Temperature

characteristics 0.05 x accuracy specifications/ ( ) at 0 to 40 (32 to 104 )

Storage temperature

range -10 to 50 (14 to 122 ) (no condensation)

Power source Rated power voltage 9 VDC

6F22 layer-built manganese battery x 1

Maximum rated power100 mVA

Battery lifetime Approx. 45 hours (continuous, no load)

External dimensions

and mass Approx. 62W x 216.5H x 39D mm, Approx. 350 g (3281)

Approx. 2.44"W x 8.58"H x 1.54"D, Approx. 12.3 oz. (3281)

Approx. 62W x 231H x 39D mm, Approx. 400 g (3282)

Approx. 2.44"W x 9.06"H x 1.54"D, Approx. 14.1 oz. (3282)

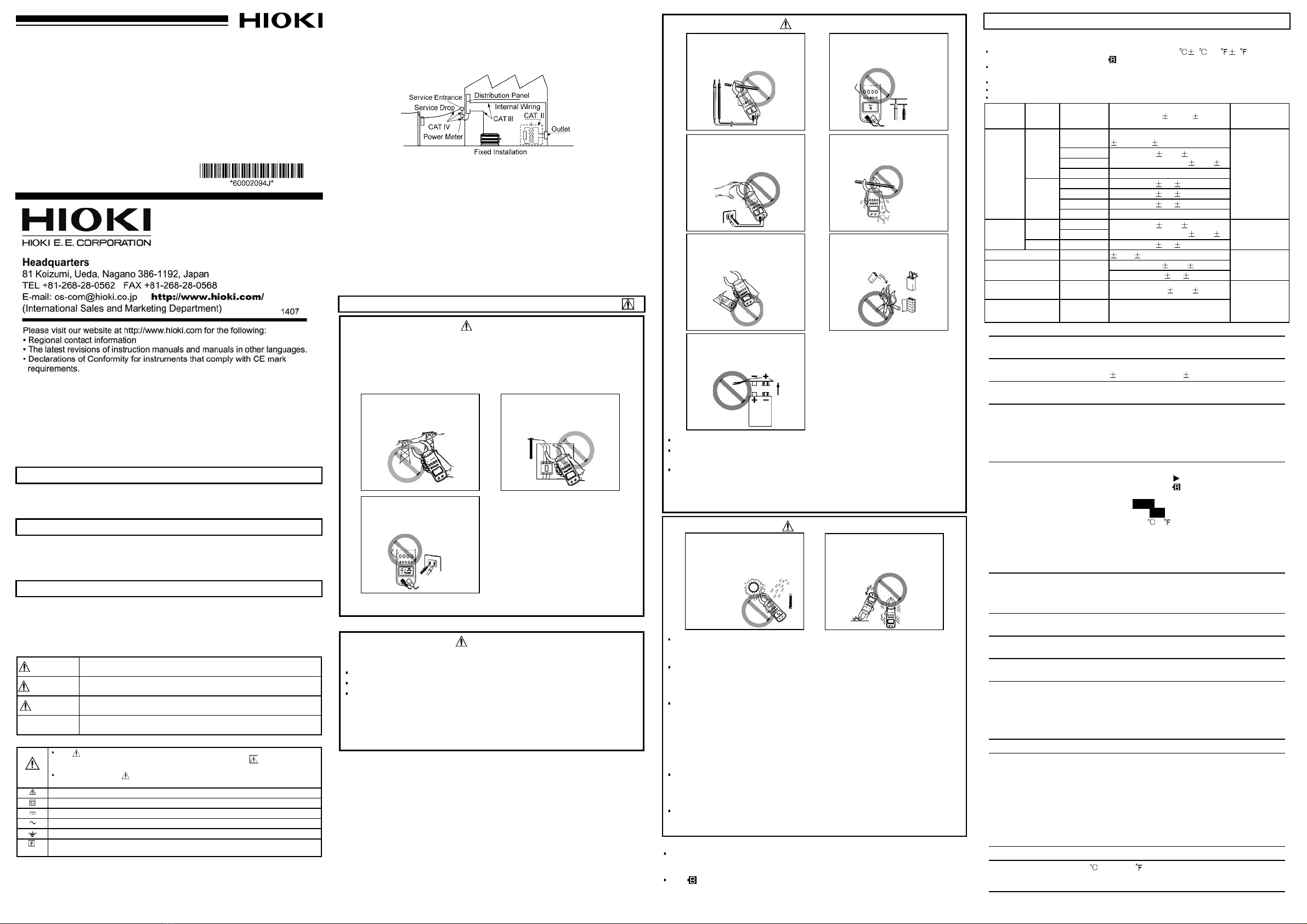

Names and Functions of Parts

Voltagae and resistance

input terminal

3281

(

600 A

)

