and the lead pad (10), with one hand and turn over the Top Plate

assembly so that the crystal (7) can fall out to drop into the palm of

your hand. If the crystal (7) is also stuck in the main body plate (4)

because of good sealing to the Kalrez gasket (11) on the top

(sampling) surface of the crystal (7), then put a soft pad or tissue on

the work bench area and lay the Top Plate assembly onto it the

same way up as it would be used when fitted to the optical unit.

Try to loosen the crystal (7) away from the Kalrez gasket (11) seal

by exerting a small pressure on either ends of the top of the crystal

(7) from inside the trough area and pushing down from above. Do

not press too hard in case the crystal (7) breaks. (ZnSe, in

particular, is a hard, but brittle crystal material.) If the crystal is

stubborn to movement try to lubricate the internal trough and Kalrez

gasket (11) area by use of some solvent (e.g. methanol) covering

the top surface of the crystal (7) whilst exerting the gentle pressure.

When the crystal (7) and the lead pad (10) have been removed, it may

now be easier to separate the lead pad (10) from the crystal. If the

crystals (7) top sampling surface looks OK and can be cleaned

carefully, then it may not be necessary to remove the lead pad (10)

away for further cleaning prior to re-assembly and use. However, if the

lead pad (10) is to be removed, it may be necessary to immerse the

whole crystal (7) and lead pad (10) assembly in a beaker of water or

methanol solvent and apply a gentle “sonication cleaning”of the items.

The action of the sonic agitation of the solvent may help to loosen the

lead pad (10) away from the crystal such that when the items are

removed from the solvent they can be easily and safely separated

without any damage to the lead pad (12) or crystal (7) parts.

Clean the ATR crystal (7) by following the Notes on Cleaning

instructions on page 20.

Changing the Kalrez Gasket Seal

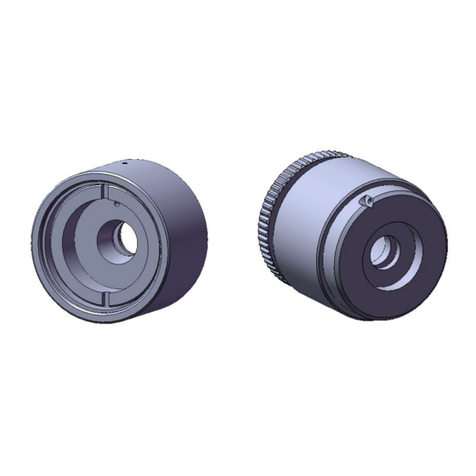

When the ATR crystal (7) has been removed from the Top Plate

assembly, access can be gained to the Kalrez gasket seal (11) for

cleaning or replacement with new if necessary. (See Fig 8.)