Chery A21 User manual

CHERY A21 SERVICEMANUAL MECHANISMOF2.0NALCENGINE

1

MECHANISMOF2.0NAENGINE

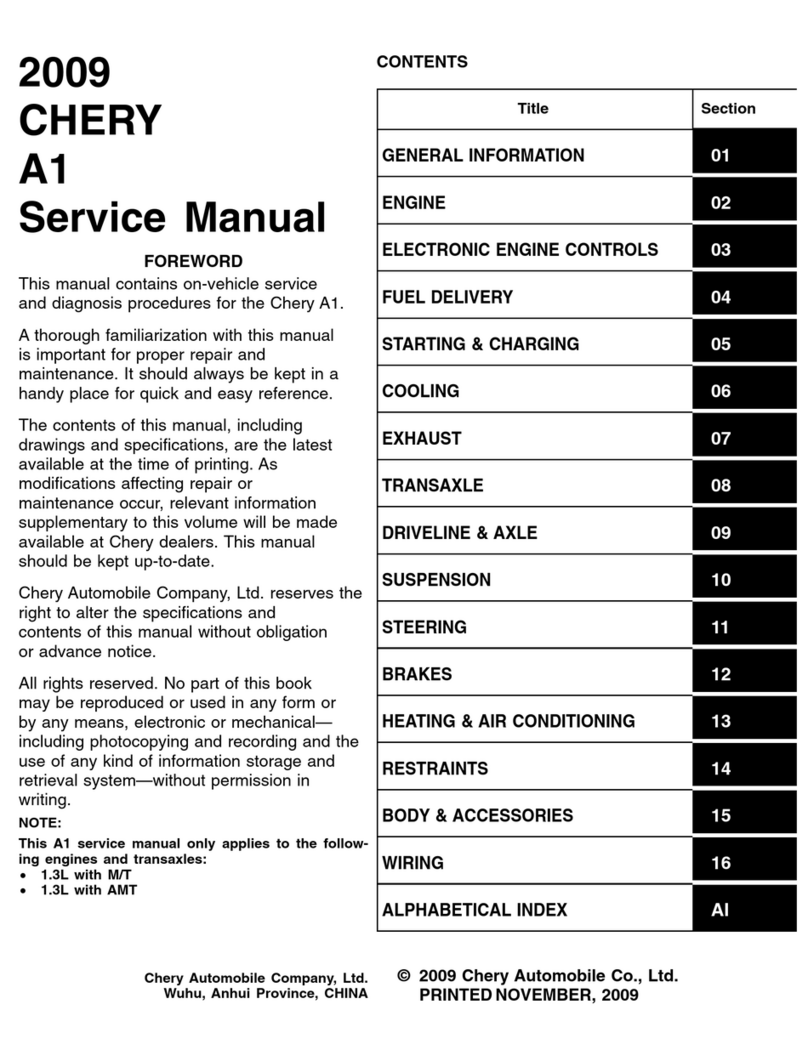

CONTENT

CHAPTER1ENGINEPARAMETERAND SPECIALMAINTENANCETOOLS....2

SECTION 1TECHNOLOGYDATAINSTRUCTION................................................2

SECTION 2SPECIALTOOLS...................................................................................5

SECTION 3ENGINENUMBERPOSITION.............................................................6

SECTION 4COLLATING METHOD OFENGINETIMING.....................................7

CHAPTER2ENGINEBODY........................................................................................9

SECTION 1WHEELTRAIN......................................................................................9

SECTION 2CYLINDERHEAD..............................................................................14

SECTION 3SHORTENGINE..................................................................................26

PDFcreated withpdfFactoryProtrialversion www.pdffactory.com

pouyapadid.com

09120539254

CHERY A21 SERVICEMANUAL MECHANISMOF2.0NALCENGINE

2

CHAPTER1ENGINEPARAMETERAND SPECIALMAINTENANCETOOLS

SECTION1TECHNOLOGYDATAINSTRUCTION

ENGINECHARACTER

EngineModel SQR481H

EngineType

4-Cylinder,WaterCooled, In-lineDouble

OverheadCamshaft, 16 Valve,

ControllableBurning Rate,VariableValve

Timing

CylinderDiameter mm)83.5

PistonStroke(mm) 90

Displacement(L) 1.971

CompressionRatio 10

RatedPower Kw)95

RevatRatedPower r/min)5500

Max.Torque NM)180

RevatMax.Torque r/mim)4000

MinimumFuelConsumptionRate g/Kw.h)

