Christ ALPHA 2-4 LDplus User manual

Translation of the original operating manual

sb

Freeze-dryer

Rev. 2.2 of 17/10/2016

Alpha 1-4 LDplus;Freeze-dryer;Alpha 2-4 LDplus; ;

Version 11/2006

Alpha 1-4 LDplus

Part no. 101541

Alpha 2-4 LDplus

Part no. 101542

Freeze-dryer

Operating Manual

Please retain for later use!

Freeze-dryer Alpha 1-4 LDplus

Freeze-dryer Alpha 2-4 LDplus

2 / 102

Version 11/2006, Rev. 2.2 of 17/10/2016 • sb

Translation of the original operating manual

Freeze-dryer Alpha 1-4 LDplus

Freeze-dryer Alpha 2-4 LDplus

Version 11/2006, Rev. 2.2 of 17/10/2016 • sb

3 / 102

Translation of the original operating manual

In case of inquiries, please state the following numbers:

Order number:

Serial number:

© Copyright by

Martin Christ Gefriertrocknungsanlagen GmbH

An der Unteren Söse 50

37520 Osterode am Harz

Germany

Tel.: +49 (0) 5522 / 5007-0

Fax: +49 (0) 5522 / 5007-12

Web: www.martinchrist.de

E-mail: info@martinchrist.de

Freeze-dryer Alpha 1-4 LDplus

Freeze-dryer Alpha 2-4 LDplus

4 / 102

Version 11/2006, Rev. 2.2 of 17/10/2016 • sb

Translation of the original operating manual

Freeze-dryer Alpha 1-4 LDplus

Freeze-dryer Alpha 2-4 LDplus

Table of contents

Version 11/2006, Rev. 2.2 of 17/10/2016 • sb

5 / 102

Translation of the original operating manual

1General information.............................................................................................................9

1.1 Importance of the operating manual..................................................................................9

1.2 Intended use.....................................................................................................................9

1.3 Warranty and liability.......................................................................................................10

1.4 Copyright........................................................................................................................10

1.5 Explanation of symbols...................................................................................................10

1.6 Standards and regulations..............................................................................................10

1.7 Scope of supply..............................................................................................................10

2Layout and mode of operation.......................................................................................... 11

2.1 Layout of the freeze-dryer...............................................................................................11

2.1.1 Functional and operating elements............................................................................11

2.1.2 Name plate................................................................................................................13

2.2 Mode of operation...........................................................................................................14

2.2.1 General information on freeze-drying.........................................................................14

2.2.2 Freeze-drying process...............................................................................................17

2.2.2.1 Preparation........................................................................................................17

2.2.2.2 Freezing.............................................................................................................17

2.2.2.3 Main drying........................................................................................................18

2.2.2.4 Final drying........................................................................................................19

2.2.2.5 End of drying and aeration.................................................................................19

2.2.2.6 Defrosting ..........................................................................................................20

3Safety..................................................................................................................................21

3.1 Marking of the unit..........................................................................................................21

3.2 Explanation of the symbols and notes.............................................................................22

3.3 Responsibility of the operator..........................................................................................23

3.4 Operating personnel .......................................................................................................23

3.5 Informal safety instructions .............................................................................................24

3.6 Safety instructions ..........................................................................................................24

3.6.1 Electrical safety .........................................................................................................25

3.6.2 Mechanical safety......................................................................................................25

3.6.3 Fire prevention...........................................................................................................26

3.6.4 Thermal safety...........................................................................................................26

3.6.5 Chemical and biological safety ..................................................................................26

3.7 Safety devices ................................................................................................................27

3.7.1 System check............................................................................................................27

3.7.2 Earth conductor check...............................................................................................27

3.8 Procedures in the event of hazards and accidents..........................................................27

3.9 Remaining hazards.........................................................................................................28

Freeze-dryer Alpha 1-4 LDplus

Freeze-dryer Alpha 2-4 LDplus

Table of contents

6 / 102

Version 11/2006, Rev. 2.2 of 17/10/2016 • sb

Translation of the original operating manual

4Storage and transport ....................................................................................................... 29

4.1 Dimensions and weight...................................................................................................29

4.2 Storage conditions..........................................................................................................29

4.3 Notes on transport..........................................................................................................30

4.4 Packaging.......................................................................................................................31

4.5 Transport safety device...................................................................................................31

5Set-up and connection ...................................................................................................... 32

5.1 Installation site................................................................................................................32

5.2 Power supply..................................................................................................................33

5.2.1 Connection ................................................................................................................33

5.2.2 Customer-provided fuses...........................................................................................33

5.3 Aeration and media drain valve.......................................................................................33

5.4 Vacuum sensor...............................................................................................................34

5.5 Vacuum pump.................................................................................................................36

5.6 Pressure control valve ....................................................................................................37

5.7 Rubber valves.................................................................................................................38

6Operation............................................................................................................................ 39

