3

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

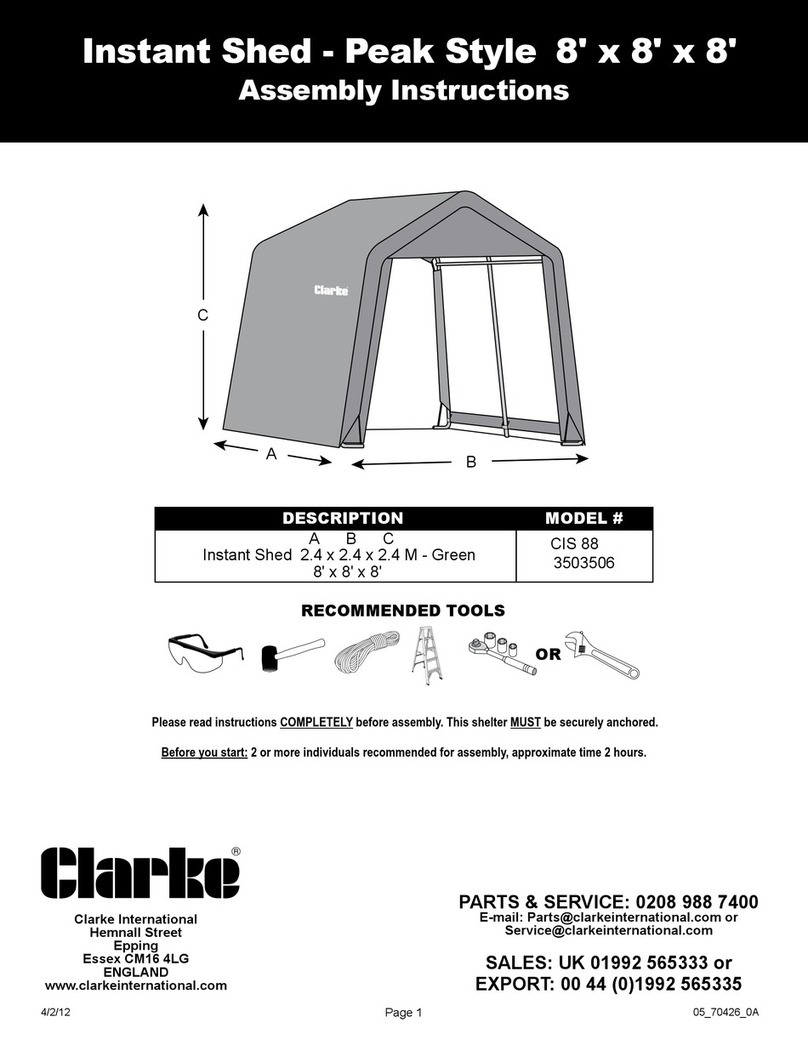

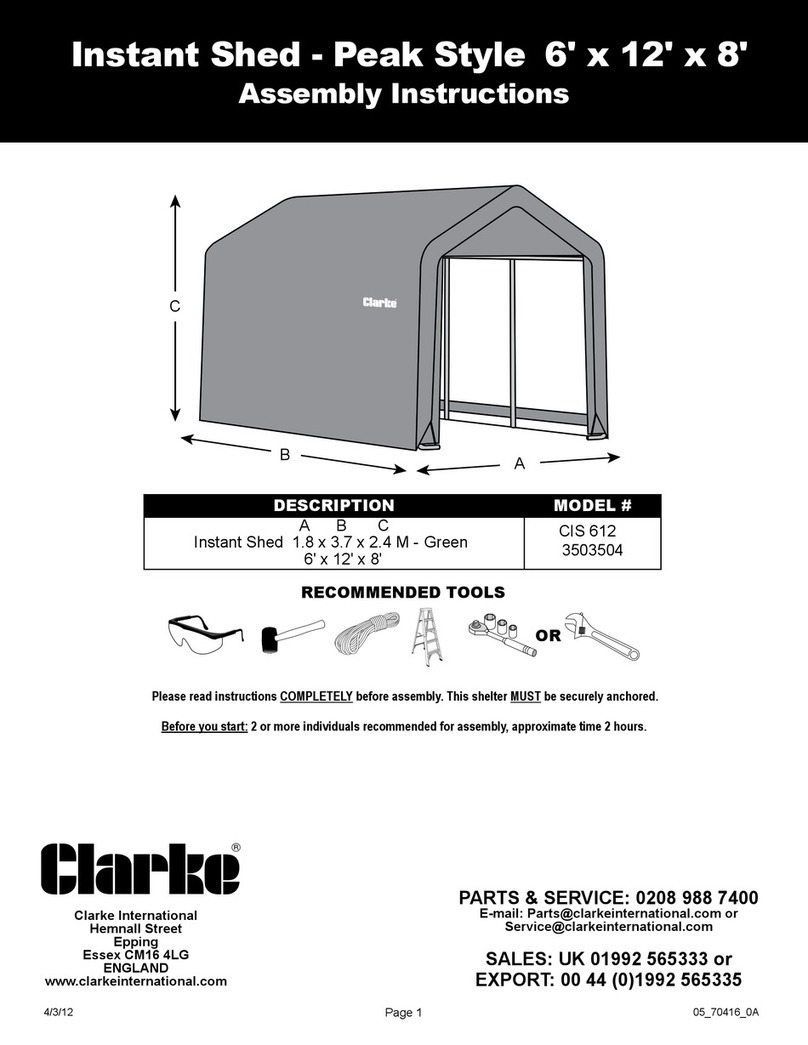

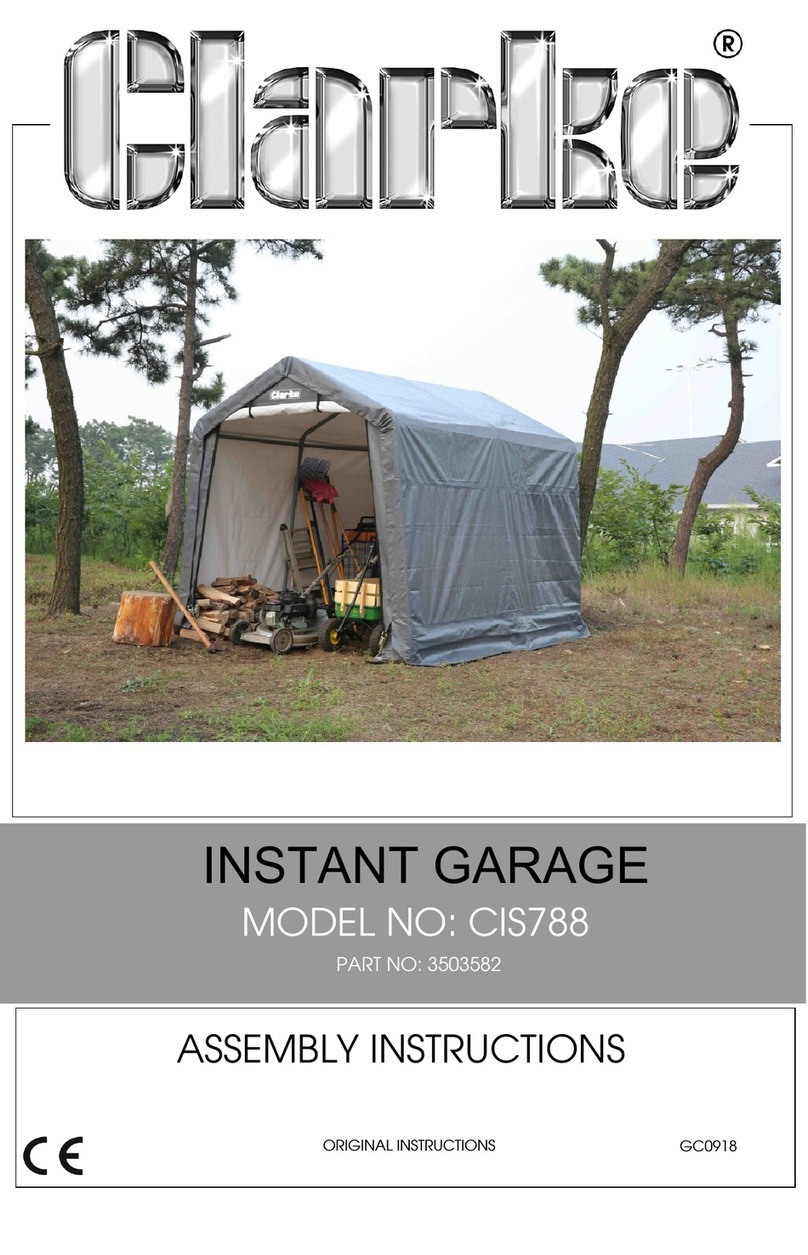

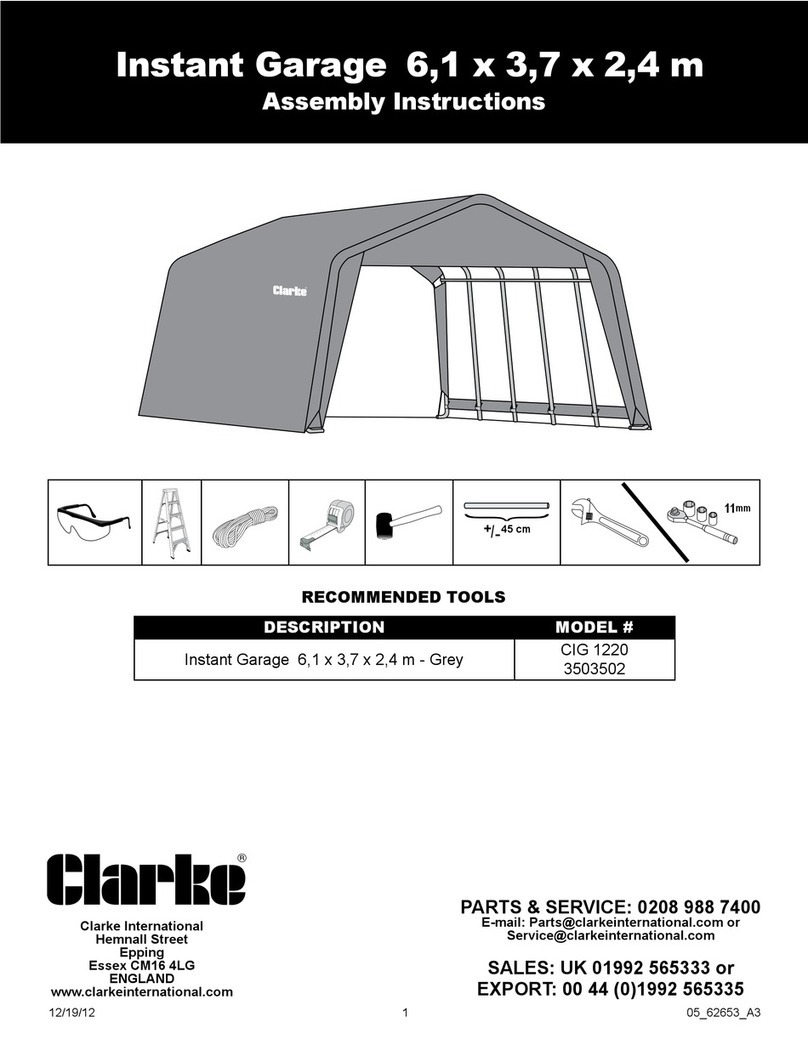

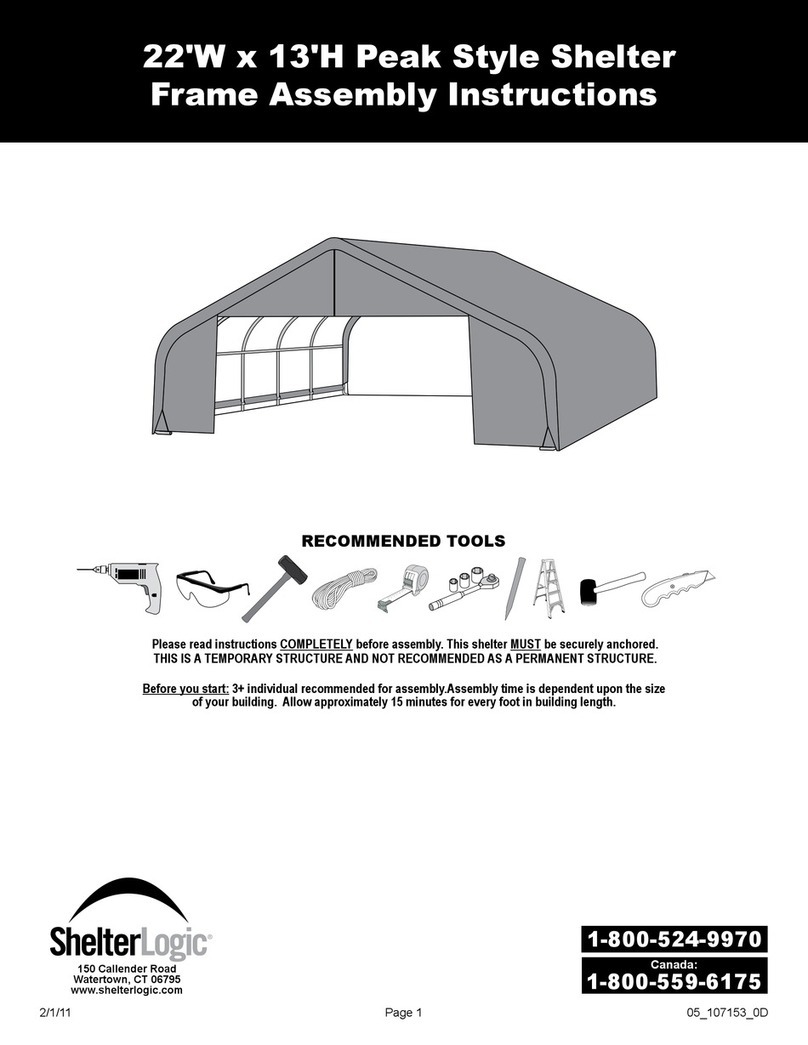

POSITIONING AND INSTALLATION OF THE SHED

POSITIONING THE SHED

This shed is a temporary structure and is not recommended as a permanent

building. It is designed to offer protection from sun, rain, light snow, tree sap

and bird droppings etc. It is not designed to shelter equipment from

excessively high winds or heavy snow.

