4

GATE CONSTRUCTION INFORMATION

SAFETY

1. GENERAL REQUIREMENTS

1.1 Gates shall be constructed in accordance with the provisions

given for the appropriate gate type listed, refer to ASTM F2200 for

additional gate types.

1.2 Gates shall be designed, constructed and installed to not fall over

more than 45 degrees from the vertical plane, when a gate is

detached from the supporting hardware.

1.3 Gates shall have smooth bottom edges, with vertical bottom

edged protrusions not exceeding 0.50 inches (12.7 mm) when

other than the exceptions listed in ASTM F2200.

1.4 The minimum height for barbed tape shall not be less than 8 feet

(2.44 m) above grade and for barbed wire shall not be less than 6

feet (1.83 m) above grade.

1.5 An existing gate latch shall be disabled when a manually operated

gate is retrofitted with a powered gate operator.

1.6 A gate latch shall not be installed on an automatically operated

gate.

1.7 Protrusions shall not be permitted on any gate, refer to ASTM

F2200 for Exceptions.

1.8 Gates shall be designed, constructed and installed such that their

movement shall not be initiated by gravity when an automatic

operator is disconnected, in accordance with the following.

1.8.1 Vehicular horizontal slide gate. Shall not result in continuous,

unimpeded movement in either lineal direction of its travel.

1.8.2 Vehicular horizontal swing gate. Shall not result in continuous,

unimpeded movement in either direction along the arc of its path

of travel.

1.9 For pedestrian access in the vicinity of an automated vehicular

gate, a separate pedestrian gate shall be provided. The pedestrian

gate shall be installed in a location such that a pedestrian shall

not come in contact with a moving vehicular access gate. A

pedestrian gate shall not be incorporated into an automated

vehicular gate panel.

2. SPECIFIC APPLICATIONS

2.1 Any non-automated gate that is to be automated shall be

upgraded to conform to the provisions of this specification.

2.2 This specification shall not apply to gates generally used for

pedestrian access and to vehicular gates not to be automated.

2.3 Any existing automated gate, when the operator requires

replacement, shall be upgraded to conform to the provisions of

this specification in effect at that time.

