Charles WIC-101010SXAN1 Operating and installation instructions

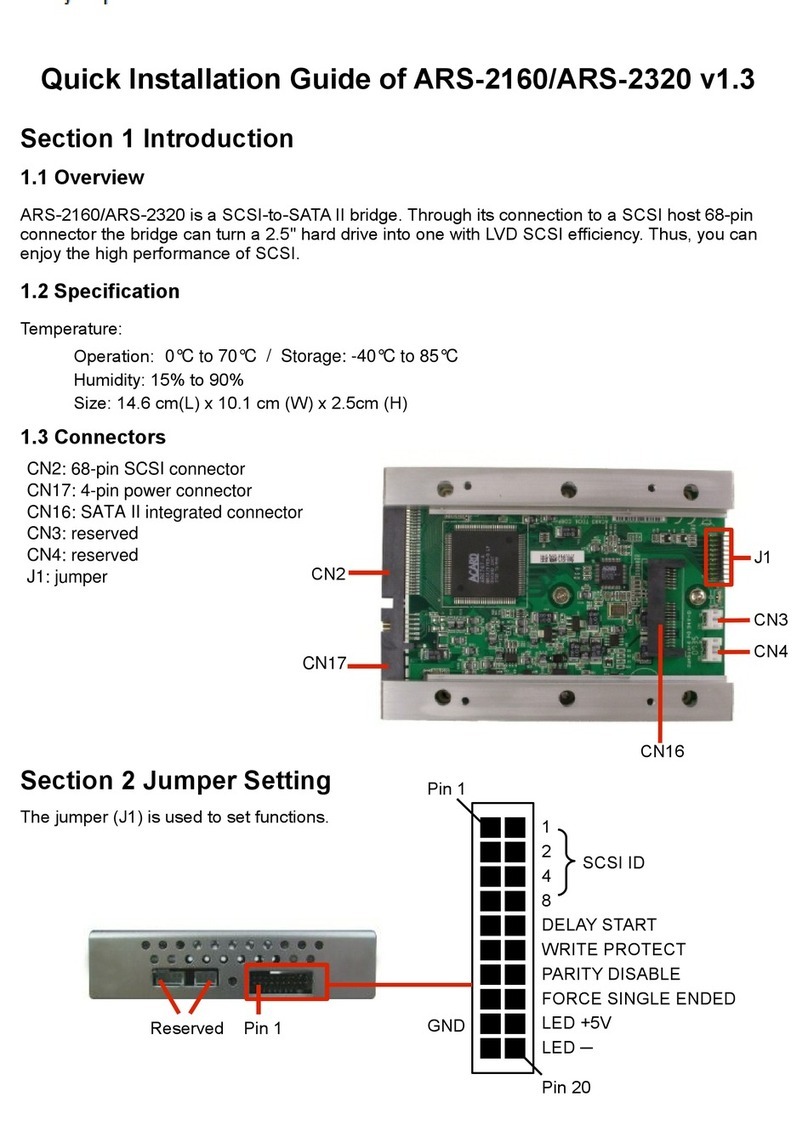

LT-WIC101010

3rd Printing, July 15, 2020

©Copyright 2020 Charles Industries LLC. All Rights reserved. Printed in the United States of America.

Availability of features and technical specifications herein are subject to change without notice.

Charles is a registered trademark of Charles Industries.

