Claydon 15m Straw Harrow User manual

OPERATORS

MANUAL

CLAYDONYIELD-O-METER LTD

BUNTERS ROAD,WICKHAMBROOK, NEWMARKET, SUFFOLK, CB8 8XY

TEL: +44 (0)1440 820 327

EMAIL: info@claydondrill.com

www.claydondrill.com

9M

STRAW

HARROW

DOC0132 REV-00

Authorised Representative

CLAYDONYIELD-O-METER LTD

BUNTERS ROAD,WICKHAMBROOK, NEWMARKET, SUFFOLK, CB8 8XY

TEL: +44 (0)1440 820 327

EMAIL: info@claydondrill.com

www.claydondrill.com

DOC0132

REV-00

©

3OPERATORS MANUAL - 9M STRAW HARROW

CONTENTS

WARRANTY REGISTRATION

DECLARATION OF CONFORMITY

IDENTIFICATION OF MACHINE

INTRODUCTION

SAFETY

DIRECTIVE PROVISIONS

PRE-WORK PREPARATION

IN FIELD OPERATION

CARE AND MAINTENANCE

PARTS MANUAL

PARTS MANUAL INDEX

A

B

C

D

E

F

G

H

I

J

K

In order to activate your Claydon Warranty this page & the Warranty check sheet and

conformation form must be completed and returned to:

Service Department

Claydon Yield-O-Meter Ltd

Bunters Road,

Wickhambrook,

Newmarket,

Suffolk,

CB8 8XY

•The Machine is washed off upon delivery to remove any road salt.

•The drills hydraulic free ow service is plugged in prior to the drill being operated.

•The drills case drain is correctly installed onto the tractor if applicable.

CUSTOMER NAME:

CUSTOMER

SIGNATURE:

TELEPHONE NUMBER:

MACHINE SERIAL

NUMBER:

DATE OF

COMMISSIONING:

ADDRESS:

RETURN REGISTRATION DOCUMENT SOYOUR MACHINE IS REGISTERED IF NOT ALL

WARRANTY CLAIMS WILL BE REJECTED.

Your Claydon product warranty cover will start 12 months from the installation date.

Receive updates about your product including safety updates.

Download your documents.

Get support.

Alternatively email completed documents to: service@claydondrill.com

COUNTY: COUNTRY:

POST CODE:

DATE:

WARRANTY

REGISTRATION CARD

PLEASE ENSURE

This form must be completed along with the Warranty Registration Card on the commissioning of a new

Claydon machine in order to activate its warranty cover. It is the dealers obligation to ensure that the

Warranty registration document is completed & the end user has signed it and the document is sent to

Claydon. In the event of a dealer not being present it is the customers responsibility to return this form to

the following address.

SUPPLYING DEALER NAME

MACHINE SERIAL NUMBER

COUNTY COUNTRY POST CODE

ADDRESS

TELEPHONE NUMBER

DATE OF COMMISSIONING

I ...................................................(Representative Name)

have on behalf of ..............................................................

(Dealer Name) commissioned the machine above

to the best of my ability and have covered all the

points in this check as a minimum.

Signed.......................................................................

Date

I …………………………………………(end user

name) have received the commissioning of my

machine from a qualied Claydon representative

and am happy with the competence of the

representative and the level of service I have

received.All the details on this form are correct to

the best of my knowledge.

Signed.......................................................................

Date

DD/MM/YYYY

TASK COMPLETED

The customer (and any operator of the machine) has been issued and read the operators manual.

Customer is aware of all transport locks on the machine and knows how to operate them correctly.

The customer understands the correct sequence for folding and unfolding the machine.

The customer understands how to set the machine level (front to rear).

The customer understands how to set the machine level (left to right).

The customer understands how to adjust and set the operating height of the machine.

The customer understands how to adjust and set the operating angle of the tines.

The customer knows all the lubrication/maintenance points on the machine.

DD MM YYYY DD MM YYYY

WARRANTY COMMISSIONING

CHECK SHEET &

CONFORMATION FORM

Your Claydon product warranty cover will start 12 months from the installation date.

Service Department, Claydon Yield-O-Meter Ltd, Bunters Road,Wickhambrook, Newmarket, Suffolk,

CB8 8XY. Alternatively email completed documents to: service@claydondrill.com

CUSTOMER NAME

9

B

DECLARATION OF CONFORMITY

OPERATORS MANUAL - 9M STRAW HARROW

EC Declaration of Conformity

In accordance with EN ISO 17050-1:2004

We: Claydon Yieldometer Ltd

of: Gaines Hall

in accordance with the following Directive(s):

2006/42/EC

The Machinery Directive

Hereby declare that Equipment: Claydon Drills

Model number: Straw Harrow

Serial Number:

is in conformity with the applicable requirements of the following documents

I hereby declare that the equipment named above has been designed to comply with the relevant sections of the above referenced

specications and is in accordance with the requirements of the Directive(s)

Oliver Claydon

Director of Operations

Done at

Gaines Hall

Wickhambrook

On: 07/03/2016

The technical documentation for the machinery is available from:

Claydon Yieldometer Ltd

Bunters Road

Wickhambrook

Newmarket, Suffolk, CB8 8XY

Ref. No.