6.1 Initial start-up..................................................................................................................39

6.2 Installation of accessories...............................................................................................39

6.3 Preparation.....................................................................................................................39

6.4 Switching the freeze-dryer on .........................................................................................39

6.5 LDplus control system.....................................................................................................40

6.5.1 User interface............................................................................................................40

6.5.2 Mode .........................................................................................................................43

6.5.3 Main menu.................................................................................................................45

6.5.3.1 Changing set values ..........................................................................................45

6.5.3.2 Special functions................................................................................................47

6.5.3.3 Process and equipment information...................................................................48

6.5.3.4 Options..............................................................................................................49

6.5.3.5 Tutorial...............................................................................................................51

6.6 Switching the freeze-dryer OFF......................................................................................52

7Malfunctions and error correction....................................................................................53

7.1 General malfunctions......................................................................................................53

7.1.1 Power failure..............................................................................................................53

7.1.2 Insufficient vacuum....................................................................................................53

7.1.2.1 Small flange connections...................................................................................53

7.1.2.2 Aeration and media drain valve..........................................................................54

7.1.2.3 Pressure control valve........................................................................................55

7.1.2.4 Rubber valves....................................................................................................55

7.1.2.5 Vacuum sensor..................................................................................................55

7.1.3 Insufficient ice condenser temperature ......................................................................55

7.2 Process and equipment messages.................................................................................56

7.3 Service contact...............................................................................................................58

Freeze-dryer Alpha 1-4 LDplus

Freeze-dryer Alpha 2-4 LDplus

Table of contents

Version 11/2006, Rev. 2.2 of 17/10/2016 • sb

7 / 102

Translation of the original operating manual

8Maintenance and service................................................................................................... 59

8.1 Maintenance...................................................................................................................59

8.1.1 General......................................................................................................................59

8.1.1.1 Ice condenser chamber......................................................................................60

8.1.1.2 Aeration valve, media drain valve ......................................................................60

8.1.1.3 Heat exchanger (only for air-cooled freeze-dryers) ............................................61

8.1.2 Vacuum pump ...........................................................................................................61

8.1.3 Exhaust filter (oil mist separator)................................................................................62

8.1.4 Vacuum sensor..........................................................................................................62

8.1.5 Accessories...............................................................................................................62

8.2 Disinfection of the drying chamber and accessories .......................................................63

8.3 Service ...........................................................................................................................64

8.4 Return of defective parts.................................................................................................64

9Disposal.............................................................................................................................. 66

9.1 Disposal of the freeze-dryer............................................................................................66

9.2 Disposal of the packaging...............................................................................................66

10 Technical data.................................................................................................................... 67

10.1 Ambient conditions .........................................................................................................69

10.2 Technical documentation................................................................................................69

11 Appendix ............................................................................................................................ 70

11.1 Brief operating instructions .............................................................................................70

11.2 EC declaration of conformity in accordance with the EC Machinery Directive.................75

11.3 Declaration of conformity –China RoHS 2......................................................................77

11.4 Resistance to stress cracking and chemical influences "Plexiglas".................................79

12 Glossary.............................................................................................................................97

13 Index................................................................................................................................... 99

Freeze-dryer Alpha 1-4 LDplus

Freeze-dryer Alpha 2-4 LDplus

Table of contents

8 / 102

Version 11/2006, Rev. 2.2 of 17/10/2016 • sb

Translation of the original operating manual

Freeze-dryer Alpha 1-4 LDplus

Freeze-dryer Alpha 2-4 LDplus

1 General information

Version 11/2006, Rev. 2.2 of 17/10/2016 • sb

9 / 102

Translation of the original operating manual

Pos: 1/ 200C hrist/360 GT- BA Labor-Pilot ( STANDARDMODULE) /010 Allgemeine Infor mationen/010 Allg emeine Informatio nen========= ======== ============== = @24\m od_140498320 7982_68.docx @ 1829 21@ 1 @ 1

1 General information

Pos: 2/ 200C hrist/360 GT-BA Labor-Pil ot( STANDARDMODU LE)/010 Allgemeine Infor mationen/010-0010 Stell enwert der Betriebsanleitung @ 25\ mod_1404983209 248_68.docx @ 182935 @ 2 @ 1

1.1 Importance of the operating manual

A fundamental requirement for the safe and trouble-free operation of the

unit is to be familiar with the fundamental safety instructions and all

possible hazards.

The operating manual includes important information concerning the safe

operation of the freeze-dryer.

This operating manual, and in particular the notes on safety and hazards,

must be observed by all persons operating the unit.

In addition, the local rules and regulations for the prevention of accidents

must be complied with.