301

CylinderPressure Bar)10±0.2

FuelPressure Bar)4

LowIdleSpeed

800±50r/min)

HighIdleSpeed

2000r/min)

EngineOil

Pressure Bar)

HighSpeed

4000r/min)

HighPressureCircuit 2--3

A/CCircuit

Pressure Bar)

LowPressureCircuit 12---16

PressureReliefValve

ReleasePressureto

Outside)88±14.5

ExpansionTank

Cap kpa)VacuumValve LeadAir

intoTank)-10~~~~-2

StartWorking

Temperature 87Thermostat

Working

Temperature )

FullWorking

Temperature 104

PDFcreated withpdfFactoryProtrialversion www.pdffactory.com

pouyapadid.com

09120539254

CHERY A21 SERVICEMANUAL MECHANISMOF2.0NALCENGINE

3

TECHNOLOGYDATAINSTRUCTION

Item StandardValue

Intakecam 37.15

CamHeight Exhaustcam 37.05

Intakecam

CamshaftDiameter Exhaustcam

Intakecam 0.15--0.20

Camshaft

Axialclearance ofCamshaft Exhaustcam 0.15--0.20

PlaneDegree ofLowerSurface 0.04

WholeHeight 140±0.41

Cylinder

Head SurfaceGrindLimit*TotalGrinding Quantityof

CylinderBlockandHead

IntakeValve 0.3±0.15

FringeThicknessonTopofValve

ExhaustValve 0.3±0.15

IntakeValve 5.98±0.008

ValveStemDiameter ExhaustValve 5.96±0.008

IntakeValve

SealBandwidth ExhaustValve

IntakeValve 0.02

GapBetweenValveStemAndGuide

ExhaustValve 0.04

IntakeValve 65°

TiltAngle ExhaustValve 68°

IntakeValve 107.998

Valve

Height ExhaustValve 106.318

Free Height 47.7

WorkingTensioninAdvance/WorkingHeightKg/mm

620N/32mm

Valve

Spring

VerticalDegree

ValveGuideLength 38±0.25

Valve

Guide InsideDiameter 5.4±0.1

24

040.0

053.0

−

−

24

040.0

053.0

−

−

PDFcreated withpdfFactoryProtrialversion www.pdffactory.com

pouyapadid.com

09120539254

CHERY A21 SERVICEMANUAL MECHANISMOF2.0NALCENGINE

4

OuterDiameter

PressureHeight 16±0.3

ProtrudingPartofValveStem 47.5

Piston PistonSkirtDiameter 83.46±0.009

1st Ring 0.04--0.08

SideClearance

2

n

d

Ring

0.01

--

0.025

1

st

Ring

0.2--0.4

EndPlay

2

nd

Ring

0.4

--

0.6

1st Ring

2nd Ring

Piston

Ring

Height

OilRing

1st Ring

2nd Ring

Ring

Groove Height/Depth

OilRing

2.5

Diameter

Length 60

PistonPin

DiameterofPistonPinHole

AxialClearance 0.076--0.265

RadicalClearance -0.0375

CoaxialDegree 0.05

Cylindricity 0.008

CrankshaftMainshaftDiameter

Roundness

0.005

Cylindricity

Crankshaft

ConnectingRodJournalDiameter

Roundness

WholeHeight 218±0.05

CylinderHoleRoundness/StraightnessAccuracy 0.008 /0.01

Cylinder

UpperSurface Planeness 0.04

RadialClearance ofConnectingRodBearing 0.016--0.051

Connectin

gRod AxialClearance ofBigEnd 0.15--0.4

11

051.0

040.0

+

+

2

.

1

05.0

03.0

+

+

5

.

1

04.0

02.0

+

+

5

.

2

03.0

01.0

+

+

21

0

005.0−

21

008.0

002.0

2

.

1

01.0

03.0

−

−

5

.

