7

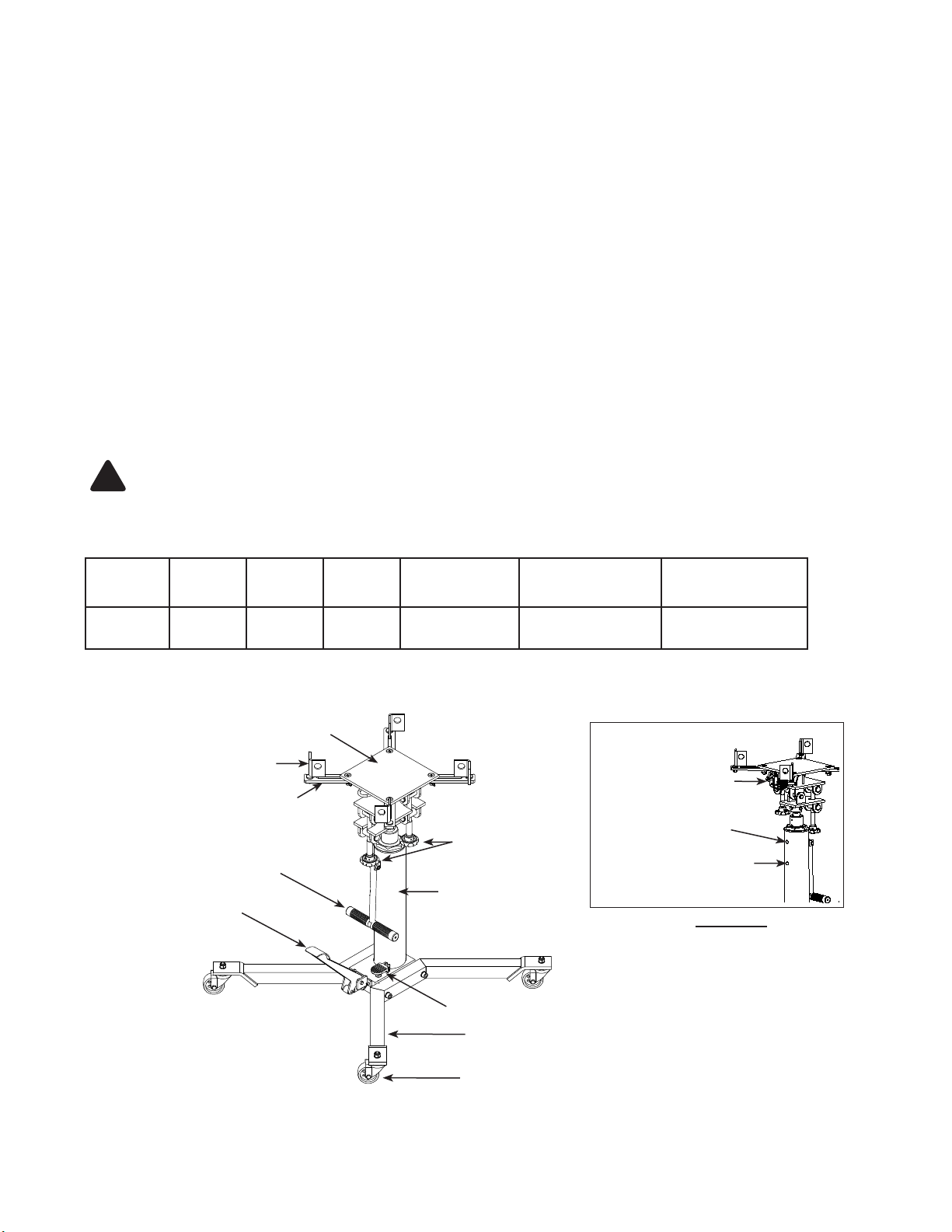

Replacement Parts List for Model 41003

Item Part No. Description Qty

1 G390-10000-000 Hydraulic Unit 1

2 G390-15001-000 Pump Piston 1

3 G390-15002-000 Pump Piston Guide 1

4 G390-10004-000 Spring 1

5 5601-00635-000 Steel Ball 5

6 5405-02018-000 Retaining Pin 1

7 G390-10005-000 Release Pedal 1

8 5405-07027-000 Pin 1

9 G390-10008-000 Spring 1

10 5601-00952-000 Steel Ball 1

11 5309-00012-000 Washer 1

12 5309-00008-000 Washer 1

13 G390-17001-000 Throttle 1

14 G390-17002-000 Spring 1

15 5601-00476-000 Steel Ball 1

16 G150-04301-000 Releave Valve Nut 1

17 G150-04002-000 Spring 1

18 G150-04001-000 Release Valve 1

19 5305-00009-000 E-clip 1

20 G251-00007-000 Handle Grip 2

21 G390-20000-000 Handle 1

22 G390-30000-000 Foot Pedal 1

23 T250-05000-000 Caster 2

24 G390-40000-000 Saddle Assembly 1

25 T250-08000-000 Screw Assembly 2

26 T250-00002-000 Spindle 2

27 5202-00010-000 Nut, M10 4

28 T250-00006-000 Bracket Bar 4

29 T250-04000-000 Bracket 4

30 5207-00012-000 Wing Nut, M12 4

31 5107-12040-000 Philips Screw, M12x40 4

32 G390-41000-000 Nylon Strap Assy. 1

33 G390-90009-K01 Capscrew Kit (4 sets) -

34 5905-00100-200 Plug, Hyd Oil 1

35 5905-00100-001 Plug, Vent 1

(*) G3900S-103 Repair Kit 1

REPLACEMENT PARTS (page 6 & 7)

Not all components of the jack are replacement items, but are illustrated as a convenient reference of location and

position in the assembly sequence. When ordering parts, please give the Model number and parts description. Call

or write for current pricing: SFA Companies 10939 N. Pomona Ave. Kansas City, MO 64153, U.S.A.

E-Mail:

[email protected] T

el: (888) 332-6419 Fax: (816) 891-6599 Website: http://www

.omegalift.com

Item Description Qty

36A U-cup Ram 2

36B O-ring 1

36C O-ring 1

36D Back-up Washer 1

36E O-ring 1

36F Back-up Washer 1

36G O-ring 1

36H O-ring 1

36J Back-up Washer 1

36K Back-up Washer 1

36L Seal 1

36M O-ring 1

36N Back-up Washer 1

36P O-ring 1

36R O-ring 1

36S Back-up Washer 1

36T O-ring 1

36U Back-up Washer 1

36V O-ring 1

36W O-ring 1

Repair Kit Parts (G3900S-103)