Pos: 3/ 010U niversalmodul e/ Leerzeile @ 0\ mod_120211624450 0_0.docx @ 114 @ @ 1

Pos: 4/ 200C hrist/360 GT- BA Labor-Pilot ( STANDARDMODULE) /010 Allgemeine Infor mationen/010- 0020 Bestimmungsg emäße Verwend ung Labor @ 25\mod_ 1404983210350_ 68.docx @ 182949 @ 2 @ 1

1.2 Intended use

CHRIST freeze-dryers have been solely designed for the freeze-drying of

solid or liquid products in ampoules, vials or dishes. They are, therefore,

solely intended for these applications.

The freeze-dryer is suitable

•for freeze-drying materials such as bacteria and virus cultures, blood

plasma, serum fractions, antibodies, sera, vaccines, and

pharmaceutical products

•for freeze-drying plant extracts, e.g. for biochemical tests

•for freeze-drying inorganic materials, e.g. nanoparticles

•for freeze-drying numerous other products (for further information

please contact our qualified personnel)

Any other use beyond this area of application is regarded as improper use.

Martin Christ Gefriertrocknungsanlagen GmbH cannot be held liable for any

damage resulting from such improper use.

The intended use also includes:

•observation of all the notes and instructions included in the operating

manual

•compliance with the inspection and maintenance instruction

•prohibition of any type of extensions to, or conversions of the unit.

Pos: 5/ 010U niversalmodul e/Seitenwechsel @ 0\mod_1 202116244312_0.d ocx@ 10 5@ @ 1

Freeze-dryer Alpha 1-4 LDplus

Freeze-dryer Alpha 2-4 LDplus

1 General information

10 / 102

Version 11/2006, Rev. 2.2 of 17/10/2016 • sb

Translation of the original operating manual

Pos: 6/ 200C hrist/360 GT- BA Labor-Pilot ( STANDARDMODULE) /010 Allgemeine Infor mationen/010- 0030 Gewährleistu ng undH aftung @ 25\m od_14049832113 77_68.docx @ 182963 @ 2@ 1

1.3 Warranty and liability

The warranty and liability are subject to our "General Terms and

Conditions" that were distributed to the operator upon the conclusion of the

contract.

Warranty and liability claims are excluded if they are due to one or several

of the following reasons:

•improper use

•non-compliance with the safety instructions and hazard warnings in the

operating manual

•improper installation, start-up, operation, and maintenance of the

freeze-dryer.

Pos: 7/ 010U niversalmodul e/ Leerzeil e@ 0\ mod_120211624450 0_0.docx @ 114 @ @ 1

Pos: 8/ 200C hrist/360 GT- BA Labor-Pilot ( STANDARDMODULE) /010 Allgemeine Infor mationen/010- 0040 Urheberrecht @ 2 5\mod_1404983 212403_68.doc x@ 182977 @ 2 @ 1

1.4 Copyright The copyright concerning the operating manual remains with Martin Christ

Gefriertrocknungsanlagen GmbH.

The operating manual is solely intended for the operator and their

personnel. It includes instructions and information that may not be

•duplicated,

•distributed, or

•communicated in any other way neither in full nor in parts.

Non-compliance may be prosecuted under criminal law.

Pos: 9/ 010U niversalmodul e/ Leerzeil e@ 0\ mod_120211624450 0_0.docx @ 114 @ @ 1

Pos: 10 /200 Christ/360 GT- BA Labor-Pilot (ST ANDARDMODU LE)/010 Allgemein eInf ormationen/010- 0050 Z eichener klärung @ 25\mod_140 4983213429_68.doc x@ 182991 @ 2 @ 1

1.5 Explanation of symbols

In this operating manual, specialist terms that are explained in the glossary

(see chapter 12 - "Glossary") are marked by an arrow and printed in italics

(e.g. sublimation).

Pos: 11 /010U niversalmodule/ Leerzeile @ 0\mod_ 1202116244500_ 0.docx@ 1 14@ @ 1

Pos: 12 /200 Christ/360 GT- BA Labor-Pilot (ST ANDARDMODU LE)/010 Allgemein eInf ormationen/010- 0061 N ormen und Vorschrif ten( ohne Druc kgeräteRL) @ 40\mod_ 145017375124 5_68.docx @ 291724 @ 2 @ 1

1.6 Standards and regulations

EC declaration of conformity in accordance with the EC Machinery

Directive (see chapter 11.2 - "EC declaration of conformity in accordance

with the EC Machinery Directive")

Pos: 13 /010U niversalmodule/ Leerzeile @ 0\mod_ 1202116244500_ 0.docx@ 1 14@ @ 1

Pos: 14 /200 Christ/361 GT- BA Labor-Pilot (PR OJEKTE)/Alpha/ Alpha 1-4_2-4 LDpl us/010 Allgemeine Infor mationen/010- 0070 Lieferumfang Alp ha 1-4_2-4 LDplus @ 35 \mod_143 0379091331_68. docx@ 25 8534@ 2 @ 1

1.7 Scope of supply

The scope of supply comprises:

•1 tube of high-vacuum grease

•1 litre of vacuum pump oil (only if a pump is included)

•1 set of flange components and several small parts for service and

maintenance purposes

•1 drain hose 0.5 m (silicone 8 x 12 mm)

•1 operating manual

Accessories and commissioning

According to your order, our order confirmation, and our delivery note.