Page 1 of 16

Charles Universal Broadband Enclosure

WIC-101010SXAN1

General Description and Installation

1. GENERAL INTRODUCTION ......................................................1

1.1. Document Purpose...................................................................1

1.2. Product Purpose.......................................................................1

1.3. Product Mounting and Location...............................................1

2. PRODUCT DESCRIPTION...........................................................2

3. INSTALLATION............................................................................6

3.1. Inspecting the Product..............................................................6

3.2. Following and Using Safety Precautions..................................6

3.3. Obtaining Tools and Equipment...............................................6

3.4. Preparing the Installation Site..................................................6

3.5. Lifting the WIC.........................................................................7

3.6. Mounting the WIC....................................................................7

3.7. WIC Wiring and Equipment....................................................10

3.8. Conduit Seals..........................................................................13

3.9. Verifying the Installation........................................................13

4. PERIODIC MAINTENANCE......................................................13

5. TECHNICAL ASSISTANCE AND REPAIR SERVICE...........13

6. WARRANTY & CUSTOMER SERVICE ...................................13

7. SPECIFICATIONS.......................................................................13

7.1. Regulatory Specifications.......................................................13

7.2. Product Specifications............................................................14

7.3. Part Numbers .........................................................................14

7.4. Alarm Connections.................................................................15

1. GENERAL INTRODUCTION

1.1. Document Purpose

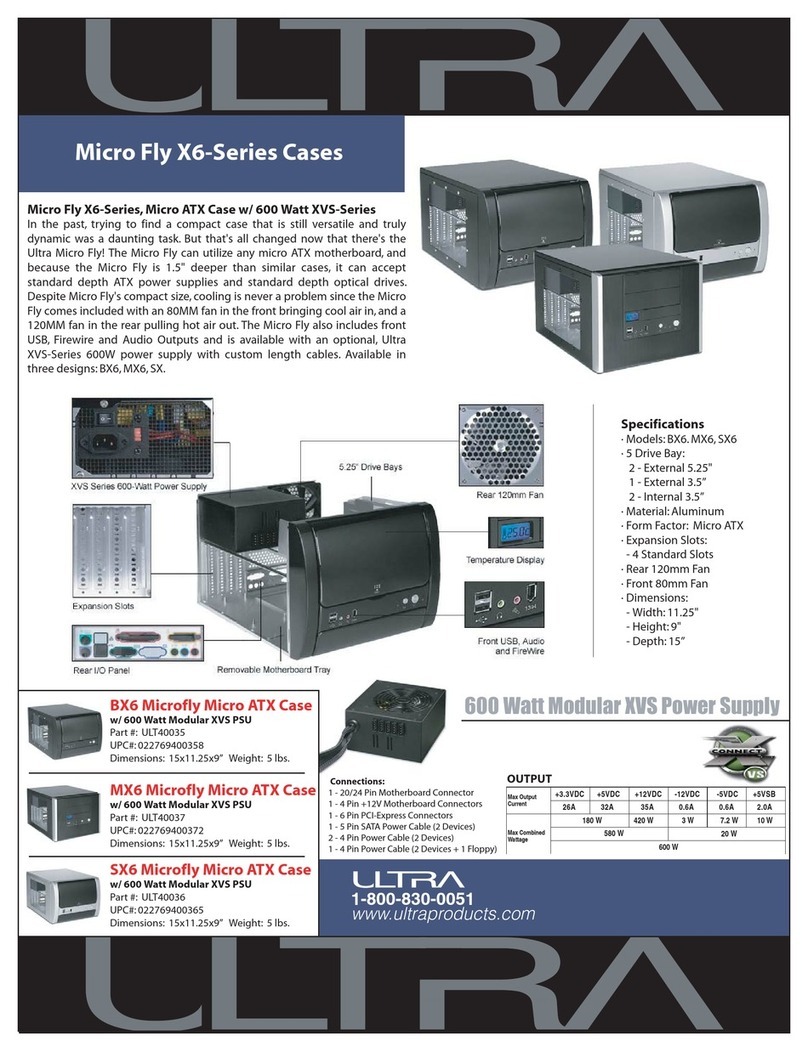

This document provides general information for the WIC-101010SXAN1 walk-in cabinet. Figure 1 shows a closed front view of the

enclosure.

-NOTE-

Hereafter, the Charles Walk-in Cabinet WIC-101010SXAN1 will be referred to as the “WIC.”

1.2. Product Purpose

The WIC consists of a protective walk-in enclosure for an integrated system of electronic components and equipment that can serve fiber

and copper interfaces. Note: this enclosure is not intended for use as a dwelling and is not suitable for human or animal habitation.

1.3. Product Mounting and Location

This enclosure is suitable for outside plant-type (OSP) locations and those that may require NEC compliance. The outdoor, weather-

resistant WIC is to be mounted on a concrete pad. The installer connects the power, fiber and copper connections. Detailed mounting and

installation information is covered in Section 3.

