Clarus PCS-10 User manual

PCS-10/35

Agitating Parts

Cleaning Stations

Manufactured by:

Clarus Fluid Intelligence, LLC

3145 Mercer Ave, Unit 104

Bellingham, WA 98225

(360) 671-1514

Rev Date 7/16

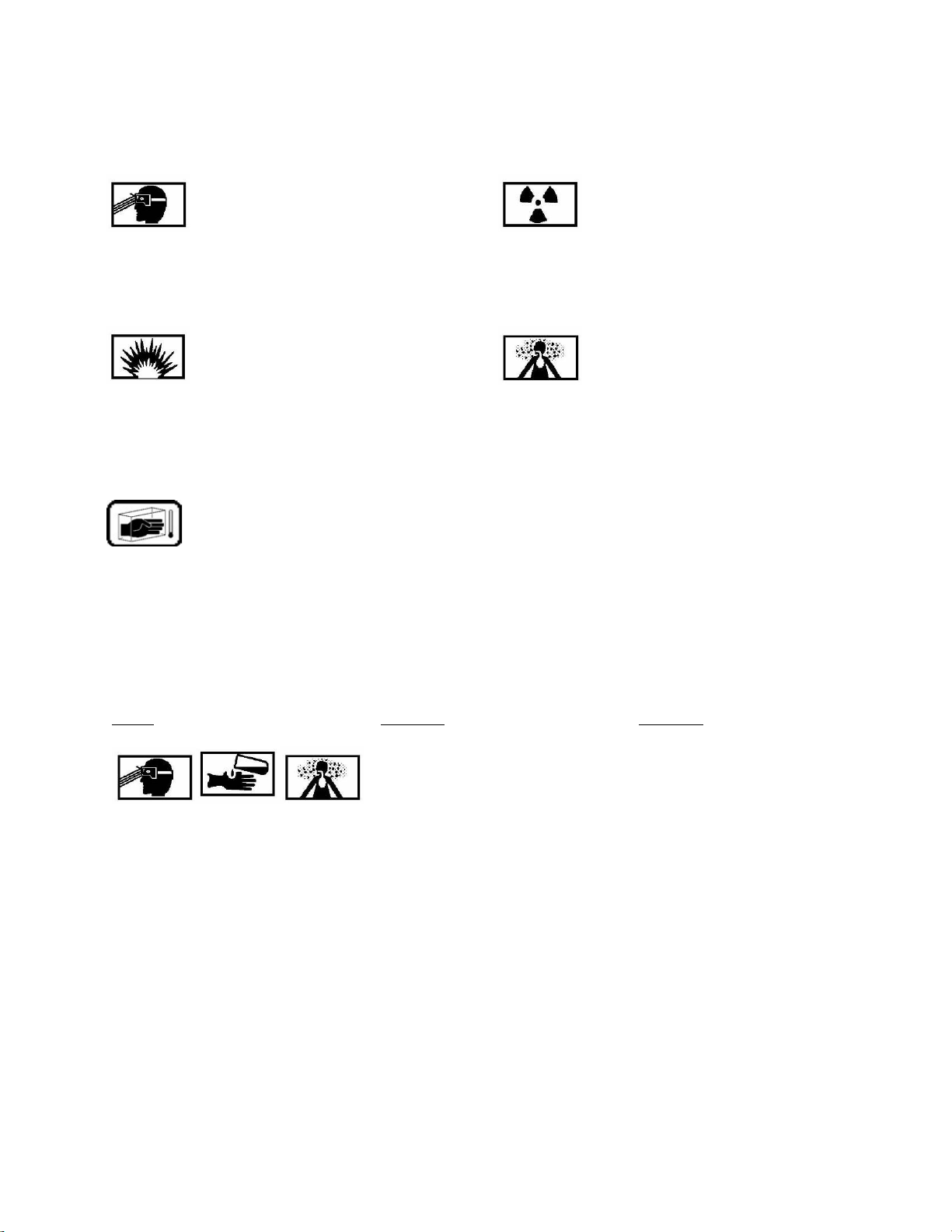

Biological Fire

The abstract symbol shows that

a

material may contain bacteria

or

viruses that present danger

to life

or health

The symbol of a flame shows

that a

material can ignite and

cause burns

Chemical Poison

The symbol of a liquid dripping

onto a hand shows that a

material

will cause burns or

irritation to

human skin or

tissue

The symbol of a skull and cross bones

shows that a material is poisonous or

is

a danger to life

OPERATION, ORGANIZATIONAL AND INTERMEDIATE MAINTENANCE

WITH ILLUSTRATED PARTS BREAKDOWN

WARNINGS APPLICABLE TO HAZARDOUS MATERIALS

AGITATING PARTS WASHER

PART NUMBER PCS-10/35

1-1

INTRODUCTION

1-2

Warnings for hazardous material listed in this manual are designed to warn personnel of hazards

associated

with such items when they come in contact with them by actual use. For each hazardous

material

used within the facility, a Material Safety Data Sheet (MSDS/SDS) must be provided and available for

review

by users. Consult your local safety and health staff concerning any questions regarding hazardous

materials;

MSDSs; personal protective equipment requirements; and appropriate handling, emergency

procedures

and disposal guidance.

