Circutor CDP Supplement

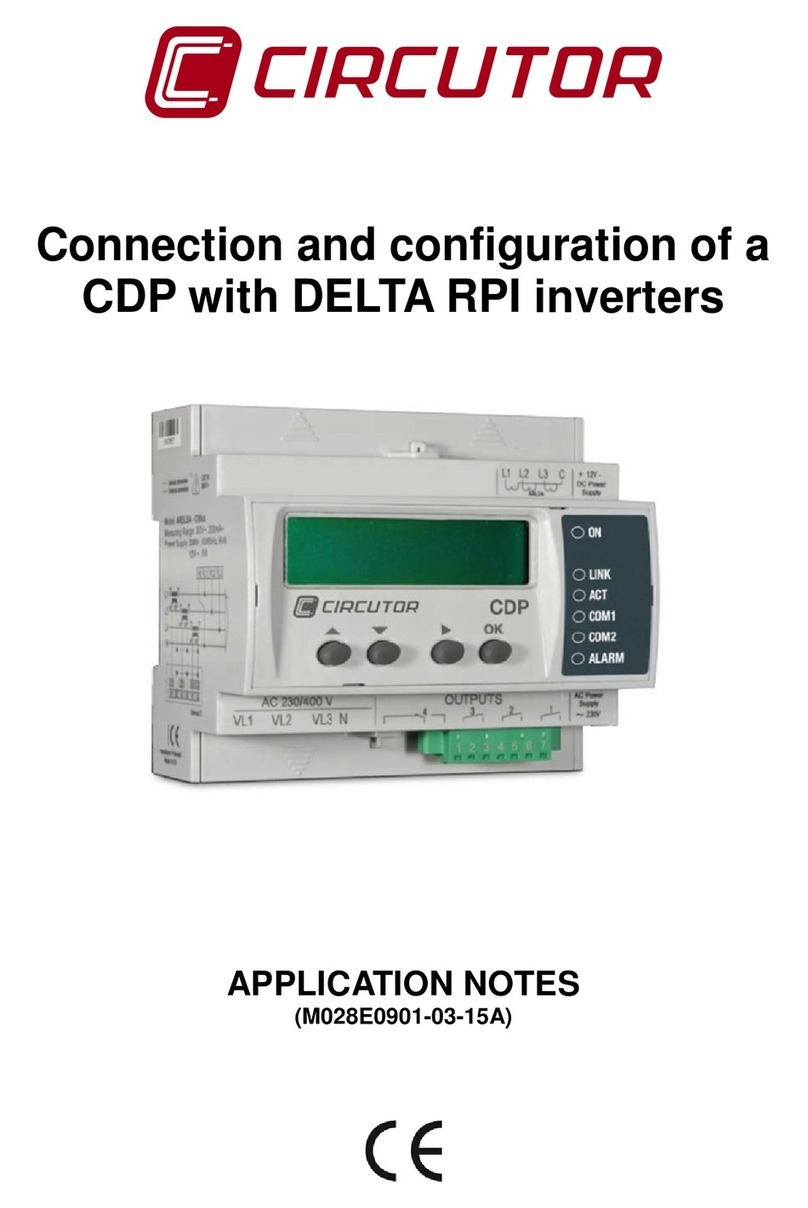

Connection and configuration of a

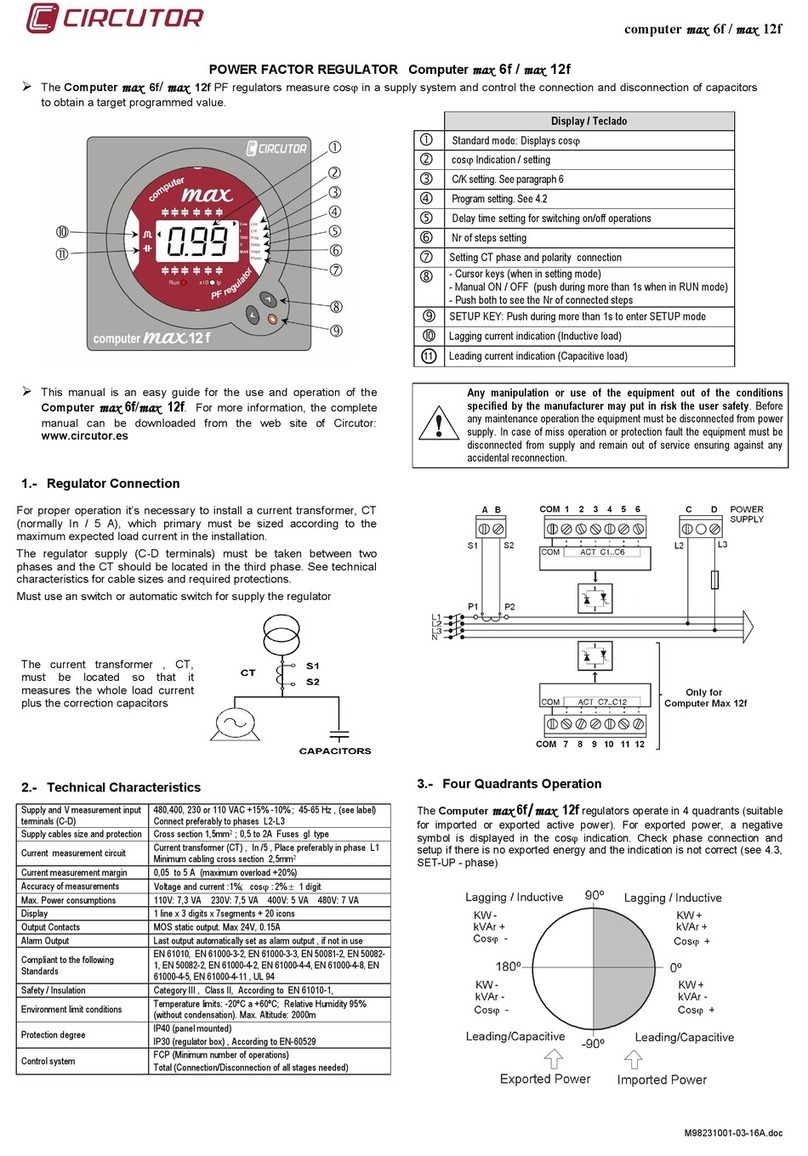

CDP with Fronius MB inverters

APPLICATION NOTES

(M028E0601-03-19A)

CDP

2Application notes

CDP

Application notes 3

SAFETY PRECAUTIONS

Follow the warnings described in this manual with the symbols shown below.

DANGER

Warns of a risk, which could result in personal injury or material damage.

ATTENTION

Indicates that special attention should be paid to a specific point.

If you must handle the unit for its installation, start-up or maintenance, the follow-

ing should be taken into consideration:

Incorrect handling or installation of the unit may result in injury to personnel as well

as damage to the unit. In particular, handling with voltage applied may result in elec-

tric shock, which may cause death or serious injury to personnel. Defective installa-

tion or maintenance may also lead to the risk of fire.

Carefully read the manual prior to connecting the unit. Follow all installation and

maintenance instructions throughout the unit's working life. Pay special attention to

the installation standards of the National Electrical Code.

Consult the instruction manual before using the unit

In this manual, if the instructions marked with this symbol are not respected or fol-

lowed correctly, it can result in injury or damage to the unit and /or installations.

CIRCUTOR, SA reserves the right to modify features or the product manual without prior notification.

DISCLAIMER

CIRCUTOR, SA reserves the right to make modifications to the device or the

unit specifications set out in this instruction manual without prior notice.

