GENERAL INFORMATION 0-2

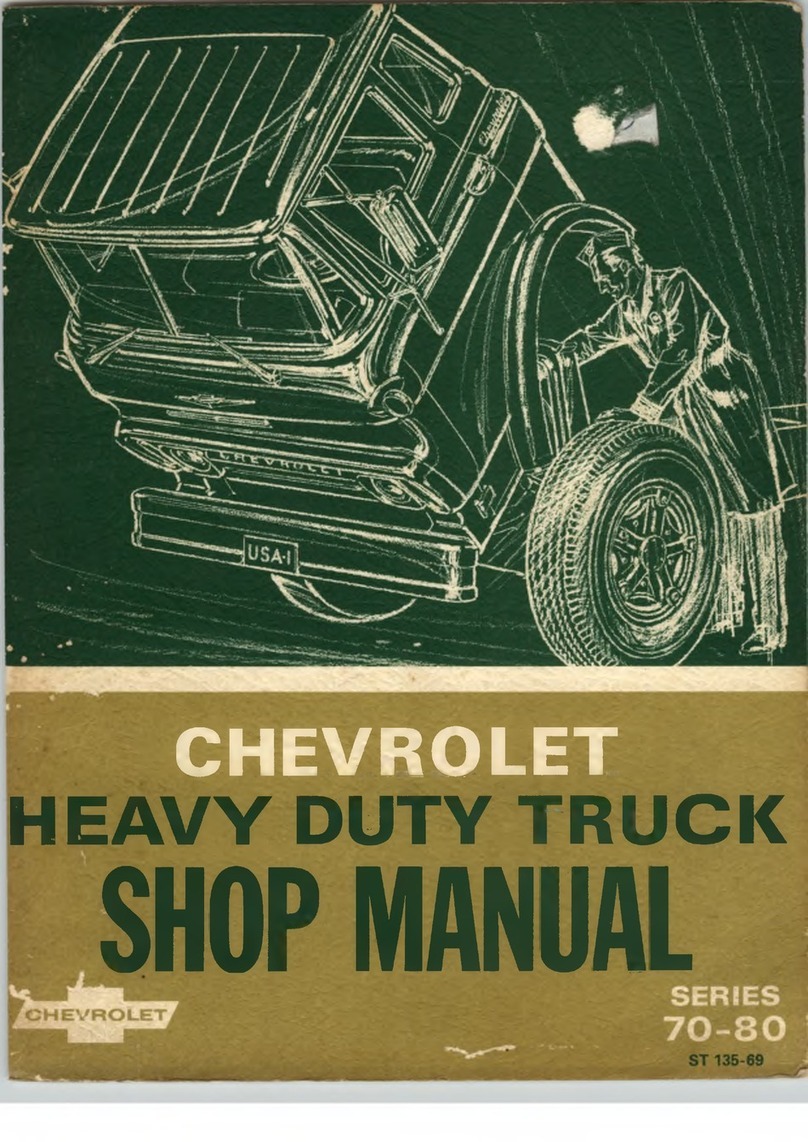

VEHICLE IDENTIFICATION NUMBER AND

RATING PLATE

A combination vehicle identification number and rating

plate used on all models (fig. 1) is located on the left

door hinge pillar of Conventional, Tilt Cab and Forward

Control models, on the upper left hand side of dash

panel on Cowl models and on the steering column of

Forward Control models. Also, included on the plate

is a space (DD) for indicating the date the truck was

delivered to the customer.

A typical vehicle identification number will decode

as follows:

CS140 800025 (See Series and Model Identification).

CS14 Series and model identification, without

second, third and fourth numbers.

0 Last number of model year 1970.

Assembly plant, = ontiac.

100025 Twenty fifth vehicle built at that plant.

Unit numbering starts at 100001 at all

plants.