1-3

Under the heading HAZARDOUS MATERIALS WARNINGS, complete warnings, including related icon(s) and

a numeric identifier, are provided for hazardous material used in this manual. Each hazardous material is

assigned only one numeric identifier. Since only those hazardous materials addressed in this manual will

be listed, the numeric identifiers may not appear in sequential order.

1-4

In the text of the manual, the caption WARNING is not used for hazardous material warnings. Hazards are

cited with appropriate icon(s), the nomenclature of the hazardous material, and the numeric identifier

that relates to the complete warning. Users of hazardous materials shall refer to the complete warnings.

EXPLANATION OF HAZARDOUS MATERIAL ICONS

Eye Protection Radiation

The symbol of a person wearing

goggles shows that the material

will injure your eyes.

The symbol of three circular wedges

shows that a material emits radioactive

energy and can injure human skin or

tissue.

Explosion Vapor

The rapidly expanding symbol

shows that the material may

explode if subjected to high

temperatures, sources of ignition,

or high pressure

The symbol of a human figure in a

cloud shows that vapors of a material

present a danger to your life and

health through inhalation.

Cryogenic

The symbol of a hand in a block of

ice shows that the material is

extremely cold and can injure

human skin or tissue.

HAZARDOUS MATERIAL WARNINGS

Index Material Warning

MIL-PRF-680

TYPE II

QUALIFIED

SOLVENT

1. Solvent is combustible. If solvent is decomposed by

heat, toxic gasses are released. Frequent or prolonged

contact may cause dermatitis. Contact may agitate

existing dermal conditions. If contact is made, remove

contaminated clothing. Thoroughly wash affected area

with soap and water; use skin cream if irritation is severe.

Liquid vapor contact may cause eye irritation or tearing or

blurring of vision. Immediately flush eyes with water for

15 minutes. Call a physician if irritation persists. If

solvent is ingested, do not induce vomiting. Immediately

give two glasses of water. Seek medical attention. When

handling solvent wear the approved gloves. If prolonged

contact with mist is likely, wear approved respirator.

PCS

-

10

/

35

Agitating

Parts Washer

1 March 2013

001 00

ALPHABETICAL INDEX

SOLVENT PARTS WASHER

PART NUMBER PCS-10/35

Title WP/Page No.

Air

Cylinder

Assembly

007 00/12

Installation

007 00/12

Removal

007 00/12

Air

Pressure

Bleed

007 00/4

Carbon Filter

Element

(OPTIONAL)

007 00/4

Installation

007 00/5

Removal

007 00/5

Description

003 00/2

Accessories

003 00/3

Agitation Circuit

and Solvent

Filtration Circuit

003 00/2

Air

Filtration Assembly

003 00/2

Operator

Door

Assembly

003 00/2

Operator

Interface

Panel

003 00/3

Pneumatic

Circuit

003 00/3

Service Door

Assembly

003 00/2

Sheet

Metal

Assembly

003 00/2

Tank

Assembly

003 00/2

Door

Switch

007 00/6

Installation

007 00/6

Removal

007 00/6

Fan (OPTIONAL)

007 00/7

Installation

007 00/8

Removal

007 00/7

Filter

Pressure

Gauge

007 00/8

Installation

007 00/8

Removal

007 00/8

Finger

Stock

(OPTIONAL)

007 00/7

Installation

007 00/7

Removal

007 00/7

Float

Switch

007 00/6

Installation

007 00/6

Removal

007 00/6

Fuse

007 00/14

Installation

007 00/14

Removal

007 00/14

Gas

Spring

007 00/7

Installation

007 00/7

1 of 4

PCS

-

10

/

35

Agitating

Parts Washer

1 March 2013

001 00

2

Title

WP/Page No.