Pos: 15 /010U niversalmodule/A bschnittswechsel @ 0\ mod_12021245140 62_0.docx @ 418 @ @ 1

Freeze-dryer Alpha 1-4 LDplus

Freeze-dryer Alpha 2-4 LDplus

2 Layout and mode of operation

Version 11/2006, Rev. 2.2 of 17/10/2016 • sb

11 / 102

Translation of the original operating manual

Pos: 16 /010U niversalmodule/S eitenwechsel @ 0\mod_ 1202116244312_ 0.docx@ 1 05@ @ 1

Pos: 17 /200 Christ/360 GT- BA Labor-Pilot (ST ANDARDMODU LE)/020 Aufbau und Wir kungsweise/02 0 A ufbau und Wirkungsweis e======== =========== ======== @ 25\mod_1404 983235994_68. docx@ 183019 @ 1 @ 1

2 Layout and mode of operation

Pos: 18 /200 Christ/360 GT- BA Labor-Pilot (ST ANDARDMODU LE)/020 Aufbau und Wir kungsweise/02 0-0010 Aufbau der Gefri ertrocknungsanlage-------------------------------------------------@ 25\mod_1404 983236941_68.doc x@ 18303 3@ 2 @ 1

2.1 Layout of the freeze-dryer

Pos: 19 /200 Christ/361 GT- BA Labor-Pilot (PR OJEKTE)/Alpha/ Alpha 1-4_2-4 LDpl us/020 Aufbau und Wir kungsweise/020-0 010-0010 Fun ktions- und Bedienelement e Alpha 1-4_2-4 LDpl us @ 35\mod_143037 9173090_68.docx @ 2 58550 @ 3 @ 1

2.1.1 Functional and operating elements

1Ice condenser

chamber with an

internal ice condenser

2User interface (see

chapter 6.5.1 - "User

interface")

3Mains power switch

Fig. 1: Total view of the freeze-dryer

4Pipe connection of the

vacuum pump (behind

the cover plate)

5Ice condenser

Fig. 2: Ice condenser chamber

Freeze-dryer Alpha 1-4 LDplus

Freeze-dryer Alpha 2-4 LDplus

2 Layout and mode of operation

12 / 102

Version 11/2006, Rev. 2.2 of 17/10/2016 • sb

Translation of the original operating manual

6Equipotential bonding

screw

7Aeration and media

drain valve

Fig. 3: Left side of the freeze-dryer

8Vacuum connection

9Name plate (see

chapter 2.1.2 - "Name

plate")

10Heat exchanger of the

refrigeration unit

11Electrical connection of

the vacuum sensor

12Power supply of the

pressure control valve

13Power supply of the

vacuum pump

14Mains fuse

15Mains cable

Fig. 4: Rear view of the freeze-dryer

Pos: 20 /010U niversalmodule/S eitenwechsel @ 0\mod_ 1202116244312_ 0.docx@ 1 05@ @ 1

Freeze-dryer Alpha 1-4 LDplus

Freeze-dryer Alpha 2-4 LDplus

2 Layout and mode of operation

Version 11/2006, Rev. 2.2 of 17/10/2016 • sb

13 / 102

Translation of the original operating manual

Pos: 21 /200 Christ/361 GT- BA Labor-Pilot (PR OJEKTE)/Alpha/ Alpha 1-4_2-4 LDpl us/020 Aufbau und Wir kungsweise/020-0 010-0020 Typenschil d Alpha 1-4_2-4 LDplu s@ 3 5\mod_143037 9174381_68.doc x@ 258565 @ 3 @ 1

2.1.2 Name plate

1Serial number

2Type

3Refrigerant data of

the 1st stage

4Nominal voltage

5Year of manufacture

(month/year)

6Part number

7Refrigerant data of

the 2nd stage

8Rated current /

apparent power

Fig. 5: Example of a name plate (here: Alpha 2-4 LDplus)

Pos: 22 /010U niversalmodule/S eitenwechsel @ 0\mod_ 1202116244312_ 0.docx@ 1 05@ @ 1

Freeze-dryer Alpha 1-4 LDplus

Freeze-dryer Alpha 2-4 LDplus

2 Layout and mode of operation

14 / 102

Version 11/2006, Rev. 2.2 of 17/10/2016 • sb

Translation of the original operating manual

Pos: 23 /200 Christ/360 GT- BA Labor-Pilot (ST ANDARDMODU LE)/020 Aufbau und Wir kungsweise/02 0-0020 Wirkungs weise------------------------@ 25\mod_140 4983253850_ 68.docx @ 183047 @ 2 @1

2.2 Mode of operation

Pos: 24 /200 Christ/360 GT- BA Labor-Pilot (ST ANDARDMODU LE)/020 Aufbau und Wir kungsweise/02 0-0020-0010 Gefriertro cknung allgem ein@ 25\mod_14 04983254815_68.d ocx @ 183061 @ 3 @ 1

2.2.1 General information on freeze-drying

What is freeze-drying?

