Abridged operation manual

ALPHA C173

Knowledge of the operation manual for the roll over wash unit and the operation terminal is required.

6502200-EN_00 26/05/21 Technical modifications reserved!

TOUCH POS

Access to the operator menu (counters, configurations, chemistry, operator settings, wash cards, door control, time setting, display, network)

Press the window on the far upper right corner

and then on the far lower right corner (see

the "Login" window opens.

Step 2:

Enter the access data in the window "Login" and

confirm with button.

To proceed to the service menu, press button.

Step 4:

To proceed to the operator menu, press but-

ton.

Input the 4-

digit operator code and confirm with

button. To leave the operator menu again, re-

peatedly press button.

For further

information, see the operation manual of

the operation terminal.

TOUCH POS

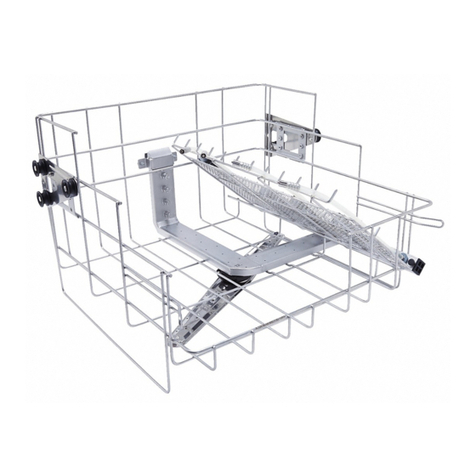

Manual operation of the unit (drive unit, horizontal nozzle, horizontal brush, HP beam, lateral nozzles, lateral brushes, wheel brushes or Wabeg)

Click the window on the extreme upper right cor-

ner and then on the extreme lower right corner

(see ); the "Login" window opens.

Step 2:

Enter the access data in the window "Login" and

confirm with button.

To proceed to the service menu, press the but-

ton.

Press the button.

The text "Manual" flashes red underneath the sta-

tus line.

Press the button.

Select the required drive (drive unit, horizontal nozzle, horizontal brush, HP beam, lateral nozzles, lateral brushes, wheel

or Wabeg) with or and confirm with button. Manual movement is now possible.

Info: Manual movement of the horizontal n

ozzle is possible only once it has moved into the starting position. For further information,

see the operation manual of the operation terminal.

Back with .

Press the button. The red text "Manual" switches off.

To leave the service menu, press the button.

If a fault occurs during the program, the program

stops in the sequence in which the fault occurred.

The machine stoppage is indicated on the window

(see figure).

Carry out the fault rectification:

•Rectify the fault

•Acknowledge the fault rectification with .

−The fault indication is reset.

For further information, see the operation manual of

the operation terminal.

Once all faults have been rectified, the programme

sequence can be cancelled with

with .

Info: The vehicle can exit if an error that cannot be acknowledged without a

repair occurs during the programme. However, this is possible only when there

are no errors in the frequency converters and the drives, and the wash syste

m

is set to manual operation (see "manual operation of the unit" in the operation

manual of the operation terminal).