CHINT ASTRONERGY Al-40 Series User manual

MOUNTING SYSTEM

INSTALLATION

1. Tile on-roof mounting system(Al-40 series) installation

1.1 Overview

1.2 Drawing

1.3 Components

1.4 Installation steps

2. Corrugated metal sheet roof mounting system

(Al-40 series) installation

2.1 Overview

2.2 Drawing

2.3 Components

2.4 Installation steps

3. Aluminum56 mounting system installation

4. After-sale service warranty

Contents

2

1 Tile on-roof mounting system

(Al-40 series) installation

1.1 Overview

Module: CHSM6610P-250W(40mm)

Arrangement: 1*4

Tilt angle: follow the roof-top

A: Aluminum rail

Used for installing module

B

A

C

3

B: End clamp/Middle clamp

Used for xing module

C: Roof hook

Used for connecting alumnium rail and roof rafter

1.2 Drawing

4

1.3 Components

(1) Roof hook (2) End clamp

(3) Middle clamp (4) Aluminum rail

(5 )M8x90 T-splice bar (6) M8*25 T-head bolt+ange nut

(7) Wood screw

5

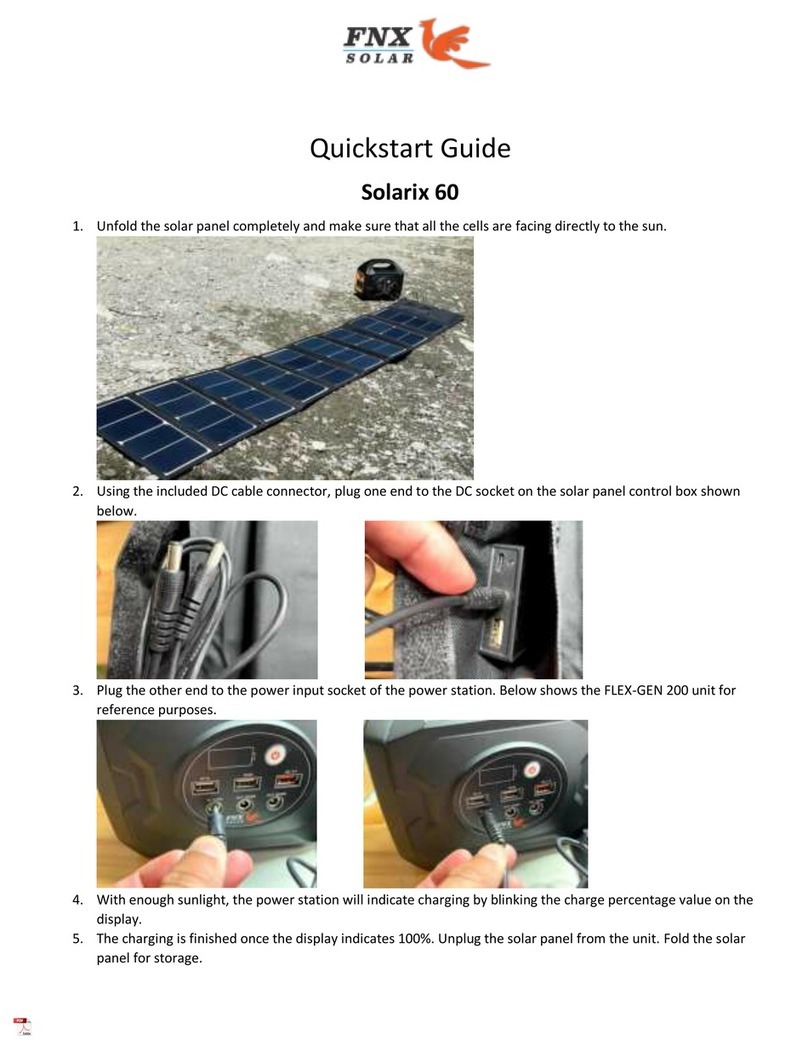

1.4 Installation steps

(1) Fix the roof hook to the roof rafter with M8 wood screw

(2) Place the roof hook on the roof as the picture below, the distance between front and back is 1020mm,

and between right and left is 1400mm

(3) Put the aluminum rail on the roof hook

Put the T-head bolt in the notch of the aluminum rail and through the hole of the roof hook,then x it

securely with ange nut

Roof

Tile

Wood

Rafter

Aluminum

1400mm

Roof hook

1020mm

6

(4) Connecting the two aluminum rail with T-splice bar and M8*10 inner ange bolt

(5) Put the module on the aluminum rail and xed with end clamp and middle clamp

Aluminum

Roof hook

T-head

Flange

Aluminum rail

T-splice bar

End

Module

Middle clamp

7

(6) Installation of clamp: put the T-head bolt in the notch of the aluminum rail with M8 inner ange bolt connected and

xed securely

End clamp xing Middle clamp xing

(7) Installing all the modules as 3.6 till complete.