Figure 1 Front View of the WIC

LT-WIC101010

Page 2 of 16

3rd Printing

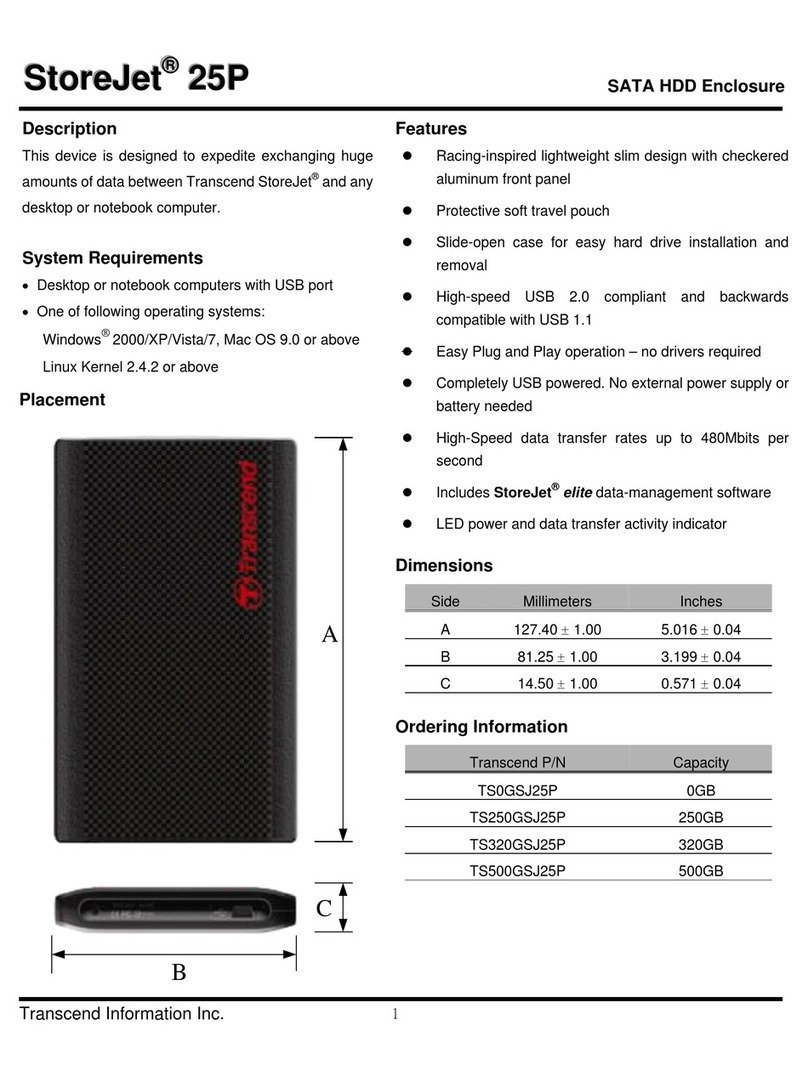

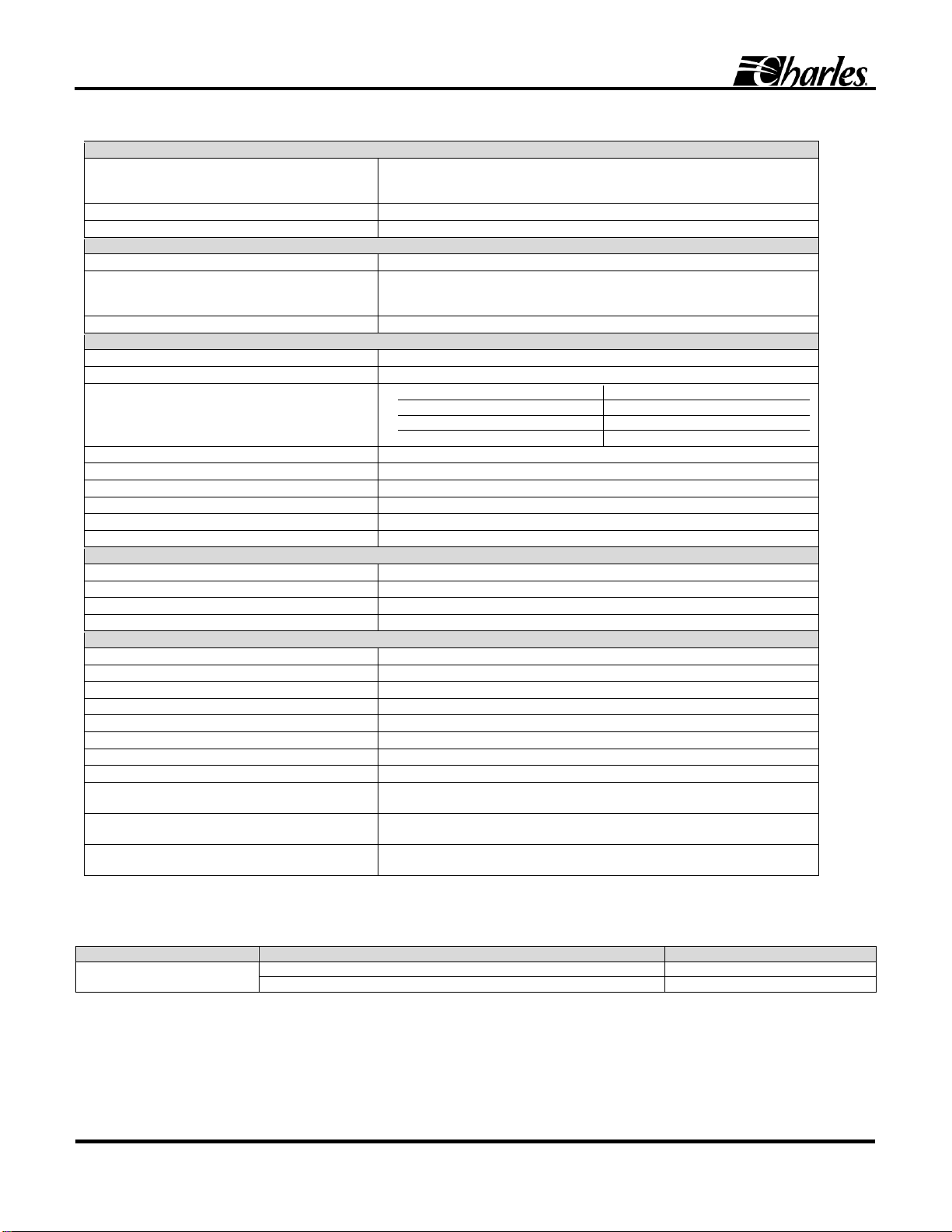

2. PRODUCT DESCRIPTION

The WIC is an enclosure that houses multiple equipment racks suitable for customer supplied equipment. The WIC has four Charles CTMS

thermal devices mounted on the side walls, as well as a Charles Intelligent Ventilation System (IVS). Motion-sensitive lighting units are

mounted on the front and rear. Multiple exterior ground bars all connect to an interior master ground bar.

Equipment and power racks are added to the WIC by Worldwide Technologies. See their documentation for information about the power

equipment included. Accessory kits are available (sold separately) that add more cable entry ports, a stair kit for the front door, and a 10k

BTU DC powered HVAC system. All kits are listed in Table 1.

Figure 2 shows the WIC dimensions. Figures 3 and 4 show the external and internal components of the WIC. Figure 5 shows the WIC with

equipment and power racks and optional kits installed.

Figure 2 WIC Dimensions (in inches)

