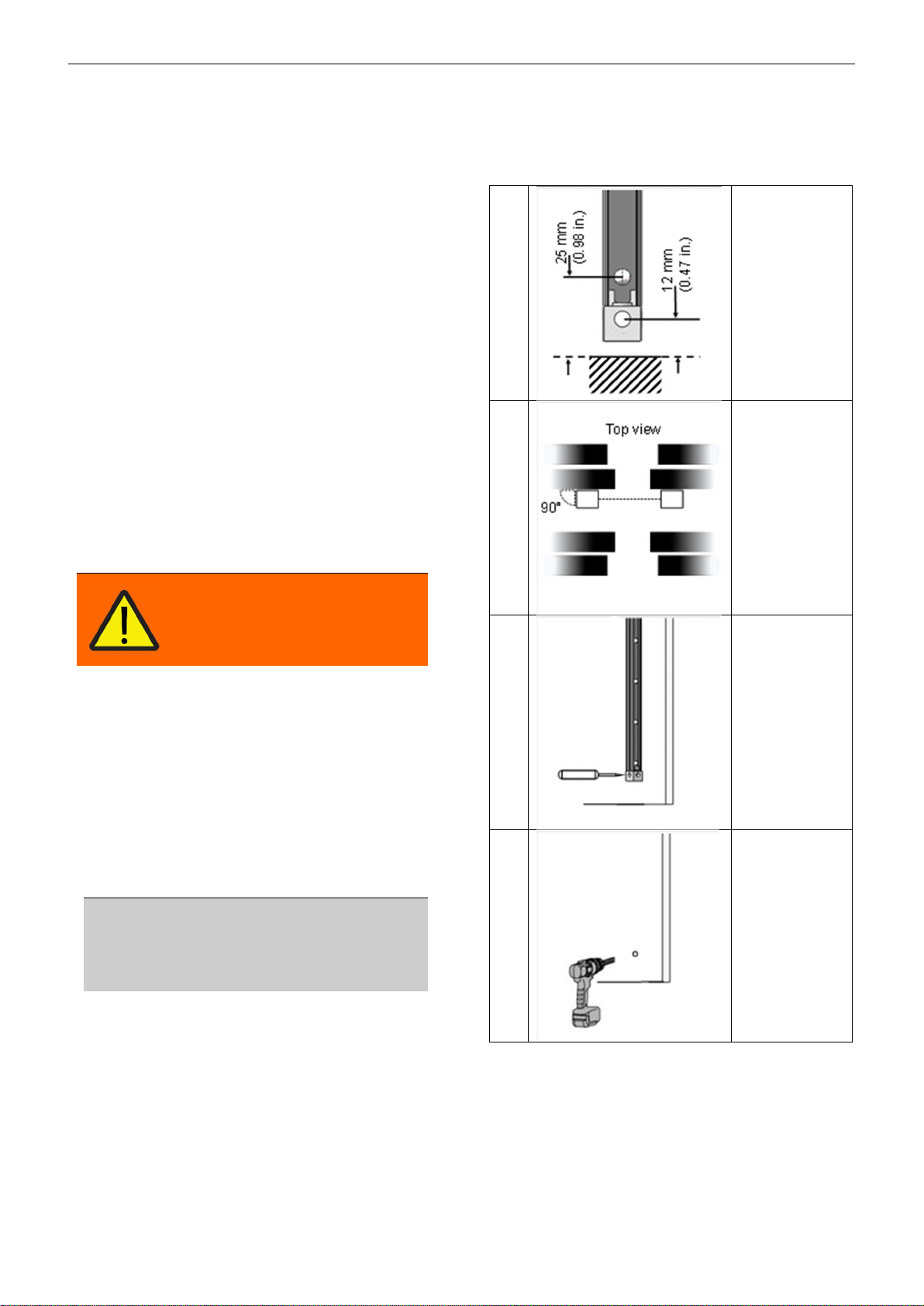

4.6.1 Alignment..........................................6

4.6.2 Mechanical installation......................6

4.6.2.1 Installation height............................... 7

4.6.2.2 Horizontal positioning......................... 7

4.6.2.3 Mounting according to EN 81-20........ 7

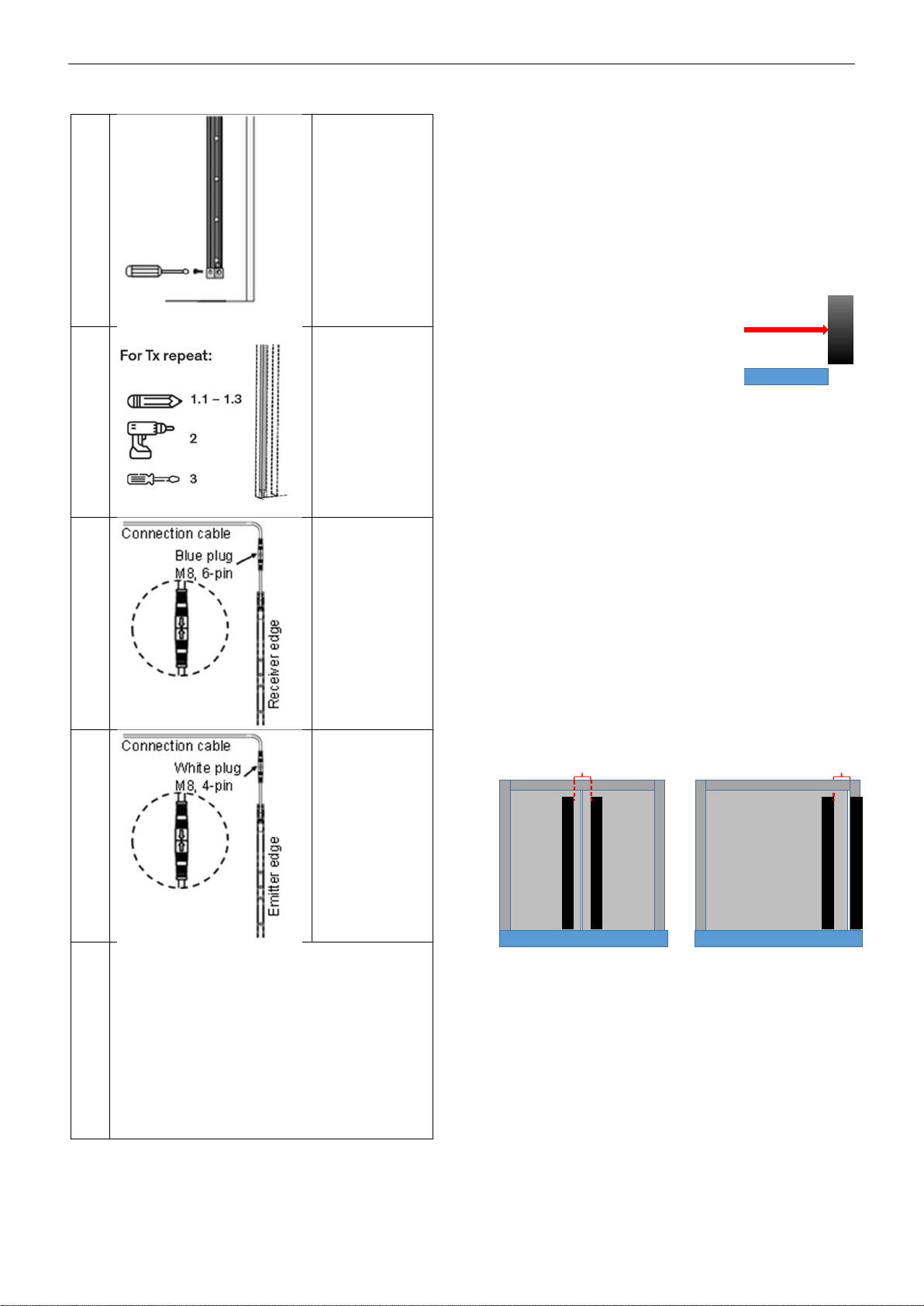

4.6.3 Electrical installation .........................8

4.6.3.1 Connected to a CabSafe Controller ... 8

4.6.3.2 Connected to an elevator controller ... 8

4.6.4 Output ...............................................8

4.6.4.1 FSSL output....................................... 9

4.6.4.2 PNP/NPN selection............................ 9

4.7 Timing diagram................................ 10

4.8 Start-up ........................................... 10

4.9 LED status description..................... 10

4.9.1 Receiver edge (Rx).........................10

4.9.2 Transmitter edge (Tx) .....................10

4.10 Troubleshooting............................... 10

4.11 Maintenance.................................... 11

4.12 Product label ................................... 11

4.13 Type description.............................. 12

4.14 Delivery package............................. 12

4.15 Accessories.....................................12

4.15.1 Vision shield and mounting profiles 12

4.15.2 Mounting clips.................................13

4.16 Technical Data ................................ 13

4.16.1 Optical.............................................13

4.16.2 Mechanical......................................13

4.16.3 Environmental.................................13

4.16.4 Electrical .........................................13

4.16.5 Connection cable & electrical

connection.......................................................13