1

005.0

030.0

−

−

PDFcreated withpdfFactoryProtrialversion www.pdffactory.com

pouyapadid.com

09120539254

CHERY A21 SERVICEMANUAL MECHANISMOF2.0NALCENGINE

5

SECTION2SPECIALTOOLS

Camshaft TimingTool

CrankshaftTimingTool

FlywheelTool

GuideSleeveofCrankshaftOil

Seal

GuideSleeveofCamshaft Oil

Seal

HydraulicHoist

PDFcreated withpdfFactoryProtrialversion www.pdffactory.com

pouyapadid.com

09120539254

CHERY A21 SERVICEMANUAL MECHANISMOF2.0NALCENGINE

6

FuelPressureGauge

CylinderPressureGauge:whenmeasurethecylinder

pressure,firstlyremovethesparkplug,screwthepipe

endofinstrumentinsteadofit,andoperatetheengineby

starter, thentakethemaximumvalueincylinderpressure

gaugeascylinderpressure.

SECTION3ENGINENUMBERPOSITION

Position ofEngineCylinderBlockNumber

EngineOil Dipstick

PDFcreated withpdfFactoryProtrialversion www.pdffactory.com

pouyapadid.com

09120539254

CHERY A21 SERVICEMANUAL MECHANISMOF2.0NALCENGINE

7

SECTION4COLLATINGMETHODOFENGINETIMING

1.Removetheuppercoverofenginetiming

belt.

2. Removethelowercoverofenginetiming

belt.

3. Loosenthecentralboltoftiming belt

tensionpulleyandremovethetiming

belt.

4. Drawoutthehighvoltageignitioncable.

PDFcreated withpdfFactoryProtrialversion www.pdffactory.com

pouyapadid.com

09120539254

CHERY A21 SERVICEMANUAL MECHANISMOF2.0NALCENGINE

8

5. Loosentheboltofvalvecoverand

removethevalvecover.

6. Rotatethecamshaftinordertoclipthe

camshafttool intotheslotattheendof

camshaft.

7. Loosentheboltsofairintakeandexhaust

camshafttensionpulleyswithtorque

wrench.

Note:Itisnottoremovebutloosen.

8. Revolving thecrankshaft,youmayrotate

inthe crankshafttool soastoitcannot

moveinbothdirection.

Note:Doitwithpatience andcarefulness lest

thecrankshaftshouldbebroken.

CamshaftTool

CrankshaftTool

PDFcreated withpdfFactoryProtrialversion www.pdffactory.com

pouyapadid.com

09120539254

CHERY A21 SERVICEMANUAL MECHANISMOF2.0NALCENGINE

9

9. Mountthetiming beltandrotatetension

pulleywithAllenwrenchinorderto

tensionthebeltandmakethefingerof

tensionerpointtothemiddleofUslot

opening.Fastentheboltoftensionpulley,

thefastening boltsofairintakeand

exhaustcamshafttensionpulleysand

camshaft.

Torque:120±5Nm.

10. Removethespecialtiming tool,and

mountthevalvecover,thehighvoltage

ignitioncableandthetiming beltcover.

CHAPTER2ENGINEBODY

SECTION1WHEELTRAIN

I. STRUCTURALDIAGRAM

PartName Torque valueNm Re-screwangle

1 Bolt–LowerPartOfTiming

FrontCover 8+3

2 Bolt–UpperPartOfTiming Front

Cover 8+3

3 Bolt–UpperPartOfTiming Front

Cover 8+3

4 LowerPartOfTiming Front

Cover

5 UpperPartOfTiming Front

Cover

6 Washer- LowerPartOfTiming

FrontCover

7 Bolt-CrankshaftTimingGear 130+10 65+5

8 Washer- CrankshaftTimingGear

9 CrankshaftTimingGear

10 TimingBelt

11 WaterPump

12 Bolt-Timing GearRearCover 5+1.5

13 TimingGearRearCover

14 CamshaftTiming Gear

15 Bolt-CamshaftTiming Gear 120+5

16 Bolt-Timing Tensioner 27+2.7

17 TimingTensioner

18 Bolt-Timing Idlerwheel 40+5

19 TimingIdlerwheel

20 ContactIdlerwheel

21 Bolt-ContactIdlerwheel 40+5

PDFcreated withpdfFactoryProtrialversion www.pdffactory.com

pouyapadid.com

09120539254

CHERY A21 SERVICEMANUAL MECHANISMOF2.0NALCENGINE

10

II. MAINTENANCE

1. Replace upperandlowercoversoftiming

belt

1.1 Neededtoolsandauxiliarymaterials

Allenwrench,10#,13#sleeve,ratchetwheel

andratchetrod.