3282

(

1000 A

)

Clamp-on

sensor

Lever

Key switchs

Display (LCD)

Back casing

(back)

Alternating current

AUTO

SLO

REC

MAX

MIN

AVE

Auto-ranging

Display update:

approx. once per three seconds

Record function

Maximum value

Minimum value

Average value = (maximum value

+ minimum value) / 2

min

hour

HOLD

APS

*

*

Ω,kΩ

One minute: one segment (bar

graph)

One hour: one segment (bar

graph)

Data hold

Auto power-off

Centigrade

Fahrenheit

Resistance

Continuity

Hz

V

A

RMS

PEAK

C.F.

Frequency

Voltage

Current

True RMS value

Peak value

Crest factor = Peak value /

Effective value

Input over (bar graph)

Battery consumption warning

Measurement Procedure

Preparation

Battery depleted.

"" lights.

The buzzer beeps three times to warn

that the battery must be replaced.

Measurements taken at this battery level

is not guaranteed for accuracy.

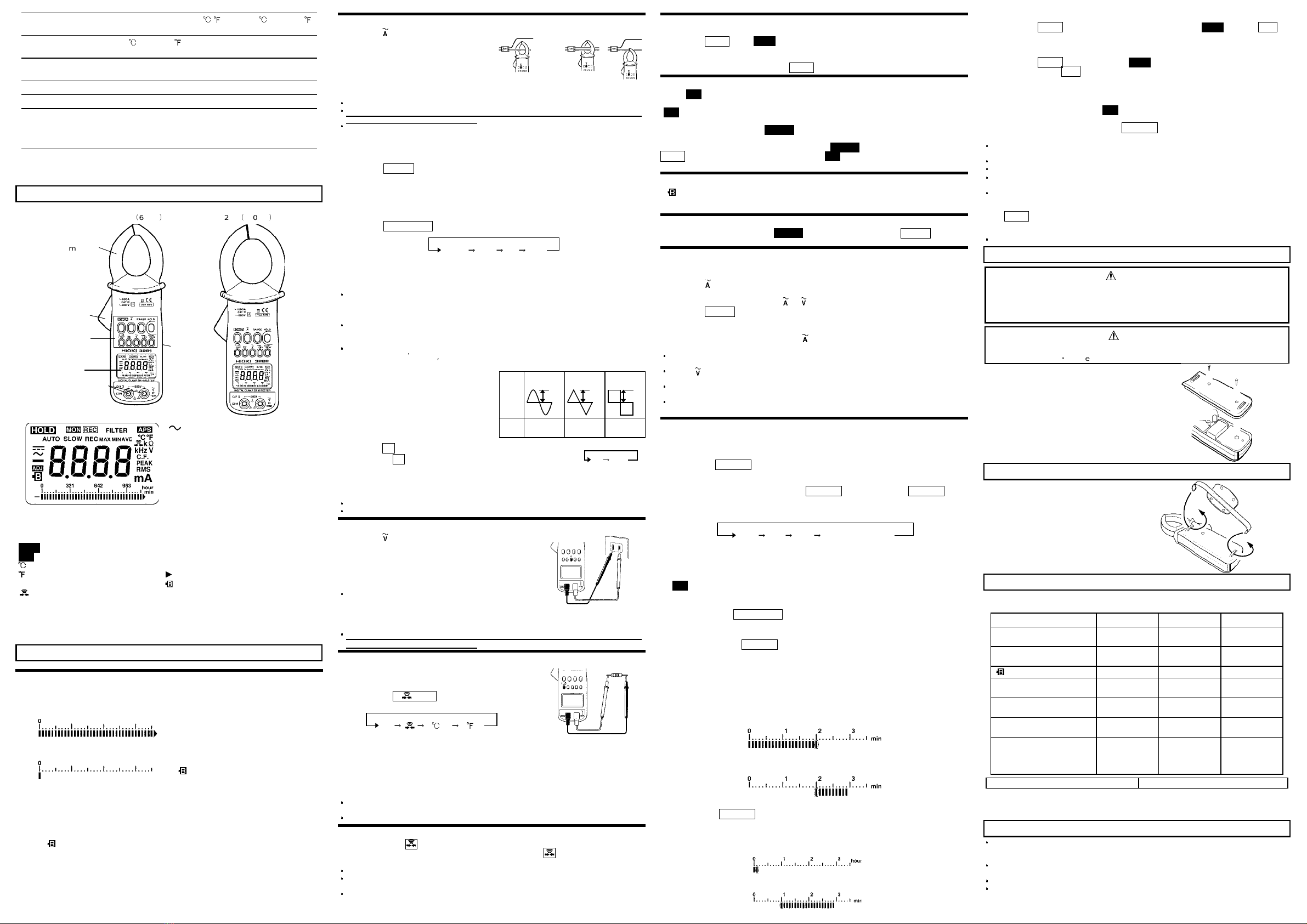

AC current (ACA) measurement A

OK

NG NG

Wave

form Peak

ave Peak

Triangular

wave Peak

C.F. 1.41 1.73 1

Hz RMS

AC voltage measurement V

Black Red

Plug in the test leads

Resistance measurement

Black Red

Continuity check

Data hold function HOLD

Auto power-off function APS

Battery consumption warning

Buzzer

FAST mode

Record function REC

MAX MIN AVE Instantaneous value

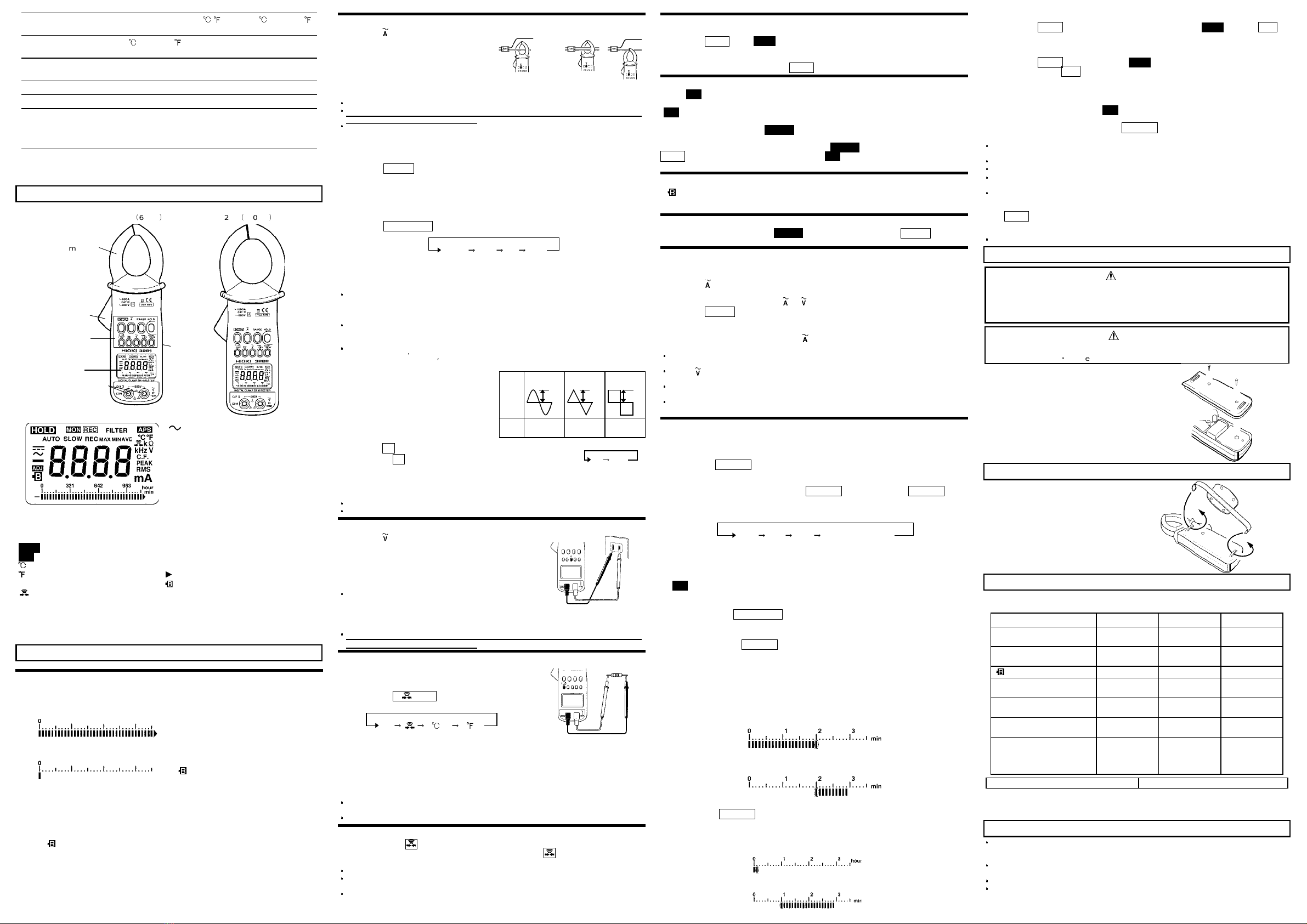

Battery Replacement Procedure

WARNING

When replacing the battery, be sure to insert them with the correct

polarity.

Otherwise, poor performance or damage from battery leakage could result.

Replace battery only with the specified type.

CAUTION

Do not fix the back casing screws too tightly.T

he torque about 0.5N