Freeze-drying or lyophilisation is a procedure for the gentle drying of high-

quality products. The product is dried by sublimation without passing

through the liquid phase.

What are typical applications for freeze-drying?

As far as their sheer quantity is concerned, foodstuffs are the major

application for freeze-drying. One widely known example is the production

of granulated instant coffee or the drying of fruit, e.g. for breakfast cereals.

Other areas of application are the restoration of water-damaged documents

or the drying of archaeological artefacts.

Another important area of application is the drying of biotechnological and

pharmaceutical products, e.g. tissues and tissue extracts, bacteria,

vaccines, and sera. Products that would not keep well when they are

dissolved in water can be preserved by freeze-drying. During this process,

the biological properties of these sensitive substances are preserved. The

compounds remain unchanged from a qualitative and quantitative point of

view. After the addition of water, the products will have the same

characteristics as the original products.

How does freeze-drying work?

Freeze-drying is a very gentle procedure for the extraction of water from a

product in the frozen state. The drying process takes place through

sublimation, i.e. the direct transition of a product from the solid phase to the

gas phase. This happens under vacuum.

The following section describes the process of sublimation based on the

example of water, since most products that are processed by freeze-drying

are aqueous solutions. Their behaviour is based on identical fundamental

principles.

The vapour pressure curve above ice describes the phase transition as a

function of the pressure and temperature. The higher the temperature is,

the higher the vapour pressure.

•If the vapour pressure is higher than 6.11 mbar (A), water passes

through all three phases: solid, liquid, and gas (see the illustration).

•If the vapour pressure is below 6.11 mbar (B) and energy is added, the

ice will be directly converted into water vapour once the sublimation

curve is reached. This transition is called “sublimation”. If thermal

energy is added to pure ice with a temperature of less than –30°C at a

pressure of 0.37 mbar, it will be converted into water vapour once it

reaches –30°C (see figure).

The vacuum prevents the melting of ice when energy is added. If thermal

energy is added to a frozen product under vacuum, thawing of the product

will be prevented and the water that is contained within the product will be

released in the form of water vapour.

Freeze-dryer Alpha 1-4 LDplus

Freeze-dryer Alpha 2-4 LDplus

2 Layout and mode of operation

Version 11/2006, Rev. 2.2 of 17/10/2016 • sb

15 / 102

Translation of the original operating manual

Fig. 6: Vapour pressure curve above ice

From a physical point of view, the freeze-drying process covers three

phases (see figure below):

(1) Freezing: The product to be dried is frozen under atmospheric pressure.

This can be done either directly in the freeze-dryer or in a separate deep-

freeze. The freezing temperature should be approximately 10°C below the

solidification point of the product.

(2) Evacuation: When the product is sufficiently frozen, the vacuum pump is

activated. The pressure inside the drying chamber will be lowered to the

value that corresponds to the freezing temperature in accordance with the

vapour pressure curve above ice.

(3) Sublimation: Thermal energy is added to the product, thus starting the

sublimation process. Due to the added energy, the water in the product is

converted into water vapour. Since the ice condenser is much colder than

the product that is to be dried, the vapour pressure in the ice condenser is

considerably lower than above the product. As a result, the water vapour

that is released by the product streams to the ice condenser, where it

condenses on the condenser coils.

Once the free water has been extracted from the product during the main

drying phase, the last traces of bound water will also be removed at a final

pressure that is as low as possible and at higher temperatures. This takes

place by way of desorption. This drying phase is also called final drying.

6.11 mbar

0.37 mbar

-30°C

B

A

Vapourpressurecurve

Vapourpressurecurveforice=

Sublimationpressurecurve

Melting

Sublimation Triple point

SOLID

LIQUID

GASEOUS

Evaporation

Meltingpoint

pressurecurve

Pressure

(mbar)

Temperature (°C)

Freeze-dryer Alpha 1-4 LDplus

Freeze-dryer Alpha 2-4 LDplus

2 Layout and mode of operation

16 / 102

Version 11/2006, Rev. 2.2 of 17/10/2016 • sb

Translation of the original operating manual

Fig. 7: Freeze-drying phases

NOTE

Please find further information about basic principles, optimum procedures

and applications in the brochure "Smart freeze-drying", which can be

downloaded at www.martinchrist.de [Applications].

