CLEAR DESIGN BOOST PRO BPROLF-F User manual

Other CLEAR DESIGN Indoor Furnishing manuals

CLEAR DESIGN

CLEAR DESIGN BLCC Series User manual

CLEAR DESIGN

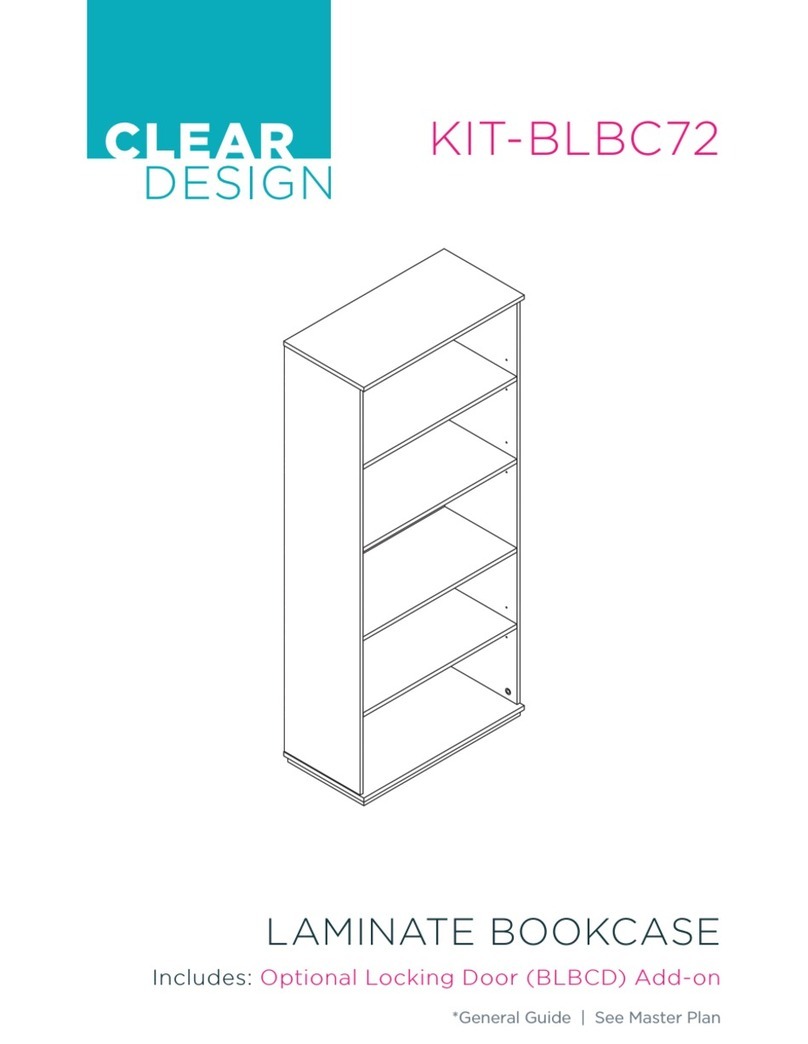

CLEAR DESIGN KIT-BLBC72 User manual

