Chigo CMV-R Serie User manual

INSTALLATION MANUAL

INSTALLATION

MANUAL

CMV-R Series

ALL DC Inverter Heat Recovery A/C

Thank you very much for purchasing our air conditioner!

This instruction manual is the universal version for ALL DC Inverter Heat Recovery A/C air conditioners, the appearance of your air conditioner may

be varying with the appearance of unit introduced in the manual, but it will not confuse you in operating and using.

Please read this manual carefully before using, and keep it for future reference.

To protect your lawful rights and interests, your air conditioner must be installed by a professional worker.

●

●

●

●

CE N TR AL AI R- CO ND I TION IN G

INSTALLATION

When installing the unit in a small room, take measures

against to keep refrigerant concentration from exceeding

allowable safety limits in the event of refrigerant leakage.

Contact the place of purchase for more information. Excessive

refrigerant in a closed ambient can lead to oxygen deficiency.

Use the attached accessories parts and specified parts for

installation.

Otherwise, it will cause the set to fall, water leakage, electrical

shock fire.

Install at a strong and firm location which is able to

withstand the set's weight.

If the strength is not enough or installation is not properly done,

the set will drop to cause injury.

The appliance shall not be installed in the laundry.

Before obtaining access to terminals, all supply circuits

must be disconnected.

The appliance must be positioned so that the plug is

accessible.

The enclosure of the appliance shall be marked by word, or

by symbols, with the direction of the fluid flow.

For electrical work, follow the local national wiring

standard, regulation and this installation instructions. An

independent circuit and single outlet must be used.

If electrical circuit capacity is not enough or defect in electrical

work, it will cause electrical shock fire.

Use the specified cable and connect tightly and clamp the

cable so that no external force will be acted on the

terminal.

If connection or fixing is not perfect, it will cause heat-up or fire

at the connection.

Wiring routing must be properly arranged so that control

board cover is fixed properly.

If control board cover is not fixed perfectly, it will cause heat-up

at connection point of terminal, fire or electrical shock.

If the supply cord is damaged, it must be replaced by the

manufacture or its service agent or similarly qualified

person in order to avoid a hazard.

An all-pole disconnection switch having a contract

separation of at least 3mm in a poles should be connected

in fixed wiring.

When carrying out piping connection, take care not to let

air substances go into refrigeration cycle.

Otherwise, it will cause lower capacity, abnormal high pressure

in the refrigeration cycle, explosion and injury.

Do not modify the length of the power supply cord or use

of extension cord, and do not share the single outlet with

other electrical appliances.

Otherwise, it will cause fire or electrical shock.

Carry out the specified installation work after taking into

account strong winds, typhoons or earthquakes.

Improper installation work may result in the equipment falling

and causing accidents.

1

Installation manual

Precautions before reading the Installation manual.

1. PRECAUTIONS

WARNING

WARNING

The safety precautions listed here are divided into two categories. In

either case, important safety information is listed which must be read

carefully.

After completing the installation, make sure that the unit operates

properly during the start-up operation. Please instruct the customer

on how to operate the unit and keep it trained. Also, inform

customers that they should store this Installation manual along with

the owner's manual for future reference.

Be sure only trained and qualified service personnel to

install, repair or service the equipment.

Improper installation, repair, and maintenance may result in

electric shocks, short-circuit, leaks, fire or other damage to the

equipment.

Install according to this installation instructions strictly.

If installation is defective, it will cause water leakage, electrical

shock fire.

Failure to observe a warning may result in death.

CAUTION

Failure to observe a caution may result in injury or damage

to the equipment.

This Installation manual is for the outdoor unit.

Refer to the indoor unit Installation manual for indoor parts

installation.

Please read the power source unit Installation manual to install

the power source unit.

Please refer to the refrigerant distributor Installation manual to

install the refrigerant distributor.

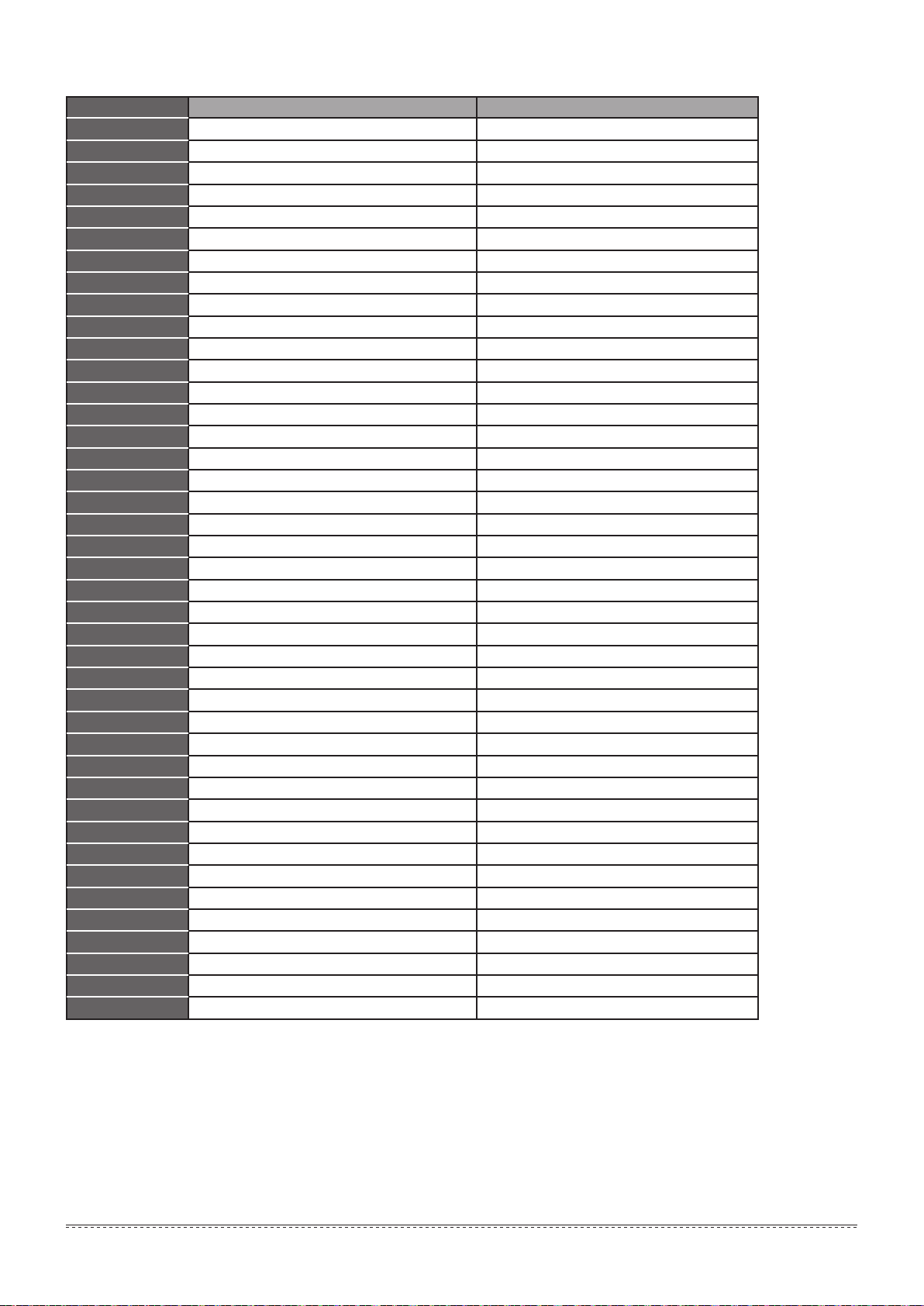

CONTENTS PAGE

1. PRECAUTIONSC..................................................................................1

2. CONSTRUCTION CHECKPOINTS..........................................................2

3. ACCESSORIES....................................................................................3

4. OUTDOOR UNIT INSTALLATION..........................................................3

5. REFRIGERANT PIPE............................................................................8

6. CONNECTING PIPE OF CS................................................................14

7. CS WIRING NAMEPLATE..................................................................14

8. ELECTRIC WIRING............................................................................15

9. TRIAL RUN

.........................................................................................21

2

Installation manual

Acceptance and Unpacking

After the machine arrives, check whether it is damaged during

the shipment. If the surface or inner side of the machine is

damaged, submit a written report to the shipping company.

Check whether the model, specification and quantity of the

equipment conform to the contract.

After removing the outer package, please keep the operation

instructions well and count the accessories.

Refrigerant pipe

Check the model and name to avoid mistaken installation.

An additionally purchased refrigerant distributor (manifold

adapter and manifold pipe) must be used for installing the

refrigerant pipes.

The refrigerant pipes must have the specified diameter.

Nitrogen of a certain pressure must be filled into the refrigerant

pipe before welding.

The refrigerant pipe must undergo heat insulation treatment.

After the refrigerant pipe is installed completely, the indoor unit

cannot be powered on before performing the airtight test and

creating a vacuum. The air-side and liquid-side pipes must

undergo the airtight test and vacuum extraction.

Airtight test

The refrigerant pipe must undergo the airtight test (with

40kgf/cm2nitrogen).

Creating a vacuum

Be sure to use the vacuum pump to create a vacuum of the

connective pipe at the air side and liquid side concurrently.

Refrigerant replenishment

If the length is greater than the reference pipe, the refrigerant

replenishment quantity for each system should be calculated

through the formula obtained according to the actual length of

pipe.

Record the refrigerant replenishment quantity, actual length of

pipe and the height difference of the indoor & outdoor unit onto

the operation confirmation table of the outdoor unit in advance

for future reference.

Electric wiring

Select the power supply capacity and wire size according to

the design manual. The power cable of the air conditioner is

generally thicker than the power cable of the motor.

In order to prevent misoperation of the air conditioner, do not

interleave or entwine the power cable with the connection

wires (low-voltage wires) of the indoor/outdoor unit.

Power on the indoor unit after performing the airtight test and

making a vacuum.

For details of setting the address of the outdoor unit, see

Outdoor unit address bits.

If the refrigerant leaks during installation, ventilate the area

immediately.

Toxic gas may be produced if the refrigerant comes into the

place contacting with fire.

After completing the installation work, check that the

refrigerant does not leak.

Toxic gas may be produced if the refrigerant leaks into the

room and comes into contact with a source of fire, such as a

fan heater, stove or cooker.

2. CONSTRUCTION CHECKPOINTS

CAUTION

This A/C is a kind of amenity unit. Don’t install it at the

place where for storing machine, precise instrument, food,

plant, animal, artwork or any other special used occasion.

Ground the air conditioner.

Do not connect the ground wire to gas or water pipes, lightning

rod or a telephone ground wire. Incomplete grounding may

result in electric shocks.

Be sure to install an earth leakage breaker.

Failure to install an earth leakage breaker may result in electric

shocks.

Connect the outdoor unit wires , then connect the indoor

unit wires.

You are not allowed to connect the air conditioner with the

power source until wiring and piping the air conditioner is done.

While following the instructions in this Installation manual,

install drain piping in order to ensure proper drainage and

insulate piping in order to prevent condensation.

Improper drain piping may result in water leakage and property

damage.

Install the indoor and outdoor units, power supply wiring

and connecting wires at least 1 meter away from

televisions or radios in order to prevent image interference

or noise.

Depending on the radio waves, a distance of 1 meter may not

be sufficient enough to eliminate the noise.

The appliance is not intended for use by young children or

infirm persons without supervision.

Young children should be supervised to ensure that they

do not play with the appliance.

Don't install the air conditioner in the following locations:

There is petrolatum existing.

There is salty air surrounding (near the coast).

There is caustic gas (the sulfide, for example) existing in the air

(near a hot spring).

The Volt vibrates violently (in the factories).

In buses or cabinets.

In kitchen where it is full of oil gas.

There is strong electromagnetic wave existing.

There are inflammable materials or gas.

There is acid or alkaline liquid evaporating.

Other special conditions.

The insulation of the metal parts of the building and the air

conditioner should comply with the regulation of National

Electric Standard.

