Super Pro spray guns are fed with paint by a siphon (or suction) effect from the paint cup.

The air flow through the air cap draws paint up the feed tube, into the nozzle assembly,

where it is atomised and sprayed forward.

Mix the paint to the correct viscosity for spraying according to the manufacturers

instructions, and strain it into the paint cup through a fine mesh filter. When mixing the

paint, make sure that you have enough thinners left to clean the spray gun after use.

Do not fill the paint cup to more than 3/4 full. Make sure that the top edge of the cup and

the cup sealing gasket are clean and free from damage before mounting the cup on

the gun. The cup locking lever must be tightened firmly to prevent any leaks from around

the cup rim, also it is very important to keep the cup vent clear.

Set the spray pattern and fluid flow using the adjustment screws on the spray gun. The

spray pattern is variable between round and fan by adjusting the air flow through the air

cap. Turn the spray fan control anticlockwise to increase flow and give a fan shaped

spray pattern, turning clockwise to close off the air flow will give a circular pattern. The fan

can be adjusted vertically or horizontally to suit your requirements by loosening the

knurled locking ring and turning the wings to the desired position. Set the fluid flow

according to the paint in use and the spray pattern by using the fluid control screw;

anticlockwise to increase, clockwise to reduce flow. As the width of the spray is increased,

fluid flow will also need to be increased.

The air pressure needed will vary according to the paint in use, with thicker paints needing

greater pressure. For most paints, a pressure of between 1.5 and 4.2 bar (approximately

22 - 60 psi) is adequate, to increase the air pressure, turn the air flow control anticlockwise

to increase, and clockwise to decrease the air pressure.

NOTE:

To reduce overspray and obtain maximum transfer efficiency, always use the lowest

possible air inlet atomising pressure that produces an acceptable spray pattern.

