Before Starting Work 4.0

Fitting Tools 5.0

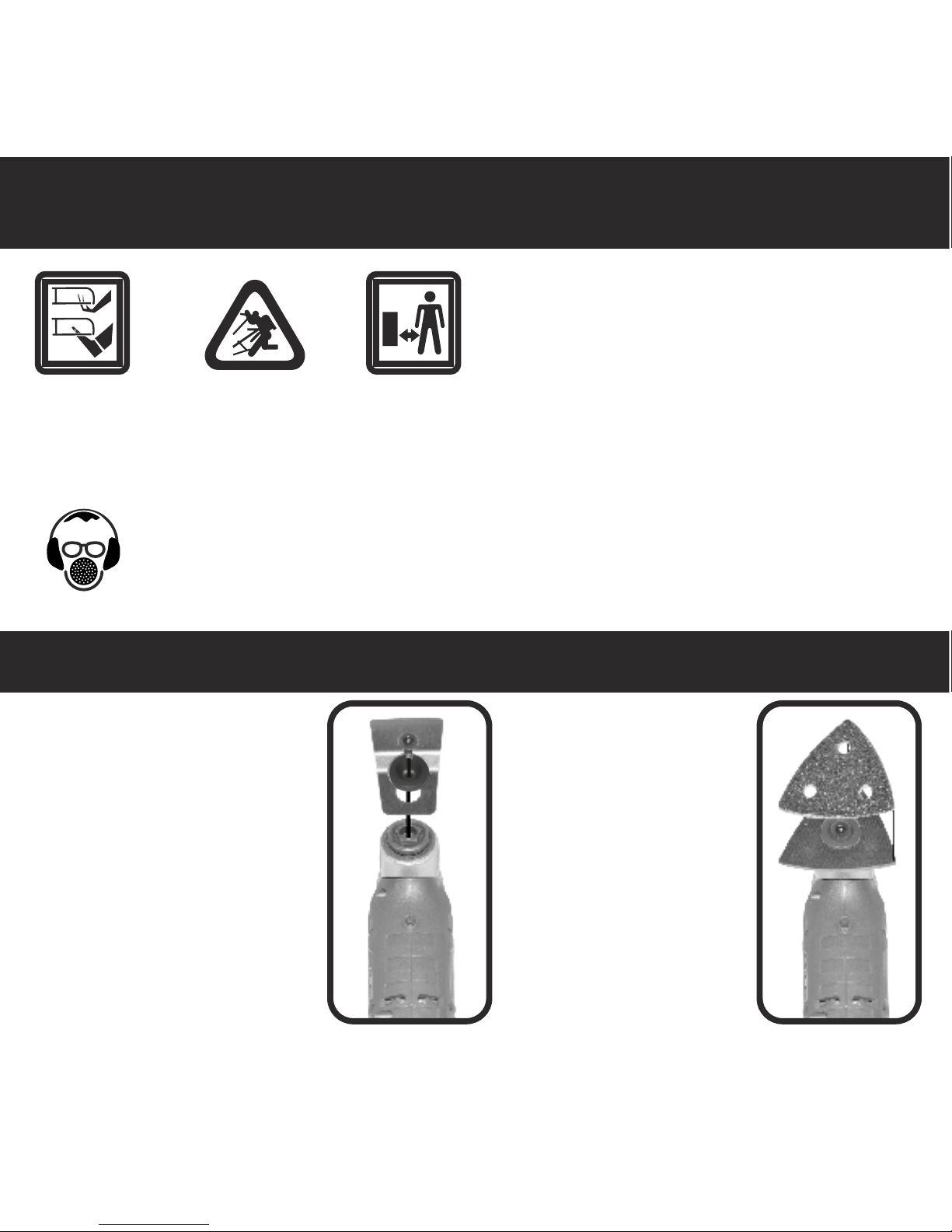

If required, remove an already

mounted tool/accessory.

Loosen the screw with the hex key

and remove the tool/accessory. Be

sure to clear any debris.

Mount a suitable tool/accessory in

such a manner on the tool holder that

the offset faces downward.

Turn the tool/accessory to a position

favourable for the respective job, and

allow it to engage into the cams of the

tool holder. 12 different positions are

possible, each offset by 30°. Fasten

the tool/accessory with Locking Bolt

and Washer. Tighten the bolt with Hex

key until the washer and bolt are flush

with the tool/accessory and firmly

fixed.