Removal

007 00/7

Illustrated

Parts

Breakdown

002 00/3

Description Column

002 00/3

Figure/Index

Number

Column

002 00/3

General

002 00/3

Group Assembly

Parts

List

002 00/3

How

to

Use

the

IPB

002 00/4

Numerical Index

of

Part

Numbers

002 00/4

Part

Number

Column

002 00/3

Part

Number

Column

002 00/4

Code

Column

002 00/4

Units

Per

Assembly

Column

002 00/4

Usable

on

Code

Column

002 00/4

Work

Package/Figure/Index

Number

Column

002 00/4

Introduction

002 00/2

Arrangement

and

Use

002 00/2

Materials

Required

002 00/3

Nonstandard Abbreviations,

Symbols,

and

Terms

002 00/2

Purpose

and Scope

002 00/2

Quality

Assurance

Requirements

002 00/2

Record

of

Applicable

Technical Directives

002 00/2

Reference

Material

002 00/3

Support

Equipment Required

002 00/3

Warnings

Applicable

to

Hazardous

Materials

002 00/2

Introduction

003 00/2

005 00/2

006 00/2

Leading Particulars

003 00/3

LED light

(L1)

007 00/13

Installation

007 00/14

Removal

007 00/13

Metering Valve

007 00/11

Adjustment

007 00/11

Operator

Door

Handle

007 00/7

Installation

007 00/7

Removal

007 00/7

Operator

Interface

Panel

007 00/13

Installation

007 00/13

Removal

007 00/13

PCS

-

10/35

Operation

005 00/4

PCS

-

10

/

35

Agitating

Parts Washer

1 March 2013

001 00

3

Title

WP/Page No.

Enter

Cycle

Time

005 00/4

Preparation for

Storage

or

Shipment

004 00/3

Storage

or

Shipment

004 00/3

Preparation for

Use

004 00/2

Air

Connections

004 00/3

Carbon Filter

Installation

(OPTIONAL)

004 00/3

Disassembly

of

Operator

Door

Handle

004 00/2

Disassembly

of

Air

Cylinder

Assembly

004 00/2

Electrical

Hook

-

Up

004 00/3

Equipment

Damage

004 00/2

Initial Inspection

004 00/2

Installation

004 00/2

Solvent

Selection

004 00/3

Unpacking

004 00/2

Waste

Handling

and

Disposal

004 00/3

Preoperational

Setup

005 00/2

10

-

key

pad

005 00/2

Edit/Clear

005 00/3

ERR: Carriage

Pos.

005 00/3

ERR:

Door

Open

005 00/3

ERR:

Solv

Level

005 00/3

ERR: Carb

Filter

(OPTIONAL)

005 00/3

Exit

005 00/3

F1

(Raise

Carriage)

005 00/2

F2

(Lower

Carriage)

005 00/2

F3

(Pump)

005 00/2

F4

(Fan)

(OPTIONAL)

005 00/2

F5

(MORE

MTCE)

005 00/2

F6

(Reset

Carbon Hours)

(OPTIONAL)

005 00/2

MTCE

005 00/2

MORE

MTCE

005 00/2

Operator

Interface

Panel

005 00/2

Reset

005 00/3

Run/Program

005 00/3

Set

005 00/3

Start

005 00/3

Status

005 00/3

Stop

005 00/3

Time

005 00/3

View/Enter

005 00/3

Preoperational

Setup

006 00/2

PCS

-

10

/

35

Agitating

Parts Washer

1 March 2013

001 00

4

Title

WP/Page No.

Proximity

Switch

007 00/11

Installation

007 00/11

Removal

007 00/11

Pump

007 00/10

Installation

007 00/10

Removal

007 00/10

Repair

Instructions

007 00/4

Service Door

007 00/5

Installation

007 00/5

Removal

007 00/5

Service Door

Gasket

007 00/5

Installation

007 00/6

Removal

007 00/6

Scheduled

Maintenance

007 00/4

Solenoid Valve

Pair

007 00/12

Installation

007 00/13

Removal

007 00/12

Solvent

Filter

Element

007 00/5

Installation

007 00/5

Removal

007 00/5

Solvent

Filter

Housing

(Front)

007 00/8

Installation

007 00/9

Removal

007 00/8

Solvent

Filter

Housing (Rear)

007 00/9

Installation

007 00/9

Removal

007 00/9

Solvent

Replacement

007 00/4

Spray

Bar

Nozzles

007 00/10

Installation

007 00/10

Removal

007 00/10

Testing

and

Troubleshooting

006 00/2

Theory of Operation 003 00/2

Transient Voltage Surge Suppressor (TVSS) (OPTIONAL) 007 00/14

Installation

007 00/14

Removal

007 00/14

Troubleshooting 007 00/4

Unscheduled Maintenance 007 00/4

PCS

-

10

/

35

Agitating

Parts Washer

1 March 2013

001 01

1

of

4

PART

NUMBER

WP NO./FIG.

