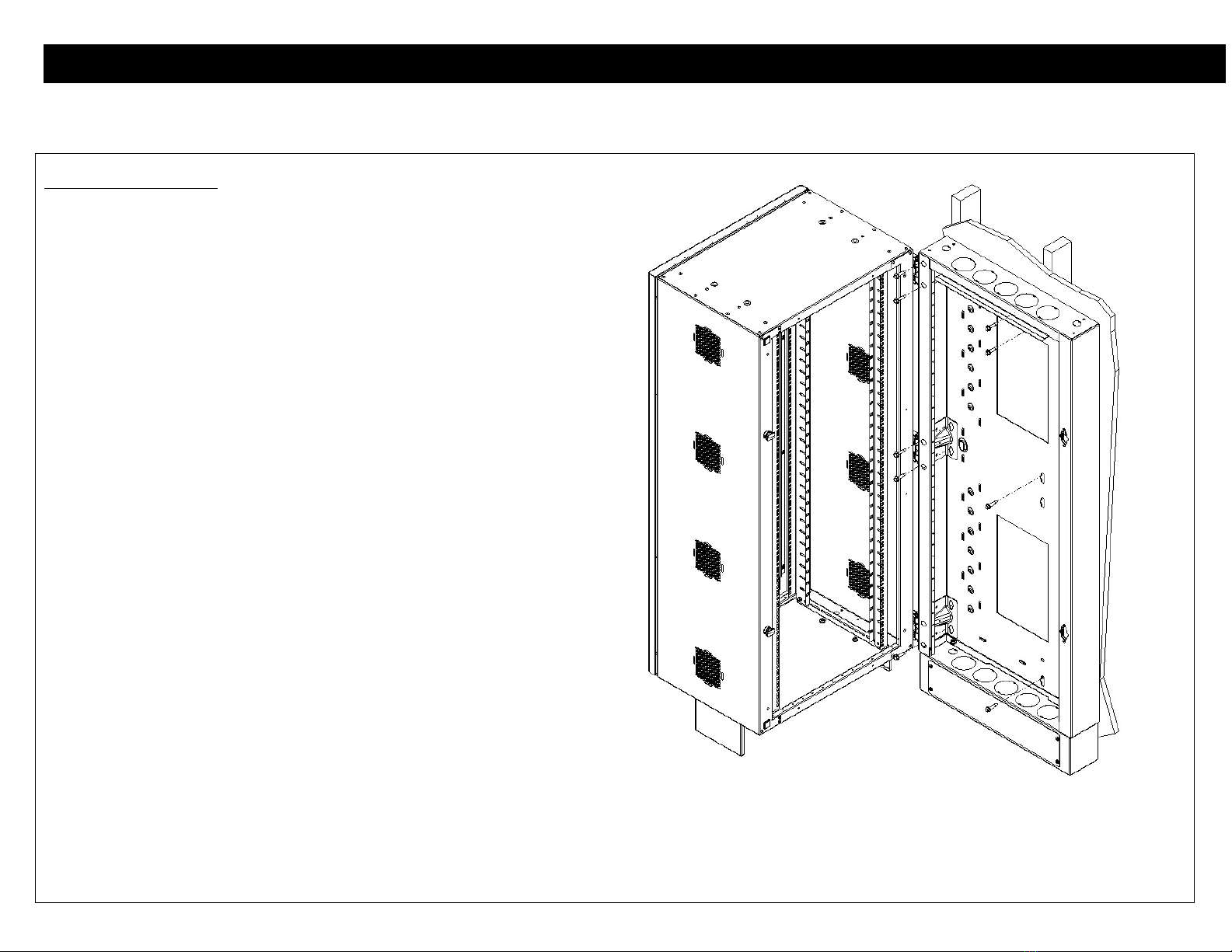

Mounting Cabinet to Wall

NOTE: These instructions are for mounting the cabinet to a wood studded wall

covered with 3/4" plywood. For masonry surface, the installer must provide

appropriate hardware.

1. Ensure the wall or mounting surface is structurally sound and able to

support the cabinet and expected payload. The mounting surface must be

flat and extend beyond the top, bottom, left, and right edges of the rear

panel.

2. Determine wall location for mounting cabinet which allows the door and

center chassis to be opened 90 degrees from the rear panel.