LT-WIC101010

3rd Printing

Page 3 of 16

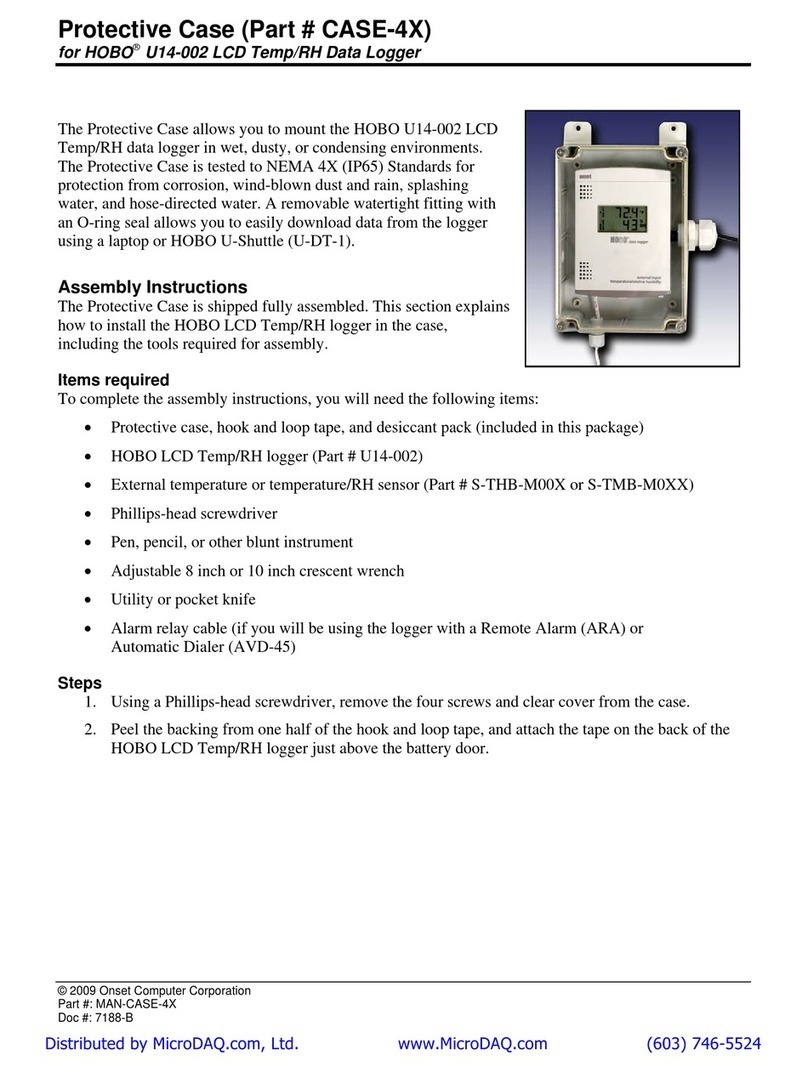

Figure 3 WIC External Components

LT-WIC101010

Page 4 of 16

3rd Printing

Figure 4 WIC Internal Components

(Front and Right Side Walls Hidden)

LT-WIC101010

3rd Printing

Page 5 of 16

Figure 5 WIC with Optional Kits and Equipment Racks Installed

(Front and Right Side Walls Hidden)

LT-WIC101010

Page 6 of 16

3rd Printing

3. INSTALLATION

3.1. Inspecting the Product

The WIC is shipped as a wide load on a flatbed trailer with shrink wrap. Unpack the unit, and dispose of the packaging material.

-INSPECTION NOTE-

Visually inspect the unit for damages prior to installation. If the equipment was damaged in transit, immediately report the extent of the

damage to the transportation company.

3.2. Following and Using Safety Precautions

Read the following site and safety tips, cautions, and warnings, then proceed with the paragraphs that follow.

For installation, follow all National Electrical Codes (NEC) ANSI/NFPA 70, local, environmental, workplace, and company

codes, safety procedures, and practices.

Minimum spacing between the accessories and components and the housing forITE equipment shall be maintained for safe

operation of the equipment when installed in accordance with NEC ANSI/NFPA 70.

Read all instructions, warnings and cautions on the equipment and in the documentation shipped with the product.

Always connect ground connections first.

Do not place this product on weak or unstable surfaces which may allow the product to fall, resulting in potentially serious

damage(s) to persons or product.

Only authorized trained personnel shall install the WIC.

3.3. Obtaining Tools and Equipment

Obtain the following recommended orneeded items for installing the WIC.

Sufficient length and quantities of fiber cable (or pigtails)

Cable scoring, opening, and cutting tools for cable sheathing, shields, wrappings, strength members and buffer tubes

Wire strippers

Crimpers

Cable, tube, wire, and fiber cleaning materials

Protective and/or insulated work gloves

Safety glasses

Tape measure

Marking utensil

#6 ground wire or rod and earth ground materials

Bond strap (optional, from cable bond clamp to bond post)

Any exterior cable strain relief, per company practice

Slotted, hex, and Phillips screwdrivers

Assorted cable ties, clips, or fasteners (optional)

Can wrench (216 type tool)

Forklift or crane for lifting

Level

3.4. Preparing the Installation Site

Observe the following site preparation recommendations.

Leave adequate horizontal and vertical space between multiple installations to allow for proper cable access, as well as enough

room around the enclosure to open the door(s).

The site must meet minimal personnel and equipment safety requirements.

The distance from the cable entry point should be consistent with local installation practices.

The pad must be able to support the weight of the WIC.

Run all fiber and copper facilities to the site.

LT-WIC101010

3rd Printing

Page 7 of 16

3.5. Lifting the WIC

See Table 1 for WIC weight. The WIC can be moved by either forklift or crane.

If using a forklift, remove the panel on the front, below the door (Figure 3) to

access the forklift pockets. When the WIC is in place, replace this panel.

If using a crane, then Charles recommends the following procedure for lifting

the WIC.

3.5.1. Required Equipment

One derrick (crane) capable of lifting the WIC

Spreader bars

Four lifting slings or chains with each having a minimum 10,000 lbs.

capacity

Connecting links to attach slings to the WIC’s lifting brackets

75-ft. long tagline rope

Insert the lifting sling connecting links securely through each of the lifting

brackets as shown in Figure 6.

3.5.2. Warnings and Specific Safety Precautions

WARNING

Improper hoisting equipment and unsafe lifting procedures can result in serious injury or death

Observe the following local safety procedures when performing the tasks in this section.

Keep the WIC away from any power lines.

Keep bystanders away fromthe work operations at all times.

Only trained operators shall operate the crane for lifting and setting the WIC.

Do not suspend loads over people or equipment.

All persons working with hoisting equipment shall wear standard safety gear according to local practices including safety

helmets and steel-toed shoes.

Do notoperate thehoisting equipment until all stabilizer are extended and in firm contact with the ground or adequate support

structure.

Do not attempt to retract or extend the stabilizers while a load is suspended.

3.6. Mounting the WIC

The WIC can be mounted on a new or existing concrete or composite pad. Ensure that the unit is level.

Two EMI mounting kits are also available (1000-0000-0101 helical mounting assembly or 1000-0000-0162 gravity mounting kit). See the

documentation that ships with the kit for mounting instructions.

3.6.1. Constructing a New Pad

Use only concrete for new pad construction. Do not use substitute

materials since they lack the rigidity for WIC placement.