Pos: 25 /010U niversalmodule/S eitenwechsel @ 0\mod_ 1202116244312_ 0.docx@ 1 05@ @ 1

1

2

1 bar

20°C

Vapourpressurecurve

Vapourpressurecurveforice=

sublimationpressurecurve

Triple point

SOLID

LIQUID

GASEOUS

Meltingpoint

pressurecurve

Pressure

(mbar)

Temperature (°C)

Freeze-dryer Alpha 1-4 LDplus

Freeze-dryer Alpha 2-4 LDplus

2 Layout and mode of operation

Version 11/2006, Rev. 2.2 of 17/10/2016 • sb

17 / 102

Translation of the original operating manual

Pos: 26 /200 Christ/360 GT- BA Labor-Pilot (ST ANDARDMODU LE)/020 Aufbau und Wir kungsweise/02 0-0020-0020 Ablauf eines Gefriertroc knungsprozesses @ 25\ mod_140498 3255939_68.docx @ 1 83075 @ 3 @ 1

2.2.2 Freeze-drying process

The main components of a freeze-dryer are:

•vacuum drying chamber with a temperature control system for adding

thermal energy

•vacuum pump for generating a vacuum inside the drying chamber

•ice condenser for binding the water vapour that is released by the

product.

Pos: 27 /010U niversalmodule/ Leerzeile @ 0\mod_ 1202116244500_ 0.docx@ 1 14@ @ 1

Pos: 28 /200 Christ/360 GT- BA Labor-Pilot (ST ANDARDMODU LE)/020 Aufbau und Wir kungsweise/02 0-0020-0020-001 0 V orbereitung @ 25\mod _1404983256926 _68.docx @ 18308 9@ 4 @ 1

2.2.2.1 PreparationThe ice condenser chamber must be clean and dry. Any water residues

from a preceding drying run must be removed.

The media drain valve and the aeration valve must be closed.

In the case of units that are equipped with a pressure control valve

(standard on LSCplus units), the vacuum pump should be warmed up

(“warm-up”) for at least 15 minutes prior to the start of the main drying

phase. Do not subject the vacuum pump to condensable gases until the

operating temperature is reached. In this way, the service life of the

vacuum pump can be extended.

At the same time, the ice condenser is pre-cooled ("cool-down"). The ice

condenser temperature does not have any influence on the product

temperature. The sole purpose of the ice condenser is to bind the released

water vapour.

Pos: 29 /010U niversalmodule/ Leerzeile @ 0\mod_ 1202116244500_ 0.docx@ 1 14@ @ 1

Pos: 30 /200 Christ/360 GT- BA Labor-Pilot (ST ANDARDMODU LE)/020 Aufbau und Wir kungsweise/02 0-0020-0020-002 0 G efrieren @ 25\mod_14 04983257955_6 8.docx @ 183103 @ 4 @ 1

2.2.2.2 Freezing First, the product that is to be dried is frozen. This can be carried out either

directly in the freeze-dryer or in a separate deep-freeze. Especially in the

case of small filling quantities, we recommend pre-cooling the shelves as

well in order to prevent the product from thawing during the evacuation.

Two very different structures of the frozen material can be distinguished:

•crystalline structures with clearly distinguishable crystals

•amorphous structures with no crystal junctions at all (e.g. glass)

The majority of the freeze-drying products have a crystalline form.

When freezing these kinds of products, one must take into consideration

that too deep and too quick freezing leads to smaller ice crystals, which has

a negative effect on the duration of the drying process.

For every product to be dried, the solidification point must be determined as

a first step. This is the point at which the water that is contained in the

product has completely crystallised. In order to ensure an optimum freeze-

drying process, the product temperature should be approximately 10°C

below the solidification point.

A layer thickness of the product of 1-2 cm should not be exceeded, since

otherwise the drying duration would be negatively affected. If liquids are to

be dried in bottles with a layer thickness of more than 1 cm, we recommend

freezing them in a cooling bath with the aid of a shell or spin freezing

device (see figure). Due to the centrifugal force, the liquid to be frozen will

rise on the inner wall of the bottle and freeze. This procedure reduces the

layer thickness and, thereby, the total drying time will be shortened to a

considerable extent (see figures on the right side).

Freeze-dryer Alpha 1-4 LDplus

Freeze-dryer Alpha 2-4 LDplus

2 Layout and mode of operation

18 / 102

Version 11/2006, Rev. 2.2 of 17/10/2016 • sb

Translation of the original operating manual

Fig. 8: Shell freezing

Fig. 9: Cooling bath with spin freezing device

Fig. 10: Spin freezing

NOTE

If the product that is to be dried contains solvents or high salt

concentrations, it may start to thaw during the drying process, which is

indicated by clearly visible foaming. In order to prevent this, the product

must be frozen as deeply as possible, e.g. with the aid of liquid nitrogen,

prior to putting it into the unit.