3

Installation manual

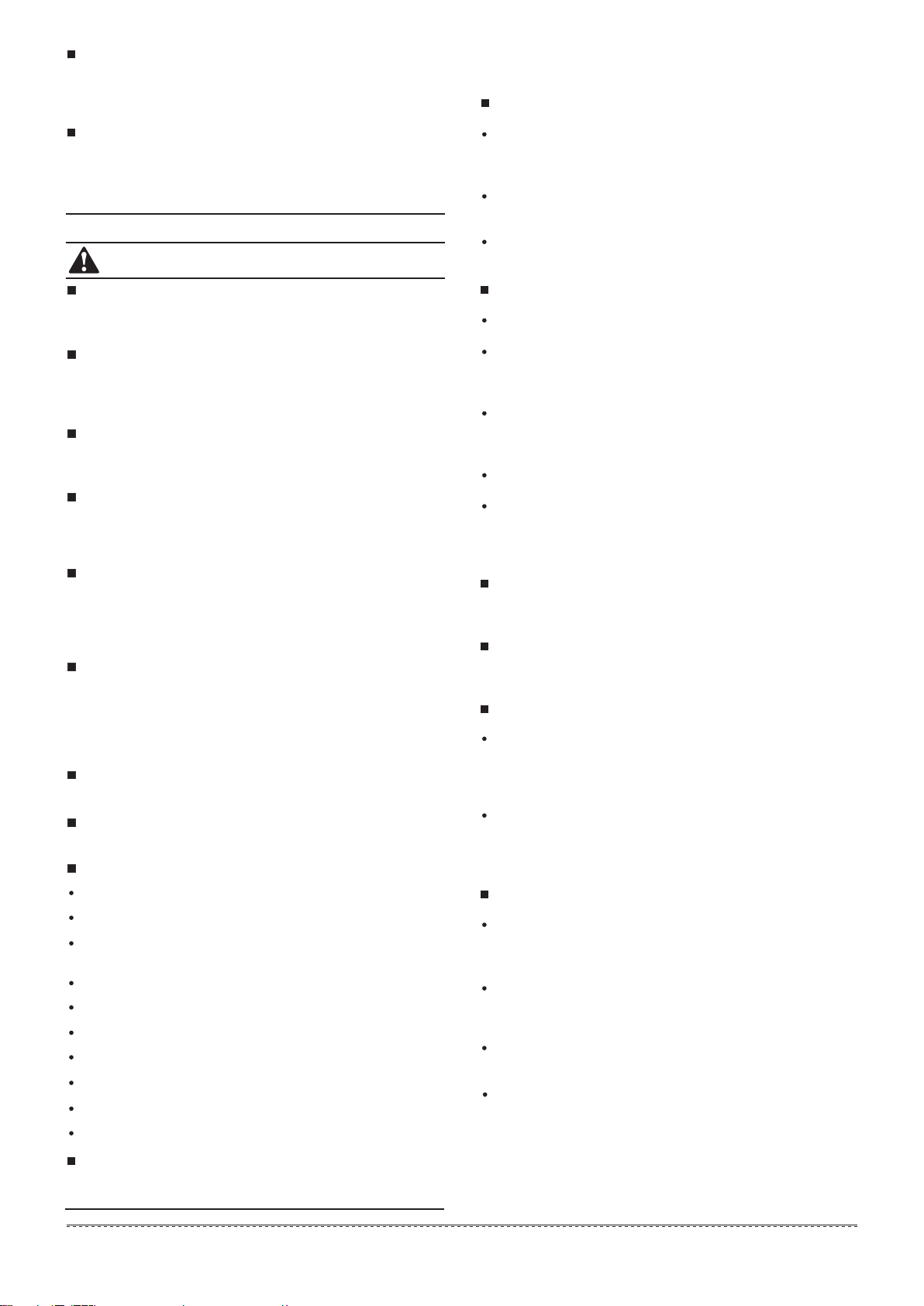

3. ACCESSORIES

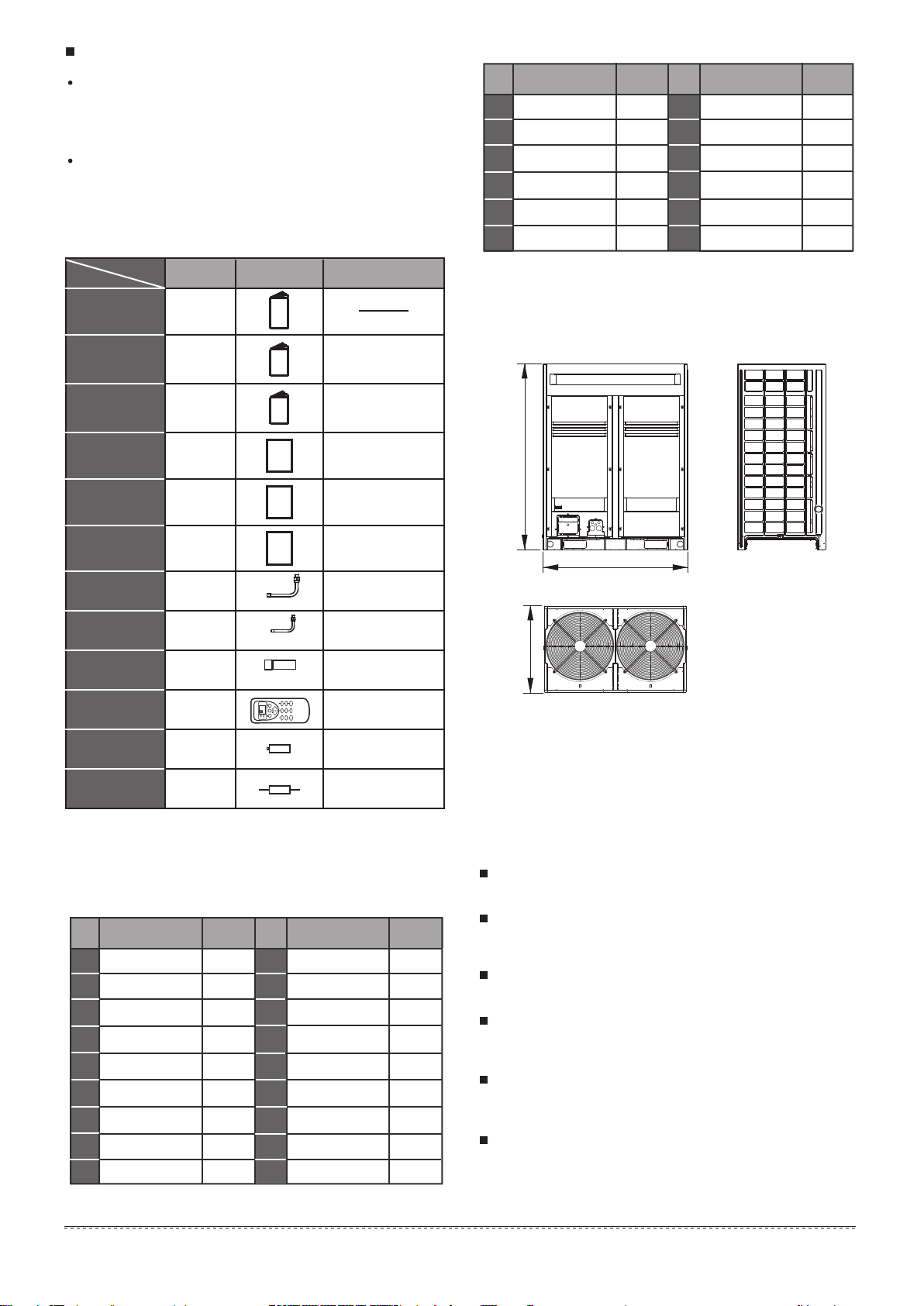

4.2 Dimension of outdoor unit

Trial run

Before operation, remove the four pieces of PE foaming which

are used at the rear of the unit for protecting the condenser. Be

careful not to damage the fin. Otherwise, the heat exchange

performance may be affected.

Perform the trial run only after the outdoor unit has been

powered on for over 12 hours.

4. OUTDOOR UNIT INSTALLATION

4.1 Outdoor unit combination

Function

Outdoor unit

installation manual

Outdoor unit

owner’s manual

Indoor unit

owner’s manual

Outdoor unit

branch pipe

installation manual

Installation manual

of indoor

manifold

VRF address

setting remote

controller manual

OutlineAll of units

Model

Name

1

1

1

1

1

1

1

1

Be sure to deliver

it to the customer

Be sure to deliver

it to the customer

Be sure to deliver

it to the customer

Be sure to deliver

it to the customer

Be sure to deliver

it to the customer

5

Table.3-1

Table.4-1

Connective pipe

accessory

Resistance

Power supply to the

remote controller

Connect to the

liquid pipe side

Connect to the

high-pressrue

gas balance side

Stored for service

(

used in 8HP~16HP

)

(

used in 8HP~16HP

)

1

Connective pipe

accessory

Connective pipe

accessory

Remote controller

2

Battery

Connect to the

low-pressure

gas pipe side

Address setting

1

16HP×3

14HP×2+16HP

14HP+16HP×2

64

64

64

44

46

48

Max Qty.of

indoor unit

ModeHP

Max Qty.of

indoor unit

Mode

HP

Table.4-2

10HP+14HP+16HP×2

14HP×3+16HP

14HP+16HP×3

16HP×4

14HP×2+16HP×2

64

64

64

64

64

56

58

60

62

64

8HP+10HP+16HP×2

10HP+12HP+16HP×2

10HP×2+16HP×2

64

64

64

50

52

54

Fig.4-1

Unit:mm

(

used in 10,12HP

)

4.3 Selecting installation position

Ensure that the outdoor unit is installed in a dry, well-ventilated

place.

Ensure that the noise and exhaust ventilation of the outdoor

unit do not affect the neighbors of the property owner or the

surrounding ventilation.

Ensure that the outdoor unit is installed in a well-ventilated

place that is possibly closest to the indoor unit.

Ensure that the outdoor unit is installed in a cool place without

direct sunshine exposure or direct radiation of high-temp heat

source.

Do not install the outdoor unit in a dirty or severely polluted

place, so as to avoid blockage of the heat exchanger in the

outdoor unit.

Do not install the outdoor unit in a place with oil pollution, salt

or high content of harmful gases such as sulfurous gas.

