Clarience Technologies Davco Penske Shop Pro ST User manual

Updated 09/08/2020

FOR UPDATED INFORMATION VISIT WWW.DAVCO.COM

PENSKE SHOPPRO®ST

WITH 50/80 PSI REGULATOR

TECHNICAL MANUAL

F1325 REV F

TABLE OF CONTENTS

Applications and Features............................................... 1

ShopPro®ST Components .............................................. 2

EImportant Safety Precautions .........................................3

Set-up and Maintenance ................................................ 4

Hoses and Adapters .................................................... 5

Hose Connections for Removing Fuel.................................... 6

Removing Fuel from the Fuel Module .................................... 7

Removing Fuel from the Fuel Pro ........................................ 8

Hose Connections for Priming........................................... 9

Priming the Engine Fuel System with ESOC .............................10

Priming the Fuel Module with Compucheck Adapter ....................11

Hose Connections for Priming At 50 PSI ................................12

Fuel Tank Sweeping with Filtration......................................15

Fuel Transfer with Filtration ............................................16

Service Parts ..........................................................17

Service Parts - Adapters................................................18

Warranty Policy ........................................................19

Parts Return Policy ....................................................20

1

DAVCO Technology, LLC www.davco.com800-328-26111600 Woodland Drive, Saline, MI 48176-1629 F1325 REV F

SHOP PRO®ST FOR PTL

WITH 50/80 PSI PRESSURE REGULATOR

TECHNICAL MANUAL

APPLICATIONS AND FEATURES

EProduct Warning: The ShopPro is only

approved for use with diesel fuel. It is

not approved for use with gasoline or

any other flammable liquids.

Applications

• Removing Fuel

• Priming after Filter Service

- Eliminates the use of hand priming pumps after

performing maintenance

- Uses on-board fuel to prime engines and filters, avoids

the hassle of keeping reserve fuel on hand

- Eliminates cross contamination of fuel

• Fuel Transfer

- Filters and transfers fuel in one operation

- Transfers fuel when repairing tanks or crossover lines

- Transfers fuel for trucks being sold or taken out of

service

• Tank Cleaning

- Removes contaminated fuel, sediment and water from

fuel tanks of diesel powered equipment or from diesel

storage tanks

- Cleans fuel tanks during service — can be a value

added service or a new revenue stream

- Eliminates downtime due to fuel contamination

Specifications

• Height: 24" handle down, 38" handle up

• Width: 21"

• Depth: 24"

• Weight: 35 lbs

• Electric Motor: 12VDC, 3000 RPM, UL

®Listed

• Flow Rate: 12VDC: 91 GPH

ShopPro Filtration

• All-in-one fuel filter and water separator for diesel fuel

• Superior fuel/water separation

• Easy to access drain

• Lightweight aluminum construction

Features

• Cart

- Heavy-duty steel construction

- Portable and self-contained

• Electrical

- UL

®Listed, rear-facing receptacle

- Waterproof ON/OFF switch

- 12VDC connection

• Pump and Motor

- Electric motor/pump combination rated for continuous

operation

- UL

®Listed and CSA approved

• Adapters and hoses

- No-drip fittings

- Color-coded for function

• Regulator

- 50 psi (handle up, range of 45 psi to 50 psi) for use on

MaxxForce Engines

- 80 psi (handle down, range of 75 psi to 80 psi) for use

on other applications

2

DAVCO Technology, LLC www.davco.com800-328-26111600 Woodland Drive, Saline, MI 48176-1629 F1325 REV F

