CLEAN Instruments DH30 User manual

4. Key panel

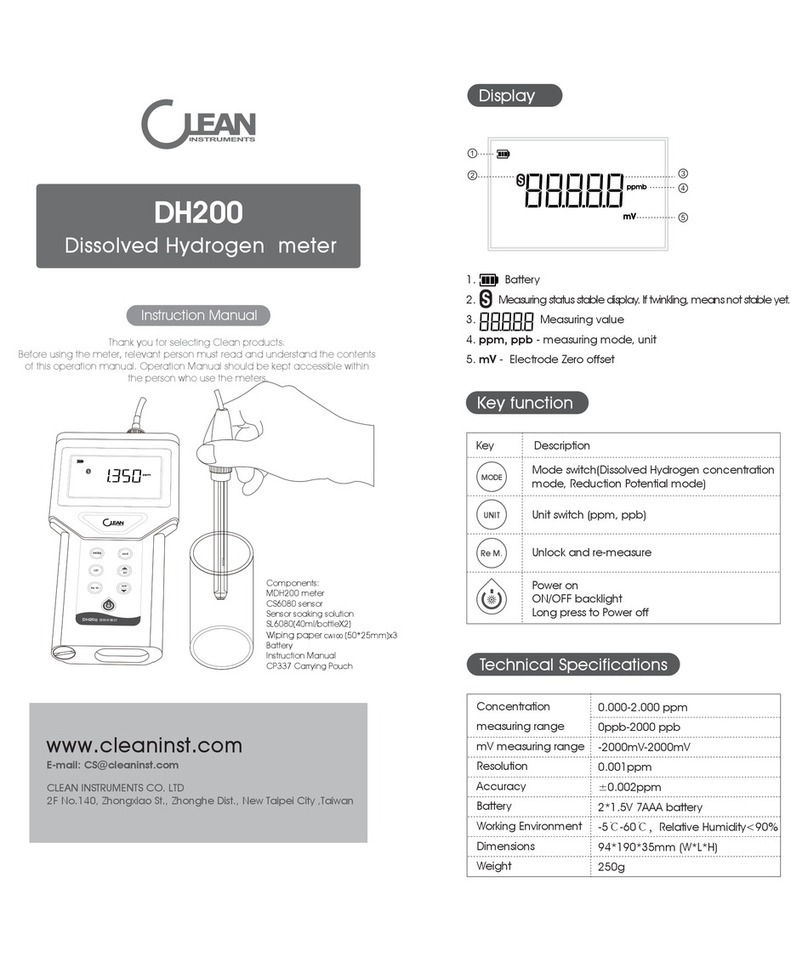

3. CONFIGURATION and LCD INTRODUCTION

2. Precautions

Thank you for selecting Clean products.

Before using the meter, relevant person must read and understand the contents

of this operation manual. Operation Manual should be kept accessible within

the person who use the meters.

Components:

MDH30 Tester

CS6931 sensor

Sensor soaking solution

SL6080(40ml/bottleX1)

Wiping paper CW100 (50*25mm)x3

Battery

Instruction Manual

Set up

Data stabilized

Low battery indicator

Measurement mode

Auto Lock function

Auto Lock after data stabilized

Measuring value

ppm,mV - measuring mode, unit

Dissolved Hydrogen Meter

H2

H2

H2

H2

H2

H2

H2

CLEAN INSTRUMENTS CO. LTD

2F No.140, Zhongxiao St.,

Zhonghe Dist., New Taipei City ,

Taiwan

Instruction Manual

1.Product Overview

-2-

-3- -4-

DH30 tester

Dissolved Hydrogen meter

1.

2.

3

4.

5.

6.

7.

8.

9.

10.

11.

12.