Pos: 31 /010U niversalmodule/ Leerzeile @ 0\mod_ 1202116244500_ 0.docx@ 1 14@ @ 1

Pos: 32 /010U niversalmodule/ Leerzeile @ 0\mod_ 1202116244500_ 0.docx@ 1 14@ @ 1

Pos: 33 /200 Christ/360 GT- BA Labor-Pilot (ST ANDARDMODU LE)/020 Aufbau und Wir kungsweise/02 0-0020-0020-003 0 Ha upttrocknung @ 25\ mod_14049832 59260_68.docx @ 183 117 @ 4@ 1

2.2.2.3 Main drying

When the product is frozen to a sufficiently deep extent, the main drying

phase commences. The vacuum pump is switched on. The pressure inside

the drying chamber will be lowered to the value that corresponds to the

freezing temperature in accordance with the vapour pressure curve above

ice. At the same time, thermal energy will be added to the product. In the

case of products in round-bottom flasks, wide-neck bottles, etc., this is

realised through the environment that is considerably warmer (direct

contact heat), in the case of unheated shelves by way of thermal radiation

from the environment, and in the case of temperature-controlled shelves

directly via the shelves. As a result, the sublimation process starts.

At the beginning of the drying process, the maximum drying rate will be

reached. The more the sublimation area recedes into the product, the

further the produced water vapour must pass through the layers that have

already been dried.

Under certain conditions, it is possible that the vacuum inside the ice

condenser chamber increases during the main drying phase (e.g. from 0.63

mbar to 0.47 mbar) although the valve towards the vacuum pump is closed.

From a physical point of view, this is due to the pumping effect of the ice

condenser ("cryo-pumping effect").

The required drying time depends strongly on the drying vacuum. At 1.0

mbar, one gram of ice takes up a volume of 1 m3of vapour, at 0.1 mbar a

volume of 10 m3of vapour, and at 0.001 mbar a volume of 100 m3. The

closer the vacuum is to the solidification point, the smaller is the resulting

vapour volume. The drying rate increases and the drying time decreases.

The end of the main drying phase is reached, when the product

temperature and the shelf temperature are nearly identical. The

temperature difference between the shelf and the product should be

approximately 3 K to 5 K.

Pos: 34 /010 Universal module/ L eerzeile @ 0\mod_ 1202116244500_ 0.docx @ 114 @ @ 1

Pos: 35 /200 Christ/360 GT- BA Labor-Pilot (ST ANDARDMODU LE)/020 Aufbau und Wir kungsweise/02 0-0020-0020-004 0 Nac htrocknung @ 25\m od_14049832603 10_68.docx @ 183131 @ 4 @ 1

Freeze-dryer Alpha 1-4 LDplus

Freeze-dryer Alpha 2-4 LDplus

2 Layout and mode of operation

Version 11/2006, Rev. 2.2 of 17/10/2016 • sb

19 / 102

Translation of the original operating manual

2.2.2.4 Final drying

Final drying is an option whenever one requires a product with minimal

residual moisture. In the physical sense, this process is a desorption

process, i.e. the removal of adsorptively bound water. Final drying is

performed under the lowest possible final pressure that depends on the ice

condenser temperature in accordance with the vapour pressure curve

above ice as well as on the final vacuum of the vacuum pump that is used.

The process is supported by a higher shelf temperature.

Pos: 36 /010U niversalmodule/ Leerzeile @ 0\mod_ 1202116244500_ 0.docx@ 1 14@ @ 1

Pos: 37 /200 Christ/360 GT- BA Labor-Pilot (ST ANDARDMODU LE)/020 Aufbau und Wir kungsweise/02 0-0020-0020-005 0 Tr ocknungsende und Bel üftung @ 25\mod_14 04983261476_6 8.docx @ 183145 @ 4 @ 1

2.2.2.5 End of drying and aeration

The end of the drying process is reached when both the product and shelf

temperature are clearly in the positive range (+15 to +20°C) and if their

difference is not greater than 5 K.

Another indication of the end of the drying process is the behaviour of the

vacuum and of the ice condenser temperature. The ice condenser is no

longer subject to load and reaches the final temperature of approximately -

55°C or -85°C. The pressure in the drying chamber decreases in

accordance with the ice condenser temperature.

The vacuum pump will be switched off and the drying chamber will be

aerated via a rubber valve or via the aeration valve. The aeration valve can

also be used to flood the unit with nitrogen or another inert gas instead of

ambient air.

Then, the product can be removed from the unit.

Pos: 38 /010U niversalmodule/S eitenwechsel @ 0\mod_ 1202116244312_ 0.docx@ 1 05@ @ 1

Freeze-dryer Alpha 1-4 LDplus

Freeze-dryer Alpha 2-4 LDplus

2 Layout and mode of operation

20 / 102

Version 11/2006, Rev. 2.2 of 17/10/2016 • sb

Translation of the original operating manual

Pos: 39 /200 Christ/360 GT- BA Labor-Pilot (ST ANDARDMODU LE)/020 Aufbau und Wir kungsweise/02 0-0020-0020-006 0 A btauen Raumtemper atur @ 25\mod_1404 983262567_68.d ocx @ 183159 @ 4 @ 1

2.2.2.6 Defrosting Defrosting of the ice condenser is carried out at room temperature or with

warm water.