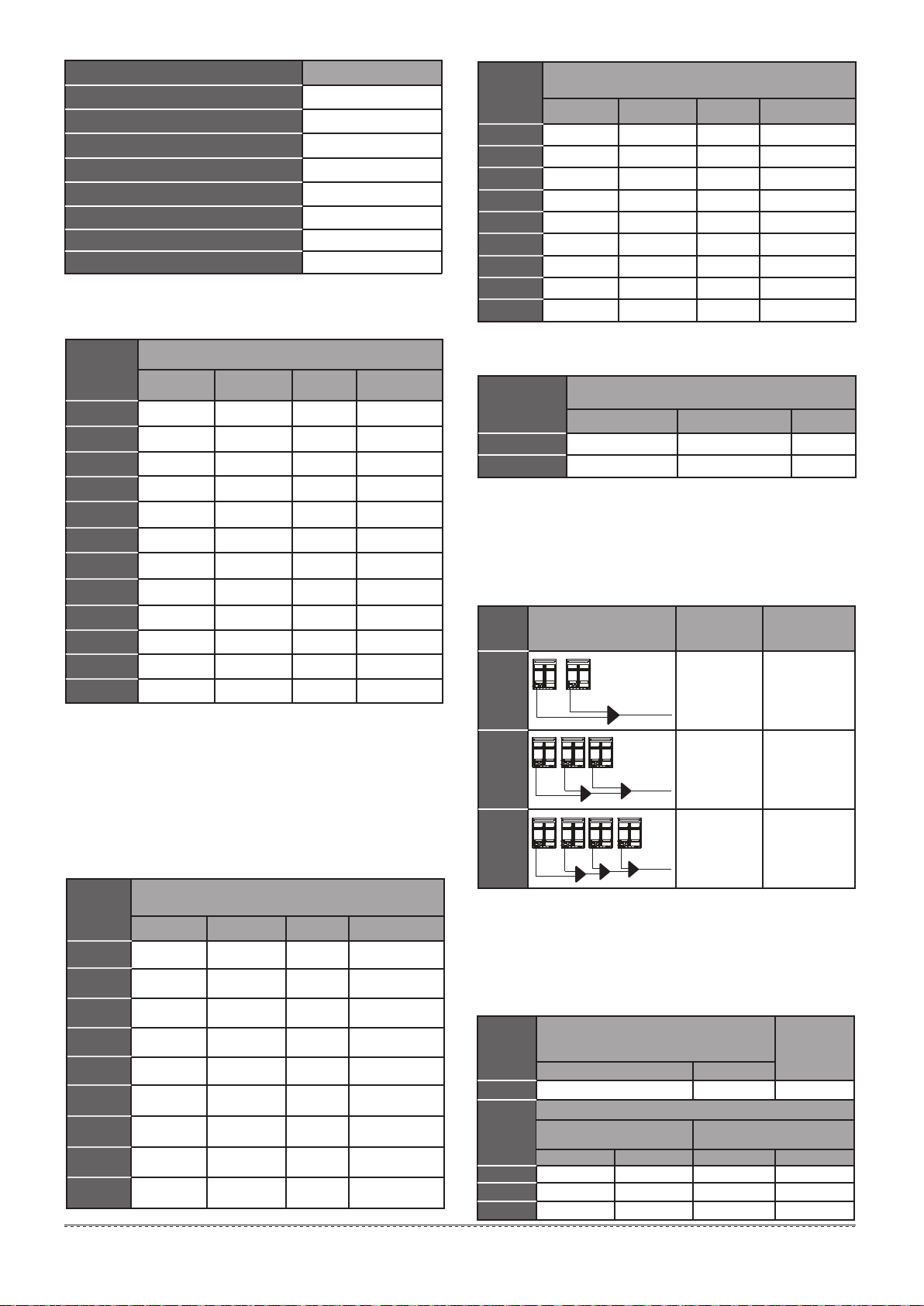

5910HP×2+16HP36

10HP+12HP+16HP

10HP+14HP+16HP

14HP×3

38 63

64

64

40

42

43

46

50

53

5610HP×2+14HP

10HP+16HP

14HP×2

14HP+16HP

16HP+16HP

26

28

30

32

34

36

39

10HP+12HP

10HP+14HP

22

24

88HP×1 13

16

20

23

26

29

33

10HP×1

12HP×1

14HP×1

16HP×1

8HP+10HP

10HP+10HP

10

12

14

16

18

20

Max Qty.of

indoor unit

ModeHP Max Qty.of

indoor unit

ModeHP

1260

1620

765

Fig.4-2

Fig.4-4

Fig.4-5

Fig.4-6

Installation manual

A solid, correct base can:

Avoid the outdoor unit from sinking.

Avoid the abnormal noise generated due to base.

Base types

Steel structure base

Concrete base (see the figure below for the general making

method)

Concrete basement

h=200mm

Outdoor unit

Φ10 Expansion bolt

Rubber shocking

proof mat

Solid ground

or roofing

200mm

Before construct the unit base, please ensure the base is

directly supporting the rear and front folding edges of the

bottom panel vertically, for the reason of these edges are the

actual supported sites to the unit.

In order to drain off the seeper around the equipment, a

discharge ditch must be setup around the basement.

Please check the affordability of the roofing to ensure the load

capacity.

When piping from the bottom of the unit, the base height should

no less than 200mm.

CAUTION

The key points to make basement:

The master unit’s basement must be made on the solid

concrete ground . Refer to the structure diagram to make

concrete basement in detail, or make after field measurements.

In order to ensure every point can contact equality, the

basement should be on completely level.

If the basement is placed on the roofing, the detritus layer isn’t

needed, but the concrete surface must be flat. The standard

concrete mixture ratio is cement 1/ sand 2/ carpolite 4, and add

Φ10 strengthen reinforcing steel bar, the surface of the cement

and sand plasm must be flat, border of the the basement must

be chamfer angle.

4

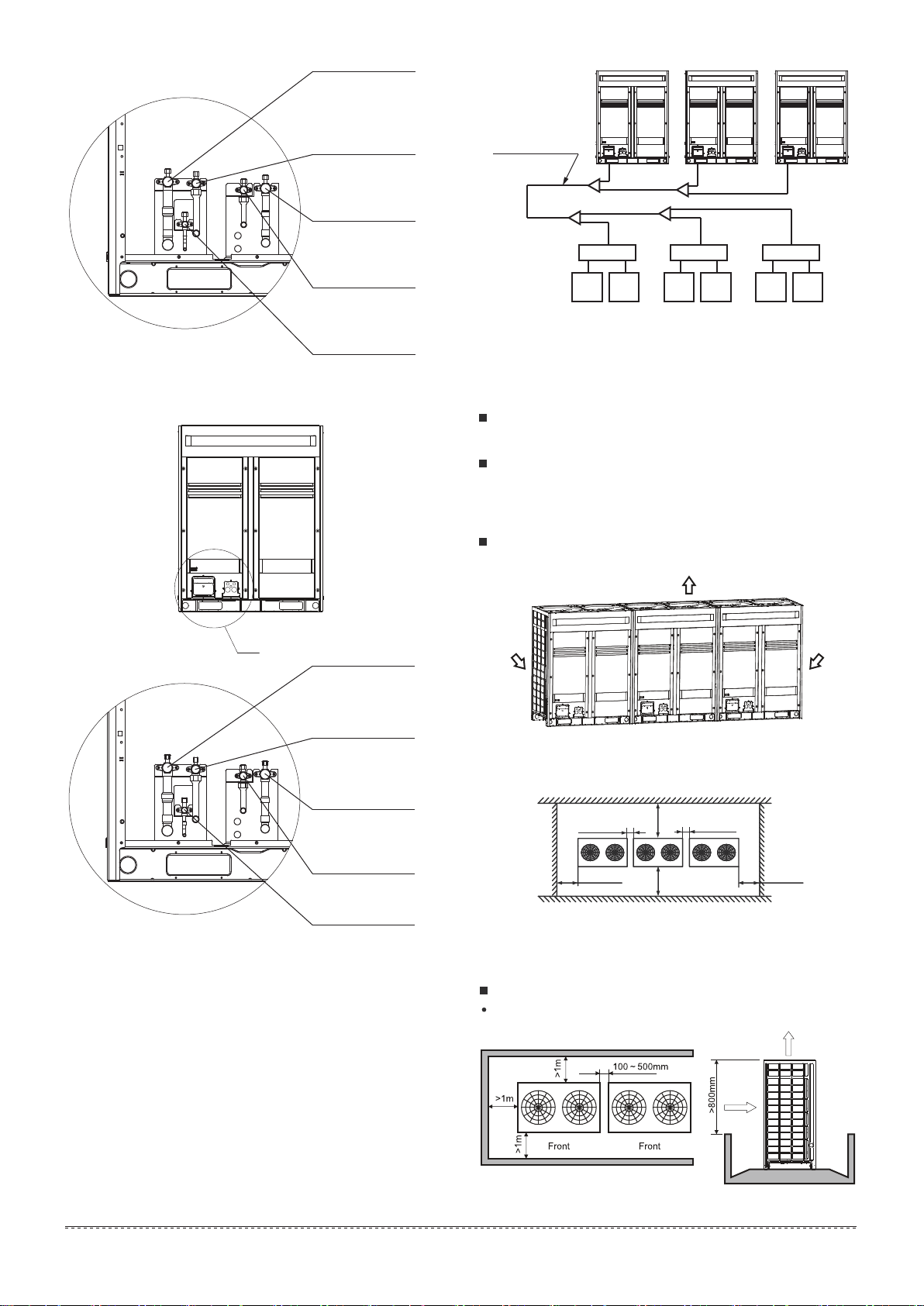

Centering position illustration of each connective pipe (Unit: mm)

1) 8HP,10HP

2) 12HP

Unit: mmTable.4-3

A

B

D

C

SIZE

HP

998

1302

703

817

8~16

Position illustration of screw bolt (Unit: mm)

Fig.4-3

15×23 long U-shape hole

B

A

C

D

R

For parallel

connection

The connective pipe

diameter Φ12.7

(by a reducer)

Oil balance valve

Liquid side of

shut-off valve

The connective pipe

diameter Φ19.05

The connective pipe

diameter Φ22

(by a reducer)

The connective pipe

diameter Φ19.05

High-pressure gas

side of shut-off valve

Low-pressure gas

side of shut-off valve

High-pressure

gas balance valve

R amplification

R

Fig.4-7

Fig.4-8

Fig.4-9

5

Installation manual

4.5 Outdoor units’ placement sequence &

master and slave units’ settings

A system, which provide with more than two outdoor units, will

be set as the followings method: The outdoor units in this

system should place sequentially from the large to the small

capacity; the largest capacity outdoor unit must be mounted at

unit address as the master Unit, while the other setting as the

Slave Unit. Take 38HP (composed by 10HP, 12HP and 16HP)

as an example:

1) Place the 16HP at a side of the first branch joint site.

2) Place the unit from the large capacity to the small (See the

detail placement illustration)

3) Set 16HP as the main unit, while the 12HP and the 10HP as

the aux. unit.

4.6 Installation space for outdoor unit

Ensure enough space for maintenance. The modules in the

same system must be on the same height.(see the Fig.4-11)

When installing the unit, leave a space for maintenance shown

in Fig.4-12..Install the power supply at the side of the outdoor

unit. For installation procedure, see the power supply device

Installation manual.

In case any obstacles exist above the outdoor unit, refer to

Fig.4-17.

Fig.4-13

4.7 Layout

When the outdoor unit is higher than the surrounding obstacle

One row

Fig.4-12

Top view of the outdoor unit

>1000mm

>1000mm

100~500mm

100~500mm

>1000mm >1000mm

Fig.4-11

(Air-out)

(Air-in)

(Air-in)

Installation and maintenance surface

Fig.4-10

3) 14HP,16HP

For parallel

connection

The connective pipe

diameter Φ12.7

(by a reducer)

Oil balance valve

Liquid side of

shut-off valve

The connective pipe

diameter Φ19.05

The connective pipe

diameter Φ25.4

(by a reducer)

The connective pipe

diameter Φ19.05

High-pressure gas

side of shut-off valve

Low-pressure gas

side of shut-off valve

High-pressure

gas balance valve

R amplification

R

For parallel

connection

The connective pipe

diameter Φ15.88

Oil balance valve

Liquid side of

shut-off valve

The connective pipe

diameter Φ22

The connective pipe

diameter Φ28.6

The connective pipe

diameter Φ19.05

High-pressure gas

side of shut-off valve

Low-pressure gas

side of shut-off valve

High-pressure

gas balance valve

R amplification

Outdoor unit

The 1st branch joint

16HP 12HP 10HP

(38HP)

CS

Indoor

unit D

Indoor

unit C

CS

Indoor

unit F

Indoor

unit E

CS

Indoor

unit B

Indoor

unit A

6

Installation manual

Fig.4-14

Two rows

Fig.4-17

When the outdoor unit is lower than the surrounding obstacle,

refer to the layout used when the outdoor unit is higher than

the surrounding obstacle. However, to avoid cross connection

of the outdoor hot air from affecting the heat exchange effect,

please add an air director onto the exhaust hood of the outdoor

unit to facilitate heat dissipation. See the figure below. The

height of the air director is HD (namely H-h). Please make the

air director on site.

If miscellaneous articles are piled around the outdoor unit, such

articles must be 800mm below the top of the outdoor unit.

Otherwise, a mechanic exhaust device must be added.

Fig.4-16

Fig.4-15

More than two rows

In snowy areas, facilities should be installed to prevent snow.

(See the figure below) (defective facilities may cause

malfunction.) Please lift the bracket higher and install snow

shed at the air inlet and air outlet.