2

3

3

4

4

5

5

6

7

7

8

8

····························································

····································································

·····················

·········································································

···································

·······················································

··········································································

······································································

··········································································

·································

················································································

··················································

ENT

SET

CAL

+

-

AAA

CAL

ENT

SET

CAL

PH30

www.cleaninst.com

Dissolved Hydrogen Meter

H2

H2

H2

H

H2

H2

Immersion

depth:

≤50mm

Operation

Manual

Product Overview

Precautions

CONFIGURATION and LCD INTRODUCTION

Key Panel

Battery and electrode installation

Measurement Mode

Set up

Specification

Package

Electrode using and maintenance

Error

GENERAL INFORMATION

TABLE OF CONTENTS

Long press to enter into mV mode

Increment values or scroll through the next options available

Long press to Power ON/OFF

Short press to ON/OFF backlight

Escape key when in mV mode and setting up

Data setting

Decrement values or scroll through the next options available

Confirm key

Press to unlock in Auto lock mode

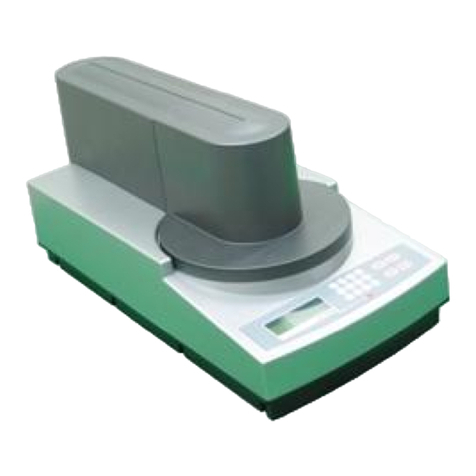

5. Battery and Electrode installation

Unscrew the screw cap by following the

arrow direction, slightly unplug the

electrode, install the battery(pay attention

to the anode and cathode of the

electrode).

Then install back the electrode and the

screw cap.

Low battery prompt is at the top of the

screen when battery power is low.( You can

refer to the LCD INTRODUCTION). Please

change the same model battery.

ENT

SET

CAL

PH30

ENT

SET

CAL

PH30

AAA

+

Short press: Short press means release the key once after pressing.

(If there is no mark out below, default it as Short press)

Long press: Long press means press the key for 3 seconds and then release it

Hold: Hold means not release the key and accelerate after a certain time. Not release the key

until the value is set as needed.

Key instruction

Precise and easy operation, Comfortable holding, All functions operated in one hand.

Large LCD with backlight, Multi-line display for easy reading, Auto-Power Off saves

battery after 5 mins non-use

1*1.5V AAA long battery life, User replaceable battery and high-impedance plane

electrode.

Field throw measurement( Auto Lock Function)

Please wipe up the electorde with clean tissue or cloth before using.

Do not throw or beat ,squash or twist the tester deliberately.

Do not expose to the direct sunlight or

put in high humidity or high temperature environment .

6. Measurement Mode

7.

Set up

Before measuring, please polish the electrode metallic diaphragm with the

wiping paper. When measuing, please stir the electrode properly.

【Notice】

1.Please keep the metallic diaphragm always clean.

2. Please rinse off the sensor tip with clean water after each use and cover

the protection bottle back. Please also check the volume of the soaking

solution. If not enough, please be sure to add more.

Note: After each use, if there is some moisture or solution liquid on and near

the metallic diaphragm, random numbers may get displayed. Rinse off the

tip with clean water and place it back in sensor protecting cap. Make sure it

displays”0” before shutting off power.

3. If there is smudginess and mineral elements adhere on the metallic

diaphragm, the responsive time will be deduced and readings might drop.

Please use the wiping paper to polish the electrode metallic diaphragm.

Make sure the sensor tip is very clean.

After cleaning, please must keep the sensor tip in soaking solution. If the

reading is not 0.000ppm when in soaking solution, please change the sensor.

4. Life expectancy of an electrode depends on frequency of use. Generally,

it should be replaced in 1 year.Generally, it should be replaced in 1 year.

Cleaning order of the electrode metallic diaphragm:

1. Spin off the sensor protection bottle (please pay attention not to spill out the

soaking solution).

2. Hold the wiping paper (with the rough surface up) and drop a few drops of

water on the paper.

3. Horizontally contact the bottom of the metallic diaphragm with the wiping

paper which having water on it. Rub rotating as you writing the Arabic

numeral “8” for around 10 times.

4. Rinse off the tip with clean water and place it back in sensor protecting

cap. Make sure it displays”0” before shutting off power.