Observe local building practices for pad construction. Charles

recommends that the pad should extend a minimum of 8” beyond

the WIC base on all sides.

Use a minimum of 6” of sand or gravel as a base for the pad for

leveling purposes.

Figure 7 shows the required conduit openings and mounting hole

dimensions for entering/mounting the bottom of the WIC. Use these

dimensions when designing the pad.

WARNING

When pad mounting, the compression strength

of the pad must be at least 4000 psi as

determined by ASTM C39 test of compression

strength of concrete cylinders.

The slump of the concrete shall be 2” to 4” as

determined by ASTM C143 test method.

Figure 6 Lifting the WIC

Figure 7 Mounting Hole Dimensions (in inches)

Viewed from Above

LT-WIC101010

Page 8 of 16

3rd Printing

3.6.2. Mounting the WIC on a Pad

Eight customer supplied, corrosion resistant, 3/4”Grade 8 hex head bolts with anchors are required for mounting the WIC to the concrete

pad. The WIC comes with a pair of washers for each mounting hole. Use both washers when securing the bolts. Use the following steps to

mount the WIC to a pad.

1. Layout, drill, and set the 3/4” anchors per manufacturer’s recommendations. The embedment depth is not to exceed 3.5”.

2. Clean any debris from the concrete pad.

3. Ensure that the WIC is parallel to the pad surface as it is placed onto the pad and that it aligns with the holes in the pad.

4. Place the WIC on the pad. Loosen the slings so that all the weight is on the pad. Check that the WIC is level and properly

aligned.

5. Secure the WIC to the pad using the 3/4" hex head bolts and washers (two washers per bolt). Tighten all bolts securely.

6. Once the WIC is secured, remove the slings and tagline and close the door.

3.6.3. Mounting with the EMI Helical Mounting Kit

This kit is ordered separately from EMI (part number 1000-0000-0101).

1. Assemble the universal driving tool on the correct Kelly bar adapter.

2. Connect the Kelly bar adapter to the Kelly bar on the drive head.

3. Move the drive tool assembly to the first helical and attach the universal

driving tool to the helical plate, ensuring that the Kelly bar is as centered in the

helical as possible. The leveling hardware can be used for this temporary

attachment.

4. Lift the helical upright, allowing it to swing free of the ground.

5. Maneuver the helical directly over the installation point.

6. Lower the helical until the point of the helical is forced into the ground on

target.

7. Screw the helical 12 inches into the ground and plumb using a level on two

sides at 90 degrees from each other.

8. Continue screwing the helical into the ground while correcting the Kelly bar’s

orientation so the helical embeds itself straight. A ground man can be of

assistance in keeping the foundation plumb during the installation.

9. Drive the helical until the helical plate is 11 inches above grade, oriented as

shown in Figure 8. Stop the driving tool assembly. Disconnect the universal

driving tool from the helical plate.

10. Repeat steps 3 through 9 for all helicals paying attention to helical plate orientations.

11. Install leveling hardware in the center on each helical. Each helical has one set of leveling hardware and each set of leveling

hardware consists of one threaded rod, four nuts, eight washers, and four lock washers.

12. Install the four corner plates on the leveling hardware, one in each corner.

13. Level and secure all the leveling hardware on the corner plates and helicals. The leveling hardware should not be installed outside

the 3 inch radius of the helical pipe. The corner plates have elongated holes for 2 inches of play.

14. Lift and set WIC on the Helical Foundation Kit. Be sure to bolt the WIC base to the corner plates prior to releasing all of the

weight of the WIC onto the corner plates.

15. Once all hardware is installed connecting the WIC base to all corner plates, tighten and secure all the hardware.

Figure 8 EMI Helical Mounting Kit

LT-WIC101010

3rd Printing

Page 9 of 16

3.6.4. Mounting with the EMI Gravity Mounting Kit

This kit is ordered separately from EMI (part number 1000-0000-0162).

Grade Considerations:

1. Ground/gravel should be normally dry and have good drainage.

2. Ground/gravel should be level or very close.

Procedure:

1. Lift and set the WIC On The Ground (Gravity) Foundation Kit in the desired

location. The WIC On The Ground (Gravity) Foundation Kit ships assembled,

stairs separate of course, so lift and set it on grade in the desired location. If

using a forklift and the forks are not long enough to get under all three bars of

the frame, make sure the frame does not tilt over during lifting. This can be

accomplished with weight on the two bars the forks did get under, or by

removing the footers from the bar the forks did not get under. This is aimed at

safety, as the frame can withstand tilting. The weight of the frame is 300 lbs.

The weight of the footers are 31 lbs each.

2. Level the frame by adjusting the leveling hardware between the frame and the

nine footers. Be sure to maintain 18 inches from grade to the top of the frame,

which is the bottom of the WIC. Start by leveling the four corners first then adjust the remaining footers.

3. Lift and set the WIC on the WIC On The Ground (Gravity) Foundation Kit in desired location. Be sure to bolt the WIC base to

the frame prior to releasing all of the weight of the WIC on the frame.

4. Once all hardware is installed connecting the WIC base to the frame, tighten and secure the hardware.

3.6.5. Mounting with the EMI Extension Mounting Kit

This kit is ordered separately from EMI (part number D1007-0000-0012).

This kit includes four concrete pad extensions for the four corners of the WIC.

1. Set the four concrete pad extensions on the four corners of the concrete pad in

the desired locations (Figure 10).

2. Lift and set the WIC on the extensions. Ensure that the WIC is level, and bolt

the WIC base to the extensions prior to releasing all of the weight of the WIC

on the extensions.

3. Once all hardware is installed connecting the WIC base to the extensions,

tighten and secure the hardware.

