Claas 930 Installation guide

Other Claas Farm Equipment manuals

Claas

Claas LEXION 570 Montana User manual

Claas

Claas LEXION 600 Operating instructions

Claas

Claas LEXION Operating instructions

Claas

Claas TUCANO 500 Installation guide

Claas

Claas AVERO Installation guide

Claas

Claas JAGUAR 8500 C Guide

Claas

Claas CROP TIGER 40 WHEEL User manual

Claas

Claas TUCANO 2017 Installation guide

Claas

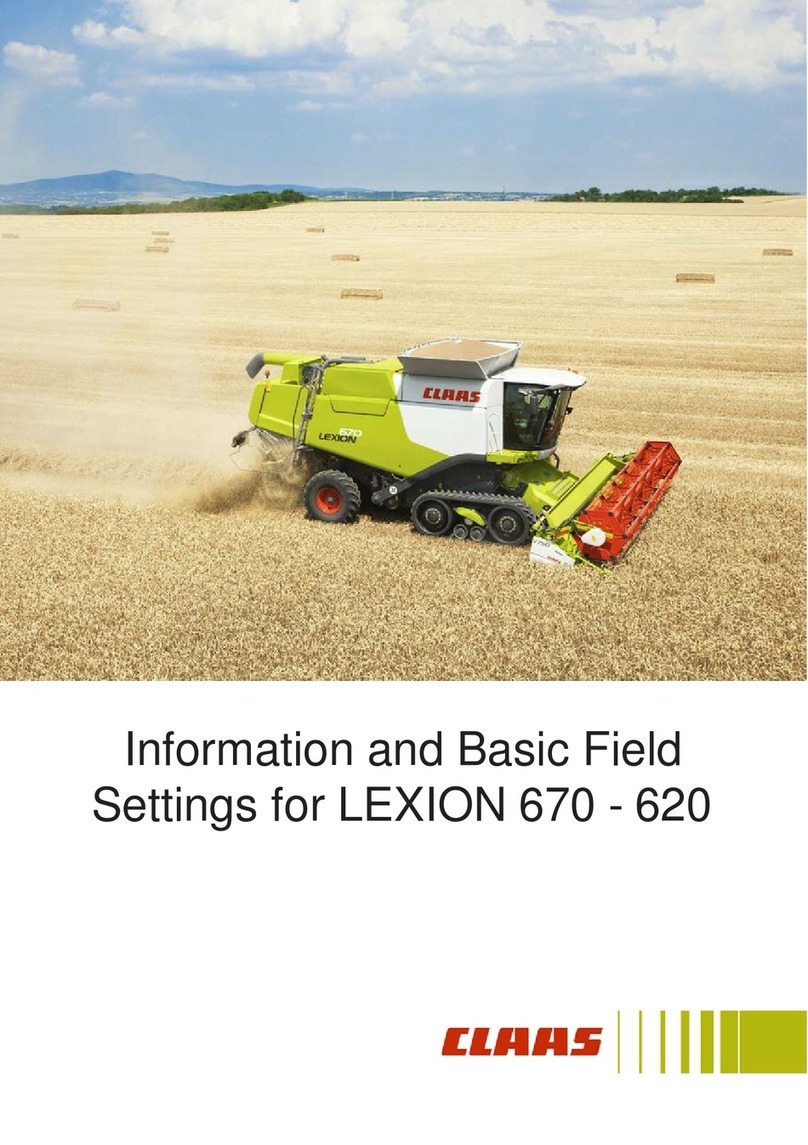

Claas LEXION 670 User manual

Claas

Claas 930 Installation guide

Claas

Claas QUANTUM 3500 Guide

Claas

Claas ROLLANT 250 Operating instructions

Claas

Claas DOMINATOR 68 S User manual

Claas

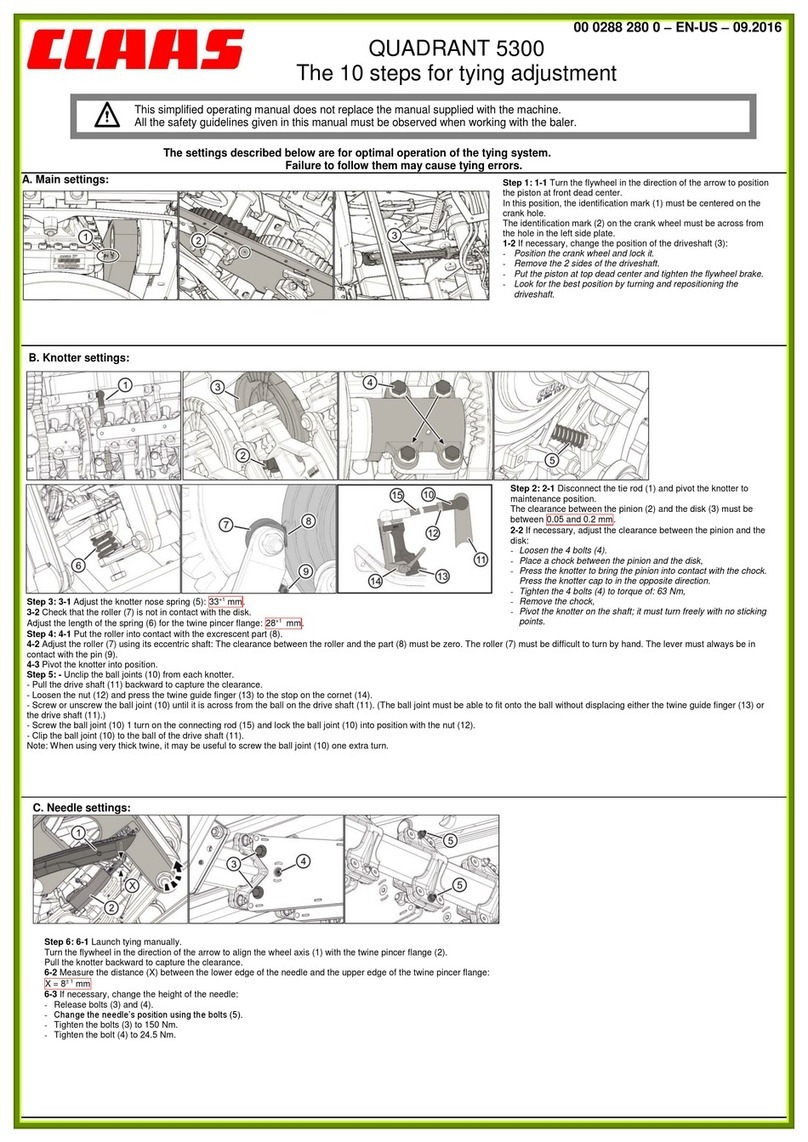

Claas QUADRANT 5300 User manual

Claas

Claas LEXION 8000 Installation guide

Claas

Claas MEDION 340 Operating instructions

Claas

Claas LEXION 480 Operating instructions

Claas

Claas TARGO K50 Operating instructions

Claas

Claas LEXION 560 User manual

Claas

Claas TUCANO 400-300 Installation guide

Popular Farm Equipment manuals by other brands

McHale

McHale Fusion 3 Operator's instruction manual

LOFTNESS

LOFTNESS Battle Ax 207460 Owner's manual and parts book

horsch

horsch Cultro 18 TC operating instructions

Pottinger

Pottinger ROLLPROFI 6165 Operator's manual

Raven

Raven AccuBoom installation manual

GOLDONI

GOLDONI SPECIAL LUX Operation and maintenance