Choose your shed location carefully. Check for overhead power lines, tree

branches, etc. DO NOT install near roofs or other structures that may shed snow,

ice or excessive run-off onto your garage.

SITING THE GARAGE

Erect your shed on level ground over a firm, level area. Allow enough space

near each corner for the ground anchors and tie-down straps supplied to be

used as intended. If the ground area is of tarmac or concrete, the use of

ground anchor holding-down bolts will be required to anchor the shed to the

floor.

Choose a dry location where dampness arising from ground water in the

environment will not undermine the protection offer by the shed.

A masonry floor such as block paving or concrete is ideal, but if this is not

being supplied, a timber or shuttering plywood floor, protected by a suitable

groundsheet should be used. This will help to create a dry storage environment

by insulating the storage space from ground moisture.

Proper anchoring and keeping the cover tight and free of snow and debris is

the responsibility of the user. Damage caused by improper anchoring is not

covered under warranty.

CARE OF THE GARAGE STRUCTURE

This shed is NOT designed to support heavy snow. Snow or ice accumulation

may cause your shed to collapse. To avoid overloading, brush snow and ice

off the roof top with a broom or mop to prevent collapse with the resultant

damage to property or personal injury.

NEVER clear the roof of snow or debris from inside the shed.

DO NOT use hard-edged tools or instruments, such as rakes or shovels to

remove snow. These can cause punctures to the cover.

DO NOT use bleach, alkaline or harsh detergents for cleaning. Doing so will

damage the material. Soap and warm water are recommended.

In order to reduce risk of burning and avoid damage, DO NOT- cook, smoke,

refuel or use any open flame devices in or around the garage.