Figure 9 EMI Gravity Mounting Kit

Figure 10 EMI Extension Mounting Kit

LT-WIC101010

Page 10 of 16

3rd Printing

3.7. WIC Wiring and Equipment

After the WIC is properly mounted in the desired location, apply No-Ox where bus bar and other 2-hole lug connections will be made.

Install ground and power connections. Always ground the equipment first, before making any other connections.

WARNING

Perform all bonding and grounding connections prior to any electrical and communications connections.

A basic electrical diagram is shown in Figure 11. This diagram shows the WIC with the power system, load center, and accessory kits

installed.

3.7.1. Torque Requirements

Torque all hardware as shown below (unless otherwise noted). These values apply to SAE Grade 1 & 2 Low Carbon Steel, ASTM A307

Low Carbon Steel, and Stainless Steel Grade 18-8.

Thread

Size

In-lbs

Ft-lbs

4-40

4±10%

6-32

8±10%

8-32

16±10%

10-32

26±10%

12-24

50±10%

1/4-20/M6

60±5%

5±5%

5/16-18

125±5%

10.4±5%

3/8-16

180±5%

15.0±5%

1/2-13

500±2%

41.7±2%

5/8-11

1000±1%

83.3±1%

Use these values for the Grade 8 mounting hardware:

Thread

Size

Ft-lbs

Coarse

Fine

1/4

9

10

5/16

18

20

3/8

33

37

7/16

52

58

1/2

80

90

9/16

115

129

5/8

159

180

¾

282

315

7/8

454

501

1

682

764

3.7.2. Ground Connection

The WIC has external ground bars on the sides and rear for grounding equipment. All cables entering the WIC must be grounded to the

2x12 position ground bars in the upper locations. The 24-position ground bars in the lower positions connect to the earth ground. Use the

pair of mounting studs on the external rear for connecting an earth ground. This requires a 3/8” lug with 0.75” spacing.

The equipment racks, as well as all equipment installed in the racks must be connected to the internal 46-position master ground bar,

located on the rear wall.

Use the pair of mounting studs on the external rear for connecting an earth ground. This requires a 3/8” lug with 0.75” spacing.

LT-WIC101010

3rd Printing

Page 11 of 16

Figure 11 Electrical Diagram

LT-WIC101010

Page 12 of 16

3rd Printing

3.7.3. AC Voltage Connection

The WIC has a mounting location and a pair of conduit knockouts on the front for mounting a customer supplied AC load center.

3.7.4. CTMS Operation

The four 6000W DC powered CTMS mounted on the sides of the WIC each have a fan speed controller and include two internal and two

external fans. The fans’ speed increases with increasing ambient temperature. Default fan settings are defined below and can be modified if

necessary.

The CTMS has a protective grate on the inside. This grate is secured in place by two bolts. To access the CTMS control panel, remove this

grate. For more information, refer to the heat exchanger documentation found inside the WIC.

Temperature range for cooling operations:

Parameter

Threshold

CTMS

Inside Temperature

< 77°F

Fans on

Inside Temperature

> 77°F

Fan Speed 25%

Inside Temperature

> 90°F

Fan Speed 100%

Temperature range for heating operations:

Parameter

Threshold

CTMS

Inside Temperature

< 50°F

Heating On

Inside Temperature

≥ 55°F

Heating Off

-NOTE-

Changing the speed controller default factory set points can lead to system performance issues, such as equipment failures, increased power

use, unnecessary alarms, noise, condensation build up, fan failure caused by excessive runtimes and vibration.

Avoid placing items in front of the CTMS’s return and supply vents. Maintain a minimum of 2” clearance to enable proper air flow.

The CTMS is shipped with the operational parameters set at the factory.

3.7.5. IVS Operation

The DC powered IVS has an on-board controller, four ventilation fans, and six dampers leading into the WIC interior space.

The IVS is turned on in two ways. First, there is a manual timer that can be set for a maximum of one hour. A technician entering the WIC

can set this timer so that fresh air will be drawn into the WIC while work is being performed. Second, the IVS can be activated by an

internal temperature probe connected to the controller that turns the fans on when the interior temperature reaches 60⁰C. The IVS will then

draw outside air into the WIC to cool the cabinet.

3.7.6. HVAC Operation

This section only applies if the 97-WIC10KHVACKT HVAC kit has been installed on the WIC.

The HVAC system is turned on manually whenever the WIC is occupied. The 10000BTU DC powered HVAC compressor and fans are

speed controlled. The compressor turns on at 30°C, reaches its high speed at 42°C, and turns off at 27°C. The internal fan is always on to

continually circulate heat within the cabinet. The heating cycle turns on at 10°C and off at 15°C. See the label on the air conditioner for

firmware information. For further information, refer to the HVAC documentation that ships with the kit.

-NOTE-

Changing the cooling or heating cycles’ default factory set points can lead to system performance issues, such as equipment failures, increased

power use, unnecessary alarms, noise, condensation build up, compressor or fan failure caused by excessive runtimes and vibration.

Avoid placing items in front of the HVAC’s return and supply vents. Maintain a minimum of 2” clearance to enable proper air flow.

3.7.7. Fiber and Copper Entry

The WIC has two cable entry holes on the front (Ø1.5” and Ø1.0”) intended for conduit entry for the customer supplied AC load center.

The two sides and the rear each have a Ø1.06” entry hole for the ground cables.

The AC disconnect panel has three Ø7/8” knockouts intended to cable entry for the customer supplied Raycap AC disconnect. These holes

can be enlarged using a Greenlee tool to a maximum of Ø2.0”.

The upper rear corners, on the sides of the WIC, each have a sealed cable entry port for GPS cable entry.

The interior floor of the WIC has four entry ports for running cable inside from the runway space beneath the floor.

LT-WIC101010

3rd Printing

Page 13 of 16

The right side of the WIC, near the top, has two panels, each with four portals. Each portal has nine Ø0.605” entry ports athat

accommodate Ø0.5” cable.