CLEAR DESIGN

CLEAR DESIGN EDGE ECH2472 User manual

CLEAR DESIGN

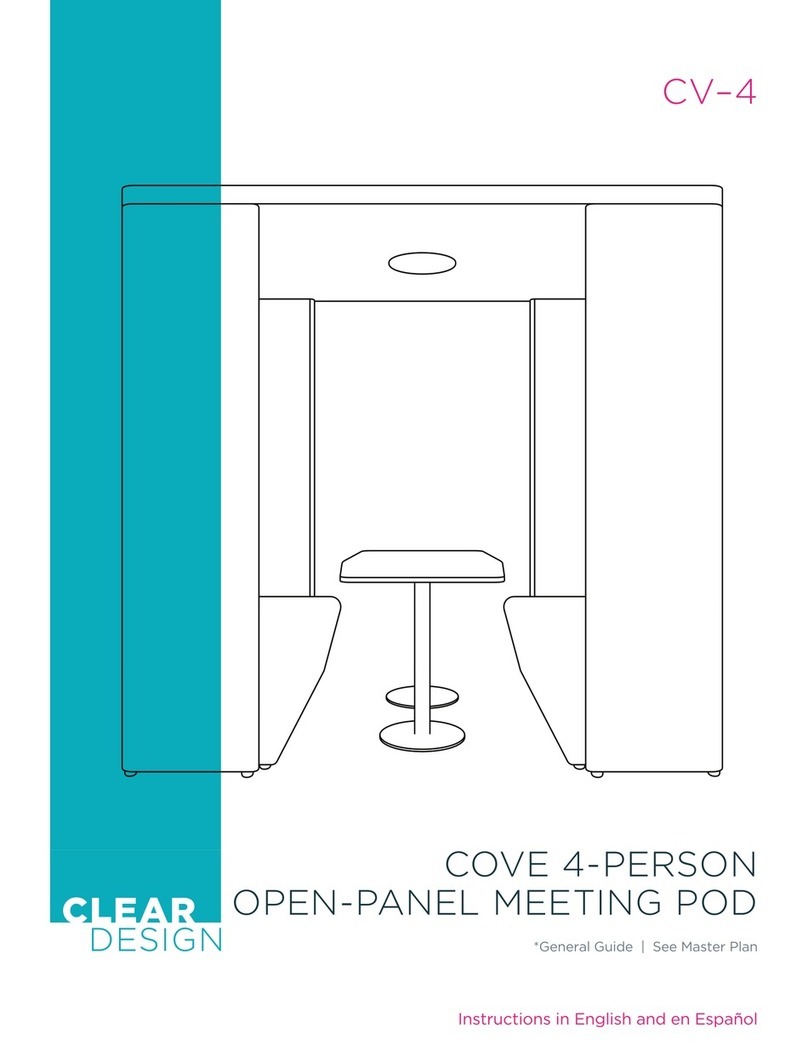

CLEAR DESIGN COVE CV-2 Configuration guide

CLEAR DESIGN

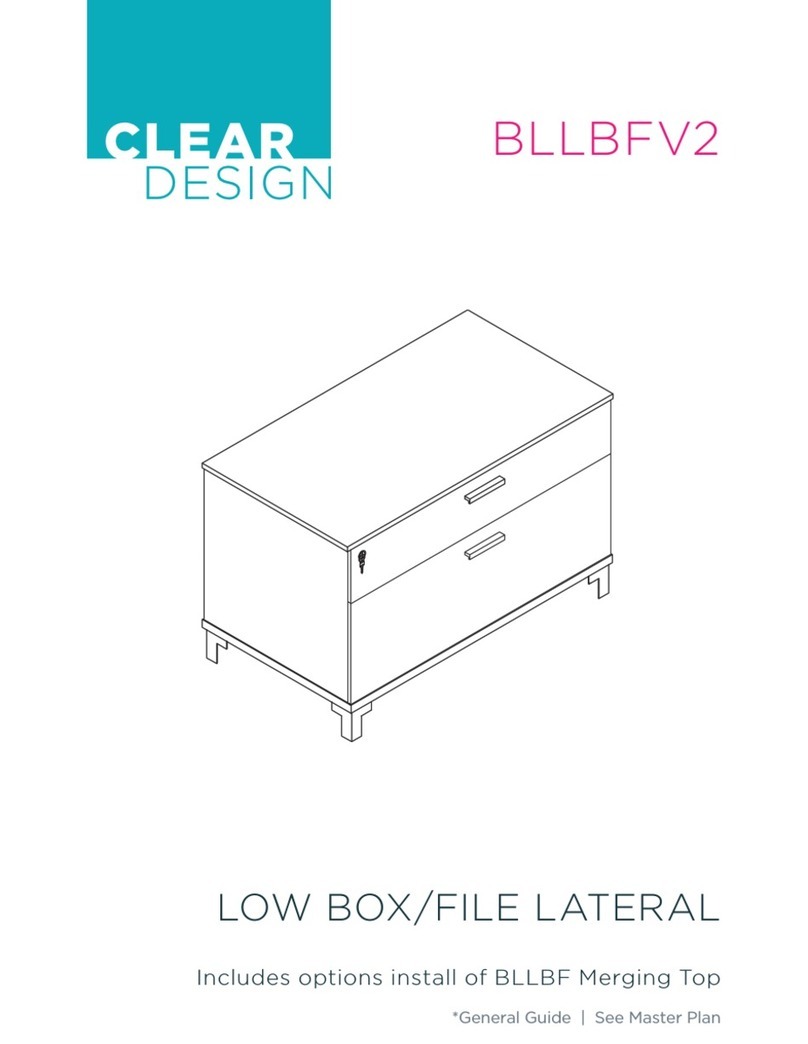

CLEAR DESIGN BLLBFV2 User manual