Module

Clamp

8

2 Corrugated metal sheet roof mount-

ing system(Al-40 series) installation

2.1 Overview

Module: CHSM6610P-250W(40mm)

Arrangement: 1*4

Tilt angle: follow the roof-top

BA

C

A: Aluminum rail

Used for installing module

B: End clamp/Middle clamp

Used for xing module

C: M10X200 hanger bolt+ EPDM

Used for connecting aluminum rail

and metal roof

9

2.2 Drawing

2.3 Components

(1) M10X200 hanger bolt+ EPDM (2) End clamp

10

M10X200hanger bolt+ EPDM

Metal roof

(3) Middle clamp (4) Aluminum rail

(5 ) M8x90 T-splice bar (6) M8*25 T-head bolt+ange nut

2.4 Installation steps

(1) Fixing the M10X200 hanger bolt+ EPDM on the upper part of the metal roof which area planed to install the

module, and check whether the ange nut is screwed securely

(2) Place the hanger bolt on the roof as the picture below, the distance between front and back is 1020mm, and

between right and left is 1000mm

1000mm

1020mm

11

(3) Put the aluminum rail on the M10X200 hanger bolt+ EPDM

Put the T-head bolt in the notch of the aluminum rail and through the hole of the hanger bolt,then x it securely with

ange nut

(4) Connecting the two aluminum rail with T-splice bar and M8*10 inner ange bolt

M10X200 hanger

bolt+ EPDM

Aluminum rail

Aluminum

T-head bolt

Metal roof

M10X200 hanger bolt+ EPDM

Flange

Aluminum rail

T-splice bar

12

(5) Put the module on the aluminum rail and xed with end clamp and middle clamp

(4) Installation of clamp: put the T-head bolt in the notch of the aluminum rail with M8 inner ange bolt connected

and xed securely

End clamp xing Middle clamp xing

(5) Installing all the modules as 3.6 till complete.

End clamp

Middle clamp

Module

Middle clamp

Module

End clamp

13

3 Aluminum56 mounting system

installation

Components List

Model name Roof Hook 01 Rails Splice End Clamp Mid Clamp

Picture

Material SUS 304 AL 6063-T5 AL 6063-T5 AL 6063-T5 AL 6063-T5

Installation Steps

Determine the position of the roof hooks according to your design

L1: Distance between rails is 0.6x panel length.

L2: Distance between roof hooks, no longer than 1200mm. L2<1200mm

(Distance between L feet, no longer than 600mm)

L1

L2

14

1. Remove the roof tiles at the marked positions or simply lift them up slightly

2. Insert the roof hook to the wooden beam. Fix the roof hooks with screws

3 Maintenance

The roof hook must not press against the roof tile. Place it at. If necessary, shim the roof hook with wood.

Wrong ! Correct !

15

If necessary, use an angle grinder or hammer to cut a concavity in the tile that covers the roof hook at the point where

the roof hook comes through. (Caution! Must not use xed roof hook as a ladder, as this extreme point load could dam-

age the tile below.

Installation of the rails on roof hooks. Your rails consist of dierent length, always begin with the shortest piece.

Install the rails on the roof hooks loosely at rst, using T-screw.

1.

2.

3.

4.

16

Installation of Clamps

Installation of the splice to connect multiple rails together. Slide the splice on the rear side of the pre-assembled rails.

Fasten the rst bolt rmly. Then slide the next rail into the splice. When comes together, fasten the other bolt. The con-

nection is nished. An expansion gap at the rail joints is suggested. Leave a gap about a nger width.

Place the rst module of the bottom row. Slide the end clamp tightly against the module and fasten it. Install the end

clamp and mid clamps.

1.1. 2.

3. 4.

5. 6.

17

The rail should leave a space of 25mm‐30mm

Clamp Installation

d=25-30mm

20%

20%

60%

18

Slide the next module against the installed module. Fasten the mid clamp. Install other modules and clamps in this way.

Keep module even.

Finished

End Clamp

Mid Clamp

19

4 After-sale service warranty

1 Installation guide and training service

(1) Provide installation guide to the customers.

(2) For project <3MW, Astronergy oers technical consultation and training by phone, Email, video clips etc.

(3) For 3MW~10MW project, free training at Hangzhou for 2 days.

(4) For project >10MW, free training at Hangzhou for 2 days, 5-10 days consultation and guidance on site where the

project is located is also available, Astronergy bares the traveling expenses.

2 Repair and replacement

Astronergy will oer free placement for the productions with defects or discrepancies in condition that the items ex-

pressed in the “Product warranty” declared by Astronergy are all satised.

(1) Astronergy will oer free placement and bear the cost of freight. (2)Astronergy will, upon getting reasonable

advance notice from Buyer, pay for the cost related to the productions with defects, including the cost of reconnais

sance to inspect the condition of defects on site, repairing and replacement works, and materials test etc.

(3) If Astronergy fails to repair or collect and replace any rejected goods as and when requested by Buyer in accord

ance with “Product warranty”, Buyer may, upon reasonable advance notice to Astronergy, itself or through third

parties, repair or replace such rejected goods, and Astronergy shall reimburse Buyer the actual costs of such repair.

(4) If the products are out of the period of warranty, customer should pay for the repairing and replacement service

that Astronergy will oer.

3 Maintenance

Astronergy has no responsibility to oer maintenance service. In special cases, Astronergy and buyer can discuss about

the maintenance service and making relative items in contract.

Chint Solar (Zhejiang) Co., Ltd.

Address: 1335 Binan Road, Binjiang District, Hangzhou, Zhejiang Province, 310053, PRC China.

Tel: +86 571 5603 1888

Fax: +86 571 5603 2383

Web: www.astronergy.com

Table of contents

Other CHINT Solar Panel manuals