Electrode

metallic

diaphragm

CW100

wiping paper

Polish the electrode

metallic diaphragm

Components:

MDH30 Tester

CS6931 sensor

Sensor soaking solution

SL6080(40ml/bottleX2)

Wiping paper CW100 (50*25mm)x3

Battery

Instruction Manual

-5- -6-

-7- -8-

In measurement mode, press “ ” to enter SET UP. Corresponding icons will be

displayed. You can press ” ” and “ ” to select the menu and then press ” ”

to confirm. Press ” ” or “ ” to set up and confirm by press ” ”. You can

also press “ ” to back to measurement mode.

The Set up menu as follow:

10.Electrode using and maintenance

9. Package

Concentration

measuring range

Resolution

Accuracy

Temperature

Sensor

LCD

Backlight

Auto power off

Power

Working Environment

Protection

Dimensions

Weight

0.000-1.800ppm

0.001 ppm

+0.002ppm

°C,°F optional

CS6931 replaceable dissolved hydrogen sensor

20*30 mm multi-line crystal display with backlight

ON/OFF optional

5 minutes without key be pressed

1x1.5V AAA7 battery

-5°C - 60°C, Relative Humidity: <90%

IP67

(HXWXD)185 X 40 X48mm

95g

Size: L*W*H 210*100*65mm

Weight: 350g

C

omp

o

M

DH3

0

C

S6

9

3

S

ensor

S

L6

0

80

W

ipin

g

B

atter

y

I

nstru

ct

W

e

i

g

ht

Se

ri

es

Tester

w.cleaninst.com ww

w.cleaninst.com www.

cleaninst.com www.cl

eaninst.com www.clea

ninst.com www.cleani

nst.com www.cleanins

t.com www.cleaninst.

com www.cleaninst.co

m www.cleaninst.com

www.cleaninst.com w

ww

Series

Tester

ww.cleaninst.com www.cleaninst.com www.cleaninst.com www.cleaninst.com www.cleaninst.com www.cleaninst.com www.cleaninst.com www.cleaninst.com www.cleaninst.com www.cleaninst.com www.cleaninst.com www.c

CLEANWater Analysis Solutions

www.cleaninst.com

Series Tester

30

PH30 pHTester

ORP30ORP Tester

CON30Conductivity/TDS/SalinityTester

DO30 DissolvedOxygenTester

FCL30 FreeChlorineTester

DOZ30Dissolved ozone Tester

P01: Unit of the temperature. You can select between °C and °F.

P03: Auto Lock. You can select “ON” or “OFF” to auto lock the data once stabilized.

P04: Factory defaults. You can select to revert to factory defaults.

8.

Specification

Press ” ” to power up. The tester will then enter into measurement mode.

The measurement icon will twinkle if the data is unstabilized. Once stabilized, the top

stabilized icon will be displayed then.

12. GENERAL INFORMATION

When ERR occurs, you can check the electrode and the standard solution.

11. Error

Authorization must be obtained from CLEAN Instruments Customer Service Center to

issue a RIR number before returning items for any reason. When applying for

authorization, please nclude date requiring the reason of return. Instruments must be

carefully packed to prevent damage in shipment and insured against possible

damage or loss. CLEAN Instruments will not be responsible for any damage resulting

from careless or insufficient packing.

Warning: Damage as a result of inadequate packaging is the User / distributor’s

responsibility.

Please follow the guidelines below before transporting.

Use the original packaging material if possible, when transporting back the unit for repair.

Otherwise wrap it with bubble pack and use a corrugated box for better protection.

Include a brief description of any faults suspected for the convenience of Customer

Service Center, if possible . If there are any questions, feel free to contact our Customer

Service Center or distributors.

Warranty

Return Of Malfunction Instruments

Guidelines Or Returning Unit For Repair

CLEAN Instruments warrants this product to be free from significant deviations in

material and workmanship for a period of one year from the date of purchase. If

repair is necessary and has not been the result of abuse or misuse within the warranty

period, please return to CLEAN Instruments and amendment will be made without

any charge. CLEAN Instruments Customer Service Center will determine if product

problem is due to deviations or customer abuse. Out of warranty products will be

repaired on a charge basis.

Other CLEAN Instruments Measuring Instrument manuals