・

m is recommended.

How to Attach the Hand Strap

Troubleshooting

Symptom Battery Battery snap Test leads

The instrument cannot be

powered on. -

Power is cut off immediately

after it is turned on.*- -

"" lights. - -

The instrument is powered

off during operation.*-

Voltage measurement does

not function. - -

Resistance measurement

does not function. - -

Remedy:

If the trouble cannot be

remedied, send the

instrument for repair.

Replace with a

new battery. The terminals of

the battery snap

are poorly

contact.

Check the test

leads wiring.

An indication E.001 to E.005 appears. Send the instrument for repair.

Service

3. Accessories

Model L9207-10 Test Lead (black and red set), Instruction manual,Model 9399 Carrying

Case, Hand strap, 6F22 (006P) battery

*: The temperature measurement function is only available for customers

who have the THERMISTOR TEMPERATURE PROBE 9462.

Model 9462 will be discontinued effective May 18, 2011

1. Loosen the case back screw, and load the battery in the unit. (Refer to Battery

Replacement Procedure on page 11.)

2. Press the POWER key to power on the unit. Check to make sure that all display

segments light.

3. The instrument is in the AC current measurement state.

Low battery voltage detection function

After the mark lights and battery voltage drops below a certain level, the power goes

off automatically. When this occurs, bAtt and Lo are displayed.

When power goes off after display of these marks, replace the exhausted battery with a

new one.

1. Press the key.

2. Position the conductor within the clamp

sensor centered.

Make sure that only one conductor is in

the clamp sensor.