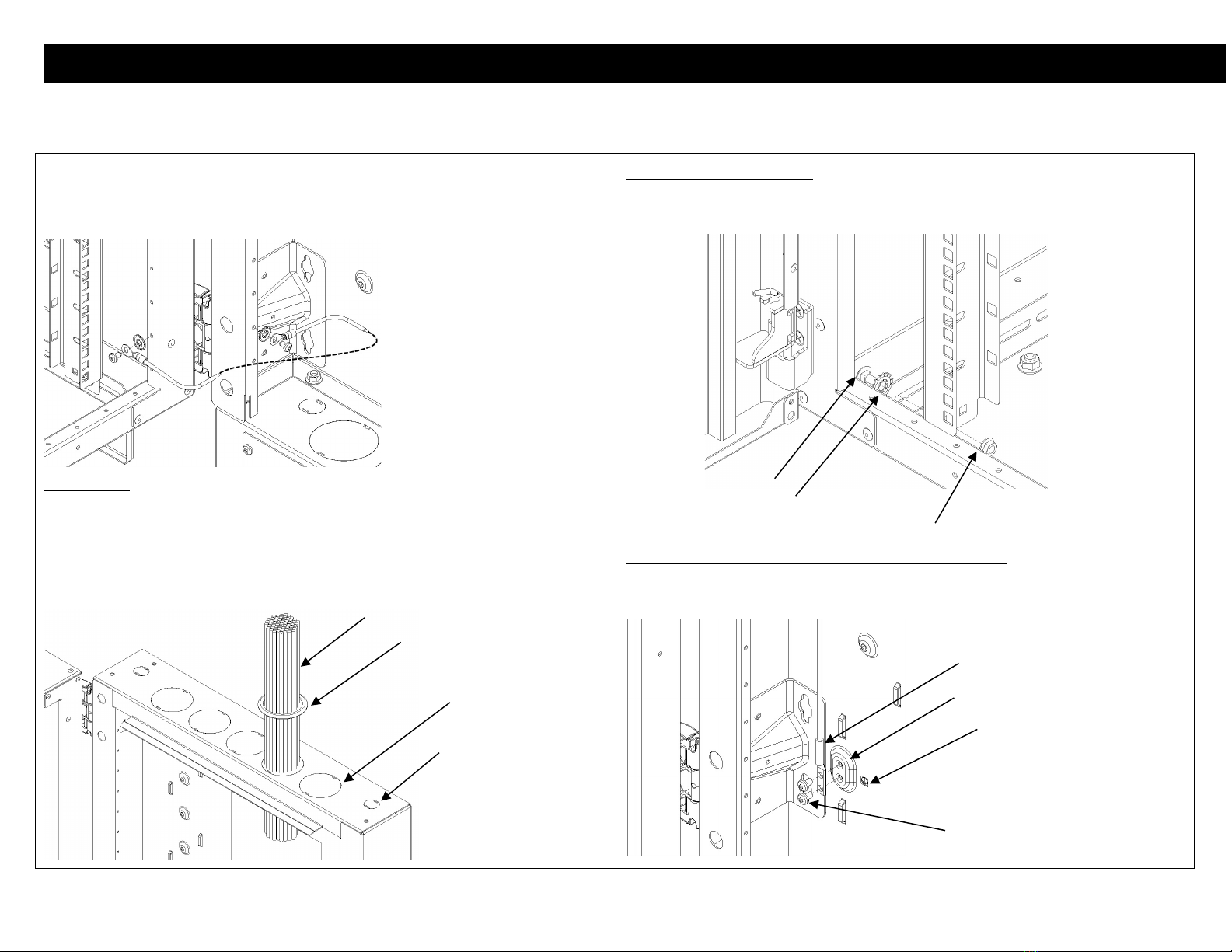

3. Mark center of selected wall studs to help position rear panel keyholes

before installing lag screws.

4. Position cabinet against the wall with mounting keyholes closest to three

main chassis hinges centered on a wall stud. Keyholes closest to center

should be located on a 16” spacing wall stud. Keyholes on opposite side

from hinges are for 24" spacing wall studs.

5. With the cabinet in position against wall, open the front door (do not hinge

cabinet body open from rear panel) to install three M8X40 Lag screws (1

at top, 1 at middle, 1 at bottom) in mounting keyholes of 16” or 24” wall

stud. Drill pilot holes using 5/32” drill bit for easier installation.

6. Open the cabinet body 90 degrees and install five M8X40 Lag screws in

mounting keyholes near hinges (2 at top, 2 at middle, 1 at bottom).

7. Install final lag bolt in top keyhole of 16” or 24” wall stud.