See Figures 2, 3, and 4 for all entry locations.

3.8. Conduit Seals

All conduit openings on the WIC must be completely sealed with a duct seal compound to prevent

moisture from entering the WIC. Use a moldable, flame-retardant putty style duct seal material. Do not

use an expanding foam seal. Mold the putty so that the open space around the wire or conduit is

completely sealed, as shown in Figure 12. If the openings must be accessed at any time, remove the

putty and set it aside. When work is complete, re-mold the putty to re-seal the opening.

3.9. Verifying the Installation

Verify that earth ground and all grounding and bonding is complete and functional. After verifying that

all installer connections are secure and complete, apply voltage.

4. PERIODIC MAINTENANCE

In the event that the enclosure must be opened in freezing conditions, use a narrow, pointed metallic object such as a screwdriver or chisel,

along with a non-metallic device like a rubber mallet, to remove excessive ice buildup around the door and locking mechanism. A

commercial aerosol de-icer spray can be used to free up locks and latches if needed. Use protective gloves and safety glasses when

applying de-icer sprays.

Reset the GFCI duplex receptacle periodically to ensure it is working. The unit meets UL-943, which requires an auto-monitoring (self-

testing) feature. A flashing or solid red LED indicates a fault. If the unit continues to show a fault after resetting, replace the unit.

Refer to the CTMS manual supplied with the CTMS for periodic maintenance requirements.

5. TECHNICAL ASSISTANCE AND REPAIR SERVICE

For questions on product repair or if technical assistance is required, contact Charles Technical Support.

847-806-8500

http://www.charlesindustries.com/techserv.htm

6. WARRANTY & CUSTOMER SERVICE

Charles Industries LLC offers a one-year warranty on the WIC product. The Charles warranty is limited to the operation of the WIC

hardware as described in this documentation and does not cover equipment which may be integrated by a third party. The terms and

conditions applicable to any specific sale of product shall be defined in the resulting sales contract. For questions on warranty or other

customer service assistance, contact your Charles Customer Service Representative.

847-806-6300

http://www.charlesindustries.com/main/telecom_sales_support.htm

7. SPECIFICATIONS

7.1. Regulatory Specifications

Designed to meet GR-487

UL-60950 Recognized

GFCI: UL-943 Listed

If WICs are field-modified, a customer provided ETL field evaluation of the modified components may be required to re-establish ETL

certification to UL standards. Consult local jurisdictions for guidance on a site-by-site basis.

Figure 12 Applying Putty Seal

LT-WIC101010

Page 14 of 16

3rd Printing

7.2. Product Specifications

Physical

Dimensions and Weight

10”Hx10”Wx10”D,

Approx. 7850 lbs. without equipment racks

Approx. 13,850 lbs. with equipment racks

Materials

Steel

Color

Exterior: Cool white; interior floor: light gray

Electrical

Ventilation System

Charles IVS, 83-008367-0, -48VDC

Bonding and Grounding

12 and 24 position ground bars on the sides and rear (external)

46 position master ground bar on rear wall (internal)

1 pair of ground studs on the rear for earth ground

Cable Entry

See Figure 2 and section 3.7.7

Thermal

6000W CTMS

Charles Industries 99-004920-0

Cooling Capacity at Full Speed

320 W/K

Heat Removal

ΔT (max. internal – ambient)

Capacity

19⁰C

6000W

10⁰C

3200W

5⁰C

1600W

Heating Capacity

500W below 15⁰C / 1000W below 10⁰C

CTMS Operating Temperature for Cooling

77⁰F to 95⁰F

CTMS Operating Temperature for Heating

50⁰F to 41⁰F

Average Shelter Temperature

90⁰F to 95⁰F

HVAC (only if using the 97-WIC10KHVACKT kit)

Dantherm 708349, -48VDC

Cooling Capacity

10000BTU

Environmental

Operating Temp. Range, Outside Enclosure

-40° to +115°F, -40° to 46°C

Operating Temp Range, Inside Enclosure

-40° to +131°F, -40° to 55°C

Humidity

0 to 95% (non-condensing)

Altitude

Up to 2,000 meters (6560 feet)

Kits and Replacement Parts

Touch-up Paint

Exterior: 02-000634-0; interior floor: 02-000736-0

4-Wire Door Alarm Switch (Black)

17-400319-0

External Stair Kit

97-1010WICSTRKIT; CEQ.46634

Microwave Port Kit

97-MICWVPRTKIT; CEQ.46671

DC Generator Port Kit

97-DCGENPORTKIT; CEQ.46636

Cable Entry Port Kit

97-9CBLPORKIT; CEQ.46663

HVAC Kit

97-WIC10KHVACKT

Exterior Light

99-005035-0

Helical Mounting Kit

EMI part number: 1000-0000-0101

AT&T part number: CEQ.19785

Gravity Mounting Kit

EMI part number: 1000-0000-0162

AT&T part number: CEQ.46388

Extension Mounting Kit

EMI part number: D1007-0000-0012

AT&T part number: CEQ.20061

Table 1 WIC Specifications

7.3. Part Numbers

Charles Part Number

Description

NESC ID

WIC-101010SXAN1

NSB 10x10 Walk-in-Cabinet (WIC) Fully Configured Ericsson RAN

ERNSB10x10WIC-01

NSB 10x10 Walk-in-Cabinet (WIC) Fully Configured Nokia RAN

NONSB10x10WIC-01

LT-WIC101010

3rd Printing

Page 15 of 16

7.4. Alarm Connections

Alarm Block 1:

Alarm 66

Block

Block#-Pair#

Pin #

BBU Wire Color

(per local market)

Normal

Contact

State

(NC or NO)