The effective value (RMS) of current is

displayed in the digital and bar graph.

Ranging is automatic (AUTO).

NOTE

Use data hold function when you abolish indication and want to read it.

Please note that waveforms that include elements outside the frequency characteristic

range may not be measured correctly.

Current measurements exceeding 600 A AC should be of short duration. Heat builds

up in the clamp sensor proportionate to the current value, and will reach a dangerous

level over a long period of time.

Range selection

Pressing the RANGE key repeatedly cycles through the 30 A, 300 A, 600 A and AUTO

ranges.

Changing the display update SLOW

When the readings fluctuate and are difficult to take, it is possible to make the display

update slow (approx. once per three seconds), and the readings easy to take. The

screen-updating speed cannot be changed for the bar-graph display.

Pressing the SLOW/PEAK key repeatedly changes the display as follows.

Peak value display PEAK

The peak value is displayed. The effective value is displayed in the bar graph.

NOTE

Mode displaying the PEAK (peak value) of a continuous wave which lasts for more

than 250 ms.

To keep the displayed value, use the recording function in the PEAK display mode

(refer to recording function REC 1.).

As there is a period whereby no sampling is done on this instrument, it may not be

possible to measure an instantaneous peak current that does not reach 250 ms, such

as the motor starting current, even when the recording function is used.

To accurately measure an instantaneous peak current such as an inrush current,

please use HIOKI

’

s 3284, 3285, and 3285-20.