NO./INDEX NO.

109321

007 00/2/11

109329

007 00/2/15

109335

007 00/2/14

109338 007 00/5/8

109339

007 00/3/4

109340 007 00/5/12

109341

007 00/3/3

109342 007 00/5/13

109343 007 00/4/7

109351

007 00/2/4

007 00/2/7

007 00/2/10

007 00/2/13

007 00/2/17

007 00/2/20

007 00/2/23

007 00/4/3

007 00/4/9

007 00/4/21

007 00/9/6

007 00/10/8

109352 007 00/5/17

109355 007 00/5/7

007 00/5/11

109366 007 00/4/11

109371 007 00/4/10

109377 007 00/4/15

109378

007 00/2/18

109379

007 00/2/21

109384 007 00/8/20

109388 007 00/8/24

109390

007 00/1/11

109393

007 00/3/2

109410

007 00/10/1

109411

007 00/10/2

NUMERICAL INDEX OF PART NUMBERS

SOLVENT PARTS WASHER

PART NUMBER PCS-10/35

PART

NUMBER

WP NO./FIG.

NO./INDEX

NO.

PCS

-

10/35

007 00/1

WP-680SR 007 00/7/3

107136 007 00/9/35

107215 007 00/7/1

107216 007 00/7/5

107223 007 00/9/23

107305 007 00/5/6

007 00/5/10

007 00/5/19

007 00/8/3

007 00/8/23

007 00/8/27

007 00/9/8

007 00/10/9

107628 007 00/8/1

109264

007 00/1/1

007 00/2

109265

007 00/2/2

109266

007 00/2/5

109270

007 00/2/1

109274

007 00/1/2

007 00/3

109275

007 00/3/1

109276 007 00/5/1

109278 007 00/5/3

109279 007 00/5/2

109282 007 00/4/1

109289

007 00/1/3

007 00/4

109290

007 00/1/4

007 00/5

109293 007 00/5/4

109316 007 00/4/4

109319 007 00/8/28

109320

007 00/2/8

PCS

-

10

/

35

Agitating

Parts Washer

1 March 2013

001

01

2

PART

NUMBER

WP NO./FIG.

NO./INDEX NO.

109524 007 00/9/24

109526 007 00/9/25

109528 007 00/9/28

109530 007 00/9/29

109532 007 00/9/26

109537 007 00/9/27

109539 007 00/4/23

109541 007 00/4/22

109547

007 00/1/9

007 00/10

109548 007 00/7/4

109559 007 00/4/24

109561 007 00/11/1

109562 007 00/11/3

109563 007 00/11/5

109564 007 00/11/7

109565 007 00/11/8

109566 007 00/11/9

109567 007 00/11/10

109568 007 00/11/11

109569 007 00/11/12

109570 007 00/11/13

109572 007 00/11/14

109590

007 00/10/13

109611

007 00/10/10

109618

007 00/10/3

109619

007 00/1/10

007 00/11

109621

007 00/2/3

007 00/2/6

007 00/2/9

007 00/2/12

007 00/2/16

007 00/2/19

007 00/2/22

007 00/2/25

007 00/4/2

007 00/4/8

007 00/4/20

PART

NUMBER

WP NO./FIG.

NO./INDEX NO.

109412 007 00/5/24

109413 007 00/5/20

109414

007 00/2/24

109416 007 00/4/19

109419 007 00/9/5

109425 007 00/4/6

007 00/5/27

007 00/9/12

109426

007 00/1/12

109427 007 00/9/1

109434

007 00/1/6

007 00/7

109442 007 00/7/6

109445 007 00/7/11

109446 007 00/7/8

109447 007 00/7/9

109448 007 00/7/12

109451 007 00/7/13

109453 007 00/7/14

109464 007 00/7/15

109469

007 00/1/7

007 00/8

109472 007 00/8/7

109474 007 00/8/4

109475 007 00/8/5

109499 007 00/9/2

109500 007 00/9/3

109505 007 00/9/4

109512 007 00/9/16

109513 007 00/9/14

109514 007 00/9/10

109515 007 00/9/15

109516

007 00/1/8

007 00/9

109518 007 00/9/19

109519 007 00/9/17

109520 007 00/9/18

109522 007 00/9/21

109523 007 00/9/22

PCS

-

10

/

35

Agitating

Parts Washer

1 March 2013

001

01

3

PART

NUMBER

WP NO./FIG.