•At a maximum, the ice condenser chamber may be half filled with water.

•Ensure that no water gets into the pipe connection of the vacuum pump

and the vacuum sensor (behind the cover plate, see figure)

1Cover plate

Fig. 11: Eis condenser chamber

•Drain the condensate through the media drain valve at the left side of

the freeze-dryer by attaching a hose on the nozzle (included in the

scope of supply) and placing a vessel underneath.

In order to avoid damage, the condensate must be removed directly after

the completion of the defrosting process. Then, any residual water must be

removed from the ice condenser chamber by way of a cloth.

Pos: 40 /010U niversalmodule/A bschnittswechsel @ 0\ mod_12021245140 62_0.docx @ 418 @ @ 1

Pos: 41 /010U niversalmodule/S eitenwechsel @ 0\mod_ 1202116244312_ 0.docx@ 1 05@ @ 1

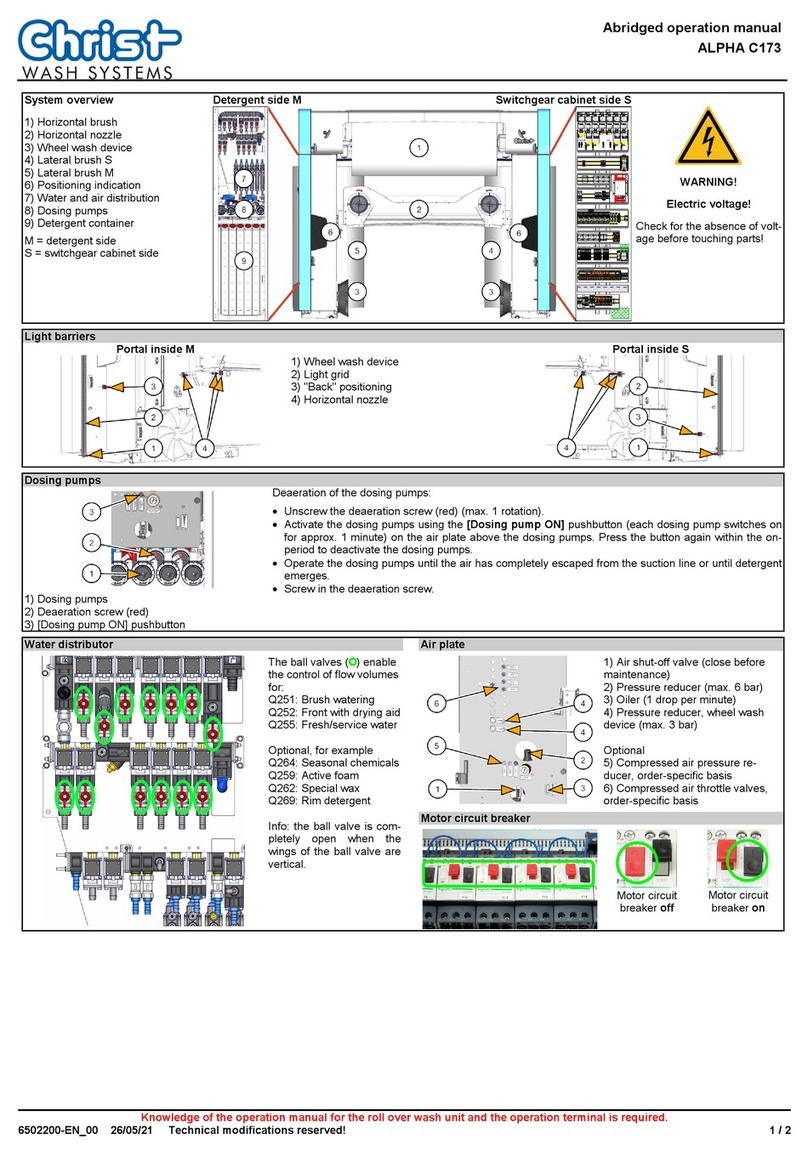

This manual suits for next models

3

Table of contents

Other Christ Laboratory Equipment manuals

Christ

Christ Epsilon 2-10D LSCplus User manual

Christ

Christ RVC 2-18 CDplus User manual

Christ

Christ ALPHA C173 User manual

Christ

Christ Epsilon 2-4 LSCplus User manual

Christ

Christ Alpha 1 LSCbasic User manual

Christ

Christ Epsilon 1-4 LSCplus User manual

Christ

Christ Epsilon 2-6D LSCplus User manual

Christ

Christ Touch-itsCE OEM glass 7 User manual

Christ

Christ RVC 2-33 CDplus User manual

Christ

Christ Epsilon 1-4 LSCplus User manual