CLEAR DESIGN

CLEAR DESIGN BL-3 Configuration guide

CLEAR DESIGN

CLEAR DESIGN COVE CV-1 Configuration guide

CLEAR DESIGN

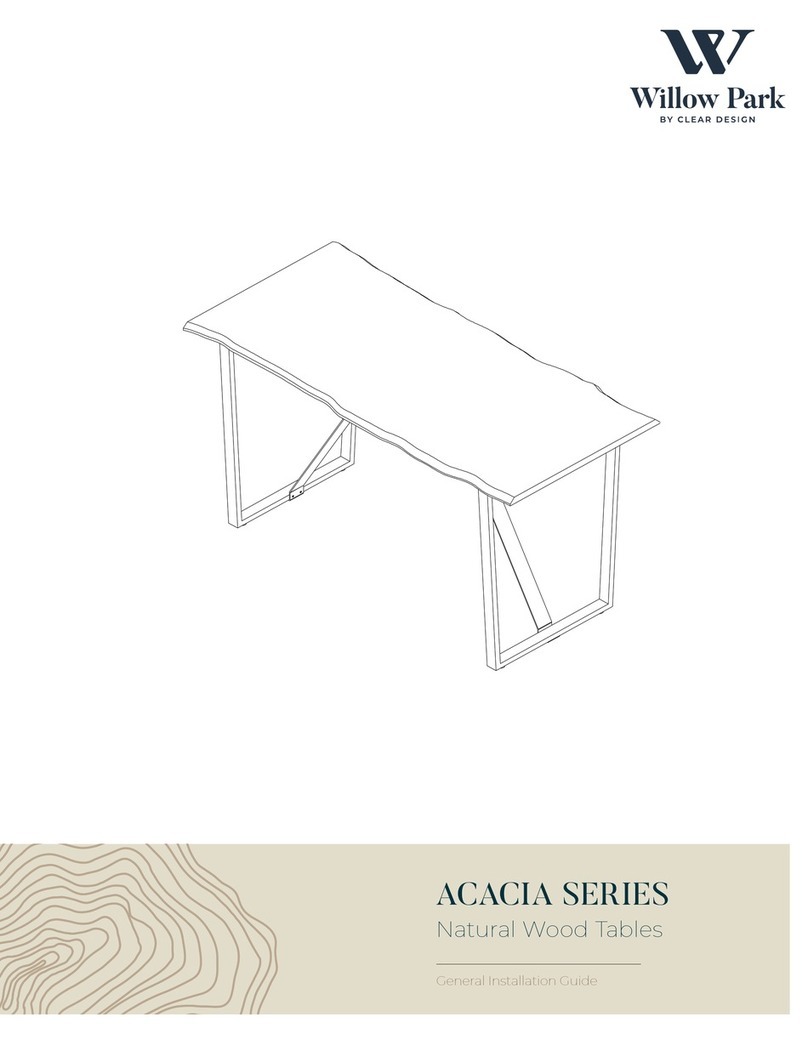

CLEAR DESIGN Willow Park ACACIA Series User manual

CLEAR DESIGN

