Repair or Warranty Contact Clayton Associates, Inc. • 1650 Oak Street • Lakewood, New Jersey 08701 • P.+1-732-363-2100 F.+1-732-364-6084

Page 8

1. Safe the vacuum.

• Disconnect the vacuum from the power source.

• Remove all tools and hoses from the vacuum.

2. Remove the power head.

• Unlatch the power head from the vacuum tank.

• Lift the power head and the attached HEPA lter o the tank using the top handle.

• Carefully place the power head on the oor – avoid damaging the HEPA lter.

3. Unbox the Reticulated Foam lter.

• Remove the Reticulated Foam lter from the box and remove it from the plastic bag.

4. Remove the HEPA lter.

• Holding the power head on its side cut the HEPA cable lock and remove it.

• Unscrew the HEPA lter from the lter adapter.

• Dispose of the HEPA lter according to company policy.

5. Install a new Reticulated Foam lter.

• Holding the power head on its side, screw the new Reticulated Foam lter onto the threaded lter adapter.

• Verify the white inner ring of the lter is in contact with the underside of the power head.

–If it is not, turn it clockwise until it comes in contact with the underside of the power head.

• Refer to the instructions included with the HEPA cable lock to install the cable lock.

6. Replace the power head.

• Carefully position the power head on the vacuum tank.

• Rotate the power head so that the power switch on the power head is in line with the inlet port on the vacuum tank.

• Latch the power head to the vacuum tank.

7. Activate the HEPA lter timer.

• Remove the old HEPA timer card from the power head.

• Attach the new HEPA timer card with a zip tie (included) to the top handle of the vacuum.

• Follow the directions on the timer card to activate.

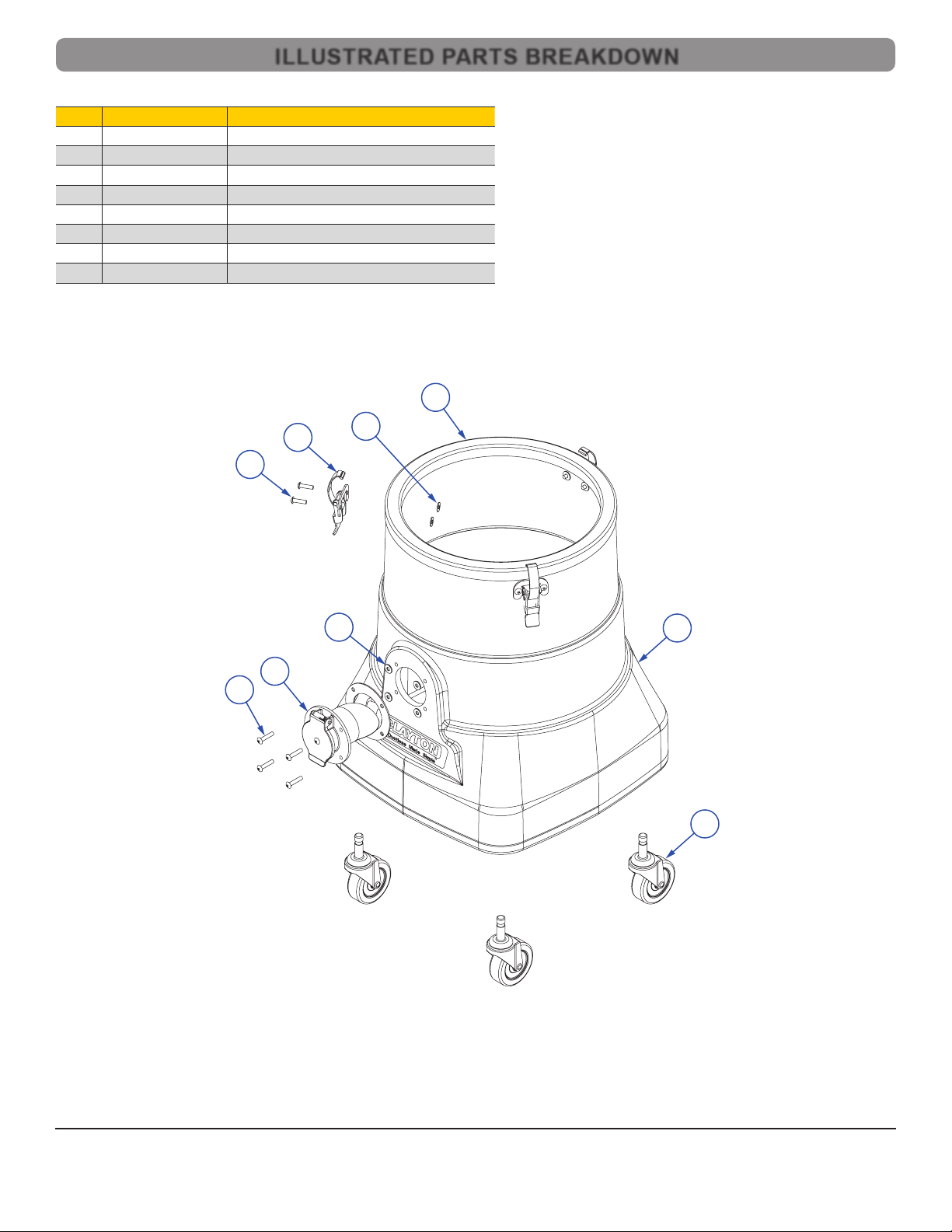

INSTALL FLOAT ASSEMBLY