SHOP PRO®ST FOR PTL

WITH 50/80 PSI PRESSURE REGULATOR

TECHNICAL MANUAL

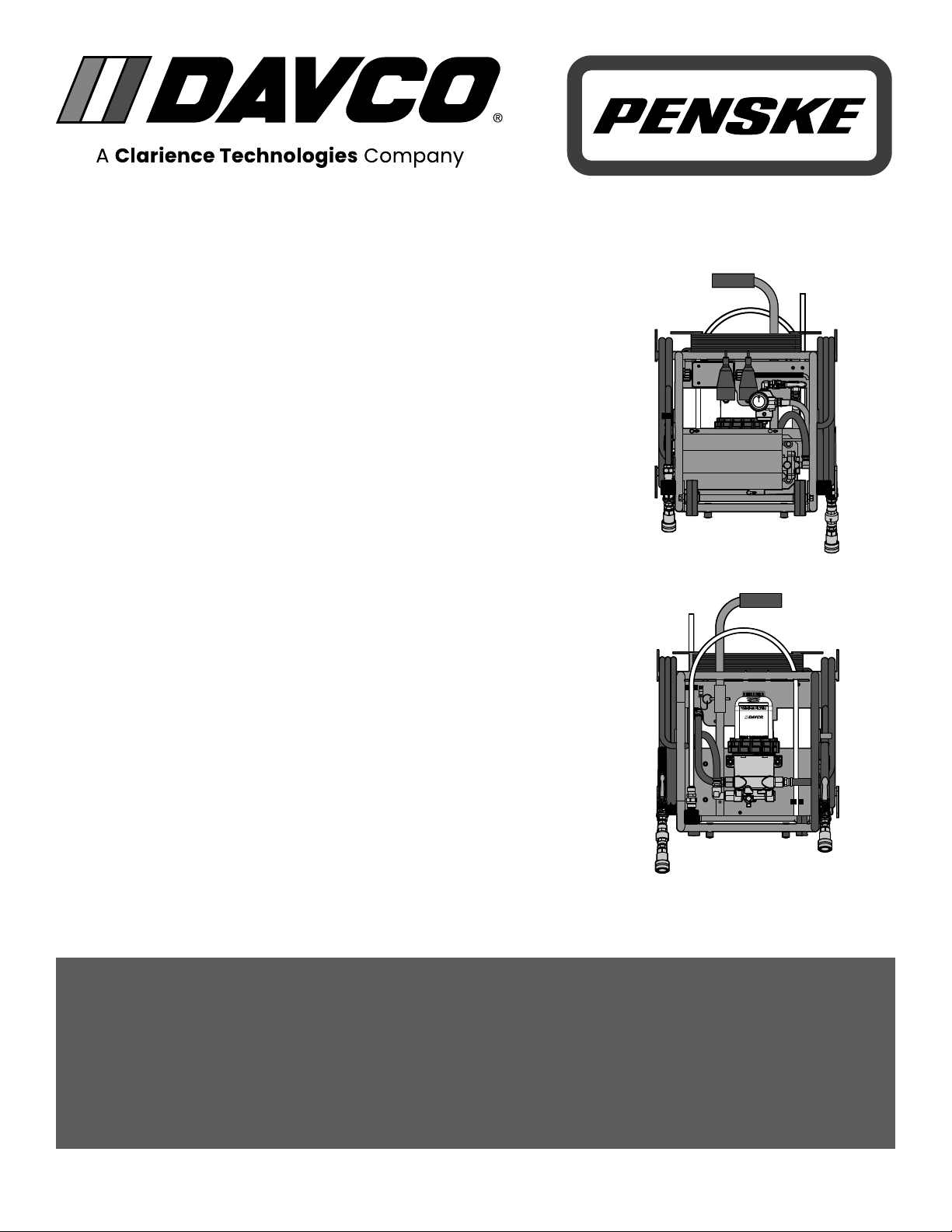

SHOPPRO®ST COMPONENTS

CAUTION: THE CORRECT ESOC ADAPTER MUST BE USED TO PREVENT FUEL LEAKAGE.

*Use Yellow Hose ESOC Adapter for (old) silver ESOC fitting. **Use Black Hose ESOC Adapter for black or (new) silver ESOC fitting.

Power Connection

Motor

Pump

On/Off Switch

Handle

Filtration

Unit

Dispensing Wand

Pressure Hose

Pick-up Wand

Drain

Suction Hose

3

DAVCO Technology, LLC www.davco.com800-328-26111600 Woodland Drive, Saline, MI 48176-1629 F1325 REV F

SHOP PRO®ST FOR PTL

WITH 50/80 PSI PRESSURE REGULATOR

TECHNICAL MANUAL

FIMPORTANT SAFETY PRECAUTIONS

General Safety Precautions

• The ShopPro is only approved for use with diesel fuel. It is not approved for use with gasoline or any other flammable

liquids.

• Read all instructions before use to avoid injury.

• To avoid serious injury or death, follow the safety information in this document.

• Keep this manual. If you need to replace the manual, call customer service at 800-328-2611 or visit www.davco.com for a

replacement.

• Read all product safety labels.

• Refer to appropriate regulations for environmental and workplace safety rules.

WARNING: To prevent personal injury

• Recommended Personal Protection Equipment:

- Eye Protection

- Chemical resistant gloves

• Avoid Fuel Spillage: When disconnecting attachments equipped with Quick connect fittings, wrap a shop rag around

the fitting to catch any residual fuel. Allow fuel to drain back into hoses before closing ball valves to avoid spillage when

returning hoses to the Cart.

• Do not leave the ShopPro running unattended. Follow engine manufacturer guidelines for proper priming procedures.

Always disconnect the power supply when the ShopPro is not in use.

• Scalding hazard: When diesel fuel is circulated through an operating engine, it can become very hot. Do not allow fuel to

come in contact with eyes or unprotected skin. Allow the engine and fuel to cool to ambient temperature before replacing

the fuel filter or performing service operations which could result in spillage of fuel from the fuel system.

• Fire Prevention: Heated fuel can form combustible vapor mixtures in the area around the fuel source. To eliminate the

potential for fire, keep open flames, sparks or other potential ignition sources away from the work area. Do not smoke during

filter replacement or service operations.

• Inhalation Precaution: Always perform engine or vehicle fuel system maintenance in a well ventilated area that is kept free

of bystanders.

• The ignition key must be in the off position, unless otherwise directed. To avoid unintentional engine startup, use a lockout

key and/or signage to alert personnel that work is being performed.

Government Regulations

• Engine fluids (oil, fuel, and coolant) may be a hazard to human health and the environment. Handle all fluids and other

contaminated materials (such as filters and rags) in accordance with applicable regulations. Recycle or dispose of engine

fluids, filters, and other contaminated materials according to applicable regulations.

Table of contents

Other Clarience Technologies Cleaning Equipment manuals

Popular Cleaning Equipment manuals by other brands

Suevia

Suevia 130.5011 EASYCLEANER Mounting instructions

i-MO

i-MO Öko 2000 user guide

unGer

unGer Hydro Power Ultra UNP01 operating instructions

Black & Decker

Black & Decker BHPC130 Original instructions

Uni-ram

Uni-ram UG5000E operating manual

Axi

Axi MTC HC-300 Installation, operating and maintenance manual