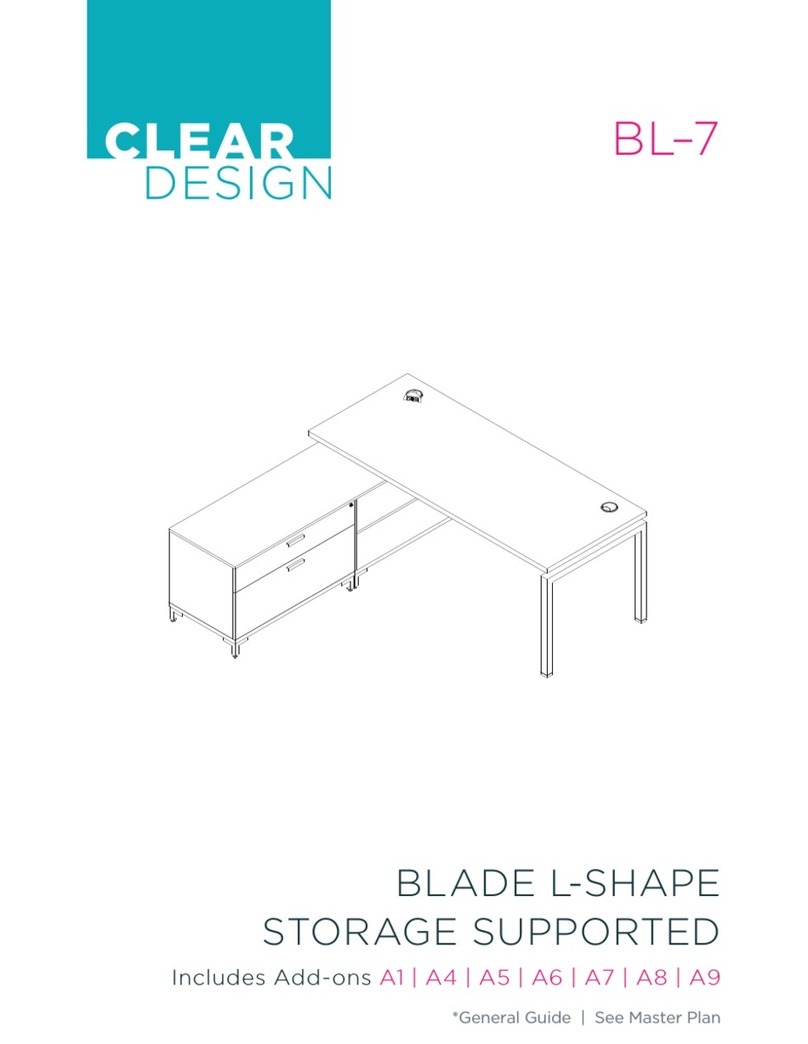

CLEAR DESIGN BL-7 User manual

CLEAR DESIGN

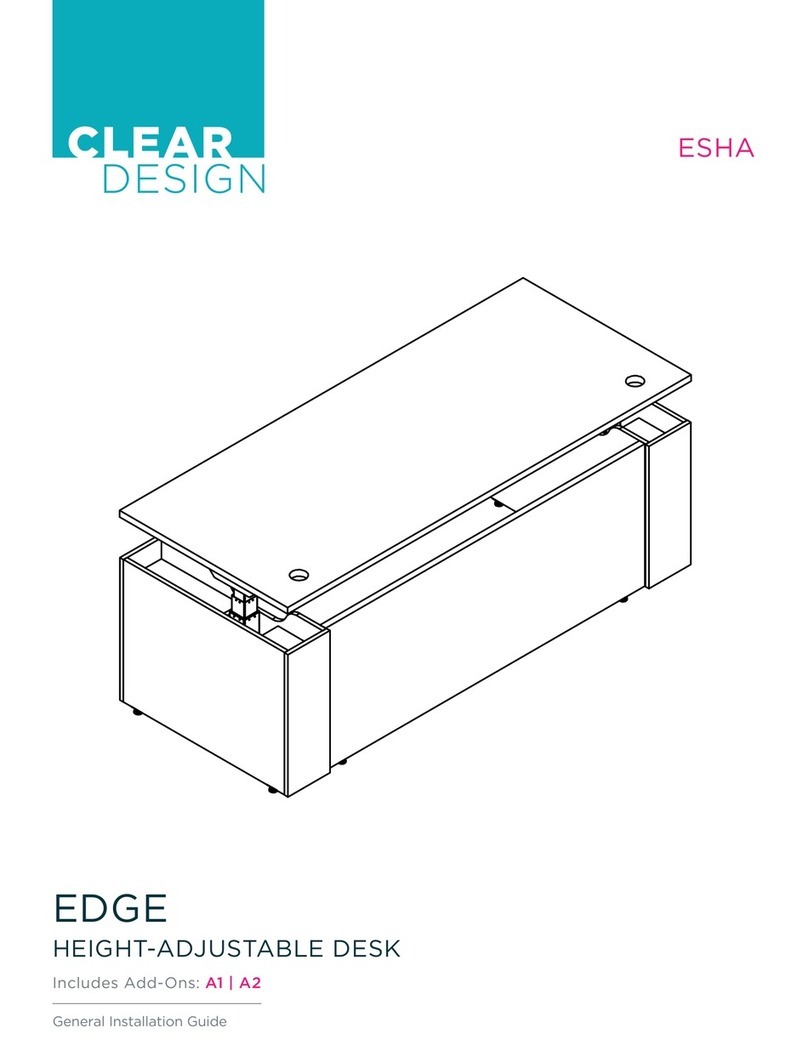

CLEAR DESIGN EDGE ESHA User manual

CLEAR DESIGN

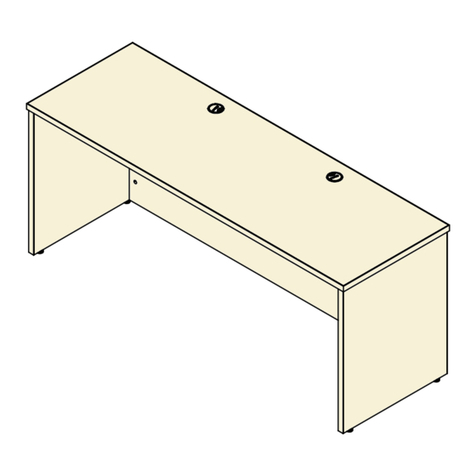