NO./INDEX NO.

109682

007 00/10/6

109683

007 00/10/4

109685 007 00/8/6

109700

007 00/10/17

109701

007 00/10/18

109702

007 00/10/19

109704 007 00/9/33

109706

007 00/10/20

109708

007 00/10/21

109709 007 00/6/6

109712

007 00/10/12

109713

007 00/10/11

109717 007 00/8/8

109719 007 00/8/9

109720 007 00/8/10

109721 007 00/8/11

109722 007 00/8/19

109723 007 00/8/15

109724 007 00/8/16

109725 007 00/8/17

109726 007 00/8/12

109729 007 00/8/13

109731 007 00/8/14

109733 007 00/8/18

109735 007 00/7/10

109737 007 00/5/25

109738 007 00/5/28

109741 007 00/6/4

109745 007 00/6/7

109749

007 00/1/13

109754

007 00/10/14

109755

007 00/10/15

109756

007 00/10/16

109759 007 00/4/25

109760 007 00/6/9

109767

007 00/10/22

109770 007 00/7/16

109774 007 00/6/11

PART

NUMBER

WP NO./FIG.

NO./INDEX NO.

007 00/5/5

109621 007 00/5/9

109621 007 00/5/18

007 00/8/2

007 00/8/21

007 00/8/25

007 00/9/7

007 00/10/7

109622

007 00/2/26

109623 007 00/4/5

007 00/4/12

007 00/4/16

007 00/5/26

109623 007 00/9/11

109624 007 00/7/2

109628 007 00/4/14

007 00/4/18

007 00/6/7

007 00/6/14

007 00/9/13

109629 007 00/5/14

007 00/5/21

109630 007 00/5/16

007 00/5/23

109631 007 00/5/15

007 00/5/22

109632 007 00/8/22

007 00/8/26

109633 007 00/9/9

109634 007 00/11/2

007 00/11/4

007 00/11/6

109650

007 00/1/5

007 00/6

109654 007 00/6/2

109661 007 00/6/3

109663 007 00/6/5

109670 007 00/6/10

109676

007 00/10/5

PCS

-

10

/

35

Agitating

Parts Washer

1 March 2013

001

01

4

PART

NUMBER

WP NO./FIG.

NO./INDEX NO.

109775 007 00/6/12

109776 007 00/6/13

109779 007 00/8/29

109780 007 00/8/30

109785 007 00/9/30

109786 007 00/9/31

109787 007 00/9/32

109842 007 00/4/13

007 00/4/17

109843 007 00/11/15

109867 007 00/7/7

109870 007 00/9/34

109982 007 00/9/20

109984 007 00/9/36

109985

007 00/10/23

109986 007 00/6/1

109990 007 00/5/31

109991 007 00/5/29

109992 007 00/5/30

PCS

-

10

/

35

Agitating

Parts Washer

1 March 2013

001

02

Page

1

of

2

(2

blank)

NUMERICAL INDEX OF REFERENCE DESIGNATORS

SOLVENT PARTS WASHER

PART NUMBER PCS-10/35

REF DES

WP NO./FIG

NO./INDEX NO.

PART NUMBER

F1

(Fuse)

007

00/10/16

109756

F2

(Fuse)

007

00/10/15

109755

F3

(Fuse)

007

00/10/14

109754

L1

(LED

light)

007

00/10/2

109411

L2 (E-stop light) 007 00/10/3 109618

M1

(pump)

007

00/8/1

107628

M2

(fan

motor)

007

00/6/6

109709

TVSS (OPTIONAL) 007 00/10/18 109701

THIS PAGE INTENTIONALLY LEFT BLANK

PCS

-

10

/

35

Agitating

Parts Washer

1 March 2013

002

00

Page

1

of

8

(8

blank)

INTRODUCTION

SOLVENT

PARTS WASHER

PART

NUMBER PCS-10/35

Alphabetical Index

Title Page No.

Illustrated Parts Breakdown

3

Description Column

3

Figure/Index Number Column

3

General

3

Group Assembly Parts List

3

How to Use the IPB

4

Numerical Index of Part Numbers

4

Part Number Column

3

Part Number Column

4

SM& R Code Column

4

Units Per Assembly Column

4

Usable on Code Column

4

Work Package/Figure/Index Number Column

4

Introduction

2

Arrangement and Use

2

Materials Required

3

Nonstandard Abbreviations, Symbols, and Terms

2

Purpose and Scope

2

Quality Assurance Requirements

2

Record of Applicable Technical Directives

2

Reference Material

3

Requisitioning

and

Automatic

Distribution

of

2

Support

Equipment Required

3

Warnings Applicable to Hazardous Materials

2

PCS

-

10

/

35

Agitating

Parts Washer

1 March 2013

002

00

2

INTRODUCTION

SOLVENT

PARTS WASHER

PART

NUMBER PCS-10/35

1.

