ii

THETABLE OF CONTENTS

1. GENERAL OUTLINE .......................................................................... 1

1.1 Features ....................................................................................................................1

1.2 Uses.......................................................................................................................... 1

2. BASIC SPECIFICATIONS .................................................................. 3

2.1 Classification of Equipment..................................................................................... 3

2.1.1 PRU Series (Presenter Unit)............................................................................ 3

2.1.2 PMU Series (Printer Mechanism Unit) ........................................................... 3

2.1.3 PHU Series (Paper Holding Unit) ................................................................... 3

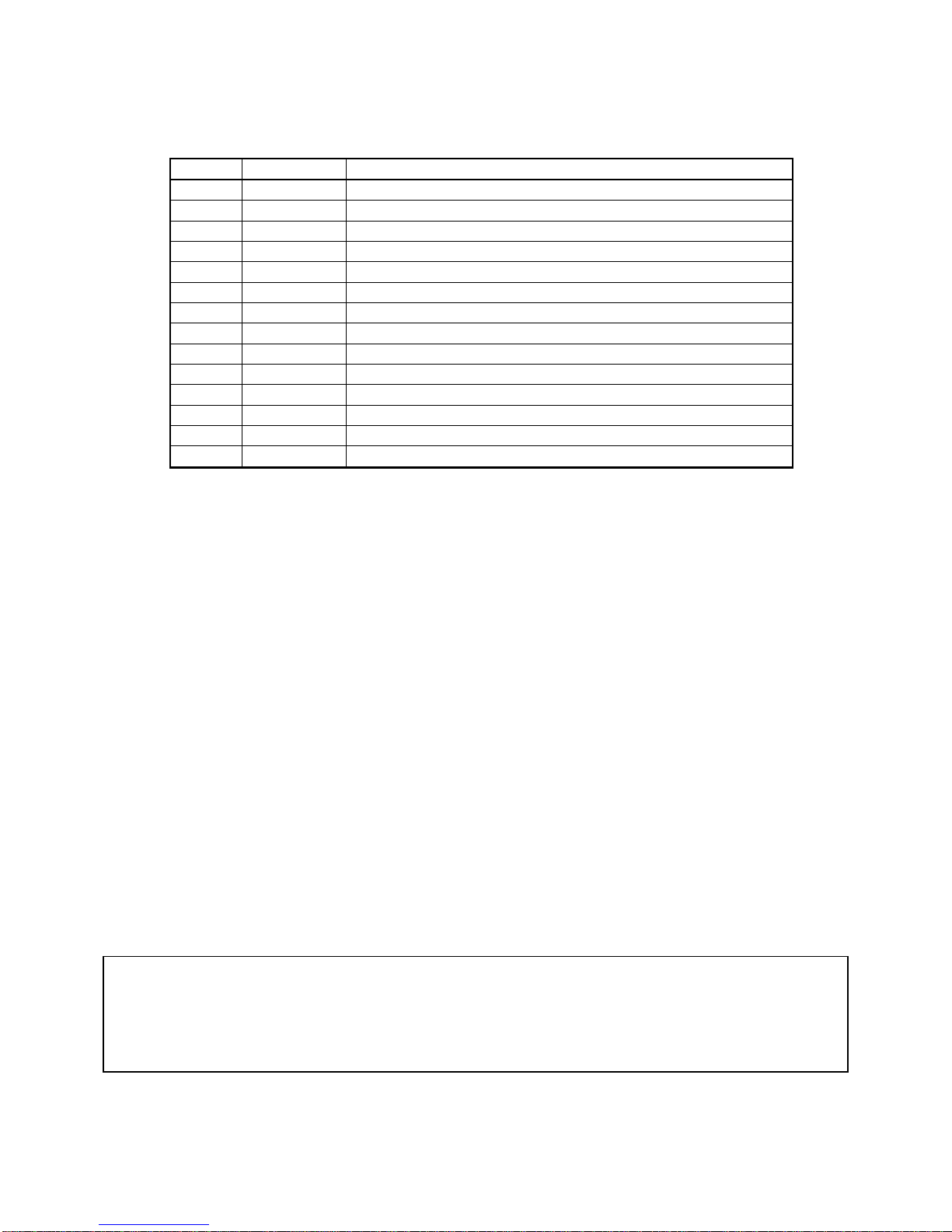

2.2 Specifications Lists .................................................................................................. 4

