4.4.9 Pins Parallel Test Description.....................................................................4-37

4.4.10 Pins Series Test Description .......................................................................4-37

4.4.11 How To Set Up

〝

DEVIATION

〞

Function ................................................4-38

4.4.12 LCRZ Parameter Analysis. (3302 only)......................................................4-39

4.4.13 Compare Test (3302 only) ..........................................................................4-40

4.4.14 BIN SET (3302 only).................................................................................4-40

4.4.15 Multi-frequency Scan Test (LIST SWEEP) (3302 only).............................4-41

4.4.16 Upload Calibration Explanation (3302 only) ..............................................4-44

4.4.17 33XX Fast Function Keys (Help Function).................................................4-45

4.4.18 33XX DCA New Additional Function & Operation (Option) .....................4-45

4.5 Low Impedance Measurement Application ........................................................4-46

4.6 Bias Current Source Connecting ........................................................................4-47

4.7 Test Application.................................................................................................4-47

4.7.1 Large Inductance Measurement..................................................................4-47

4.7.2 Low Coupling Coefficient Turn Ratio Measurement...................................4-47

4.7.3 Bias Current Connecting ............................................................................4-47

4.7.4 Nonlinear Inductor,Transformer Measurement ..........................................4-47

5. Application of Interface ................................................................................................5-1

5.1 Transformer Automatic Scan Interface (Scan Box)...............................................5-1

5.1.1 Description The Test Function......................................................................5-1

5.1.2 Notice before Using .....................................................................................5-1

5.1.3 Scan Box Front Panel Description................................................................5-2

5.1.4 Scan Box Rear Panel Description.................................................................5-4

5.1.5 Scan box Description ...................................................................................5-5

5.1.6 Test Fixture (Scan Box) Description.............................................................5-6

6. PRINT(OPTION) Operational Procedure...............................................................6-1

7. Handler Interface (Option)...........................................................................................7-1

7.1 General................................................................................................................7-1

7.2 Timing .................................................................................................................7-2

8. RS-232C Control Interface ...........................................................................................8-1

8.1 Overview.............................................................................................................8-1

8.2 RS-232C Specification.........................................................................................8-1

8.2.1 RS-232C Interface Connector.......................................................................8-1

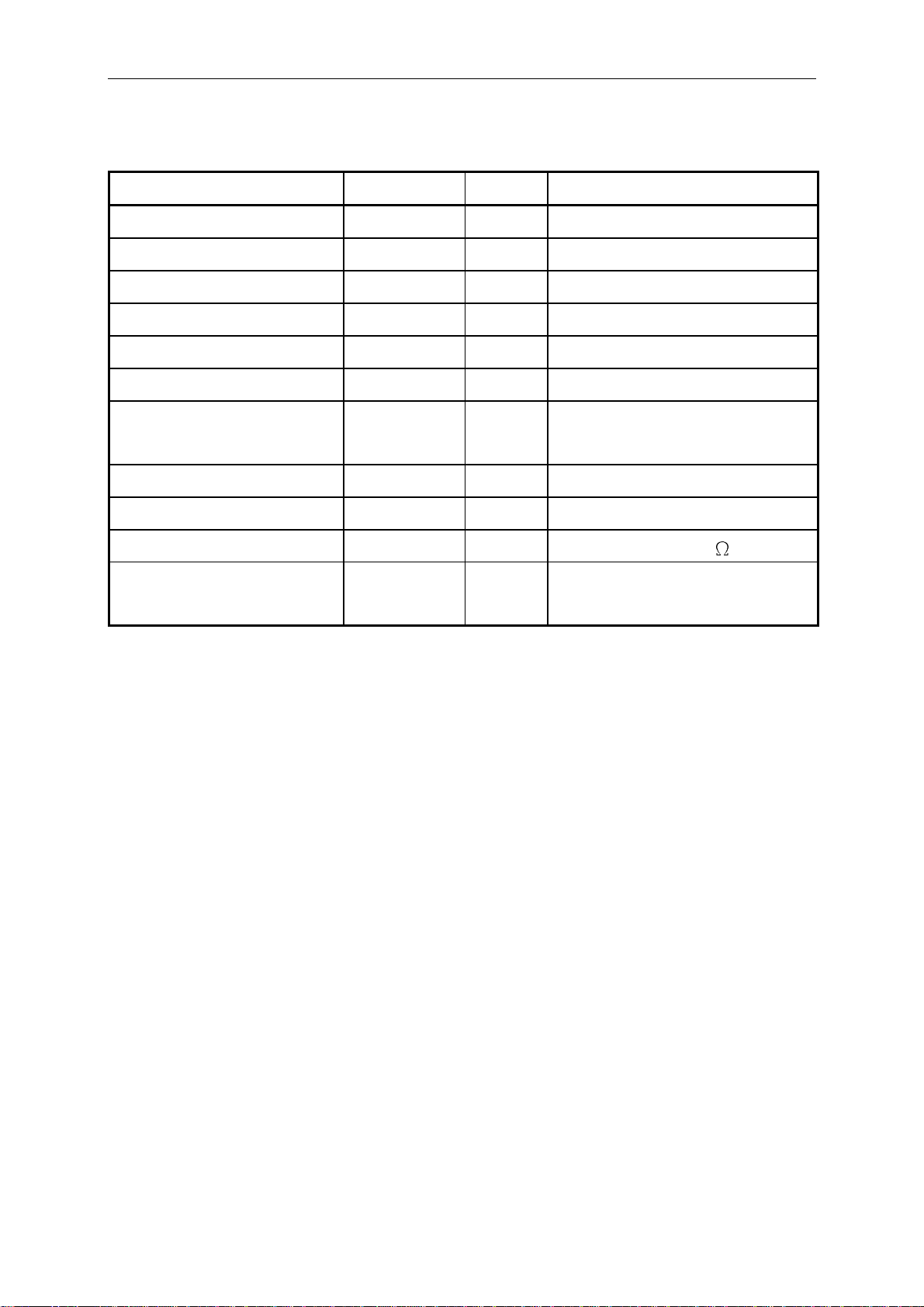

8.2.2 Table of RS-232C Signal Line and Pin .........................................................8-1

8.3 Setting 33XX RS-232C Interface.........................................................................8-1

8.3.1 Setting BAUD RATE ...................................................................................8-2

8.3.2 Setting PARITY CHECK.............................................................................8-2

8.3.3 Setting WORD LENGTH.............................................................................8-2

8.3.4 Setting of DEFAULT....................................................................................8-2

8.3.5 RS-232 ON/OFF..........................................................................................8-2

8.4 Setting 33XX RS-232C Interface.........................................................................8-2

8.5 Data Output Format for 33XX .............................................................................8-5

8.5.1 Transformer Output Format..........................................................................8-5

8.5.2 Data Output Format for LCR (3302 only).....................................................8-6

8.5.2.1 LCR Pure Value Output Format................................................................8-6

8.5.2.2 BIAS SCAN Output Format.....................................................................8-7

8.6 Example Programs of RS-232C Interface Control................................................8-8

9. Additional Description of Memory Card......................................................................9-1