INTRODUCTION

PURPOSE AND SCOPE. This manual contains

operation and intermediate maintenance

instructions with detailed parts lists for the PCS-

10/35

Solvent Parts Washer. This section lists all the

special tools and test

equipment required for testing

and maintaining the

PCS-10/35.

2.

3. ARRANGEMENT AND USE. This manual is

broken down into separate work packages (WPs)

which detail specific major subassemblies and

operations necessary for maintenance of the PCS-

10/35

Solvent Parts Washer. General information,

operation, and routine

maintenance are covered in

the first six WPs of the

manual. The following WPs

cover detailed

maintenance and repair, and include

repair parts

lists. Each WP is assigned a five-digit

number, which,

with its applicable publication

number, provides a

means of locating a specific WP

in a manual. To find

a WP when only the subject

matter is known, refer

to the alphabetical index

(001 00).

4.

WARNINGS APPLICABLE TO HAZARDOUS

MATERIALS. Warnings applicable to hazardous

materials used in this manual are listed in the

Hazardous Materials Warning Sheet (HMWS).

5.

QUALITY ASSURANCE REQUIREMENTS.

Certain procedures or steps of procedures in this

manual may be followed by “(QA)” indicating a

quality assurance phase. These procedures, if

improperly performed, will affect equipment

performance or safety of personnel. A quality

assurance inspection of each procedure or step

followed by “(QA)” shall be performed before

proceeding to the next step, unless it can be

determined that such inspection can be performed

after completion of the entire procedure.

6.

OPTIONAL EQUIPMENT. The PCS-10/35 can

be

equipped with optional equipment to enhance

performance. The air filtration assembly system

(carbon filter and fan), agitation system (spray bars

and a higher capacity pump), EMI suppression

system and the foundation weld bracket are optional

features that are included in this manual. When an

optional feature is discussed, it is notated with

(OPTIONAL).

7.

If additional or replacement copies of this

manual are required they may be ordered from

Clarus Fluid Intelligence at

info@clarustechnologies.com

or by calling 360-715-

1356.

8.

SUPPORT EQUIPMENT REQUIRED. Table 2

lists all support equipment required to perform the

maintenance procedures in this manual.

9.

MATERIALS REQUIRED. Consumable

materials and expendable items required to

accomplish prescribed maintenance are listed in

Table 4. Suitable equivalent items may be

substituted unless noted otherwise.

10.

ILLUSTRATED PARTS BREAKDOWN.

11.

GENERAL. The IPB provides information

necessary for requisitioning, identifying parts, and

illustrating disassembly and assembly relationships.

12.

GROUP ASSEMBLY PARTS LIST. The group

assembly parts list (GAPL) consists of a breakdown of

the item into assemblies and detail parts. Attaching

parts are identified immediately following the item

they attach. The GAPL uses a six column format. All

symbols and abbreviations used in the GAPL are in

accordance with MIL-STD-12, Abbreviations for Use

on Drawing and in Specifications, Standards and

Technical Documents.

13.

FIGURE/INDEX NUMBER COLUMN. In this

column, index numbers are assigned in numerical

sequence. The index numbers are used on the

illustration(s) to locate the item.

14.

PART NUMBER COLUMN. This column lists

manufacturer part numbers, government standard

part numbers, or other vendor part numbers.

15.

DESCRIPTION COLUMN. The description

column lists item nomenclature, plus modifiers

necessary to identify the item. The assemblies,

PCS

-

10

/

35

Agitating

Parts Washer

1 March 2013

002

00

3

subassemblies, detail parts, and attaching parts are

properly identified (named and indented) to show

their relationship to the item. The description may

include special notes in slashes “(/ /)” to explain or

clarify any unique conditions that pertain to the

item.

a.

Attaching parts are listed immediately after

the part they attach, and precede any

breakdown of the item attached. The caption

“ATTACHING PARTS” appears in the description

column, preceding the attaching parts. The

symbol “---*---“ is used to indicate the end of

the attaching parts for a specific assembly or

part.

b.

The notation “(See Figure for bkdn)”

following the description of a part number

indicate that further breakdown of the part is

shown in the figure noted.

c.