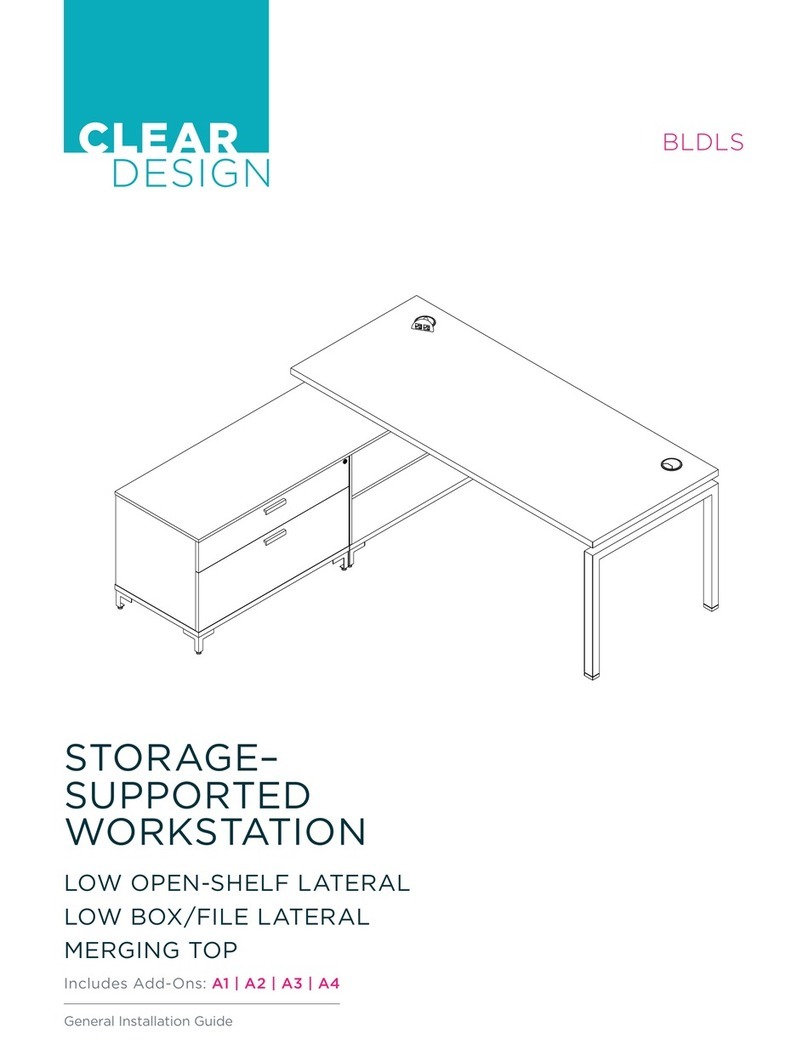

CLEAR DESIGN BLDLS User manual

CLEAR DESIGN

CLEAR DESIGN EDGE CASEGOODS EBDF3571 User manual

CLEAR DESIGN

CLEAR DESIGN BHA2GSA User manual

CLEAR DESIGN

CLEAR DESIGN BLADE BSW User manual

CLEAR DESIGN