2.2.1 PRU Series (Presenter Unit)............................................................................ 4

2.2.2 PMU Series (Printer Mechanism Unit) ........................................................... 7

2.2.3 PHU Series (Paper Holding Unit) ................................................................... 7

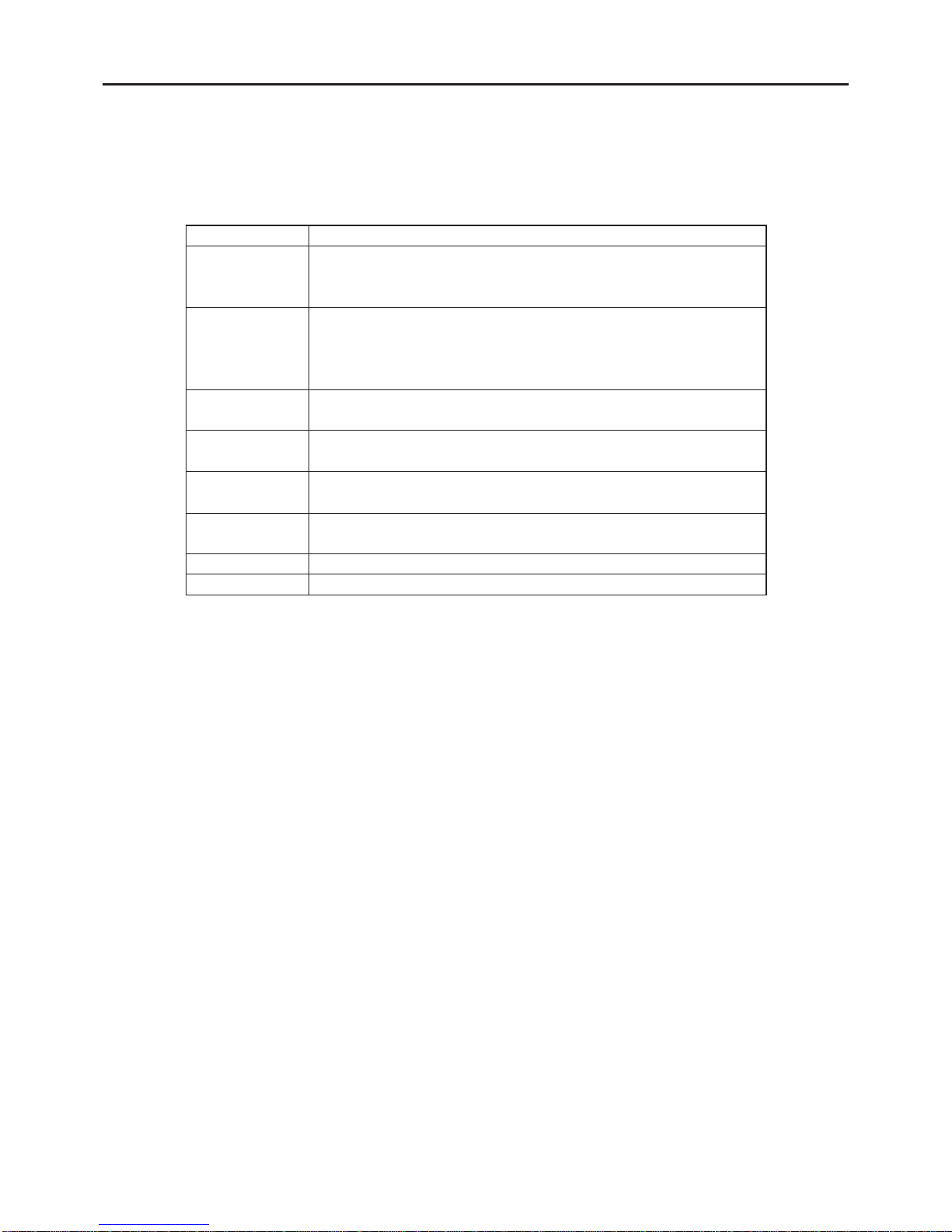

2.3 Designing PRU and PMU Unit Installation ............................................................. 8

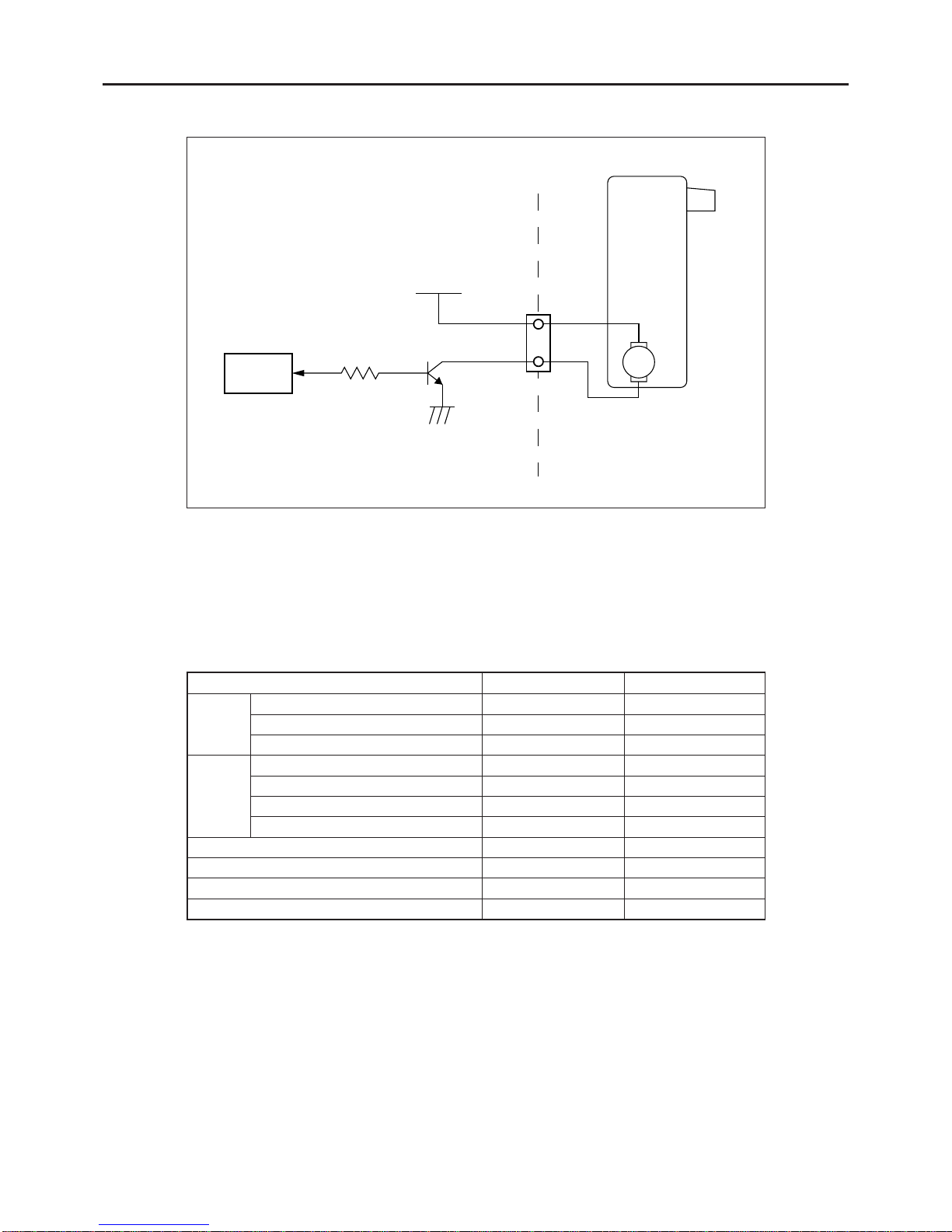

3. CONNECTION TERMINALS........................................................... 10

3.1 Connection Terminals ............................................................................................ 10

3.1.1 Presenter’s Connection Terminals ................................................................. 10

3.1.2 Auto-Cutter’s Connection Terminals............................................................. 11

3.2 PMU Connection Terminals .................................................................................. 12

4. FLOW CHART ........................................................................... 15

4.1 PRU Unit Initialization at Power On ..................................................................... 15

4.2 Printing (Issuing Receipts)..................................................................................... 17

4.3 Outputting Printed Paper ....................................................................................... 18

5. TIMING CHART ........................................................................ 19

5.1 PRU Timing Chart ................................................................................................. 19

5.2 PPU Timing Chart (Controlled by paper sensor)................................................... 20

6. DESIGN CONSIDERATIONS .................................................... 21