1.2 Removal

1) Loosenthefiveboltsontheuppercover

withAllenwrench.

2) Removetheuppercoveroftiming belt.

3) Cliptheflywheelwithflywheeltool.

4) Removethecrankshaftpulleywith13#

sleeve.

FlywheelTool

PDFcreated withpdfFactoryProtrialversion www.pdffactory.com

pouyapadid.com

09120539254

CHERY A21 SERVICEMANUAL MECHANISMOF2.0NALCENGINE

11

5) Removethe5boltsonthelowercover

oftiming beltwith10# sleeve,ratchet

wheelandratchetrod.

6) Removethelowercover.

1.3 Inspection

Observethetiming coverandthetiming belt.

Replace thetiming beltcoveroradjustthe

positionoftiming beltifanytrailfromcrack

orfrictionisfound.

1.4 Installation

Theinstalling stepsarereversetothosefor

removal.

Note:Installthelowercoverfirstandthen

install theupperone.

2.Replace timing belt

2.1Neededtoolsandauxiliarymaterials

Allenwrench,10#,13#sleeve,ratchetwheel

andratchetrod.

2.2Removal

1) Removetheupperandlowercoversof

timing belt(see “replace coversof

PDFcreated withpdfFactoryProtrialversion www.pdffactory.com

pouyapadid.com

09120539254

CHERY A21 SERVICEMANUAL MECHANISMOF2.0NALCENGINE

12

timing belt”fordetails).

2) Loosenthecentralboltoftensionpulley

andremovethetiming belt.

2.3Inspection

Checkthetiming beltcarefully;replace the

partsifanyfollowing situationoccurs.

(1)Chapofback-siderubber

(2)Chapofdedendum,chapofseparated

cordfabric.

(3)Wearing,gearmissing andincomplete

gearofcordfabric.

(4)Abnormalwearingofbeltflank.

Replace thebeltasanyfollowing situationoccurs,eventhoughabrasioncannotbefound

directly.

1)Thewaterpumpleakswaterout, andrequirescontinuing infusion.

2)Ifthebeltisspottedwithmuchoil stains,andtherubbermaybedamageddueto

expansion,youshouldreplace thebelt.

Chap

Chap

Wearing

AbnormalWearing

GearMissing

Belt CoreDesquamation

PDFcreated withpdfFactoryProtrialversion www.pdffactory.com

pouyapadid.com

09120539254

CHERY A21 SERVICEMANUAL MECHANISMOF2.0NALCENGINE

13

2.4 Installation

Theinstalling stepsarereversetothosefor

removal.

Note:Doenginetiming.

3. Replace idlerwheel,tensionerand

contactbeltpulley

3.1 Neededtoolsandauxiliarymaterials

Allenwrench,10#,13#and15# sleeve,

ratchetwheelandratchetrod.

3.2 Removal

1) Removethetiming belt(see “replace

timing belt”fordetails).

2) Removeidlerwheel,tensionpulleyand

contactbeltpulley.

3.3 Inspection

1) Checkfromappearance

Checkidlerwheel,tensionpulleyandcontact

beltpulleycarefullyforanydamages, suchas

sunkentrace andsliding damageetc.

2) Checkperformance

Revolvetensionpulley,idlerwheeland

contactbeltpulleyrespectivelytoinsurethat

theycanrunfreelywithoutstagnancy.

Replace itwiththesparepartifanyabove

problemisfound.

3.4 Installation

1) Theinstalling stepsoftensionpulley,

idlerwheelandcontactbeltpulleyare

reversetothoseforremoval.

2) Mountthetiming beltandcollateengine

timing.

3) Mountotherparts.