Fig.4-18

4.8 Set the snow-proof facility

4.9 Explanation of valve

Table.4-4

Fig.4-19

Connect oil balance pipe

Connect liquid pipe

(accessory, field installation)

Connect high-pressure gas pipe

(accessory, field installation)

Connect low-pressure gas pipe

(accessory, field installation)

Connect high-pressure gas balance pipe(accessory, field installation)

Notes:16HP as an example

1

2

3

Fig.4-20

Fig.4-21

Example A

Installation illustration

4

5

B(mm)

B >

Airflow deflector

B

A

θ

7

Installation manual

Fig.4-22

Fig.4-23

Curve diagram of static pressure, air flow volumn.

Fig.4-27

Fig.4-28

Fig.4-29

Example B

NOTE

Before install the air deflector, please ensuring the mesh

enclosure has been took off, otherwise the air supply efficiency

would be block down.

Once mounting the shutter to the unit, air volume, cooling

(heating) capacity and efficiency would be block down, this

affection enhance along with the angle of the shutter. Thus, we

are not recommend you to mount the shutter, if necessary in

use, please adjust the angle of shutter no larger than 15°.

Only one bending site to be allowanced in the air duct (see as

above figure), otherwise, misoperation may led out.

Install the flexible connector between the unit and the air pipe,

for avoiding to produce vibration noise

Fig.4-24

8/10HP Air pressure curve diagram

(take down the mesher)

Static pressure (Pa)

Air volume

9500

10000

10500

11000

11500

12000

12500

0 5 10 15 20 25

Fig.4-25Static pressure (Pa)

Air volume

10500

11000

11500

12000

12500

13000

13500

0 5 10 15 20 25

12HP Air pressure curve diagram

(take down the mesher)

Fig.4-26Static pressure (Pa)

Air volume

12500

13000

13500

14000

14500

15000

15500

0 5 10 15 20 25

14/16HP Air pressure curve diagram

(take down the mesher)

Unit: mmTable.4-5

A≥300A

B

C

D

B≥250

C≤8000

600≤D≤760

θ≤15°θ

Unit: mmTable.4-6

A≥300A

B

C

B≥250

C≤8000

θ≤15°

θ

8

Installation manual

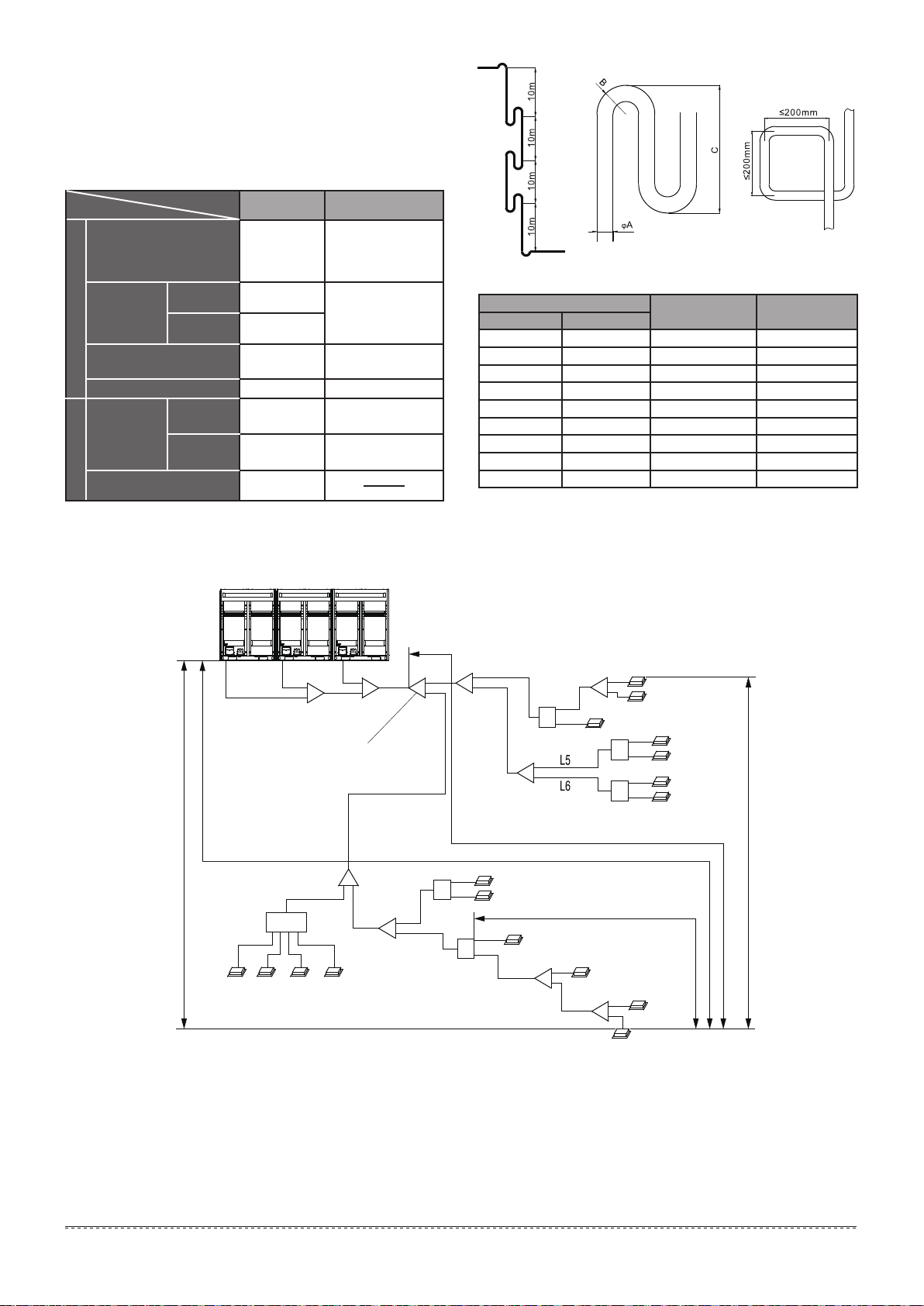

Fig.5-1

5.1 Length and drop height permitted of the

refrigerant piping

5. REFRIGERANT PIPE

Note: Assume equivalent pipe length of the branching pipe header to

be 0.5m,of the CS to be 1m(for calculation purposes).

Fig.5-2

Table.5-1

Permitted value

Piping

Total pipe length (Actual)

Indoor unit to indoor unit drop height

Piping (farthest from the first line

pipe branch) equivalent length

Pipe lengthDrop height

Equivalent length

Actual length

Maximum

piping (L)

outdoor unit up

outdoor unit down

Indoor unit to

outdoor unit

drop height

30m

40m

L1+

(

L2+L3+L4+L5+L6+

L7+L8+L9+L10+L11

)

×2+

a+b+c+d+e+f+g+h+i+j+k

+l+m+n+o+p+q+r+s+t

L1+L7+L9+L11+l+n+p

L7+L9+L11+l+n+p

l+n+p

CS to indoor unit equivalent lengthequivalent length

1000m

(Please refer to

the caution 5 of

conditions 2)

175m

200m(Please

refer to caution 1)

(Please refer to

caution 3)

(Please refer to

caution 4)

40m/90m(Please

refer to caution 5)

70m

110m

Oil return bend

Φ19.05

Φ28.6

Φ25.4

Φ22.2

Φ34.9

Φ38.1

Φ41.3

Φ44.5

Φ54.1

A

Mm Inch

B

mm( )

C

mm( )

3/4

7/8

1/1

9/8

11/8

12/8

13/8

14/8

17/8

≥34

≥36

≥45

≥55

≥60

≥60

≥80

≥80

≥90

≤150

≤150

≤150

≤150

≤250

≤350

≤450

≤500

≤500

Mode 1 Mode 2

Indoor unit

Outdoor unit

(one or more outdoor units)

(From the first line branch pipe) Maximum

piping equivalent length L≤40m/90m

Max piping equivalent length L≤200m

CS to indoor unit equivalent length L≤40m

The first line branch pipe

Drop height between indoor

unit and outdoor unit H≤110m

indoor unit to indoor unit

drop height H≤30m

N17N16

(140)(56)(28) (28)

N15N14

q r s t

CS6

L8

L9 L10

L11

D

E

CS4

CS5

i

j

k

lm

no

p

N11(28)

N12(56)

N13(56)

N8(71)

N9(71)

N10(140)

g1 g2 g3

G1

MLL1 A

L7

L2 B

L3

L4

CS1

a

b

c

de

f

g

h

C

N1(71)

N2(71)

N3(28)

N4(56)

N5(28)

N6(71)

N7(71)

CS2

CS3

Ⅰ

Ⅱ

Ⅲ

9

Installation manual

5.2 Select the refrigerant piping type

Fig.5-3

CAUTION

The reduced length of the branch joint is the 0.5m of the equiva-

lent length.

The inner units should as equal as possible to be installed in the

both sides of the U-shape branch joint.

When the outdoor unit is on the top position and the difference of

level is over 20m, it is recommended that set a oil return bend

every 10m in the gas pipe of the main pipe, the specification

of the oil return bend refers to Fig.5-2.

When the outdoor unit is on the low positon, H≥40m, the liquid

pipe of the main pipe need to increase one size.

The allowable length of the fist branch joint which connected to

the indoor unit should be equal to or shorter than 40m.

But when the following conditions are all meeted, the allowable

length can extended to 90m.

1.

2.

3.

4.

5.

Conditions

Examples

need to increase the pipe diameter of the distribution pipe

Increasing size as the following

1. It is needed to increase all the pipe diameters of the main

distribution pipe which between the first and the last branch joint

assembly. (Please change the pipe diameter at field) If the pipe

diameter of the main slave pipe is the same as the main pipe, then

it is not needed to be increased.

3. The length from the indoor unit to the nearest branch joint

assembly or CS ≤40m;

b,c,d,e,f,g,h,i,j,k,m,o,p,q,r ,s,t≤40m(Pipe diameter requirements,

please refers to table .5-8).

4. The distance difference between [the outdoor unit to the farthest

indoor unit] and [the outdoor unit to the nearest indoor unit] is

≤40m.

The farthest indoor unit

The nearest indoor unit

(L1+L7+L9+L11+l+n+p)-(L1+L7+L8+p) ≤40m

L7+L9+L11+l+n+p≤90m L2~L11

N3

N13

Reference Figure. 5-1

Reference Figure .5-1

Reference Figure .5-1

Examples

Conditions

Conditions

Conditions

Examples

Examples

2. When counting the total extended length, the actual length of

above distribution pipes must be doubled.(Expect the main pipe

and the distribution pipes which no need to be increased. )

L1+(L2+L3+L4+L5+L6+L7+L8+L9+L10+L11)×2+a+b+c+d+e+f+

g+h+i+j+k+l+m+n+o+p+q+r+s+t≤1000m

Φ9.52→Φ12.7 Φ12.7→Φ15.88 Φ15.88→Φ19.05

Φ19.05→Φ22 Φ22→Φ25.4 Φ25.4→Φ28.6

Φ28.6→Φ31.8 Φ31.8→Φ38.1 Φ38.1→Φ41.3

Φ41.3→Φ44.5 Φ44.5→Φ54.0

W3

(10)

W2

(12)

W1

(16)

N17N16

(140)(56)(28) (28)

N15N14

q r s t

CS6

L8

L9 L10

L11

D

E

CS4

CS5

i

j

k

lm

no

p

N11(28)

N12(56)

N13(56)

N8(71)

N9(71)

N10(140)

g1 g2 g3

G1

MLL1 A

L7

L2 B

L3

L4

CS1

a

b

c

de

f

g

h

C

N1(71)

N2(71)

N3(28)

N4(56)

N5(28)

N6(71)

N7(71)