4.16.6 General ...........................................13

4.17 Dimensions ..................................... 14

5 Disposal ................................................ 14

1 About this manual

This installation and operation manual in English, with

metric measurements is the original version.

The version number is printed at the bottom of each

page.

To make sure you have the latest version, visit

www.cedes.com where this manual and related doc-

uments can be downloaded.

1.1 Measurements

Measurements are, if not stated otherwise, given in

mm (non-bracketed numbers) and imperial dimen-

sions (numbers in brackets).

1.2 Related documents

116 105 CE confirmation

115 944 User manual CabSafe 3D Sensor and

CabSafe Controller

1.3 CEDES headquarters

CEDES AG

Science Park

CH-7302 Landquart

Switzerland

2 Safety information

IMPORTANT READ BEFORE IN-

STALLATION!

The cegard/Pro (CabSafe 2D) light curtain system

was developed and manufactured using state-of-the-

art systems and technologies. However, injury and

damage to the sensor can still occur.

To ensure safe conditions:

►Read all enclosed instructions and infor-

mation.

►Follow the instructions given in this manual

carefully.

►Observe all warnings included in the docu-

mentation and attached to the sensor.

►Do not use the sensor if it is damaged in any

way.

►Keep the instruction manual on site.

The cegard/Pro (CabSafe 2D) light curtain system

should only be installed by authorized and fully

trained personnel! The installer or system integrator

is fully responsible for the safe integration of the sen-

sor. It is the sole responsibility of the planner and/or

installer and/or buyer to ensure that this product is

used according to all applicable standards, laws and

regulations in order to ensure safe operation of the

whole application.