CLEAR DESIGN EDGE CASEGOODS EDF3059 User manual

CLEAR DESIGN

CLEAR DESIGN COVE CV-3 Configuration guide

CLEAR DESIGN

CLEAR DESIGN BLLOSV2 User manual

CLEAR DESIGN

CLEAR DESIGN THREE60 User manual

CLEAR DESIGN

CLEAR DESIGN BOOST PRO BP-1 User manual

CLEAR DESIGN

CLEAR DESIGN BLLBFV2 User manual

Popular Indoor Furnishing manuals by other brands

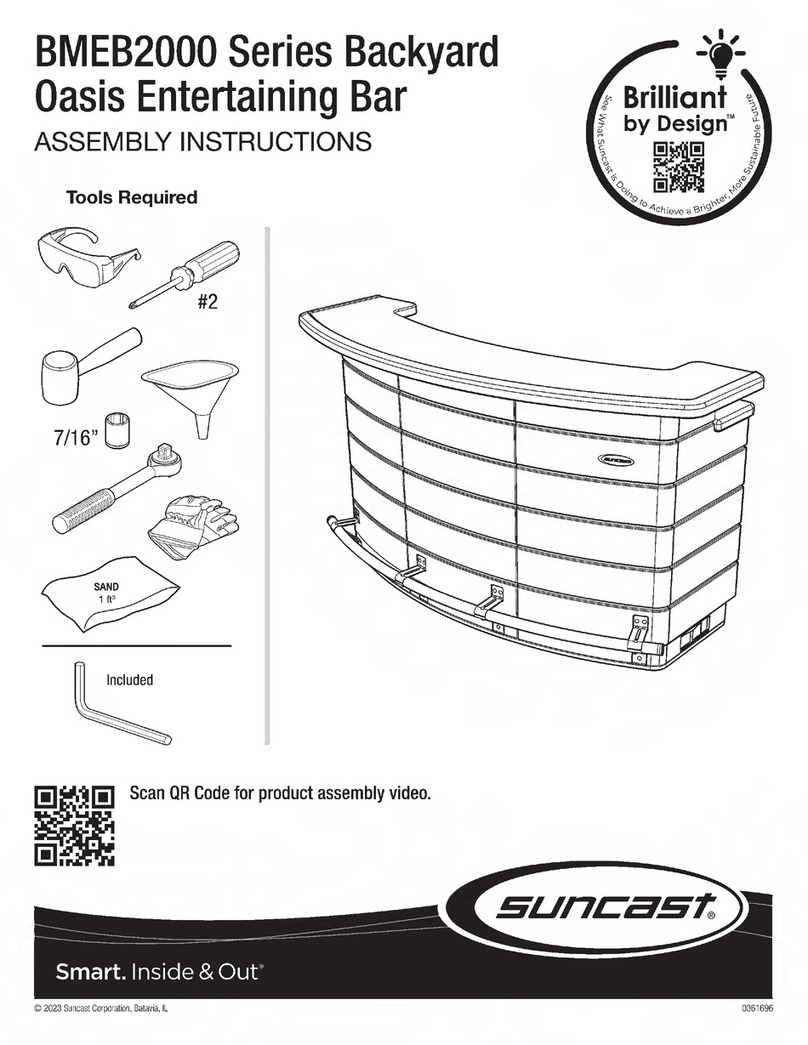

Suncast

Suncast Brilliant by Design BMEB2000 Series Assembly instructions