The sanding plates are fitted

with Velcro backing for quick

and easy fastening of sanding

sheets with Velcro adhesion.

Before attaching the sanding

sheet , free the Velcro backing

of the sanding plate from any

debris by tapping to enable

optimum adhesion.

Position the sanding sheet flush

alongside one edge of the

sanding plate, then lay the

sanding sheet onto the sanding

plate and press firmly.

To remove the sanding sheet,

grasp it at one of the tips and

pull it off from the sanding plate.

Check the tight seating of the

tool/accessory while fitting and

regularly while working there is

a risk they can come loose

during operation and be

damaged or hazardous .

Switching On and Off

To start the machine, push the

On/Off switch forward so that "ON" is

indicated on the switch.

To switch off the machine, push the

On/Off switch toward the rear so that the

"OFF" is indicated on the switch.

Selecting the rate of oscillation

Use the thumbwheel to select the rate of

oscillation.

The required rate of oscillation depends

on the material and the working

conditions and can be determined

through practical testing.

Sawing

~ Use undamaged faultless saw blades

only.

Deformed, blunt saw blades or saw

blades that are otherwise damaged can

break or shatter.

~ Continuously move the blade to clear

debris and dissipate heat. Beware of

hot blades.

~ Plunge cuts may only be applied to

soft materials, such as wood, gypsum

plaster boards, etc.

~ Before sawing with AC12 saw blades

in wood, particle board, building

materials, etc., check these for foreign

objects such as nails, screws, or similar.

If required, remove foreign objects or

use AC11 saw blades.

Separating

Note: When separating wall tiles take into

consideration that the application tools/accessories

wear heavily when used for longer periods of time.

Sanding

The removal rate and the sanding pattern are

primarily determined by the choice of sanding

sheet, the preset oscillation rate and the applied

pressure, the corners of the sheet have the

longest oscillating travel and so will perform the

most vigorously.

Flawless sanding sheets achieve the

best sanding capacity and extend

the service life of the machine.

Try to apply uniform sanding pressure;

this increases the working life of the sanding

sheets. Low/medium speed is recommended.

Additional pressure does not lead to an

increased sanding capacity, only increased

wear of the machine and the sanding sheet.

For precise on-the-spot sanding of edges,

corners and hard to reach areas, it is also

possible to work only with the tip or an edge of

the sanding plate.

When selectively sanding on the spot, the

sanding sheet can heat up considerably. Reduce

the oscillation rate and allow the sanding sheet to

cool down regularly.

A sanding sheet that has been used for metal

should not be used for other materials.

Use only original CEL sanding accessories.

Scraping

For scraping, select a high oscillation rate. Work

on a soft surface (e.g. wood) at a flat angle, and

apply only light pressure. Otherwise the scraper

can cut into the surface. Do not press to hard,

allow the tool to work and reduce the risk of a slip.

Operating 6.0

Sharp blades, heat buildup and flying debris are a

danger to user and bystanders. Use of suitable

protective clothing, gloves, footwear, eye and ear

protection as well as safe working practices can reduce

these risks.

Dusts from materials such as lead-

containing coatings, some wood types,

minerals and metal can be harmful to

one's health. Touching or breathing-in the

dusts can cause allergic reactions and/or

lead to respiratory infections of the user

or bystanders.

Certain dusts, such as oak or beech dust, are

considered as carcinogenic, especially in connection

with wood-treatment additives (chromate, wood

preservative). Materials containing asbestos may only

be worked by specialists.

- Use dust extraction whenever possible.

- Provide for good ventilation of the working place.

- It is recommended to wear a P2 filter class respirator.

Observe the relevant regulations in your country for the

materials to be worked

Do not cover the venting slots of the machine while

working, as this reduces the working life of the

machine.

This tool vibrates at very high frequency. Regular

breaks must be taken to reduce the chance of injury. At

the first sign of discomfort work should immediately

cease.

Sharp blades, heat

buildup and flying

debris are a danger

to user and

bystanders. Use of

suitable protective

clothing, gloves,

footwear, eye and

ear protection as

well as safe

working practices

can reduce these

risks.

Variable

Speed

ON

OFF

NOTE:

The AC17 adaptor washer is not required to fit CEL blades on CEL tools.