Crest factor display C.F.

The crest factor of a waveform is displayed.

Crest factor = Peak value / Effective value

The crest factor of a sine waveform where

no distorted, and the harmonic components

are included.

When the crest factor of current is being

displayed, "A" flashes. The effective value is

displayed in the bar graph.

Frequency display Hz

1. Press the Hz key.

2. Pressing the Hz key changes the display.

3. The frequency of the current being measured is displayed.

When no input is applied, "----" is displayed. When measuring the current frequency,

"A" flashes. The effective value is displayed in the bar graph.

NOTE

When the frequency is lower than 30 Hz, "----" is displayed.

The AUTO range display indicates the current range.

1. Press the key.

2. The effective value (RMS) of voltage is displayed in

the digital display and bar graph.

The display update changing, and the peak value,

crest factor and frequency displays are possible as

well as in the AC current measurement.

NOTE

Be sure to use the test leads with the sleeves

attached when performing measurements in the CAT

III and CAT IV measurement categories. In the

CATII environment, if the tips of the test leads do not

reach the measurement object, remove the rigid insulating sleeve before measuring.

Please note that waveforms that include elements outside the frequency characteristic

range may not be measured correctly.

1. Insert test lead in the instrument as the figure.

2. Attach or remove the rigid insulating sleeve as

required by the measurement object.

3. Pressing the Ω//TEMP key repeatedly, and let me

indicate Ω. Changes the display as follows.

Ω

(Centigrade) (Fahrenheit)

*:The temperature measurement function is only

available for customers who have the THERMISTOR TEMPERATURE PROBE 9462.

Model 9462 will be discontinued effective May 18, 2011

4.The resistance value is displayed in the digital display and bar graph. Ranging is

automatic (AUTO).

NOTE

If a voltage is input, a warning beep will sound. Stop measurement immediately. (The

internal circuit is protected against up to AC 600 V.)

In some cases, the alarm does not beep for DC or DC weighted components.

1. Let me indicate " " in the same way as the resistance measurement.

2. The buzzer beeps at less than approximately 30 Ω, and " " flashes.

NOTE

The digital display indicates the measured resistance value.

If a voltage is input, a warning beep will sound. Stop measurement immediately. (The

internal circuit is protected against up to AC 600 V.)

In some cases, the alarm does not beep for DC or DC weighted components.

Data hold functions to "stop" the display at its present reading.

1. Press the HOLD key. "HOLD" appears, and the digital and bar graph displays are

held.

This function is effective for all measurement functions and modes.

To release this function, press the HOLD key again.

When "APS" is being displayed, the auto power-off function is effective.

The unit is powered off in approx. 10 minutes unless any key is pressed.

"APS" flashes and the alarm beeps for approx. 30 seconds just before the unit is

powered off.

Pressing a key other than the POWER key prolongs the auto power-off function for 10

minutes.

To release the auto power-off function, press the POWER key while holding down the

HOLD key to power on the unit. In this case, "APS" does not appear.

When using the record function, the auto power-off function is ineffective.

If is indicated, the battery power is running low and accuracy cannot be guaranteed.

Replace with a new battery. Refer to "Preparation" for the confirmation of the capacity of

the battery.

To turn off the buzzer, press the POWER key while holding down the RANGE key to

power on the instrument. The alarm and continuity buzzers cannot be turned off.

Make it FAST mode when you measure load currents with variations.

The digital display update can be set to approx. 4 times per second.

1. Press the key twice to set to the FAST mode.

"F" appears for an instance, and the unit enters the FAST mode.

Then "F" appears each time the or key is pressed.

2. Press the RANGE key to fix the current range.

3. It is convenient for taking readings to hold the maximum value (MAX) by using the

record function.

4. To release the FAST mode, press the key twice again.

NOTE

The stable measurement cannot be made unless the waveform lasts for more than

250 ms.

Push a key in the case of the voltage measurement as well after it is made FAST

mode.

This mode is not effective for the resistance, continuity and temperature

measurements.

If setting to the SLOW display in the FAST mode, the display update is the same as

in the normal mode (approx. twice per second).

Use the recording function to hold the maximum and minimum measured values and

maximum/minimum averages.

