INSTALLATION AND OPERATING INSTRUCTIONS: CSR series collision protection

Zimmer GmbH ●Im Salmenkopf 5 ●77866 Rheinau, Germany ●Phone: +49 7844 9138-0 ● Fax: +49 7844 9138-80 ●www.zimmer-group.de

DDOC00267 enu / 2018-03-13 / a

1.Installation,commissioning,maintenanceandrepairsmayonlybeundertakenbyqualiedexpertsinaccordancewith

these installation and operating instructions.

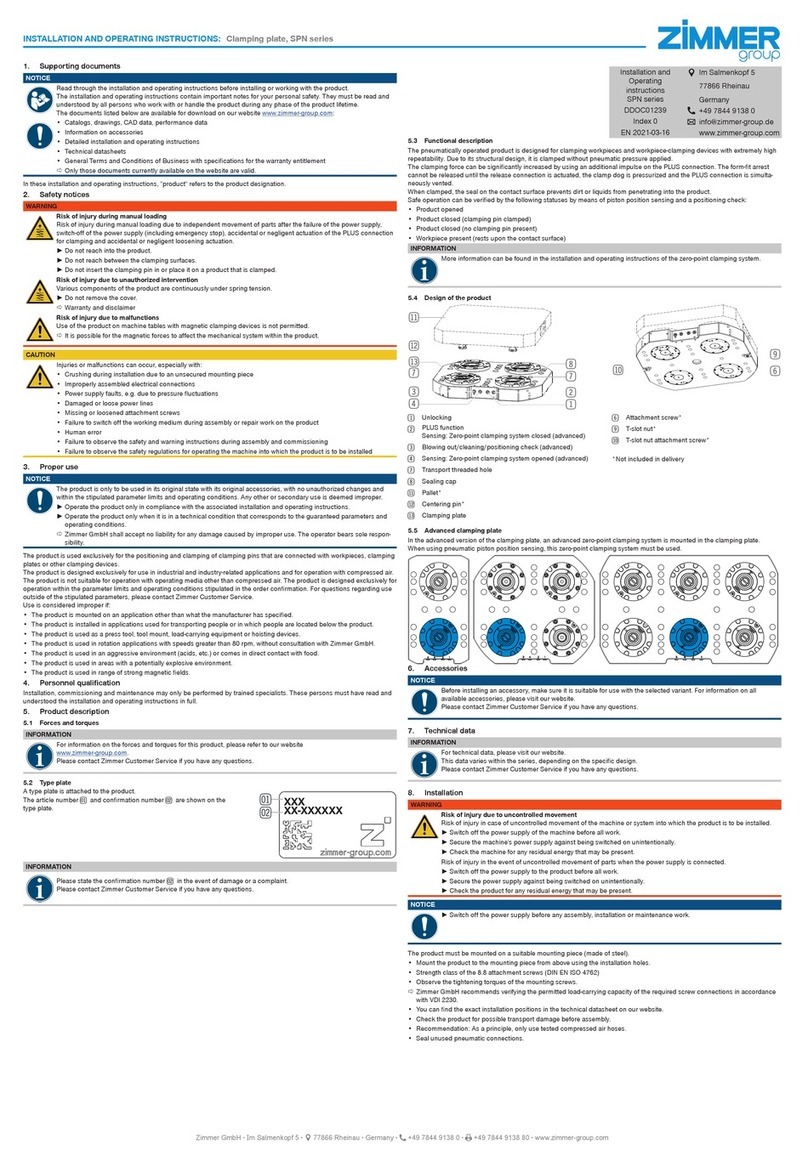

2.ThecollisionprotectionoftheCSRseriesisstate-of-the-art.Itisttedtoindustrialmachinesandusedtoholdtoolsor

mounting pieces.

Hazards can originate from the collision protection only if,

forexample, -Itistted,usedormaintainedimproperly

- It is not used for its intended purpose

- The local regulations (legislation, guidelines, directives), such as the EC Machinery Directive,

- The Accident Prevention Regulations and installation and operating instructions are not observed.

3.Thecollisionprotectionmaybeusedonlyinaccordancewithitsintendedpurposeandtechnicaldata.

ZIMMER GmbH shall accept no liability for any damage caused by improper use.

4.AnyuseotherthantheintendeduserequireswrittenapprovalfromZimmerGmbH

5. Do not reach into the operating range of the collision protection or machine.

6.Makesurethatthetransmissionlinesaredisconnectedbeforeyout,set,retool,maintainorrepairthecollisionprotec-

tion.

7.Incaseofmaintenance,retrottingorexpansionwork,removethecollisionprotectionfromthemachineandcarryout

theworkoutsidethedangerzone.

8. When commissioning or testing, make sure that the machine cannot be actuated by mistake.

9.Modicationstothecollisionprotection,suchasaddingboreholesorthreads,maybemadeonlywithpriorapproval

from ZIMMER GmbH.

10.Thespeciedmaintenanceintervalsandcompressedairqualityspecicationsaretobeobserved;alsorefertothe

Maintenancesection.Whenthecollisionprotectionisusedunderextremeconditions,themaintenanceintervalmustbe

adapteddependingontheextentofthecontamination.Pleasecontactourhotlineforthispurpose.

11.Useofthecollisionprotectionunderextremeconditions,suchasaggressiveliquidsandabrasivedust,issubjecttoprior

approval from Zimmer GmbH

12.Whendisassemblingthecollisionprotection,exerciseincreasedcautionduetothealways present spring tension. This

workistobeperformedbyZimmer'scustomerservicedepartment.

1. Supporting documents

NOTE:

Thefollowingdocumentsareavailablefordownloadonourwebsite.Onlythedocumentscurrentlyavailable

onthewebsitearevalid.

• Catalog

• Drawings,performancedata,informationaboutaccessoryparts,etc.

• Technical data (data sheets)

• GeneralTermsandConditionsofBusiness,includingwarrantyinformation

2. Proper use

TheCSRcollisionprotectionisdesignedforoperationwithcompressedaironly.Itisnotsuitedforoperationwithothermediasuch

as liquids or gases. Proper use for CSR collision protection is in closed spaces for protecting the tool and/or the machine during a

collision or overload. It is not suitable for use as an active compensation module.Itisnotsuitablefordirectcontactwithperishable

goods.

NOTE:

ThecollisionprotectionoftheCSRseriesmayonlybeusedinitsoriginalstate,withoriginalaccessories,

withoutanyunauthorizedchangesandwithinthescopeofitsdenedparametersforuse.

Zimmer GmbH shall accept no liability for any damage caused by improper use.

OnlytheaccessoriespermittedfortheCSRtypeseriesareallowedtobeinstalledonthecollisionprotection.

Regarding this, see the Handling Technology catalog

3. Safety notes