The notation “(NHA, Fig. )” following the

description of a part number indicates that the

correct next higher assembly relationship of

the part is shown in the figure noted.

d.

The notation “(use only on)” following the

description of a part number indicates that the

part is used only on the particular assembly

noted.

e.

Make From. When an item is coded for

local manufacture, the material from which it is

made is included following the item

nomenclature.

f.

Manufacturers that have not yet been

assigned CAGE codes by the government are

identified herein by a temporary CAGE

identifier. Temporary CAGE identifiers are 5-

digit codes comprised of Arabic numbers

preceded by a series of dashes. The identifier -

---1 is representative of the first used in a

publication.

16.

UNITS PER ASSEMBLY COLUMN. This

column lists the quantity of each part required per

assembly and is not necessarily the total number

used in the end item of equipment. Quantities of

attaching parts are listed per assembly,

subassembly, or part attached. The letters “AR” (as

required) are used to identify bulk items. The

abbreviation “REF” indicates that the part is listed

elsewhere in the IPB and that it is included in the

present listing for reference only.

17.

USABLE ON CODE COLUMN. This column

indicates the usability of parts on different models or

series of the equipment. Codes appear as uppercase

letters. If no letter appears in this column, the part

may be used on all models/series of the equipment.

Usable on codes are listed and defined in the WP

containing the IPB.

18.

Interchangeable Parts. Interchangeable

parts have the same index number and

nomenclature and are denoted by an asterisk (*) in

the Usable On Code column of the GAPL. When all

parts of an index number are asterisked, they are

completely interchangeable and no part is

preferable. When one of these parts is a preferred

replacement, it appears last without an asterisk in

the Usable On Code column. The appearance of an

asterisk and a usable on code (for example, *B)

indicates that interchangeability is limited to the

extent of the usable on code.

19.

NUMERICAL INDEX OF PART NUMBERS.

The numerical index of part number (WP 001 01) is a

complete alphanumerical tabulation of part

numbers, or names if part numbers have not been

assigned.

20.

PART NUMBER COLUMN. This column lists

all part number that appear in the part number

column of the GAPL. The column also lists the

identifying noun name in lieu of a part number when

no part number has been assigned. Part numbers

are listed in alphanumerical sequence.

21.

WORK PACKAGE / FIGURE / INDEX NUMBER

COLUMN. This column lists the WP, figure, and

i n d ex

numbers assigned to the associated part

number. The numbers are separated by slashes, the

first number representing the work package in which

the part number is located. The second number

represents the figure that illustrates the part in

question, and the third number is the index number

identifying the part within the figure.

22.

HOW TO USE THE IPB. The following

paragraphs describe how to obtain specific

information from the IPB.

PCS

-

10

/

35

Agitating

Parts Washer

1 March 2013

002

00

4

23.

When The Part Number is Not Known.

Proceed as follows:

a.

Determine the function and application of

the part required.

b.

Select the most appropriate IPB figure title.

c.

Turn to the figure indicated and locate the

desired part on the illustration.

d.

From the illustration, obtain the index

number assigned to the part desired.

24.

Refer to the GAPL for the identifying name

and any other specific information, including the

part number.

25.

When The Part Number is Known. Proceed

as follows:

a.

Refer to the numerical index of the part

numbers (WP 001 01).

b.

Locate the part number and note the WP,

figure, and index number assigned to the

part number.

c.

Turn to the WP and figure indicated and

locate the number referenced.

If a pictorial representation or a location of the part

is desired, refer to the same index number on the

accompanying illustration.