CIRCUTOR, SA, on its web site, supplies its customers with the latest versions

of the device specifications and the most updated manuals.

www.circutor.com

CDP

4Application notes

CONTENTS

SAFETY PRECAUTIONS.................................................................................................................... 3

DISCLAIMER........................................................................................................................................ 3

CONTENTS .......................................................................................................................................... 4

LOG OF REVISIONS ........................................................................................................................... 5

1.- INTRODUCTION............................................................................................................................. 6

2.- FRONIUS GALVO, PRIMO, SYMO AND ECO INVERTER WITH WLAN ................................. 7

2.1.-COMMUNICATION CABLE ..........................................................................................................7

2.1.1. INVERTER CONNECTION ...................................................................................................8

2.1.2. CONNECTION OF SEVERAL INVERTERS .......................................................................9

2.2.-INVERTER COMMUNICATION CONFIGURATION ...............................................................10

2.2.1. PERIPHERAL NUMBER CONFIGURATION....................................................................10

2.2.2 PROTOCOL TYPE CONFIGURATION...............................................................................11

3.- FRONIUS IG PLUS INVERTER WITH MODBUS CARD.......................................................... 12

3.1.-COMMUNICATION CABLE ........................................................................................................12

3.1.1. INVERTER CONNECTION .................................................................................................12

3.1.2. CONNECTION OF SEVERAL INVERTERS .....................................................................13

3.2.-INVERTER COMMUNICATION CONFIGURATION ...............................................................14

4.- CDP CONFIGURATION ............................................................................................................... 20

5.- COMMUNICATIONS TEST AND REGULATION....................................................................... 22

5.1.-COMMUNICATIONS TEST ........................................................................................................22

5.2.-REGULATION TEST....................................................................................................................23

6.- MAINTENANCE AND TECHNICAL SERVICE .......................................................................... 24

7.- GUARANTEE................................................................................................................................ 24

CDP

Application notes 5

LOG OF REVISIONS

Table 1: Log of revisions.

Date

Revision

Description

03/15

M028E0601-03-15A

Original version

09/15 M028E0601-03-15B

Changes in the following sections:

2.- 2.1.2. – 3.1.- 3.1.2.- 4.1.2.

10/15 M028E0601-03-15C

Changes in the following sections:

1. – 2.1. – 3.1. – 4.1. – 4.2.1.- 5 – 6

11/15 M028E0601-03-15D

Changes in the following sections:

2.2.1. – 3.2. – 6.2.1.

03/16 M028E0601-03-16A

Changes in the following sections:

2.2.1. – 3.2. –4.2.1.- 5.2.1.- 6.2.1.

05/19 M028E0601-03-19A

Changes in the following sections:

1– 2.

Note:The images of the units are solely for the purpose of illustration and may differ

from the original unit.

CDP

6Application notes

1.- INTRODUCTION

Fronius offers several inverter models that can be managed via the CDP Dynamic

power controller.

For the CDP controller to be able to correctly manage the inverter, communication

between the two devices must be correct and both products must be correctly

programmed.

These application notes are not meant as a substitute for the CDP

or

inverter manuals, but ra

ther as additional support for individuals who

need to interconnect the two devices.

However, the guides and manuals of each product are the documents to be

consulted and each company will provide the respective technical assistance.

In these application notes, we will work with five different Fronius models:

1. Fronius Galvo WLAN (single-phase)

2. Fronius IG Plus with MODBUS CARD (single-phase or three-phase)

3. Fronius Symo WLAN (three-phase)

4. Fronius ECO WLAN (three-phase)

5. Fronius Primo WLAN (single-phase)

The CDP stores the nominal power value of the inverter to be controlled in its

configuration and periodically sends the inverter the percentage of said power to

be generated. Consequently, when the CDP communicates with the Fronius

inverter it is constantly sending it a regulation percentage.

Some models do not accept a regulation that is less than 10% of the nominal

power, and thus if consumption is below this threshold the inverter will not inject

any power into the mains even during periods of maximum insolation.

Consequently, it is advisable to consult this data in the inverter manual in

order to clarify any doubts.

CDP

Application notes 7

2.- FRONIUS GALVO, PRIMO, SYMO AND ECO INVERTER WITH WLAN

Figure 1: Communications card integrated in the inverter.

Communication between the CDP and the inverter is done through the Fronius

integrated communications card via an RS-485 bus.

Note:This connection is as well valid for inverters with Data Manager Box 2.0

external card.

2.1.- COMMUNICATION CABLE

List of communication cable terminals between the CDP and the integrated

communications card of the Fronius inverter:

Table 2: List of communication cable terminals.