PDFcreated withpdfFactoryProtrialversion www.pdffactory.com

pouyapadid.com

09120539254

CHERY A21 SERVICEMANUAL MECHANISMOF2.0NALCENGINE

14

SECTION2CYLINDERHEAD

I. STRUCTURALDIAGRAM

1. Gasket—IntakeManifold

2. IntakeManifoldAssembly

3. HexagonalFlangeBolt

4.ThrottleValveBodyAssembly

5. Gasket—ThrottleValveBodyAssembly

6. OilinjectorAssembly

7. FuelDistributionPipeAssembly

8. Bracket

4

7

6

2 1

3

5

8

PDFcreated withpdfFactoryProtrialversion www.pdffactory.com

pouyapadid.com

09120539254

CHERY A21 SERVICEMANUAL MECHANISMOF2.0NALCENGINE

15

1. IntakeValve

2.ValveOil Seal

3.ValveSpringSeat

4.ValveSpring

5.ValveSpringRetainer

6. Keeper

7. ExhaustValve

8. IntakeCamshaftAssembly

9. BearingCapAssembly

10. ControlValve-CamshaftPhaserAssembly

11. FirstBearingCapAssembly

12. FrontCamshaftOilSeal

13. ExhaustCamshaftAssembly

14. RockerArmAssembly

15. HydraulicTappetAssembly

16. StudBolt(9Bars)

17. CylinderHeadGasket

18.TemperatureSensor

19. EngineHanger

20. CylinderHeadBolt

21. CylinderHeadAssembly

11

15

14

13

8910

17 7

18

1

5

4

3

2

6

12

16

19

20

21

PDFcreated withpdfFactoryProtrialversion www.pdffactory.com

pouyapadid.com

09120539254

CHERY A21 SERVICEMANUAL MECHANISMOF2.0NALCENGINE

16

II. MAINTENANCE

2.1 Replace intakemanifold,deliverypipe

andoilinjector

2.1.1 Neededtoolsandauxiliarymaterials

Ratchetwheel,ratchetrod,10#sleeveand

crossheadscrewdriver

2.1.2 Process ofremoval

1) PuttheignitionkeyattheOFF position.

2) Loosentheplug ofoilinjector.

3) Removetheconnectingboltbetween

engineoildipstickandintakemanifold.

4) Removetheclampbetweenintakehose

andthrottlevalvebody.

5) Removetheconnectingboltofthrottle

valvebody,andtakeoutthrottlevalve

body.

Note:Becausethisthrottlevalvebodyis

electronic,donotforce themiddlevanes

turningmanuallyorwithotherobjects.

6) Loosenthejointofoil intakepipe.

7) Removethefastening nutofintake

manifoldandtakeouttheintake

manifold.

PDFcreated withpdfFactoryProtrialversion www.pdffactory.com

pouyapadid.com

09120539254

CHERY A21 SERVICEMANUAL MECHANISMOF2.0NALCENGINE

17

2.1.3 Installationsteps

Theinstalling stepsarereversetothosefor

removal.

2.2 Replace camshaft,bearingbushings,

valveandvalveoilseal.

2.2.1 Neededtoolsandauxiliarymaterials

Specialtoolsforvalveoil seal,engine

transmissionoil,asetofsleevetools,an

adjustablespanner,specialtoolsfortiming

andasetofAllenwrenches

2.2.2 Removal

1) Removethedynamobelt(see “removal

ofdynamobelt”fordetails).

2) Removethetiming belt(see

“replacementofenginetiming beltand

timing calibration”fordetails).

3) Removethecoverofenginevalve

chamber.

4) Clampthetiming specialtoolinto

camshaftslotandfastenthebolt.

CamshaftTool

PDFcreated withpdfFactoryProtrialversion www.pdffactory.com

pouyapadid.com

09120539254

CHERY A21 SERVICEMANUAL MECHANISMOF2.0NALCENGINE

18

5) Dismantlethebeltpulleyofairintake

andexhaustcamshaftswithtorque

wrench.

6) Removethebackcoveroftiming belt.

7) Dismantlethebearingcapsofairintake

andexhaustcamshaftrespectivelyand

putthemdowninthesequence.

Note:Thesecond,third,fourthandfifth

camshaftbearingcapsaremarkedwithI1, I2,

I3,I4(E1,E2,E3,E4),whichstandsforthe

correspondingbearingcapof1,2,3,4

cylinderrespectively.(“I”referstointake

camshaft, “E”referstoexhaustcamshaft).