CS2

CS3

Ⅰ

Ⅱ

Ⅲ

10

Installation manual

5.4 Size of joint pipes for outdoor unit

Model

gas side

Low-pressure

gas side

High-pressure

Liquid side

Φ22.2 Φ19.05

Φ25.4 Φ19.05

Φ28.6 Φ22.2

Φ31.8 Φ28.6

Φ28.6

Φ28.6

Φ34.9

Φ34.9

Φ12.7

Φ12.7

Φ15.88

Φ15.88

Φ15.88

Φ19.05

When the equivalent length of all liquid

pipes < 90m, the size of main pipe(mm)

8HP

10HP

14~16HP

18~22HP

24HP

26~32HP

Size of joint pipes for R410A outdoor unitTable.5-4

SP-FQG-N03S

SP-FQG-N04S

Φ25.4 Φ19.05 Φ12.7

12HP SP-FQG-N04S

SP-FQG-N05S

SP-FQG-N06S

SP-FQG-N06S

SP-FQG-N06S

Φ34.9Φ41.3 Φ19.05

34~48HP SP-FQG-N07S

Φ38.1Φ44.5 Φ22.2

50~64HP SP-FQG-N08S

Model

Liquid side

Φ25.4

Φ25.4

Φ31.8

Φ31.8

Φ34.9

Φ38.1

Φ19.05

Φ19.05

Φ22.2

Φ28.6

Φ28.6

Φ28.6

Φ12.7

Φ12.7

Φ15.88

Φ19.05

Φ19.05

Φ22.2

When the equivalent length of all liquid

pipes ≥ 90m, the size of main pipe(mm)

8HP

10HP

14~16HP

18~22HP

24HP

26~32HP

Size of joint pipes for R410A outdoor unitTable.5-5

SP-FQG-N04S

SP-FQG-N04S

Φ28.6 Φ19.05 Φ15.8812HP SP-FQG-N05S

SP-FQG-N06S

SP-FQG-N06S

SP-FQG-N09S

SP-FQG-N06S

Φ41.3 Φ34.9 Φ22.234~48HP SP-FQG-N09S

Φ44.5 Φ38.1 Φ25.450~64HP SP-FQG-N10S

Base on the following tables, select the diameters of outdoor

unit main connective pipe. In case of the main accessory pipe

of indoor unit larger than outdoor unit main connective pipe,

take the large one for the selection.

The 1st branching

pipe for indoor unit

The 1st branching

pipe for indoor unit

gas side

Low-pressure

gas side

High-pressure

e.x.1: Refer to Fig.5-3 , the capacity of downstream units to L3 is

71×2+28=170, i.e. low pressure gas pipe for L3 is Φ22.2,high pressure gas

pipe is Φ19.05,high pressure liquid pipe is Φ12.7.

5.3 Size of joint pipes for indoor unit

5.5 Branch pipes for outdoor unit

gas side

Low-pressure

gas side

High-pressure

Capacity of

indoor unit

A(×100W)

Indoor unit main pipe(mm)

Liquid side

Φ15.88

Φ19.05

Φ22.2

Φ25.4

Φ28.6

Φ12.7

Φ15.88

Φ19.05

Φ22.2

Φ22.2

Φ9.52

Φ9.52

Φ12.7

Φ12.7

Φ12.7

65≤A<90

A<65

90≤A<170

170≤A<280

280≤A<335

335≤A<400

Size of joint pipes for R410A indoor unitTable.5-3

Table.5-6

SP-FQG-N02S

SP-FQG-N02S

Φ12.7 Φ9.52

Φ9.52 SP-FQG-N01S

SP-FQG-N04S

SP-FQG-N03S

SP-FQG-N04S

Φ28.6

Φ31.8

Φ22.2

Φ25.4

Φ15.88

Φ15.88

400≤A<532

532≤A<680

680≤A<730

SP-FQG-N05S

SP-FQG-N06S

Φ34.9 Φ28.6

Φ15.88 SP-FQG-N06S

Φ34.9

Φ41.3

Φ28.6

Φ34.9

Φ19.05

Φ19.05

730≤A<960

960≤A<1350

A≥1350

SP-FQG-N06S

SP-FQG-N07S

Φ44.5 Φ38.1

Φ22.2 SP-FQG-N08S

8~12HP

Model

Φ22.2 Φ19.05 Φ15.88

14~16HP Φ28.6 Φ22.2 Φ15.88

Low-pressure gas side High-pressure gas side

Liquid side

5.7 Example

Available

branching pipe Outdoor unit pipe connective

opening dimension(mm)

Take (10+12+16) HP that composed by three modules as an

example to clarify the pipe selection.

Take Fig.5-3 as an example. Provided that the equivalent

length of all pipes in this system is larger than 90m, the branch

pipe’s length is less than 10m.

1)

2)

5.6 Multi connecting pipe assembly and pipe

diameter for outdoor unit

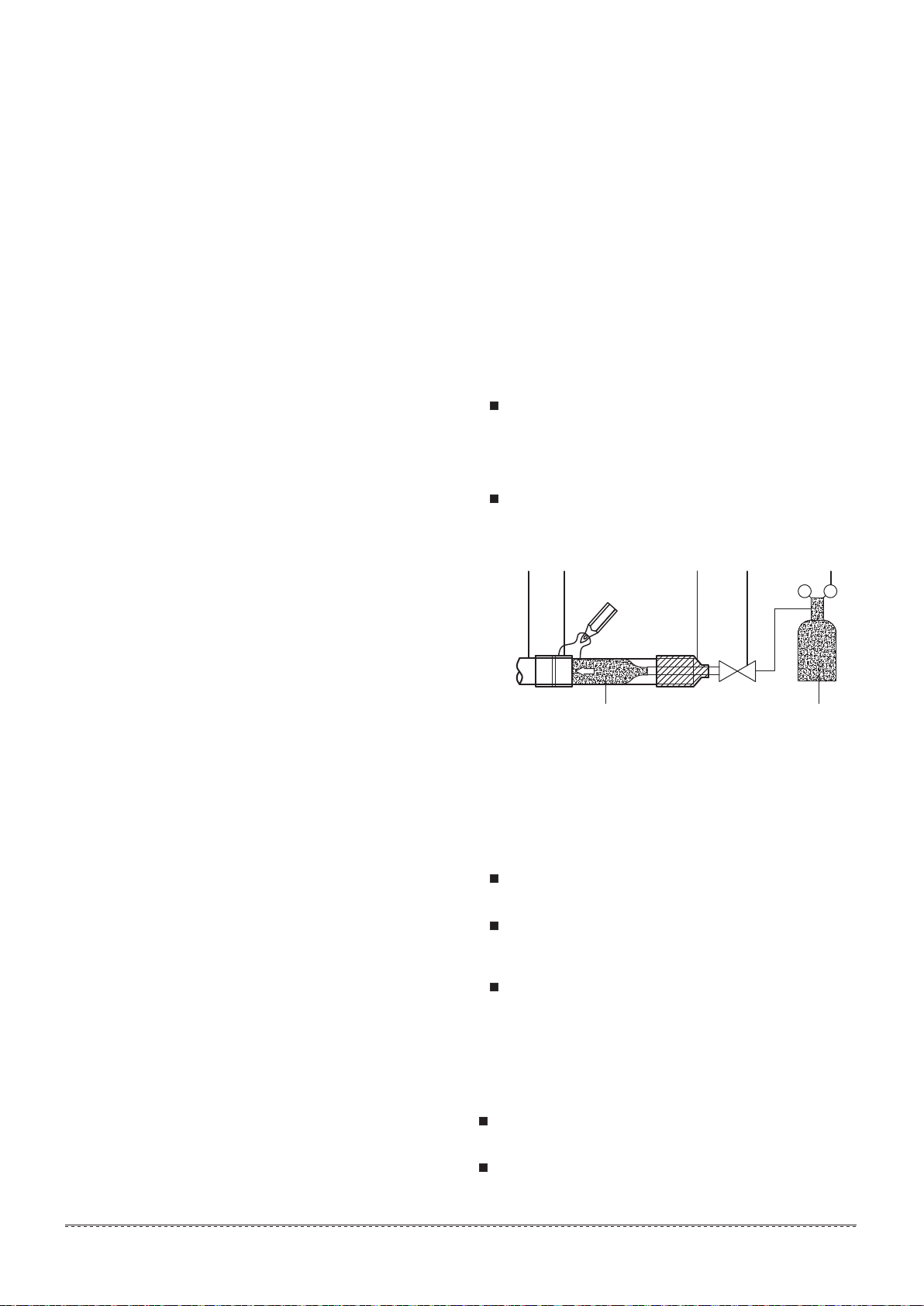

Table.5-7 Outdoor unit multi connecting pipe assembly (Illustration)

Base on Table 5-7 select the multi connecting pipe assembly of

outdoor unit. Before installation, please read the Outdoor Unit

Branching Pipe Installation Manual carefully.

Illustration

Parallel connect

with the branch

pipes

Outdoor unit

connective

pipe diameter

g1,g2:

8~12HP:

Φ22.2/Φ19.05/Φ12.7

14、16HP:

Φ28.6/Φ22.2/Φ15.88

g1,g2,g3:

8~12HP:

Φ22.2/Φ19.05/Φ12.7

14、16HP:

Φ28.6/Φ22.2/Φ15.88

G1:Φ34.9/Φ28.6/Φ19.05

g1,g2,g3,g4:

8~12HP:

Φ22.2/Φ19.05/Φ12.7

14,16HP:

Φ28.6/Φ22.2/Φ15.88

G1:

Φ34.9/Φ28.6/Φ19.05

G2:Φ41.3/Φ34.9/Φ22.2

L+M:

SP-FQG-W3C

L+M+N:

SP-FQG-W4C

L:

SP-FQG-W2C

Outdoor

unit Qty.

2 units

3 units

4 units

LM

g1g2

G1

g3

Main pipe

LMN

g1g2

G1 G2

g3g4

Main pipe

Main pipe

L

g1g2

Table.5-2

L2~L11

L1

a, b,c...t

g1, g2, g3, G1

CS1,...CS6

A, B, C, D, E

L, M

Pipe name Code (As per the Fig. 5-3)

Main pipe

Indoor unit main pipe

Indoor unit aux. pipe

Indoor unit main pipe branching pipe assembly

Indoor unit aux.pipe branching pipe assembly

Outdoor unit branching pipe assembly

Outdoor unit connective pipe

CS equipment

Ⅰ,Ⅱ,Ⅲ

Table.5-8

Indoor unit aux. pipe

(between branch joint and branch joint/CS)

(

mm

)

Indoor unit aux. pipe(between indoor unit and branch joint/CS)

(

mm

)

Liquid side

The branch

pipe assembly

of indoor unit

aux. pipe

Gas side

Capacity of

indoor unit

A(×100W)

Capacity of

indoor unit

A(×100W)

A<160 Φ15.88 Φ9.52 SP-FQG-N02S

22≤A≤28

36≤A≤56

Liquid side Liquid sideGas side Gas side

Φ9.52 Φ6.35

Φ12.7 Φ6.35 Φ15.88 Φ9.52

71≤A≤160 Φ15.88 Φ9.52 Φ19.05 Φ12.7

Φ12.7 Φ9.52

When branching

pipe’s length ≤10m

When branching

pipe’s length>10m

Branching pipe at the inside of the unit.

There are b,c,d,e,f,g,h,i,j,k,m,o,p,q,r,s,t branching pipes at the

inside of the unit, the branching pipe diameter should be select

as per Table 5-8.

Main pipe and aux.pipe at the inside of the unit (Refer to Table

5-3 and Table 5-8)

The aux. pipe a with N1, N2 downstream indoor units that total

capacity is 71×2=142, the pipe a diameter is Φ15.88/Φ9.52, thus

select SP-FQG-N02S for the branching pipe Ⅰ.

The main pipe L3 with N1, N2, N3 downstream indoor units that

total capacity is 71×2+28=170, the pipe L3 diameter is Φ22.2/

Φ19.05/Φ12.7, thus select CS02 for CS1.

The main pipe L5 with N4, N5 downstream indoor units that total

capacity is 56+28=84, the pipe L5 diameter is Φ15.88/Φ12.7/

Φ9.52, thus select CS02 for CS2.

