15m Straw Harrow

Contents

1.0 Straw Harrow Warranty Registration........................................................................... 1

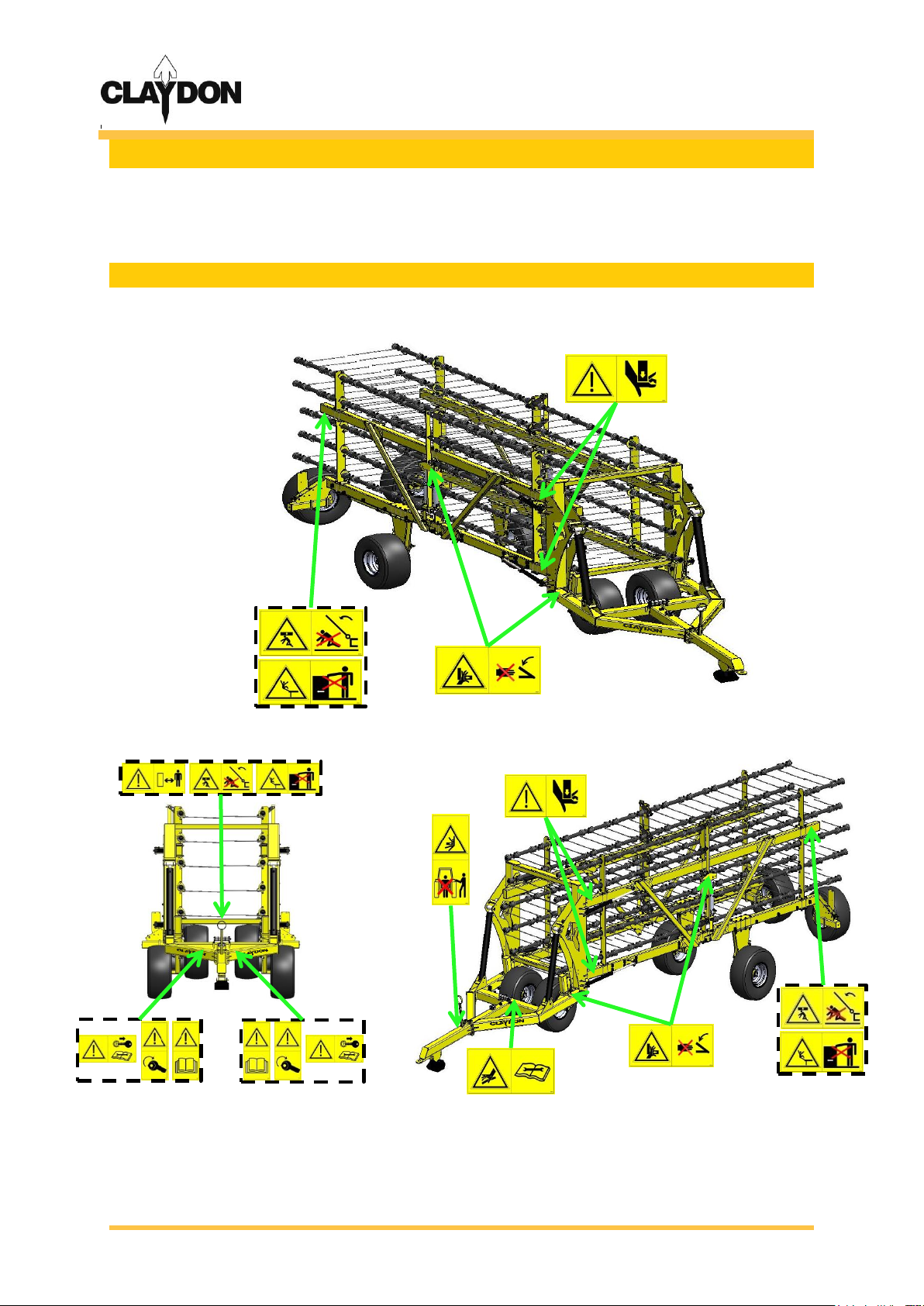

2.0 Safety............................................................................................................................. 3

2.1 Warning Symbols ........................................................................................................3

3.0 Introduction................................................................................................................... 5

3.1 Identification of the Machine........................................................................................5

3.2 Warnings and Cautions ...............................................................................................6

4.0 Equipment Overview..................................................................................................... 6

5.0 Connecting the Straw Harrow to the Tractor............................................................... 7

6.0 Field use ........................................................................................................................ 9

6.1 Working Height..........................................................................................................10

7.0 Care and Maintenance ................................................................................................ 13

7.1. Tyre Pressures.........................................................................................................13

7.2 Lubricating Points......................................................................................................13

Appendix A –Straw Harrow Specifications .................................................................... 15

Appendix B –Declaration of Conformity......................................................................... 16

Part's Manual

15m Straw Harrow Parts Manual...................................................................................... 17

Pole Assembly .................................................................................................................. 18

Centre Chassis Assembly ................................................................................................ 19

Harrow Wing Assembly - RH............................................................................................ 21

Harrow Wing Assembly - LH ............................................................................................ 23

Scharmüller Hitch –Optional Extra ................................................................................. 25

Stand.................................................................................................................................. 26

Hydraulics –Rake Angle Circuit...................................................................................... 27

Hydraulics –Depth Control Circuit.................................................................................. 28