CDP

R2 channel

communications connector

Communications card

Terminal

Description

Terminal

1

A+

D+

3

B -

D-

5

GND

GND

The communications card has a final switch bus for communications between

CDP and the inverter which is located on the bottom of the antenna WLAN that

must be on “ON” position as shown in the Figure 2.

CDP

8Application notes

Figure 2: Final switch bus position.

2.1.1. INVERTER CONNECTION

Figure 3 shows the connection between the CDP and a single inverter.

Connect the end bus terminal to the IN and OUT terminals.

Figure 3: Connection between a CDP and a single Fronius inverter.

The master / slave selector must be in the Master position (Figure 4).

Figure 4: Master / Slave selector.

CDP

Application notes 9

2.1.2. CONNECTION OF SEVERAL INVERTERS

Figure 5 shows the connection between the CDP and several inverters.

Figure 5: Connection between a CDP and several Fronius inverters.

The master / slave selector must be in the Master position (Figure 4).

If there are several inverters, the communication cable connecting them must go

from the “OUT” terminal of the first inverter to the “IN” terminal of the next inverter.

The same holds for the remaining inverters until the last one is reached, which

must always have the bus end terminal on the "OUT" connector.

The communication cable between the inverters is a pin-to-pin cable with RJ45

connectors on both ends. This type of cable can be purchased at any computer

supply store as it is a common connector used for PCs and other devices with an

Ethernet port.

The bus end terminal must always be connected to the last inverter of the bus.

This terminal is an RJ45 connector that must always be connected to the ‘OUT’

terminal of the inverter.

Table 3: Bus end terminal

Connector PIN

RJ45

Description

of the signal

Description of the

connection

1

Power supply

2

GND

3 and 4

RxD+ / TxD+

Cross cables 3 and 4

5 and 6

TxD- / RxD-

Cross cables 5 and 6

7

GND

8

Power supply

CDP

10 Application notes

2.2.- INVERTER COMMUNICATION CONFIGURATION

The following describes how to use the display to configure the inverter for

ensuring correct communication with the CDP.

The AC side of the inverter must be connected to the mains before it can

turn on.

Consult the inverter manual if you have any doubts.

The parameters to be configured are:

Peripheral number

Protocol type

2.2.1. PERIPHERAL NUMBER CONFIGURATION.

Go to the following path to change the peripheral number of the inverter:

Config

DATCOM

Inverter number

Figure 6: Access to the setup menu.

Press ‘+’ and ‘-‘ to increase or lower the value.

Press the button to move through the digits and to confirm the programmed

value

If there is only 1 inverter, the peripheral number must be 01 (the default value is

01).

If there are several inverters in cascade, which can either be single-phase

connected to the same phase or three-phase connected to the same three-phase

AC mains (all connected to the same phase), they must have consecutive

numbers from 01.

If there are multiple sets of 3 single-phase inverters connected to a three-phase

network, with each occupying one phase, the configuration must be as follows:

- Inverters connected to phase 1: peripheral number between 01-33

- Inverters connected to phase 2: peripheral number between 34-66

- Inverters connected to phase 3: peripheral number between 67-99

CDP

Application notes 11

2.2.2 PROTOCOL TYPE CONFIGURATION

For correct communication between the CDPand the inverter, the inverter must

be set up with the SOLAR NET protocol.

Go to the following path to change the protocol of the inverter:

Config

DATCOM

Protocol type

1. Use the arrows to move until the SOLAR NET text appears.

2. Confirm the selection with the button, and the SOLAR NET text will flash.

3. Press the button again to validate the selection.

Enter the following menu path to ensure correct inverter programming:

Config

DATCOM

DATCOM Status

The display will show the following parameters:

Status: Solar Net

Baudrate: 9600

OkCnt: 0(1)

ErCnt: 0(2)

(1) Indicates the frames sent correctly between the CDP and the inverter.

(2) Indicates the frames sent incorrectly between the CDP and the inverter.

CDP

12 Application notes

3.- FRONIUS IG PLUS INVERTER WITH MODBUS CARD

The CDP and the inverter communicate via an RS-422 bus. This RS-422 bus can

connect up to 100 inverters, although the number of inverters in the vast majority

of domestic installations ranges from 1 to 3.