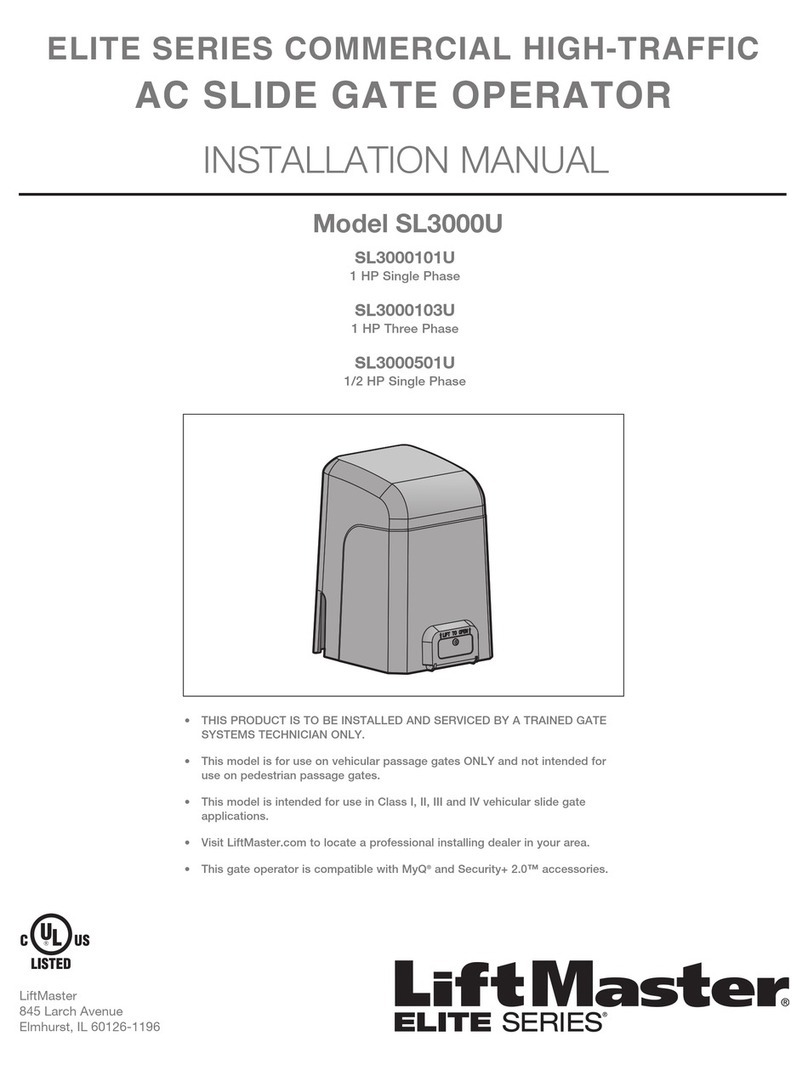

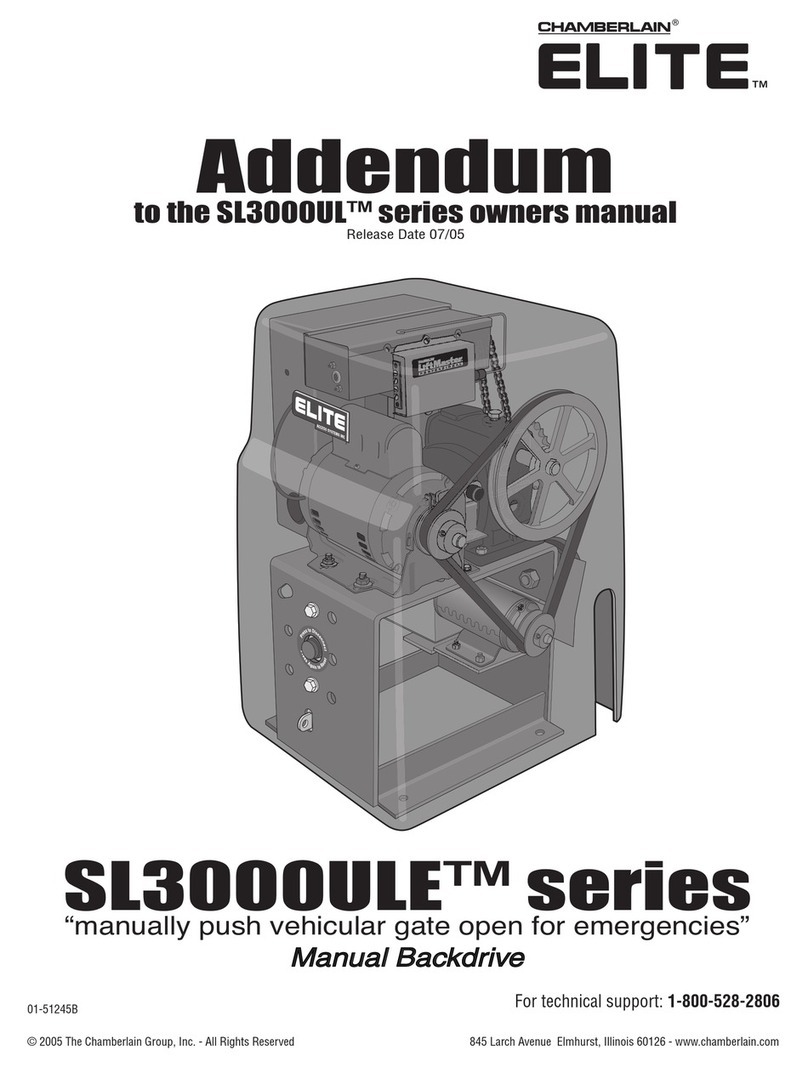

3. VEHICULAR HORIZONTAL SLIDE GATES

3.1 The following provisions shall apply to Class I, Class II and Class

III vehicular horizontal slide gates:

3.1.1 All weight bearing exposed rollers 8 feet (2.44 m), or less, above

grade shall be guarded or covered.

Vehicular gates should be installed in accordance with ASTM F2200: Standard Specification for Automated Vehicular Gate Construction. For a copy,

contact ASTM directly at 610-832-9585 or www.astm.org.

3.1.2 All openings shall be designed, guarded, or screened from the

bottom of the gate to the top of the gate or a minimum of 72 in.

(1.83 m) above grade, whichever is less, to prevent a 2 1⁄4 in.

(57 mm) diameter sphere from passing through the openings

anywhere in the gate, and in that portion of the adjacent fence

that the gate covers in the open position. The gate panel shall

include the entire section of the moving gate,including any back

frame or counterbalance portion of the gate.

3.1.3 A gap, measured in the horizontal plane parallel to the roadway,

between a fixed stationary object nearest the roadway, (such as a

gate support post) and the gate frame when the gate is in either

the fully open position or the fully closed position, shall not

exceed 2 1/4 inches (57 mm), refer to ASTM F2200 for Exception.

3.1.4 Positive stops shall be required to limit travel to the designed fully

open and fully closed positions. These stops shall be installed at

either the top of the gate, or at the bottom of the gate where such

stops shall horizontally or vertically project no more than is

required to perform their intended function.

3.1.5 All gates shall be designed with sufficient lateral stability to

assure that the gate will enter a receiver guide, refer to ASTM

F2200 for panel types.

3.2 The following provisions shall apply to Class IV vehicular

horizontal slide gates:

3.2.1 All weight bearing exposed rollers 8 feet (2.44 m), or less, above

grade shall be guarded or covered.

3.2.2 Positive stops shall be required to limit travel to the designed fully

open and fully closed positions. These stops shall be installed at

either the top of the gate, or at the bottom of the gate where such

stops shall horizontally or vertically project no more than is

required to perform their intended function.

4. VEHICULAR HORIZONTAL SWING GATES

4.1 The following provisions shall apply to Class I, Class II and Class

III vehicular horizontal swing gates:

4.1.1 Gates shall be designed, constructed and installed so as not to

create an entrapment area between the gate and the supporting

structure or other fixed object when the gate moves toward the

fully open position, subject to the provisions in 4.1.1.1 and

4.1.1.2.

4.1.1.1 The width of an object (such as a wall, pillar or column) covered

by a swing gate when in the open position shall not exceed 4

inches (102 mm), measured from the center line of the pivot

point of the gate, refer to ASTM F2200 for exception.

4.1.1.2 Except for the zone specified in Section 4.1.1.1, the distance

between a fixed object such as a wall, pillar or column, and a

swing gate when in the open position shall not be less than 16

inches (406 mm), refer to ASTM F2200 for exception.

4.2 Class IV vehicular horizontal swing gates shall be designed,

constructed and installed in accordance with security related

parameters specific to the application in question.