6

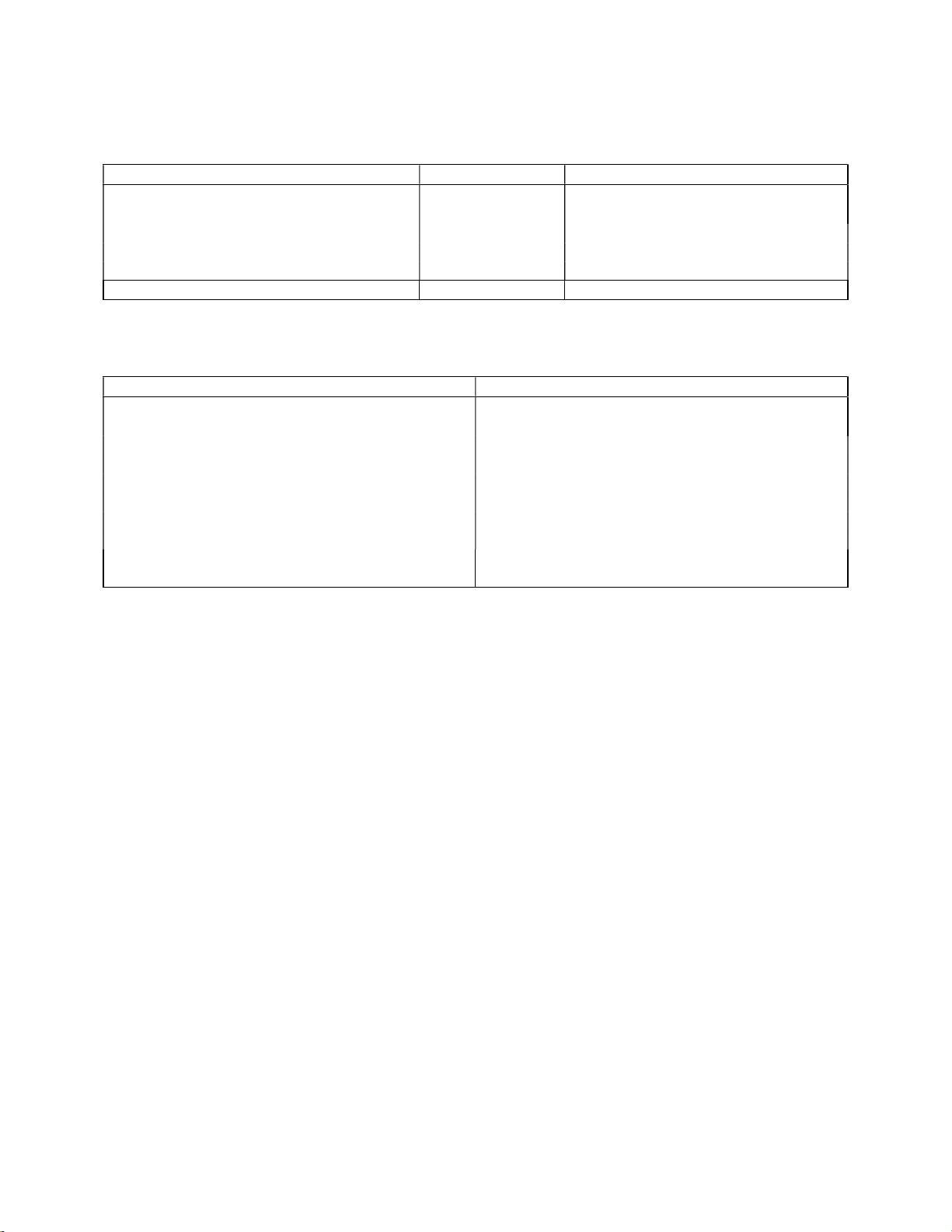

TABLE 2. SUPPORT EQUIPMENT REQUIRED

Nomenclature

CAGE

Code

Part

Number

Container, waste (1 gallon).

---

Container,

waste

(minimum

40

gallon)

---

Forklift.

---

Welder

(OPTIONAL)

---

TABLE 3. MATERIALS REQUIRED

Nomenclature

Specification/Part

No.

Alcohol, Isopropyl

109628

Nut,

¼

-

20

,

Nylock,

SS

Nut,

5/16

-

18

18

-

8

Nylock,

SS

107305

Rag,

wiping

---

Screw

109634

Solvent

MIL

-

PRF

-

680

Type

II

Sealant,

thread

A

-

A

-

58092

String

or

duct

tape

---

THIS PAGE INTENTIONALLY LEFT BLANK

This manual suits for next models

1

Table of contents

Other Clarus Cleaning Equipment manuals

Popular Cleaning Equipment manuals by other brands

Wetrok

Wetrok Monovac Comfort 6/11 operating instructions

Rexair

Rexair Rainbow Squeegee manual

ICE COBOTICS

ICE COBOTICS ICE USA i20NBL Operator's & parts manual

Elma

Elma Elmasonic xtra TT operating instructions

Light Progress

Light Progress UV-DUCT-FL 2/35HP-NX manual

Sola-Tecs

Sola-Tecs F Series Assembly instructions

Nilfisk-Advance

Nilfisk-Advance Topax Hygiene System user guide

Mod-U-Blast

Mod-U-Blast Twister HD Operation & maintenance manual

TEGRAS Concept

TEGRAS Concept iFoam Mini user manual

ThermaCor

ThermaCor Thermax Therminator DV12 Owner's/operator's manual

RIDGID

RIDGID 0095691386786 manual

Kärcher

Kärcher WV 70 plus manual