-8-

PROPILOT 725 INSTALLATION & SERVICING MANUAL

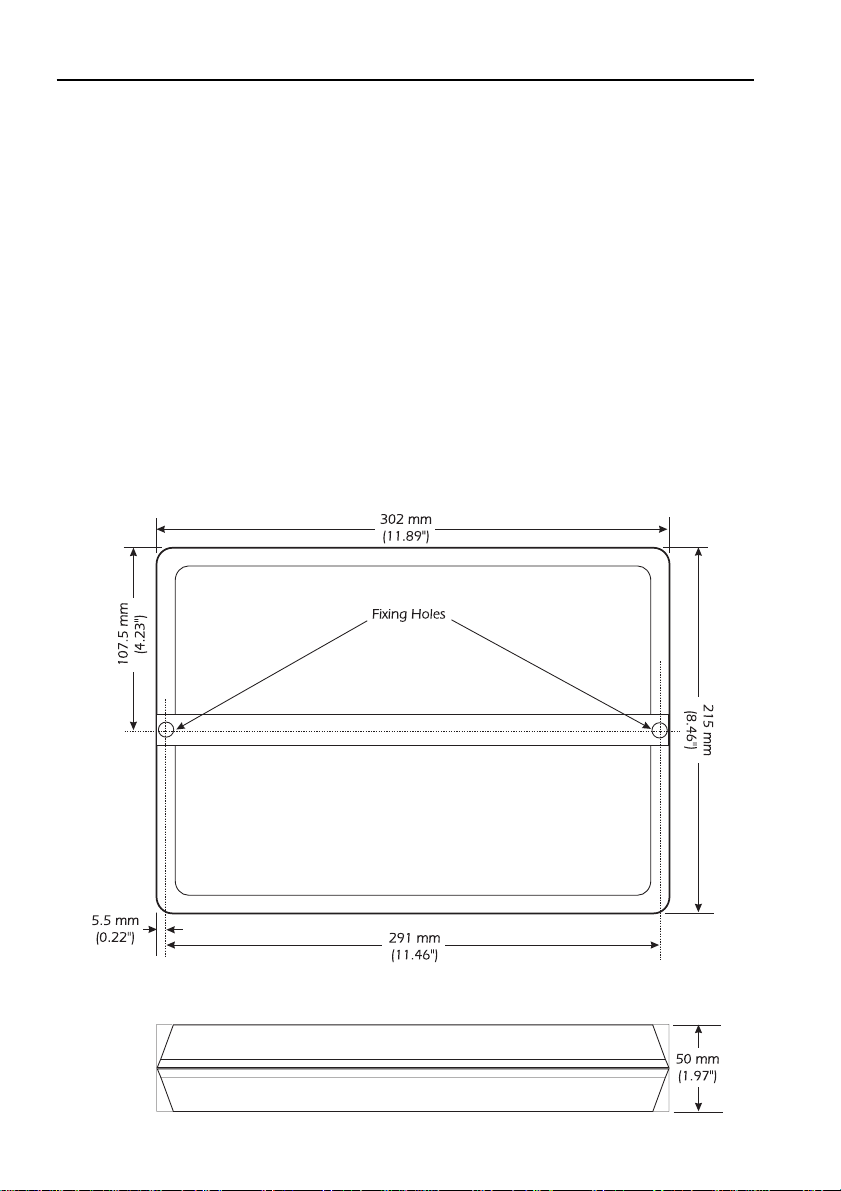

Installing your Propilot 725

information for fuse ratings.

Distribution This is the heart of the system and must be installed in a DRY,

Box accessible position.

Ideally the box should be positioned so that the heavy duty

power supply cables from the batteries to the distribution box

and from the distribution box to the drive unit are kept to a

minimum length. This is particularly important on sailing

vessels where often you are operating on batteries which are

not fully charged.

If the distribution box has to be installed in the engine room

please ensure that the area is properly ventilated to avoid high

ambient temperatures and abnormal condensation levels.

Compass The Compass Sensor needs to be carefully located. The

Sensor optimum position is to mount it on a convenient (vertical)

bulkhead, as low and as close to the centre line of the boat as

possible. On fast vessels, it is advisable to fit the compass

sensor at least half way back along the centre line.

On steel vessels it is necessary to mount the sensor 2 to 3

metres above the superstructure or to use a Gyro or Pick-off

coil system working from the vessel's main steering compass.

The compass sensor must be installed away from sources of

magnetic interference, such as:

Radios, RDF, Depth Recorders, etc: at least 1 metre clearance

Power cables carrying more than 0.5 amp: at least 1 metre clearance

Radar Magnetrons: at least 3 metre clearance

Ship's engines, large mass steel (soft iron) etc: at least 1 metre clearance

Also, do not install the compass in a position where magnetic

material i.e. tool boxes, drink cans, chain etc. may be stowed

at any time.

Check the proposed location with a hand bearing compass.

This will indicate whether there is a large deviation that may

cause problems. Switch on any electrical equipment that may

cause deviation and check the hand-bearing compass to see if

there has been any change on heading. If a change is observed

the Sensor should not be installed in this position as the

compass heading may not reflect the true heading of the craft,

therefore making autopilot control inaccurate.