Torque:

PDFcreated withpdfFactoryProtrialversion www.pdffactory.com

pouyapadid.com

09120539254

CHERY A21 SERVICEMANUAL MECHANISMOF2.0NALCENGINE

19

See thefollowing pictureforremovalsequence ofintakeandexhaustcamshaft-bearing caps:

8)Takeoutthecamshaftandthehydraulictappet.

9)Removethevalvespringwithspecialtools. (Pictureisunavailable)

10)Removetheusedvalveoil sealwithspecialtools. (Pictureisunavailable)

2.2.3 Inspection

1) Checkthevalvespring.

Measurethefree length,theverticalityand

thelengthunderspecialpressurewithcaliper.

Standard

Value(mm)

Free length 47.7

Lengthof

620N 32

Replace withthenewvalvespringifthe

measuredvalueexceedsthelimitvalue.

PDFcreated withpdfFactoryProtrialversion www.pdffactory.com

pouyapadid.com

09120539254

CHERY A21 SERVICEMANUAL MECHANISMOF2.0NALCENGINE

20

2)Checkcamshaft

Measurethe camshaft diameterwith

micrometercaliper.

StandardValue

mm)LimitValue

(mm)

Diameter

¢24-0.053-0.040

Replace withthenewcamshaftifthe

measuredvalueexceedsthelimitvalue.

3)Examinecamshaft

Measurethehighofcamwithmicrometer

caliper.

StandardValue

mm)

limitvalue

mm)

Intake

Cam 37.15

Exhaust

Cam 37.05

Replace withthenewcamshaftifthe

measuredvalueexceedsthelimitvalue.

4) Examinediameterofvalvestem

a: Measurethediameterofvalvestemwith

micrometercaliper.

See thepictureformeasuringpoints:theyare

26,52,and78 mmfrommeasurepositionsto

bottomofvalve.

Valve

Guide

ExternalDiameter

OfValveStem

InternalDiameter

OfValveGuide

MeasuringPoint

PDFcreated withpdfFactoryProtrialversion www.pdffactory.com

pouyapadid.com

09120539254

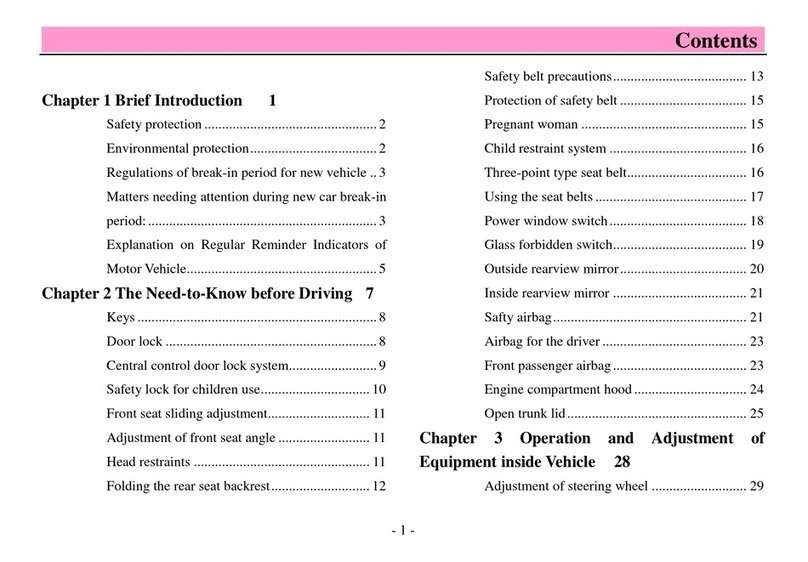

Table of contents

Other Chery Automobile manuals

Chery

Chery SQR7240T User manual

Chery

Chery V5 User manual

Chery

Chery RIICH 2 series User manual

Chery

Chery A1 2009 User manual

Chery

Chery A113 User manual

Chery

Chery Automobile User manual

Chery

Chery A5 2007 Service manual

Chery

Chery Tiggo 2009 User manual

Chery

Chery M16 Arrizo 7 2014 User manual

Chery

Chery A21 2005 User manual