The main pipe L6 with N6, N7 downstream indoor units that total

capacity is 71×2=142, the pipe L6 diameter is Φ19.05/Φ15.88/

Φ9.52, thus select CS02 for CS3.

The main pipe L4 with N4~N7 downstream indoor units that total

capacity is 71×2+56+28=226, the pipe L4 diameter is Φ22.2/

Φ19.05/Φ12.7, thus select SP-FQG-N03S for the branching

pipe C.

The main pipe L2 with N1~N7 downstream indoor units that total

capacity is 71×4+56+28×2=396, the pipe L2 diameter isΦ28.6/

Φ22.2/Φ12.7, thus select SP-FQG-N04S for the branching pipe

B.

The aux. pipe n with N12, N13 downstream indoor units that total

capacity is 56×2=112, the pipe n diameter is Φ15.88/Φ9.52, thus

select SP-FQG-N02S for the branching pipe Ⅲ.

The aux. pipe l with N11, N12, N13 downstream indoor units that

total capacity is 56×2+28=140, the pipe l diameter is Φ15.88/

Φ9.52, thus select SP-FQG-N02S for the branching pipe Ⅱ.

The main pipe L10 with N8, N9 downstream indoor units that

total capacity is 71×2=142, the pipe L10 diameter is Φ19.05/

Φ15.88/Φ9.52, thus select CS02 for CS4.

The main pipe L11 with N10~N13 downstream indoor units that

total capacity is 56×2+140+28=280, the pipe L11 diameter is

Φ25.4/Φ22.2/Φ12.7, thus select CS02 for CS5.

The main pipe L9 with N8~N13 downstream indoor units that

total capacity is 140+71×2+56×2+28=422, the pipe L9 diameter

is Φ28.6/Φ22.2/Φ15.88, thus select SP-FQG-N05S for the

branching pipe E.

The main pipe L8 with N14~N17 downstream indoor units that

total capacity is 28×2+56+140=252, the pipe L8 diameter is

Φ22.2/Φ19.05/Φ12.7, thus select CS04 for CS6.

The main pipe L7 with N8~N17 downstream indoor units that

total capacity is (140+71)×2+(28+56)×3=674, the pipe L7

diameter is Φ31.8/Φ25.4/Φ15.88, thus select SP-FQG-N06S for

the branching pipe D.

Main pipe (Refer to Table 5-3, Table 5-5):

Main pipe L1 in the Fig.5-3, which upstream outdoor units total

capacity is 16+12+10=38, base on table 5-5, the low-pressure

gas/high-pressure gas/liquid pipe diameter are Φ41.3/Φ34.9/

Φ22.2, total capacity of the downstream indoor unit(N1~N17) is

28×5+56×4+71×6+140×2=1070, base on table 5-3, the

low-pressure gas/high-pressure gas/liquid pipe diameter are

Φ41.3/Φ34.9/Φ19.05, take the large one for your selection, final

confirm the main pipe diameter is: low-pressure gas/ high-pres-

sure gas/ liquid pipe Φ41.3/Φ34.9/Φ22.2, thus select

SP-FQG-N09S for the branching pipe A.

Parallel connect the outdoor units

The outdoor unit linked by Pipe g1 is 10HP, parallel connects

with outdoor unit. the connective pipe diameter to be selected

according to its connector size is Φ22.2/Φ19.05/Φ12.7;

The outdoor unit linked by Pipe g2 is 12HP, parallel connects

with outdoor unit. the connective pipe diameter to be selected

according to its connector size is Φ22.2/Φ19.05/Φ12.7;

The outdoor unit linked by Pipe g3 is 16HP, parallel connects

with outdoor unit. the connective pipe diameter to be selected

according to its connector size is Φ28.6/Φ22.2/Φ15.88.

G1 is the upstream of the two parallel connected outdoor units,

refer to Table 5-7 select the two parallel connected outdoor unit,

the pipe diameter is Φ34.9/Φ28.6/Φ19.05.

Parallel connect the three outdoor units, refer to Table 5-7 should

select SP-FQG-W3C for outdoor unit connective pipes (L+M).

A.

B.

1)

2)

3)

4)

5)

6)

7)

8)

9)

10)

11)

12)

13)

C.

D.

1)

2)

3)

Fig.5-4

11

Installation manual

5.8 Caution for brazing

5.9 Remove dirt or water in the piping

Make sure there is no any dirt or water before connecting

the piping to the outdoor units.

Wash the piping with high pressure nitrogen, never use

refrigerant of the outdoor unit.

Make sure to blow through with nitrogen when brazing.

Blowing through with nitrogen prevents the creation of large

quantities of oxidized film on the side of the pipe. An oxidized

film adversely affects valves and compressors in the

refrigerating system and prevents proper operation.

The nitrogen pressure should be set to 0.02Mpa(i.e.,just

enough so it can be felt on the skin)with a pressure-reducing

valve.

Do not use anti-oxidants when brazing the pipe joints.

Residue can clog pipes and break equipment.

Do not use flux when brazing copper-to-copper refrigerant

piping. Use phosphor copper brazing filler alloy(BCuP) which

does not require flux.

Flux has an extremely harmful influence on refrigerant pipe

systems. For instance,if chlorine based flux is used, it will

cause pipe corrosion or, in particular, if the flux contains

fluorine, it will deteriorate the refrigerant oil.

1 Refrigerant pipe

2 Part to be brazed

3 Taping

4 Hands valve

5 Pressure-reducing valve

6 Nitrogen

1 2 3 4 5

6 6

CAUTION

CAUTION

5.12 Refrigerant amount to be added

Calculate the added refrigerant according to the diameter

and the length of the liquid side pipe of the outdoor/indoor

unit connection. The refrigerant is R410A.

Fill the additional quantity of calculated refrigerant from the

low-pressure pipe and liquid pipe.

The system is back to electricity after power outages, and

then quit from the vacuum state.

Pipe size on

liquid side(mm)refrigerant to be

Added per meter(kg)

Φ6.35

Φ9.52

Φ12.7

Φ15.88

Φ19.05

Φ22.2

Φ25.4

Φ28.6

0.023

0.060

0.120

0.180

0.270

0.380

0.520

0.680

Table.5-9

Don’t mix up the different refrigerants or abuse the tools and

measurements which directly contact with refrigerants.

Don’t adopt refrigerant gas for air vacuuming.

If vacuum level could not get to -0.1MPa, please check whether

resulted by leakage and confirm the leakage site. If no leakage,

please operate the vacuum pump again 1 or 2 hours.

During the vacuum operation, in order to keep related valves open

and discharge air inside the system, please power on all outdoor

units, CS mode switch boxes and indoor units.

After finish vacuum, please repower on the system and system

will exit the vacuum mode automatically.

Pressurized nitrogen(3.9MPa;40kgf/cm2)is used for

airtightness test.

It is not allow to bring pressure on the float valve directly.

(See Fig. 5-4)

It is not allow to use oxygen, combustible gas or toxic gas

to conduct the airtightness test.

When welding, please use wet cloth insulating the low

pressure valve for protection.

For avoid the equipment be damaged, the pressure

maintained time should not last too long.

Fig.5-7

●

●

●

●

●

Note:

1. Assume equivalent pipe length of the branching pipe header to be 0.5m.

2. The refrigerant amount to be added of CS02 is 0.3kg/per, of CS04/CS06

is 0.5kg/per.

12

Installation manual

5.10 Gas tight test

Charge 40kgf/cm2 nitrogen gas from the pistion of high-pressure

gas side valve from the meter connector. Pressure inside should

be maintained at there no less than 24 hours.

Fig.5-5

Indoor unit

Outdoor unit

CS

Nitrogen

Nitrogen

Nitrogen High-pressure gas pipe

Low-pressure gas pipe

Liquid pipe

Fig.5-6

Use the vacuum pump which vacuum level lower than

-0.1MPa and the air discharge capacity above 40L/min.

The outdoor unit is not necessary to vacuum, don’t open the

outdoor unit gas and liquid pipe shut-off valves.

Make sure the vacuum pump could result as -0.1MPa or

below after 2 hours or above operation. If the pump operated

3 hours or above could not achieve to -0.1MPa or below,

please check whether water mix or gas leak inside of the

pipe.

Pressure gauge with the switch is installed between vacuum

pump and system pipes.

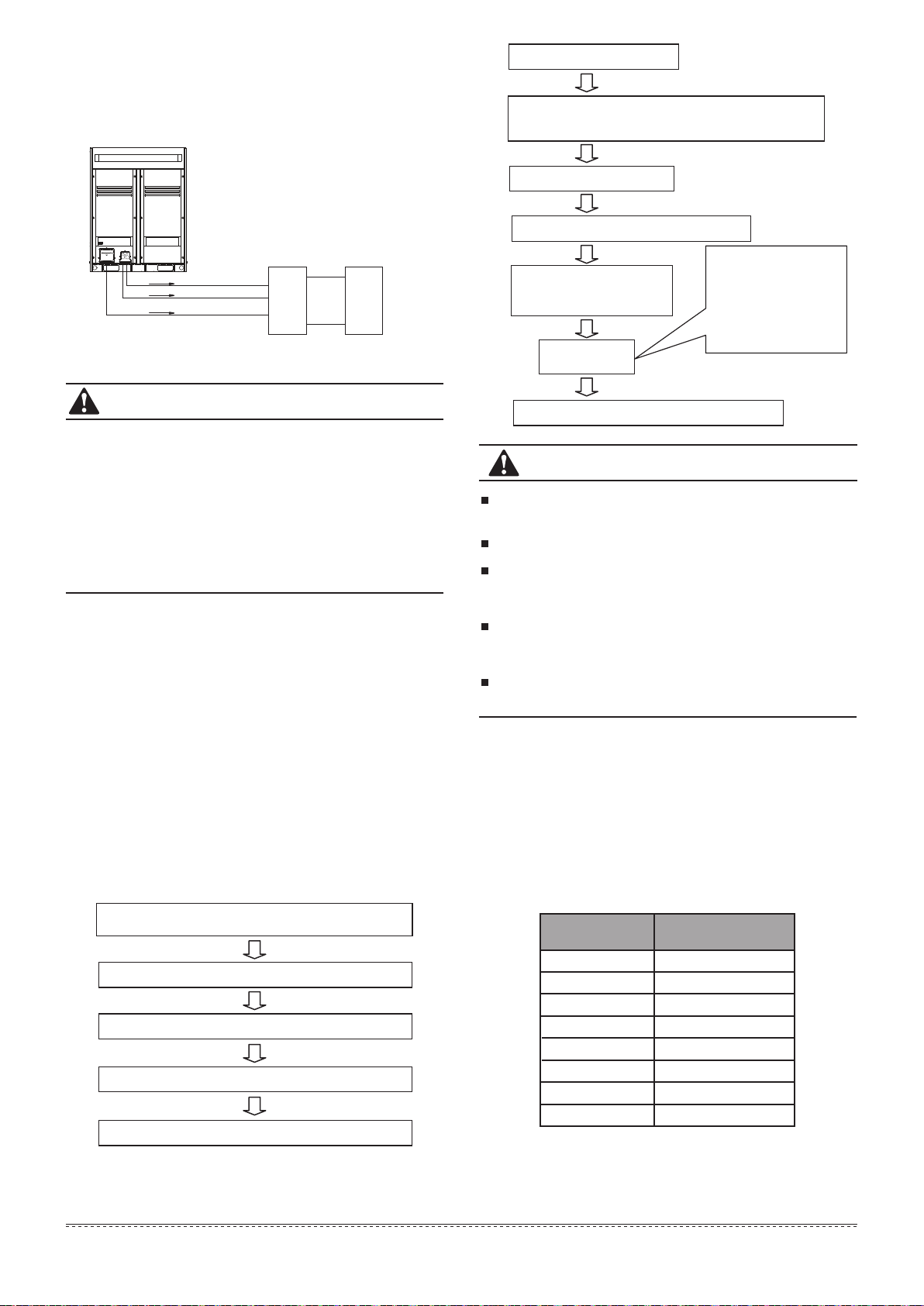

5.11 Vacuum with vacuum pump

1)

2)

3)

4)

1)

2)

3)

Respectively connect the vacuum pump in the gas

balance valve and oil balance valve

Perform the pump (last for 10 minutes or above)

Close the pressure gauge and vacuum pump in turn

Open the gas balance valve and oil balance valve of the outdoor unit

Remove the pressure gauge and vacuum pump

After the system power outages.