1. Measurement indicated value

Pressing the MAX/MIN key during measurements of current, voltage, or frequency

activates the recording function. REC flashes and the instrument saves the

maximum value (MAX), minimum value (MIN), and average value (AVE) in internal

memory from the instant you press the MAX/MIN key. Pressing the MAX/MIN key

with the recording function activated switches the display as shown below. If MAX,

MIN, or AVE is not displayed, an instantaneous value is assumed.

Data (MAX, MIN, AVE) remains displayed while the display is switched. If maximum

or minimum data is updated in the meantime, however, the data values will change.

With the recording function activated, the auto power-off function remains disabled.

(APS off.)

The average value (AVE) displayed is calculated by: Average Value = [(Maximum

value + Minimum Value)/2].

After pressing the SLOW/PEAK key to display the peak value, activate the recording

function and select MAX. The peak hold function will be activated.

2. Display of Elapsed Time

When you press the MAX/MIN key to activate the recording function, the bar graph

segments flash and the elapsed time appears.

When "min" is shown in the right-hand corner of the bar graph, each segment of the

bar graph corresponds to one minute. Every time one minute elapses, one segment

of the flashing bar graph goes on. When all segments on the bar graph go on, the

elapsed time is 30 minutes.

When the elapsed time exceeds 30 minutes, one segment of the flashing bar graph

goes off every time one minute elapses.

When the segments left of a flashing segment remain on: the number of "on"

segments represents the elapsed time (0 to 29).

The illustration below shows when 20 minutes have elapsed:

When the segments right of a flashing segment remain on: the number of "off"

segments (+30) represents the elapsed time (30 to 59).

The illustration below shows when 50 minutes have elapsed:

When digital display switches the average value (AVE) to a instantaneous value when

you press the MAX/MIN key, the right corner of the bar graph indicates hours. In this

mode, each segment of the bar graph corresponds to one hour. The way to read the

bar graph here is similar to reading it in minutes. When all bar graph segments

remain on, the elapsed time is 29 hours.

The illustration below shows when one hour, 40 minutes have elapsed.

3. Deactivation of Recording Function

Pressing the HOLD key deactivates the recording function. HOLD goes on, REC

stops flashing and goes on, and the elapsed time stops incrementing. While the

recording function is being deactivated, data is not updated, even if the clamp sensor

is disconnected from the conductor.

Pressing the HOLD key again cancels HOLD display and activates the recording

function again, with REC flashing again.

4. Cancellation and Resetting of Recording Function

To cancel the recording function, press the related function key (A, V or Hz) for the

measurement in progress. Once the recording function is canceled, the auto power-

off function becomes effective. (APS goes on.)

To restart the unit after resetting the data, temporarily cancel the recording function,

then activate it again by pressing the MAX/MIN key.

Note

An instantaneous power failure and a surge cannot be detected. The record function

is not effective for the resistance and temperature measurements.

The maximum recording duration depends on the remaining battery capacity.

The lowest possible frequency that can be displayed is 30 Hz.

If changing the range when "O.L." is being displayed in any of the displays, the held

data and elapsed time are cleared.

When you need minimum value and average value data, make sure to activate the

recording function during measurement. If the function is activated when there is no

input, the minimum value will remain zero. To deactivate the recording function, press

the HOLD key to terminate measurement. If you disconnect the clamp sensor or test

lead from the circuit under measurement without deactivating the recording function

beforehand, the minimum value will be zero.

When the unit is turned off, accumulated data are lost.

1. Remove the two back casing screws, and take

off the back casing.

2. Remove the old battery without pulling the

codes of the snap.

3. Install a new battery in the battery snap

securely.

4. Attach the back casing.

The hand strap improves the operation.

Although the instrument seems to be out of order in the following cases, there may be

the causes of the troubles. Check it again before you send it for repair.

*:When the battery is drained, the relay may be operated immediately after the power

is turned on or when the measurement function is changed, and the power may

suddenly be cut off. Replace the battery with a new one when this arises.

To clean the instrument, wipe it gently with a soft cloth moistened with water or mild

detergent. Never use solvents such as benzene, alcohol, acetone, ether, ketones,

thinners or gasoline, as they can deform and discolor the case.

The shortest period for possession of the repair parts is 5 years after stopping the

production.

For inquiries about service, contact your dealer or Hioki representative.

Pack the instrument carefully so that it will not be damaged during shipment, and

include a detailed written description of the problem. Hioki cannot be responsible for

damage that occurs during shipment.