AT&T Alarm

Label/Verbiage

Comments or

Factory/OEM Alarm

BBU 1-4

1-1

1

WHITE/BLUE

NC

RBS INTRUSION

Entry door switch

contacts

2

BLUE/WHITE

1-2

3

WHITE/ORANGE

NC

RBS COMMERCIAL

POWER FAIL

from PTLC power fail

relay

4

ORANGE/WHITE

1-3

5

WHITE/GREEN

NC

RBS PWR AC SPD

from PTLC surge

protector

6

GREEN/WHITE

1-4

7

WHITE/BROWN

NC

RBS SMOKE

Smoke Detector

8

BROWN/WHITE

BBU 5-8

1-5

9

WHITE/SLATE

NC

RBS TEMP HIGH

High temp

10

SLATE/WHITE

1-6

11

RED/BLUE

NC

RBS TEMP LOW

Low temp

12

BLUE/RED

1-7

13

RED/ORANGE

NC

RBS HUMIDITY HIGH

Humidity Sensor

14

ORANGE/RED

1-8

15

RED/GREEN

NC

RBS HVAC 1 FAIL

HVAC Fail

16

GREEN/RED

BBU 9-12

1-9

17

RED/BROWN

NC

RBS GEN TRANSFER

SW FAIL

350A (-48VDC) CB AUX

contacts

18

BROWN/RED

1-10

19

RED/SLATE

NC

RBS FIF PDU FUSE

FAIL

FIF Fuse Fail

20

SLATE/RED

1-11

21

BLACK/BLUE

(SPARE)

22

BLUE/BLACK

1-12

23

BLACK/ORANGE

(SPARE)

24

ORANGE/BLACK

BBU 13-16

1-13

25

BLACK/GREEN

NC

RBS LTE RRU AT DC

SYS SPD

Raycap #1 alarm

26

GREEN/BLACK

1-14

27

BLACK/BROWN

NC

RBS LTE RRU AT DC

SYS SPD

Raycap #2 alarm

28

BROWN/BLACK

1-15

29

BLACK/SLATE

NC

RBS LTE RRU AT DC

SYS SPD

Raycap #3 alarm

30

SLATE/BLACK

1-16

31

YELLOW/BLUE

NC

RBS 5G RRU AT DC

SYS SPD

Future (5G) Raycap #1

Alarm

32

BLUE/YELLOW

1-17

33

YELLOW/ORANGE

NC

RBS 5G RRU AT DC

SYS SPD

Future (5G) Raycap #2

Alarm

34

ORANGE/YELLOW

1-18

35

YELLOW/GREEN

NC

RBS 5G RRU AT DC

SYS SPD

Future (5G) Raycap #3

Alarm

36

GREEN/YELLOW

1-19

37

38

1-20

39

40

1-21

41

42

1-22

43

44

1-23

45

46

1-24

47

48

1-25

49

50

NOTE: The Alarm Block configurations shown are standard on all new metal and concrete WICs (Walk-In-Cabinet). Additional

alarms should be added as applicable

LT-WIC101010

Page 16 of 16

3rd Printing

Alarm Block 2:

Alarm 66

Block

Block#-Pair#

Pin #

BBU Wire Color

(per local market)

Normal

Contact

State

(NC or NO)

AT&T Alarm

Label/Verbiage

Comments or

Factory/OEM Alarm

BBU 17-20

2-1

1

WHITE/BLUE

NC

RBS DC CR

DC PLANT PCR

2

BLUE/WHITE

2-2

3

WHITE/ORANGE

NC

RBS DC MJ

DC PLANT PMJ

4

ORANGE/WHITE

2-3

5

WHITE/GREEN

NC

RBS DC HIGH VOLT

DC PLANT HV1

6

GREEN/WHITE

2-4

7

WHITE/BROWN

NC

RBS DC LOW VOLT

DC PLANT LV1

8

BROWN/WHITE

BBU 21-24

2-5

9

WHITE/SLATE

NC

RBS FUSE FAIL

DC PLANT FA

10

SLATE/WHITE

2-6

11

RED/BLUE

NC

RBS DC RECT MJ

DC PLANT RFA

12

BLUE/RED

2-7

13

RED/ORANGE

NC

RBS DC RECT CR

DC PLANT RFA(MULT)

14

ORANGE/RED

2-8

15

RED/GREEN

NC

RBS BATT TEMP HIGH

DC PLANT HITEMP1

16

GREEN/RED

BBU 25-28

2-9

17

RED/BROWN

(SPARE)

18

BROWN/RED

2-10

19

RED/SLATE

(SPARE)

20

SLATE/RED

2-11

21

BLACK/BLUE

(SPARE)

22

BLUE/BLACK

2-12

23

BLACK/ORANGE

NO

RBS GENERATOR

RUNNING

Gen run

24

ORANGE/BLACK

BBU 29-32

2-13

25

BLACK/GREEN

NO

RBS GENERATOR

FUEL LOW

Gen low fuel

26

GREEN/BLACK

2-14

27

BLACK/BROWN

NO

RBS GENERATOR

SHUT DOWN

Gen shutdown

28

BROWN/BLACK

2-15

29

BLACK/SLATE

NO

RBS GENERATOR MJ

Gen major

30

SLATE/BLACK

2-16

31

YELLOW/BLUE

NO

RBS GENERATOR

FUEL LEAK

Fuel basin rupture

32

BLUE/YELLOW

2-17

33

WHITE/BLUE

NC

RBS DC CR

DC PLANT PCR

34

BLUE/WHITE

2-18

35

WHITE/ORANGE

NC

RBS DC MJ

DC PLANT PMJ

36

ORANGE/WHITE

2-19

37

38

2-20

39

40

2-21

41

42

2-22

43

44

2-23

45

46

2-24

47

48

2-25

49

50

Gray highlighted cells: fixed gen sites only

Table of contents

Other Charles Enclosure manuals