EN ISO 12100-1:2003

EN ISO 12100-2:2003

Title

Safety of Machinery - Basic Concepts

Safety of Machinery - Basic Concepts

Edition / Date

2003

2003

SH0001 - SH****

10 OPERATORS MANUAL - 9M STRAW HARROW

CIDENTIFICATION OF MACHINE

Identication Plate

Mass Min/Max - Maximum/Minimum laden mass of the vehicle in ‘Kg’

Model - Machine information

Serial No - Serial number of machine

Year -Year of manufacture

Claydon Yeildmeter Ltd

Gaines Hall, Wickhambrook

Newmarket, Suolk,

CB8 8YA, England

+44 (0)1440 820327

www.claydondrill.com

Model:

Serial No:

Year:

Mass Min/Max:

MSH9

MSH9000

2021

1500/2000

11OPERATORS MANUAL - 9M STRAW HARROW

C

IDENTIFICATION OF MACHINE

MACHINE WORKING

WIDTH

TRANSPORT

WIDTH

WEIGHT

(APPROX)

NUMBER OF HARROW

TINES

HORSE POWER

REQUIREMENTS

(ESTIMATED)

9M 9M 3M 2100KG 75 175HP

When ordering spare parts always

quote:

- Model

- Serial No.

- Year of manufacture

- Part numbers of required parts

(located in parts book)

- Account Name

Record your serial number here: …………………………………………………………………

TECHNICAL DATA

Identication of Machine

Data plate location

Please ensure separate warranty registration card is lled in upon purchase of your machine to validate

warranty claims.This is located at the rear of the operators manual.

You may need to quote the serial number of your machine when you order spare parts in the future.

WARRANTY REGISTRATION

SPARE PARTS ORDERING PROCEDURE

VIN number location

DINTRODUCTION

12 OPERATORS MANUAL - 9M STRAW HARROW

Thank you for your purchase of a new Straw Harrow.

The purpose of this Operator’s Manual is to explain to the operator how to set up, use and maintain the

machine.

It is important that the operator reads this manual carefully to correctly set up, use and maintain the machine

safely.

For any further assistance or explanation on the use and maintenance of your machine, please contact your

supplying dealer or alternatively ClaydonYield-O-Meter Ltd using the contact details given on the front cover.

The Claydon Straw Harrow will give many years of excellent service with little maintenance due to its robust

construction and its small number of moving parts. However, regular routine maintenance will give you the

optimum efciency and working machine life of your machine.

In the interest of product development Claydon may (at their discretion) issue updates or component changes

which may improve your machines performance or longevity.

9M STRAW

HARROW

13

D

INTRODUCTION

OPERATORS MANUAL - 9M STRAW HARROW

Safety decals can be found located on your machine in numerous locations, these decals must be observed to

ensure your safety and that the machine is operated in a safe manner.

If any of the decals become illegible or damaged, new decals can be ordered and attached in the appropriate

position.The decals must not be removed.

Decal Locations

ESAFETY

14 OPERATORS MANUAL - 9M STRAW HARROW

Decal Locations

15

E

SAFETY

OPERATORS MANUAL - 9M STRAW HARROW

DECAL MEANING

Read the operating manual carefully.

Prior to operating the machine the manual must be read fully and

understood.

Do not stand between the tractor and the machine.

Standing between tractor and the drill is especially prohibited

during coupling and uncoupling.

Remove the key before servicing.

Before any repairs or servicing turn off the engine and take out

the key.

Riding on the machine is prohibited.

Serious or fatal injury can occur as a result of riding on the

machine.

Proceed with care in the event of leaking hydraulic

uid.

Defective hydraulic hoses or incorrectly seated hydraulic

couplings can trigger unpredictable machine movements. High

pressure uid can puncture skin causing serious injury or death.

Keep clear of slewing range.

There is an extreme risk of injury or death from slewing or

folding machine parts.

Decal Meanings

DC0026

DC0034

DC0027

DC0036

DC0037

DC0039

ESAFETY

16 OPERATORS MANUAL - 9M STRAW HARROW

DECAL MEANING

Risk of crushing.

Gaps between components may become smaller or

disappear completely.

Re-tighten all nuts and bolts.

All nuts should be checked and re-tightened after a few

operating hours. Nuts may come loose due to machine

vibration.

Avoid overhead cables.

Hydraulic connections.

Hydraulic connections overview.

