iii

Warranty

All of Chroma’s instruments are warranted against defects in material and

workmanship for a period of one year from date of shipment. Chroma agrees to

repair or replace any assembly or component found to be defective, under normal

use during this period. Chroma’s obligation under this warranty is limited solely to

repairing any such instrument, which in Chroma’s sole opinion proves to be

defective within the scope of the warranty when returned to the factory or to an

authorized service center. Purchaser is responsible for the shipping and cost of

the service item to Chroma factory or service center. Shipment should not be

made without prior authorization by Chroma.

This warranty does not apply to any products repaired or altered by persons not

authorized by Chroma, or not in accordance with instructions furnished by Chroma.

If the instrument is defective as a result of misuse, improper repair, or abnormal

conditions or operations, repairs will be billed at cost.

Chroma assumes no responsibility for its product being used in a hazardous or

dangerous manner either alone or in conjunction with other equipment. High

voltage used in some instruments may be dangerous if misused. Special

disclaimers apply to these instruments. Chroma assumes no liability for

secondary charges or consequential damages and in any event, Chroma’s liability

for breach of warranty under any contract or otherwise, shall not exceed the

purchase price of the specific instrument shipped and against which a claim is

made.

Any recommendations made by Chroma regarding the use of its products are

based upon tests believed to be reliable; Chroma makes no warranty of the results

to be obtained. This warranty is in lieu of all other warranties, expressed or

implied, and no representative or person is authorized to represent or assume for

Chroma any liability in connection with the sale of our products other than set forth

herein.

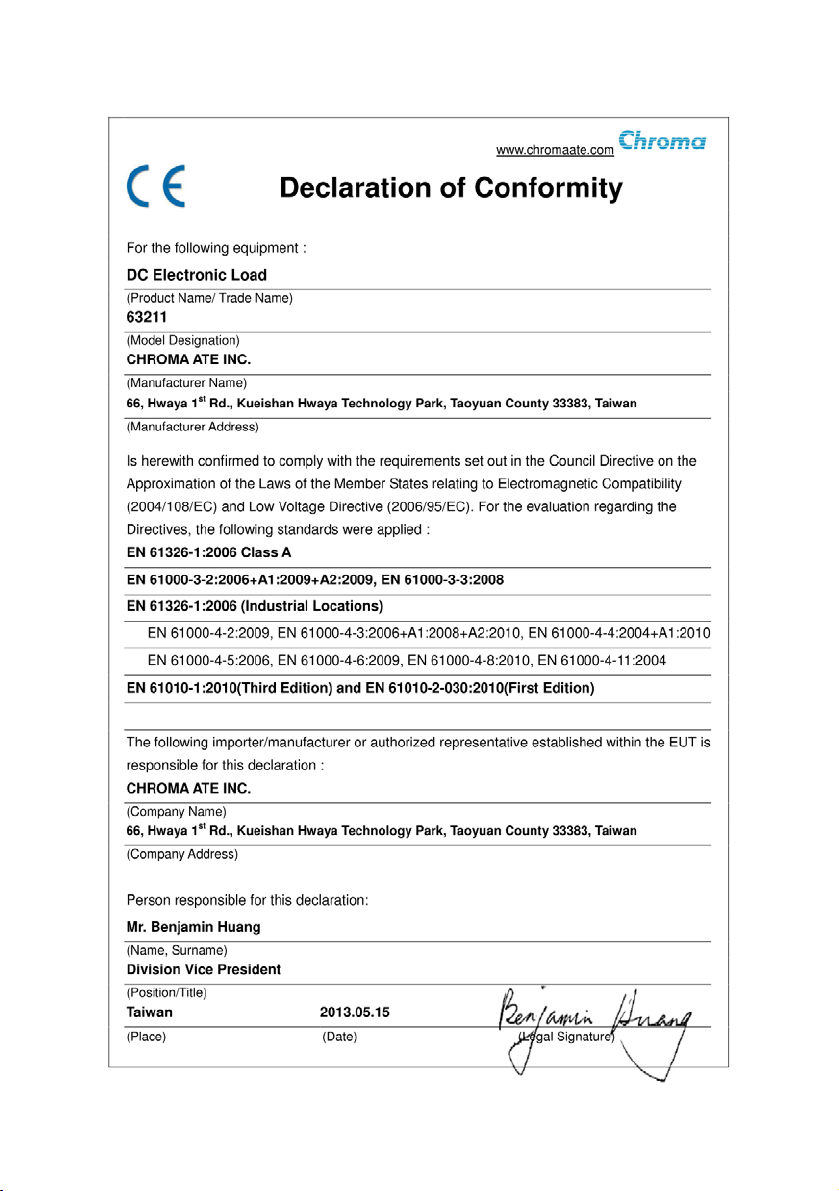

CHROMA ATE INC.

66 Hwaya 1st Rd., Kueishan Hwaya Technology Park,

Taoyuan County 33383, Taiwan

Tel: 886-3-327-9999

Fax: 886-3-327-2886

www: http://www.chromaate.com/