After the system is powered on, long press SW14 check

button for 5 senonds until displaying 000. And then press

the key of forced cooling,UA is displayed.

Into the vacuum state

Connect with vacuum pump

Perform the pump (last for 2 hrs or above)

When get the vacuum level

-0.1MPa, the pump should

keep running for 20-60 mins

Shut down the

vaccun pump

Place the vaccum state unused (1 hrs or above)

1. Close-off the valve of

vacuum meter.

2. Cut off the connection

between pressure meter

and vacuum pump.

3. Close the vacuum

pump.

5.13 The Installation key points of connective

pipes between outdoor units

Connect the pipes between outdoor units, the pipes should

place horizontally (Fig.5-8,Fig.5-9), it is not allow the concave

at junction site(Refer to Fig.5-10).

All connective pipes between the outdoor units are not

allowed to over than the height of every outlets of the

pipes(Refer to Fig.5-11).

1)

2)

13

Installation manual

Fig.5-12

Fig.5-13

Fig.5-14

The branching pipe must be installed horizontally, error angle

of it should not large than 10°. Otherwise, malfunction will be

caused.

CorrectWrong

U-shaped branching pipe

Horizontal surface

A direction view

For avoid oil accumulate at the outdoor unit, please install the

branching pipes properly.

3)

4)

Fig.5-8

Correct way

Correct way

× Wrong way

Fig.5-9

Fig.5-10

Fig.5-11

× Wrong way

6. CONNECTING PIPE OF CS

7. CS WIRING NAMEPLATE

14

Installation manual

Fig.6-3

Fig.6-2

Fig.6-1

Fig.7-1

Fig.7-2

7.1 the nameplate of CS02

7.2 the nameplate of CS04

Liquid pipe(Φ9.52)

Gas pipe(Φ15.88)

Liquid pipe(Φ15.88)

High-pressure gas pipe(Φ22)

Low-pressure gas pipe(Φ32)

CS06

Liquid pipe(Φ9.52)

Gas pipe(Φ15.88)

Liquid pipe(Φ15.88)

High-pressure gas pipe(Φ22)

Low-pressure gas pipe(Φ32)

CS04

Liquid pipe(Φ9.52)

Gas pipe(Φ15.88)

Liquid pipe(Φ12.7)

High-pressure gas pipe(Φ19.05)

Low-pressure gas pipe(Φ25.4)

CS02

Solenoid valve coil

RD RED

BL BLUE

BK BLACK

YE YELLOW

WH WHITE

OR ORANGE

PR PURPLE

EXV

SV

Electronic

expansion valve

Supercooled pipe

intlet temperature

TB Terminal block

T1C1

TIC2

Supercooled pipe

outlet temperature

Solenoid valve coil

RD RED

BL BLUE

BK BLACK

YE YELLOW

WH WHITE

OR ORANGE

PR PURPLE

EXV

SV

Electronic

expansion valve

Supercooled pipe

intlet temperature

TB Terminal block

T1C1

TIC2

Supercooled pipe

outlet temperature

NOTE: Units need to use a dedicated power supply, avoid sharing the same circuit with other appliances. In connection

with the dedicated power supply, be sure to use the specified cross-section of the power cord, and match the

corresponding specifications of the circuit breakers, use the specified capacity fuse.

NOTE: Units need to use a dedicated power supply, avoid sharing the same circuit with other appliances. In connection

with the dedicated power supply, be sure to use the specified cross-section of the power cord, and match the

corresponding specifications of the circuit breakers, use the specified capacity fuse.

380-415V 3N~50Hz

Fig.8-1

8.1 Terminal base function

Fig.8-2

8. ELECTRIC WIRING

15

Installation manual

Fig.7-3

single group pipe means a piece of liquid pipe and a piece of gas

pipe.

If the indoor units do not have auto mode function, then each

group pipe of CS only can be connected 4 indoor units at most

for one time; if the indoor units have auto mode function, then

each group pipe of CS only can be connected 1 indoor unit at

most for one time.

Indoor units in the same group pipe of CS can not operate

cooling and heating at the same time, or operate heating and air

supplying at the same time, otherwise it will be modes conflict.

Please install the CS at the places where do not have highly

request for noise, such as the corridor or washroom and so on.

The CS must be installed horizontally.

There shall be at least 1m distance between the CS and the

branch pipes while doing installation.

There will be 30 seconds auto-checking function after the indoor

and outdoor units have been started up.

The indoor unit must use the remote controller for setting

address, the addresses of the indoor units connected with the

CS in the same system can not be the same (no matter whether

connected with the same CS).

7.3 The nameplate of CS06

Table.7-1

CS02 CS04 CS06

40m

4

16kW

28kW 45kW

Model of CS

Maximum

capacity of single

group pipe

Maximum indoor

units quantity of

single group pipe

Maximum

capacity of CS

Downstream of

the largest length

NOTE

Outdoor units

communication

Digital electricity

meter

Indoor units

centralized

controls

CS

communication

Outdoor units

centralized

monitoring

NOTE: Units need to use a dedicated power supply, avoid sharing the same circuit with other appliances. In connection

with the dedicated power supply, be sure to use the specified cross-section of the power cord, and match the

corresponding specifications of the circuit breakers, use the specified capacity fuse.

Solenoid valve coil

RD RED

BL BLUE

BK BLACK

YE YELLOW

WH WHITE

OR ORANGE

PR PURPLE

EXV

SV

Electronic

expansion valve

Supercooled pipe

intlet temperature

TB Terminal block

T1C1

TIC2

Supercooled pipe

outlet temperature

8.2 Spot inspection for outdoor unit

Table.8-1

Displays when system is running

Displays when system standby

0,1,2,3

0,1,2,3

0,1,2,3

8,10,12,14,16

0,1,2,3

Inverter compressor frequency

Number of indoor units

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

Reference valuesDisplay

Outdoor unit itself capacity

Outdoor unit address

Modular outdoor unit qty.

Available for main unit

Available for main unit

Available for main unit

0,2,3,4,5,6

No.

Total capacity of outdoor unit

Night noise control mode

Static pressure mode

Cooling capacity

Heating capacity Auxiliary unit only display capacity of main mode

Auxiliary unit only display capacity of main mode

T4 ambient temp. revision of cooling capacity

T4 ambient temp. revision of heating capacity

Outdoor unit running mode

The outdoor unit actual operation capacity Capacity requirement

Capacity requirement

Speed of left fan

Speed of right fan

0, 1,······,14,15

0, 1,······,14,15

T2 average temp. Actual value

Actual value

T3-L

T3-R

Actual value

Actual value

Actual value

Actual value

Actual value+60

Actual value=Display value×8

Actual value=Display value×8

Actual value=Display value×0.1MPa

Actual value

Actual value

Mode priority

Actual value

Actual value

Actual value=Display value×40

T2B average temp.

T3 pipe temp. (Left heat exchanger pipe temp. )

T5 pipe temp. ( Right heat exchanger pipe temp. )

T4 ambient temp.

Discharge temp. of A/B inverter compressor

Top temp.of A/B inverter compressor

Discharge high-pressure corresponding to the saturation temp.

Opening degree of rihgt EXV

Opening degree of left EXV

Reserve

Reserve

High pressure

Software version

Last protection code or error code

Qty. of indoor units

Qty. of cooling indoor units

Qty. of heating indoor units

That can communicate with indoor units

AC voltage

Secondary current

No protection or fault display 00

State of the evaporator or condenser

Spot inspection finished

Secondary voltage

Current of A/B inverter compressor

The display contents as followings:

Normal display:

When standby, the high position displays the address of the outdoor unit,and the low position displays the Qty. of indoor units

that can communicate with outdoor unit.When it is operating,it will display the rotation frequency of the compressor.

Outdoor unit running mode:

0-Off; 2-Cooling; 3-Heating; 4-Forced cooling; 5-Mixed cooling; 6-Mixed Heating.

Fan speed:

0-stop; 1~15 speed increase sequentially, 15 is the max. fan speed.

State of the evaporator or condenser:

0-All condenser; 1-Left evaporator/right condenser; 2-All evaporator; 3-Left evaporator/close.

Night noise control mode:

0-Night noise control mode;1-silent mode;2-Most silent mode;3-No priority.

Static pressure mode:

0-static pressure is 0 Mpa;1-Low static pressure;2-Medium static pressrue;3-High static pressure.

16

Installation manual

8.3 Explanation of mainboard

17

Installation manual

Fig.8-3

Table.8-2

1

No.

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

Content

Functional port for phase sequence detection

F1,F2,POWER,HEATER outlet

Power output of mainboard transformer

Power supply input of mainboard and module transformers

Program download port 1

Drive ports of the electronic expansion valve 2

Interface for the exhaust sensor of No.2 frequency-variable

compressor

Interface for the exhaust sensor of No.1 frequency-variable

compressor

Input port for detection of the system low pressure

SV1,SV2,SV3,SV4 outlet

The left four-way valve and The right four-way valve

Drive ports of the electronic expansion valve 1

Power output of module board transformer

IPM module 15V power port

Module board communication port 2

Module board communication port 1

Communication port between outdoor units

Input port for detection of the system high pressure

Drive ports of the electronic expansion valve 3 and 4(Reserved)

SV5,SV6,4-WAY outlet

Port for detection of the outdoor ambient temperature and the

left condenser coil temperature (T3)

Port to detect the primary side current A converter and B

inverter compressors

Input port for signal of the system low-pressure detector switch

Input port for signal of the system high-pressure detector switch

Control port of the DC fan 2 (Right fan)

Control port of the DC fan 1 (Left fan and Single fan)

Interface for electric meter for online control and charging of

the outdoor unit

Port for indoor-outdoor unit communications and indoor unit

network wiring

The right condenser coil temperature (T5)