Decal Meanings

DC0029

DC0035

DC0038

DC0122

17

E

SAFETY

OPERATORS MANUAL - 9M STRAW HARROW

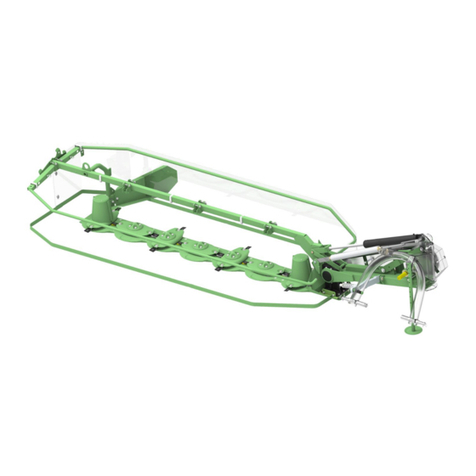

Machine Overview

The terms ‘front’ ‘rear’ ‘left’ and ‘right’ in this manual refer to the machine as follows:

‘Front’ indicates the 3 point linkage end of the machine

‘Rear’ indicates the machine end when viewed from the rear

‘Left’ indicates the left of the machine as you look at the machine from the rear

‘Right’ indicates the right of the machine as you look at the machine from the rear.

Front

Rear

Left

Right

FDIRECTIVE PROVISIONS

18 OPERATORS MANUAL - 9M STRAW HARROW

1. Manual holder

2. Electronic junction box

3. Machine folding ram

4. Harrow tines

5. Harrow tine folding ram

6. Rear lights

Machine Overview

1.

4.

3.

6.

5.

2.

19

F

DIRECTIVE PROVISIONS

OPERATORS MANUAL - 9M STRAW HARROW

Directive Provisions

This Claydon Straw Harrow conforms to Machinery Directive 2006/42/EC (see Declaration of Conformity

at the front of the manual).

AIRBORNE NOISE EMISSIONS

N/A

WARNING AND CAUTION

These warnings and cautions must be observed when operating the Straw Harrow

• Ensure total weight of tractor/machine combination does not exceed permitted limits and weight of tractor

is sufcient for safe eld and road use.

• Do not allow anyone to stand between tractor and machine during coupling/uncoupling procedures.

• For maintenance/adjustment of the machine ensure that it is lowered to the ground on the 3 point linkage.

• The hydraulic system on the machine operates under high pressure. Pressurised hydraulic oil is dangerous

so connecting/disconnecting the machine must only be undertaken with the tractor engine turned off and the

pressure in the hoses released.

• Before operating the machine ensure no-one is standing within range of its turning circle

Directive Provisions

!

WARNING SYMBOLS

Warning - Always pay extra attention to any text next to this symbol.This symbol could

relate to something which can cause damage to the machine, serious injury or death. Please

take the relevant precautions to avoid dangerous situations.

Eye Protection is required - In the interest of safety, eye protection must be worn.

Gloves are required - In the interest of safety, gloves must be worn.

!Please Note - Information relating to this symbol may be worth noting as a useful tip to

help use the machine more effectively.

GPRE-WORK PREPARATION

20 OPERATORS MANUAL - 9M STRAW HARROW

The Claydon Straw Harrow can be mounted onto any compatible three point linkage with the linkage pins

supplied and CATIII balls (not supplied).

Once the Straw Harrow is attached and at the correct working depth, the top link should be set at an angle

in which the convergence point between the upper and lower link arms should fall at the front axle.This

can be achieved by altering the top link pin attachment points on the tractor and machine.This ensures

stability and the mass of the implement is used correctly.

To connect the Straw Harrow:

1. Connect the 7 pin connection plug (5) to the 7 pin socket at the rear of the tractor using a safe route so

the cable can’t be caught or snagged.

2. Connect the fold and unfold 1/2” ISO connectors (1,2, 3 & 4) to the tractor.

Connecting Straw Harrow to the Tractor

1. Upper link point

2. Upper hitch point

3. Lower link point

4. Lower hitch point

5. Vertical virtual hitch point

1. Straw Harrow increased tine aggression

2. Straw Harrow decreased tine aggression

3. Straw Harrow fold connection

4. Straw Harrow unfold connection

5. 7 pin connection plug

1. 2.

3. 4.

5.

HYDRAULIC & ELECTRICAL CONNECTIONS

4.

3.

2.

1.

5.

Other manuals for 15m Straw Harrow

2

Table of contents

Other Claydon Farm Equipment manuals

Claydon

Claydon HYBRID T4 User manual

Claydon

Claydon 15m Straw Harrow User manual

Claydon

Claydon TERRA STAR User manual

Claydon

Claydon 15m Straw Harrow User manual

Claydon

Claydon Hybrid Front Hopper User manual

Claydon

Claydon HYBRID T6 User manual

Claydon

Claydon HYBRID M3 User manual

Claydon

Claydon TERRABLADE User manual

Claydon

Claydon HYBRID M3F User manual

Claydon

Claydon TERRASTAR Programming manual