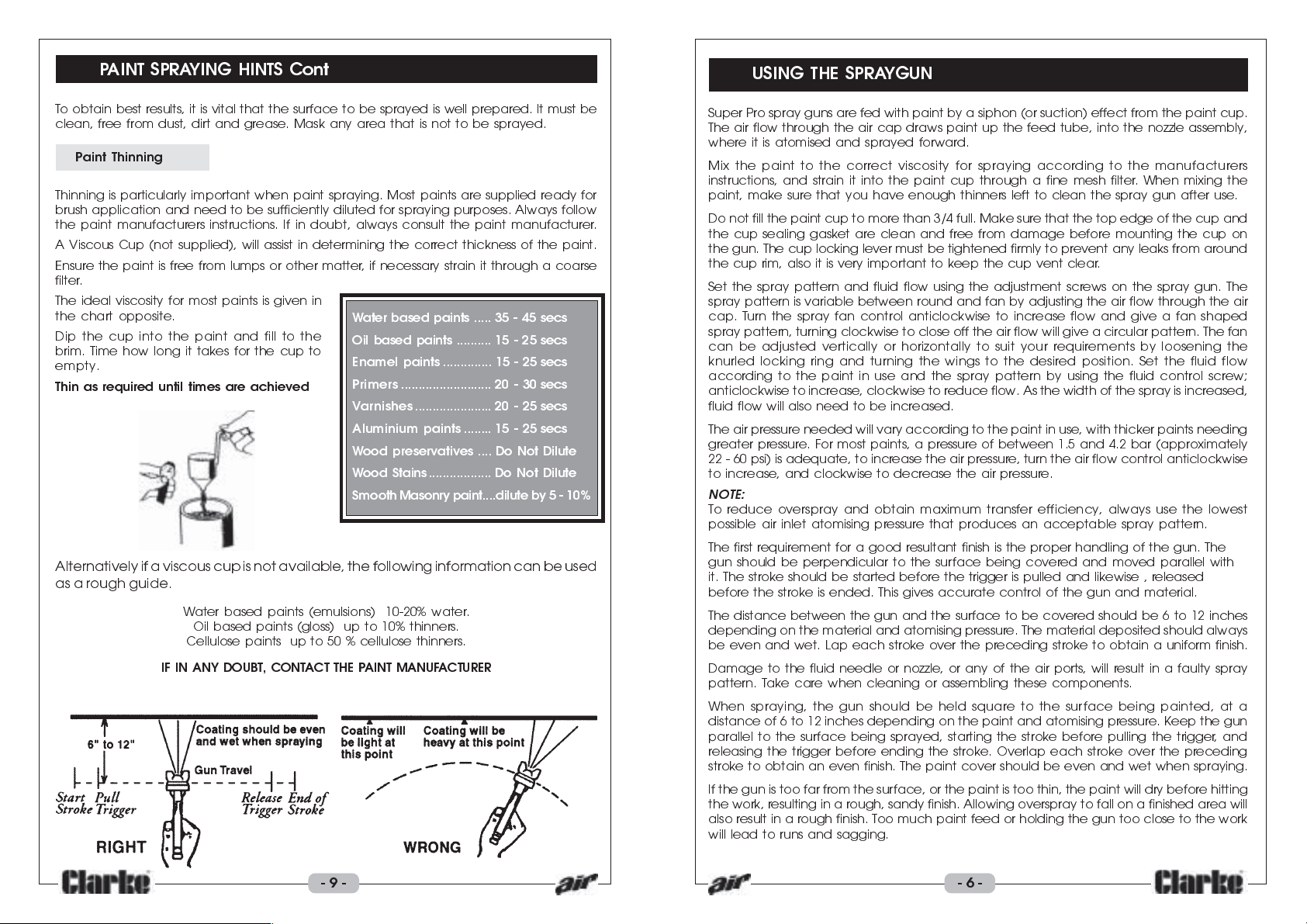

The first requirement for a good resultant finish is the proper handling of the gun. The

gun should be perpendicular to the surface being covered and moved parallel with

it. The stroke should be started before the trigger is pulled and likewise , released

before the stroke is ended. This gives accurate control of the gun and material.

The distance between the gun and the surface to be covered should be 6 to 12 inches

depending on the material and atomising pressure. The material deposited should always

be even and wet. Lap each stroke over the preceding stroke to obtain a uniform finish.

Damage to the fluid needle or nozzle, or any of the air ports, will result in a faulty spray

pattern. Take care when cleaning or assembling these components.

When spraying, the gun should be held square to the surface being painted, at a

distance of 6 to 12 inches depending on the paint and atomising pressure. Keep the gun

parallel to the surface being sprayed, starting the stroke before pulling the trigger, and

releasing the trigger before ending the stroke. Overlap each stroke over the preceding

stroke to obtain an even finish. The paint cover should be even and wet when spraying.

If the gun is too far from the surface, or the paint is too thin, the paint will dry before hitting

the work, resulting in a rough, sandy finish. Allowing overspray to fall on a finished area will

also result in a rough finish. Too much paint feed or holding the gun too close to the work

will lead to runs and sagging.

USING THE SPRAYGUN

PAINT SPRAYING HINTS Cont

To obtain best results, it is vital that the surface to be sprayed is well prepared. It must be

clean, free from dust, dirt and grease. Mask any area that is not to be sprayed.

Paint Thinning

Thinning is particularly important when paint spraying. Most paints are supplied ready for

brush application and need to be sufficiently diluted for spraying purposes. Always follow

the paint manufacturers instructions. If in doubt, always consult the paint manufacturer.

A Viscous Cup (not supplied), will assist in determining the correct thickness of the paint.

Ensure the paint is free from lumps or other matter, if necessary strain it through a coarse

filter.

The ideal viscosity for most paints is given in

the chart opposite.

Dip the cup into the paint and fill to the

brim. Time how long it takes for the cup to

empty.

Thin as required until ti es are achieved

Water based paints ..... 35 - 45 secs

Oil based paints .......... 15 - 25 secs

Ena el paints .............. 15 - 25 secs

Pri ers .......................... 20 - 30 secs

Varnishes ...................... 20 - 25 secs

Alu iniu paints ........ 15 - 25 secs

Wood preservatives .... Do Not Dilute

Wood Stains .................. Do Not Dilute

S ooth Masonry paint....dilute by 5 - 10%

Water based paints (emulsions) 10-20% water.

Oil based paints (gloss) up to 10% thinners.

Cellulose paints up to 50 % cellulose thinners.

IF IN ANY DOUBT, CONTACT THE PAINT MANUFACTURER

Alternati ely if a iscous cup is not a ailable, the following information can be used

as a rough guide.

- 6 -

- 9 -