Reserved

Reserved

Program download port 2

31

32

18

Installation manual

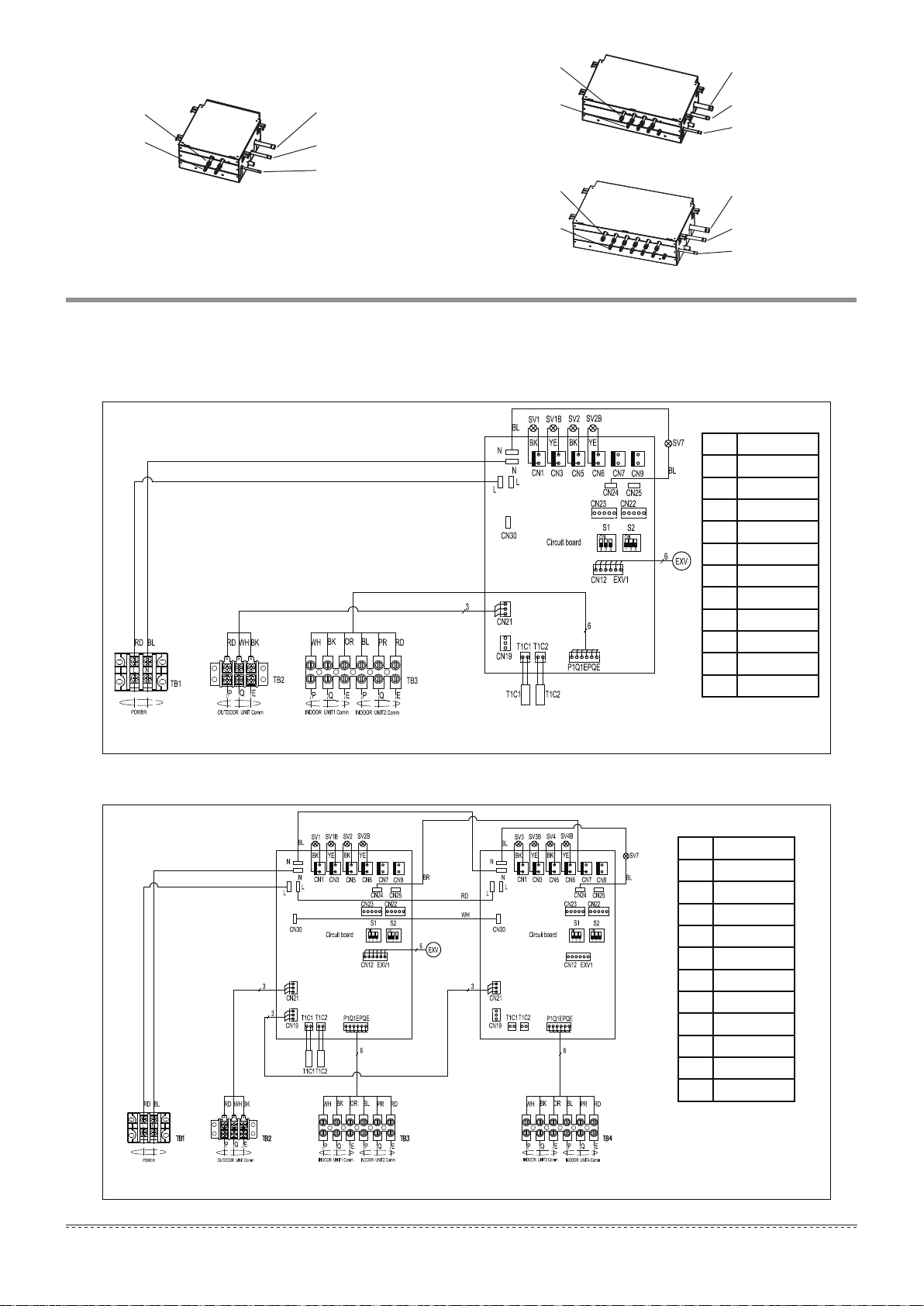

1) 8~12HP

2) 14~16HP

8.4 Outdoor unit wiring connection diagram

Caution 1: E1,E2 electrolytic capacitors release electricity after power outage.

Caution 2: Mutual reactors must be connected through with power cord.

Caution 1: E1,E2 electrolytic capacitors release electricity after power outage.

Caution 2: Mutual reactors must be connected through with power cord.

Fig.8-4

Fig.8-5

E1 Electrolytic

Capacitor

E2 Electrolytic

Capacitor

XT1 Main Power

Terminal

XT2 Comm.

Terminal

DZ1 Triphase

Bridge

DZ2 Uniphase

Bridge

SV2 Bypass

Solenoid Valve

SV4 Oil Balance

Solenoid Valve

SV5 Defroist

Solenoid Valve

SV6 Flow valve

ST3 Main

4-way valve

POWER Start contactor

control

PTC PTC

ST1

ST2

CS Unit

4-way valve

4-way valve

Right

Left

Refrigerant

conversion

device

N

P

IPM

CN3

CN9

J1

1

U

V

W

2

CN2

5

3

FM BRD

MOTER

FB JOINT

TO MAIN

BRD

JOINT

P3

P4

P2 P1

CN1 CN2

P6

P5

L

N

L1

N1

CN11

A

INPUT

LOAD

L1 L2 L3 N

N

P

IPM

CN3

CN9

J1

1

U

V

W

2

CN2

MOTER

FB

JOINT

TO MAIN

BRD

JOINT

BCN

A1 B1 C1 N1

HEATER

POWER

F1

F2

4-WAY

SV6

SV5

SV4

SV3

SV2SV1

SV7

SV8

N

Filter BRD

AC

AC

Reactor

SV2 SV4 SV5 SV6 ST3

Fan

Motor

5

3

RD YE BL BK

YE

BK

RD YE BL BK

OR

OR

RD

RD

BK

BK

BL

YE

RD

RD

RD

RD

RD

BR

BL

BK

RD

BR

BL

4

BK

RD

3-phase power input

FM BRD

FM PW

BRD

RD

BK

L1 L2 L3 N

CN1

E1

E2

XT1

DZ1

DZ2

HEAT

INV

HEAT

INV

PTC1 PTC2

Mutual

Inductor

2

BK

ST1

IPM

Module

BRD

P

U

V

W

N

Inverter

Compressor

P1

N1

U

V

W

RD

YE

BL

BK

RD

CN7

CN5

LED1

LED2

LED3

CN4

CN18

CN14

CN21

CN2

CN1

CN20

CN19

CN17

CN28 CN30 CN26 CN25 CN27 CN28 CN13 CN34 CN6

CN24 CN22

CN23CN32

CN3

3-Phase power

Check

T2 TX4 TX3

IDU COMM

ODU

Centralized

controller &

Ammeter

Fan

Drive1#

Fan

Drive2#

HP LP

Hi.

Pressure

sensor

ODU

COMM.

Comm.

IPM B

T3

I A B

T4

1#

Transformer Input

SV8 SV7 SV1 SV2 SV3 SV4 SV5 SV6 4-WAY

F2 F1 POWER HEATER

2#

1

#

EXV

CHECK_A

Forced

refrigeration

ODU MAIN

CONTROL BRD

Condensing

temp

Environment

temp. Hi.

Pressure

sensor

A1

B1

C1

N1

Hi.

Prss

swicth.

Lo.Prss

swicth.

2#

±

15V

CN35 CN36

2

#

EXV

CHECK_B

System A System B

CN33CN12

Comm.

IPM A

1 2 3

ON DP

1 2 3

ON DP

1 2 3

ON DP

1 2 3

ON DP

1 2

ON

0

1

2345

6

7

8

9

A

B

C

D

E

F

SW4SW10 SW5 SW9SW8

SW12

1 2

ON

1 2

ON

0

1

2345

6

7

8

9

A

B

C

D

E

F

0

1

2345

6

7

8

9

A

B

C

D

E

F

SW7 SW15 SW6 SW11

1 2

1 2

ON

SW13

CN15

3

T1

4

T2

INV

A

EXHAUST TEMP

3

T1

4

T2

CN8

CN16

Condensing

temp(T5)

Current

1#

Transformer Output

CN2'

TRANS1

6

5

34

5

LCD

DISPLAY

N N N N N N N N NNNN

1 2

ON

SW12

K1K2 E D A E X Y E P QE H1H2 E

ODU Monitor

Digital Ammeter

IDU Centralized

Controller

CS Units

COMM.

ODU COMM.

XT2

1#EVX

RC

BOARD

BK

RD

ST2

Top Pip

Fan

Motor

Right

Left

5

BK

Reactor

OR

OR

OR

BK

OR

RD

RD

RD

RD

RD

RD

RD

RD

RD

BK

BK

BK

BK

RD

RD

YE

BL

E2

E1

RD E4

E3

RD

RD

COMP

(INV-B)

COMP

ST2 ST3

BL

BL

YE

YE

RD

RD

5

Top Pip

Top Pip

Right

Left

ST1

CN35 CN36

2

#

EXV

CHECK_B

System A System B

CN33CN12

Comm.

IPM A

1 2 3

ON DP

1 2 3

ON DP

1 2 3

ON DP

1 2 3

ON DP

1 2

ON

0

1

2345

6

7

8

9

A

B

C

D

E

F

SW4SW10 SW5 SW9SW8

SW12

1 2

ON

1 2

ON

0

1

2345

6

7

8

9

A

B

C

D

E

F

0

1

2345

6

7

8

9

A

B

C

D

E

F

SW7 SW15 SW6 SW11

1 21 2

ON

SW13

CN15

3

T1

4

T2

INV

A

EXHAUST TEMP

3

T1

4

T2

INV

B

CN8

CN16

Lo.

Pressure

sensor

Condensing

temp(T5)

Current

1#

Transformer Output

CN2'

LCD

DISPLAY

HEATER

POWER

F1

F24-WAYSV6

SV5

SV4

SV3

SV2SV1

SV7

SV8

N

SV2 SV4 SV5 SV6

BK

N N N N N N N N NNNN

HEAT

INV A

HEAT

INV B

L1 L2 L3 N

RD YE BL BK

3

-phase power input

XT1

Reactor

OR

1# Mutual

Inductor 2# Mutual

Inductor

CN11

A

INPUT

LOAD

BCN

A1 B1 C1 N1

Filter BRD B

RD YE BL BK

L1 L2 L3 N

CN11

A

INPUT

LOAD

BCN

A1 B1 C1 N1

Filter BRD A

RD YE BL BK

L1 L2 L3 N

BL

WH

BK YE

DZ1-B

DZ1-A

PTC1

PTC2

BK

PTC1

PTC2

N

P

IPM

CN3

CN9

J1

1

U

V

W

2

CN2

MOTER

FB

JOINT

TO MAIN

BRD

JOINT

Fan

Motor

5

3

FM BRD

CN1

N

P

IPM

CN3

CN9

J1

1

U

V

W

2

CN2

5

3

FM BRD

Fan

Motor

MOTER

FB JOINT

TO MAIN

BRD

JOINT

FM PW

BRD

BK

BK

BK

YE

RD

BL

BL

BR

BR

BL

BR

RD YE BL RD YE BL

1 2

ON

SW12

K1K2 E D A E X Y E P QE H1H2 E

ODU Monitor

Digital Ammeter

IDU Centralized

Controller

CS Units

COMM.

ODU COMM.

XT2

TRANS1

6

5

3

4

5

P3

P4

P2 P1

P6

P5

L

N

L1

N1

AC

AC

DZ2

2

4

1#EXV

2#EXV

A IPM

Module

BRD

P

U

V

W

N

P1

N1

U

V

W

RD

YE

BL

BK

RD

BK

(INV-A)

B IPM

Module

BRD

P

U

V

W

N

P1

N1

U

V

W

RD

YE

BL

BK

RD

CN7

CN5

LED1

LED2

LED3

CN4

CN18

CN14

CN21

CN2

CN1

CN20

CN19

CN17

CN28 CN30 CN26 CN25 CN27 CN28 CN13 CN34 CN6

CN24 CN22

CN23 CN32

CN3

3-Phase power

Check

T2 TX4 TX3

IDU COMM ODU

Centralized

controller &

Ammeter

Fan

Drive1#

Fan

Drive2#

HP LP Hi.

Pressure

sensor

ODU

COMM.

Comm.

IPM B

T3

I A B

T4

1#

Transformer Input

SV8 SV7 SV1 SV2 SV3 SV4 SV5 SV6 4-WAY

F2 F1 POWER HEATER

2#

1

#

EXV

CHECK_A

Forced

refrigeration

ODU MAIN

CONTROL BRD

Condensing

temp

Environment

temp. Hi.

Pressure

sensor

A1

B1

C1

N1

Hi.

Prss

swicth.

Lo.Prss

swicth.

2#

±

15V

Electrolytic

Capacitor

Electrolytic

Capacitor

XT1

Main Power

Terminal

XT2

Comm.

Terminal

DZ1

Triphase

Bridge

DZ2

Uniphase

Bridge

SV2

Bypass

Solenoid Valve

SV4

Oil Balance

Solenoid Valve

SV5

Defroist

Solenoid Valve

SV6

Flow valve

ST3

Main

4-way valve

POWER

Start contactor

control

PTC PTC

3-phase

relay

KZ

E1/E2

E3/E4

ST1

ST2

4-way valve

4-way valve

Right

Left

CS Units

Refrigerant

conversion

device

Table of contents

Other Chigo Inverter manuals

Popular Inverter manuals by other brands

Huawei

Huawei 01075345 user manual

MSW

MSW MSW-CPI-380MS user manual

Latronics

Latronics PV Edge Grid Connect instruction manual

Giandel

Giandel PS-300C user manual

FSP Technology

FSP Technology LightUp L8000 user manual

Rayleigh Instruments

Rayleigh Instruments RI-ENERGYFLOW-MODULAR Series Quick start installation guide