For data communication between inverters, each inverter must have a Com Card

communications card installed (this card is ordered as optional for the inverters).

3.1.- COMMUNICATION CABLE

List of communication cable terminals between the CDP and the inverter:

Table 4: List of communication cable terminals.

CDP

R2 channel communications

connector

INVERTER

Conector OUT (RJ45)

Terminal

Description

Terminal

Description

1

TxD+

3

RxD+

4

RxD+

4

TxD+

2

RxD -

5

TxD-

3

TxD -

6

RxD-

3.1.1. INVERTER CONNECTION

Figure 6 shows the connection between the CDP and a single inverter.

The communication cable must be connected to the inverter "OUT" terminal and

the bus end terminal must be connected to the "IN" terminal.

Figure 7: Connection between a CDP and a single Fronius IG Plus inverter.

CDP

Application notes 13

3.1.2. CONNECTION OF SEVERAL INVERTERS

Figure 7 shows the connection between the CDP and several inverters.

Figure 8: Connection between a CDP and several Fronius IG Plus inverters.

If there are several inverters, the communication cable connecting them must go

from the “IN” terminal of the first inverter to the “OUT” terminal of the next inverter.

The same holds for the remaining inverters until the last one is reached, which

must always have the bus end terminal on the "IN" connector.

The communication cable between the inverters is a pin-to-pin cable with RJ45

connectors on both ends. This type of cable can be purchased at any computer

supply store as it is a common connector used for PCs and other devices with an

Ethernet port.

The bus end terminal must always be connected to the last inverter of the RS-

422 communication bus. This terminal is an RJ45 connector that must always be

connected to the ‘IN’ terminal of the inverter.

Table 5: Bus end terminal

Connector PIN

RJ45

Description

of the signal

Description of the

connection

1

Power supply

2

GND

3 and 4

RxD+ / TxD+

Cross cables 3 and 4

5 and 6

TxD- / RxD-

Cross cables 5 and 6

7

GND

8

Power supply

CDP

14 Application notes

3.2.- INVERTER COMMUNICATION CONFIGURATION

Three parameters need to be changed in this type of inverter in order to obtain

correct communication between the CDP and the inverter.

Table 6: Configuration parameters for communication with the CDP.

Description

Value for communication

with the CDP

Peripheral number 00

Communications protocol DAT_COM

Communication speed 9600

If there are several inverters in cascade, which can either be single-phase

connected to the same phase or three-phase connected to the same three-phase

AC mains (all connected to the same phase), they must have consecutive

numbers from 01.

If there are multiple sets of 3 single-phase inverters connected to a three-phase

network, with each occupying one phase, the configuration must be as follows:

- Inverters connected to phase 1: peripheral number between 01-33

- Inverters connected to phase 2: peripheral number between 34-66

- Inverters connected to phase 3: peripheral number between 67-99

Part of the 42_0410_1564_168027_snapshot.pdf Fronius document is shown

below, in which the configuration process is explained.

(Documentation taken with the authorisation of Fronius).

CDP

Application notes 15

CDP

16 Application notes

CDP

Application notes 17

CDP

18 Application notes

CDP

Application notes 19

CDP

20 Application notes

4.- CDP CONFIGURATION

The CDP has a configuration web site where all the parameters of the connected

inverter have to be entered.

To do so, enter "/setup" at the end of the navigation bar where the CDP is

monitoring so that the following, for example, appears in the navigation bar:

“10.0.110.212/setup”

The CDP configuration window will then open ( Figure 9).

Figure 9: CDP configuration web site:

Table of contents

Other Circutor Controllers manuals

Circutor

Circutor computer MAX 6 User manual

Circutor

Circutor Computer SMART III FAST 6 User manual

Circutor

Circutor FastComp 12rt User manual

Circutor

Circutor max 12f User manual

Circutor

Circutor Computer SMART III 6 User manual

Circutor

Circutor Computer SMART III FAST 12Vdc User manual

Circutor

Circutor CDP series Supplement

Circutor

Circutor CDP series Supplement

Circutor

Circutor CDP series Supplement

Circutor

Circutor computer max 6f User manual