ENGINE NUMBER

The engine number indicates manufacturing plant,

month and day of manufacture, and transmission type. A

typical engine number would be F1210FA, which would

breakdown thus:

F - Manufacturing lant (F-Flint, T-Tonawanda)

12 - Month of manufacture (December)

r\ CHEVROLET MOTOR DIVISION

^ GENERAL MOTORS CORPORATION o

WARRANTY MAY BE VOIDED IF WEIGHT

EXCEEDS ANY OF THE RATINGS SHOWN

GROSS VEHICLE WEIGHT INCLUDES WEIGHT OF

BASE TRUCK, ALL ADDED EQUIPMENT, DRIVER

AND PASSENGERS, AND ALL PROPERTY LOADED

INTO TRUCK.

PREFER TO OWNER’S MANUAL FOR EQUIP

MENT REQUIRED FOR INTERMEDIATE OR

MAXIMUM GVW RATINGS, AND FOR OTHER

LOADING INFORMATION, INCLUDING TIRE

INFLATION.

RATING IN POUNDS

AS M A N U - * MAXIMUM

FACTURED CAPABILITY

GROSS VEHICLE WEIGHT

FOR THIS VEHICLE

MAXIMUM FRONT END

WEIGHT AT GROUND

MAXIMUM REAR END

WEIGHT AT GROUND

VEHICLE IDENTIFICATION NO.

OO

Fig. 1—V ehi le Identifi atio n Number and Rating

Plate Information

10 - Day of manufacture (tenth)

FA - Transmission and engine type

UNIT AND SERIAL NUMBER LOCATIONS

For the convenience of service technicians and engi

neers when writing up certain business papers such as

Warranty Reports, roduct Information Reports, or re

porting product failures in any way, the location of the

various unit numbers have been indicated. These unit

numbers and their prefix or suffix are necessary on these

papers for various reasons - such as accounting, follow-

up on production, etc.

The prefixes on certain units identify the plant in

which the unit was manufactured and thereby permits

proper follow-up of the plant involved to get corrections

made when necessary.

Always include the prefix in the number.

Axles

• Rear Axle Serial Number Located at the Bottom

Flange of Carrier Housing.

• Rear Axle (Except Half Ton) Forward Upper Surface

of Carrier.

• 2-Speed Axle Serial Number on Face of C arrier.

Tandem A xle, Forw ard Unit— Unit and Assem bly

Numvers Stamped on Left Side of C arrier.

• Tandem Axle, Rear Unit—Unit and Assembly Num

bers Stamped on Upper ortion of Carrier.

Transmissions

• 3-Speed Transmission Unit Number Located on

Lower Left Side of Case Adjacent to Rear of Cover.

• 4-Speed Transmission Unit Number Stamped on

Rear of Case, Above Output.

• New rocess 5-Speed Unit Number Stamped on

Rear Face of Case to Left of Drain lug. Spicer

3000 Series above lug. Spicer 5000 Series on

Nameplate Left Side of Case at Rear.

• 5-Speed Clark Transmission Unit Number Stamped

on Left Rear of Case, Near .T.O. late.

• 4-Speed Auxiliary Transmission Unit Number on

Left Side of Case.

• Allison Transmission art Number and roduction

Date on Tag Left Side of Case.

• owerglide and Turbo Hydra-Matic 350 Transmis

sion Unit Number Located on Right Rear Vertical

Surface of Oil an.

• The Turbo Hydra-Matic Transmission 400 Serial

Number is Located on the Light Blue late on the

Right Side of the Transmission.

Engines

• 6-Cylinder Engine Unit Number Located on ad at

Right Hand Side of Cylinder Block at Rear of

Distributor.

• 8-Cylinder Engine Unit Number Located on ad at

Front, Right Hand Side of Cylinder Block.

• Diesel Engine (Four Cycle) Serial Number Forward

of Right Cylinder Head on Cylinder Block.

• Diesel Engine Serial Number 6-Cylinder Forward of

Right Cylinder Head, 3, 4-Cylinder Rear Right of

Cylinder Head.

Delcotrons

Delcotron Unit Serial Number--Top of Rear Housing.

CHEVROLET TRUCK SERVICE MANUAL