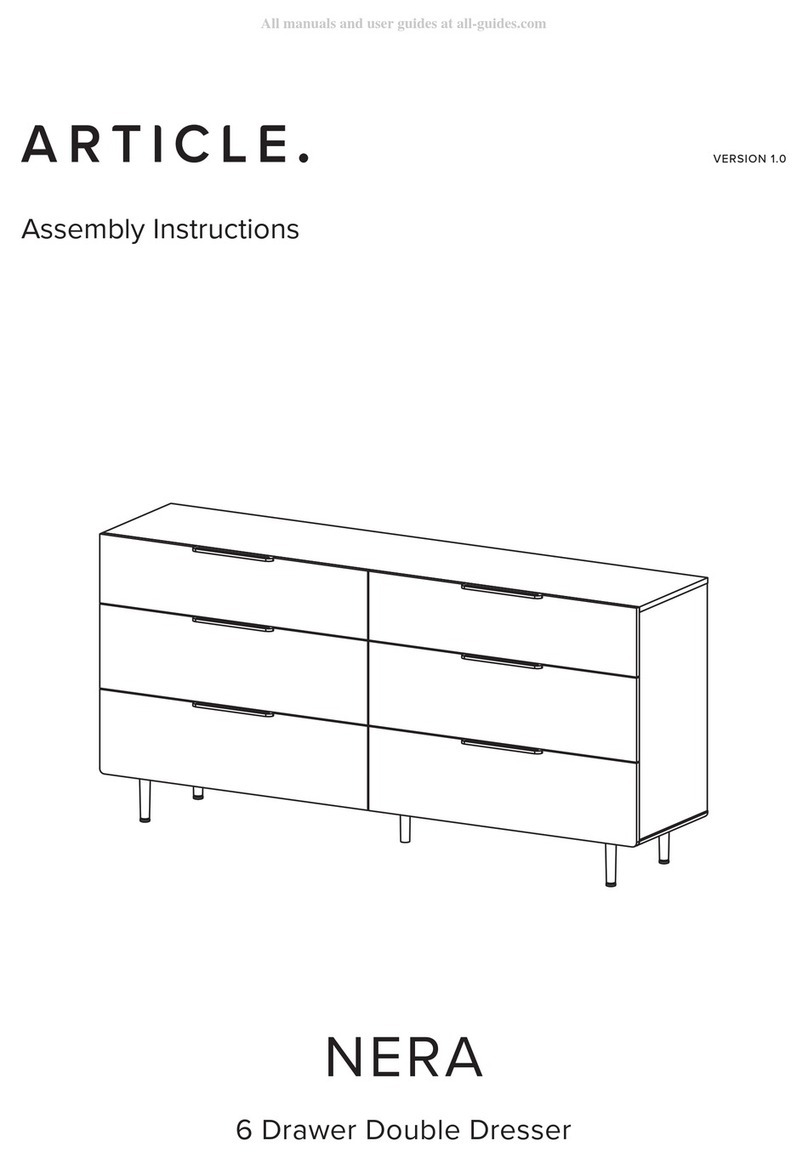

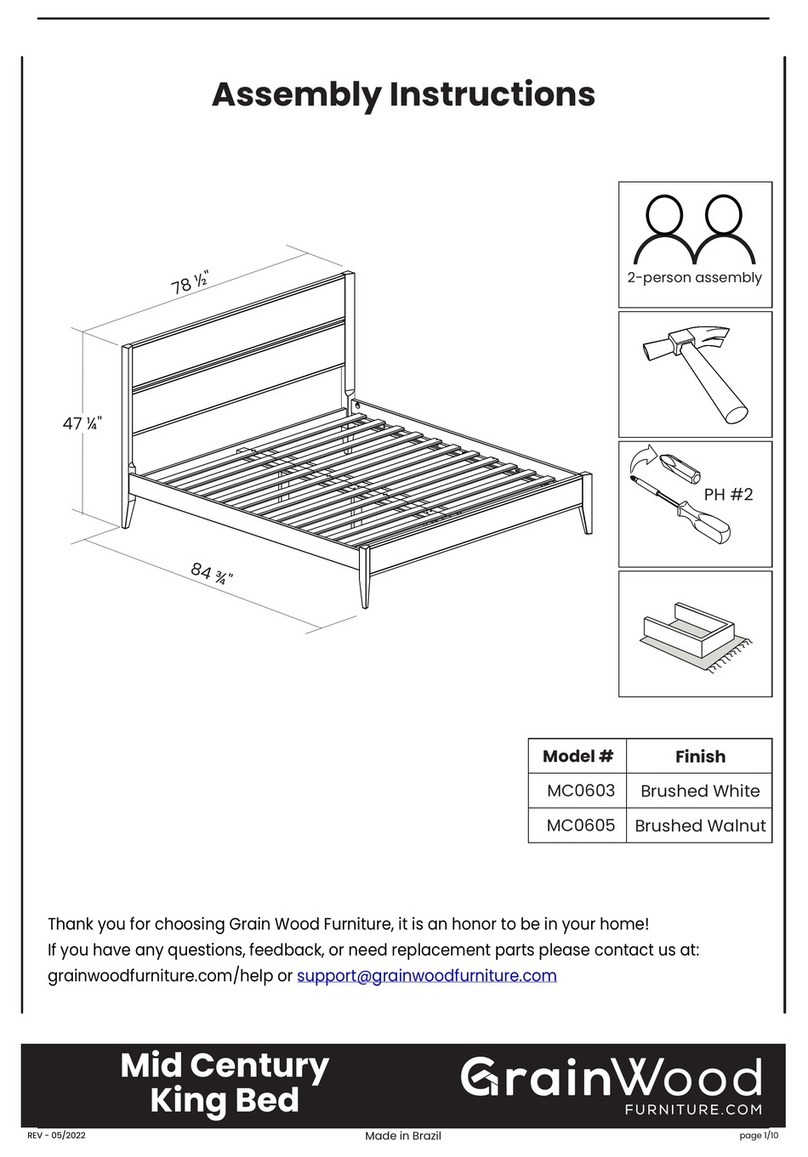

GrainWood

GrainWood MC0603 Assembly instructions

HoMedics

HoMedics EnviraScape Tabletop Relaxation Fountain... Instruction manual and warranty

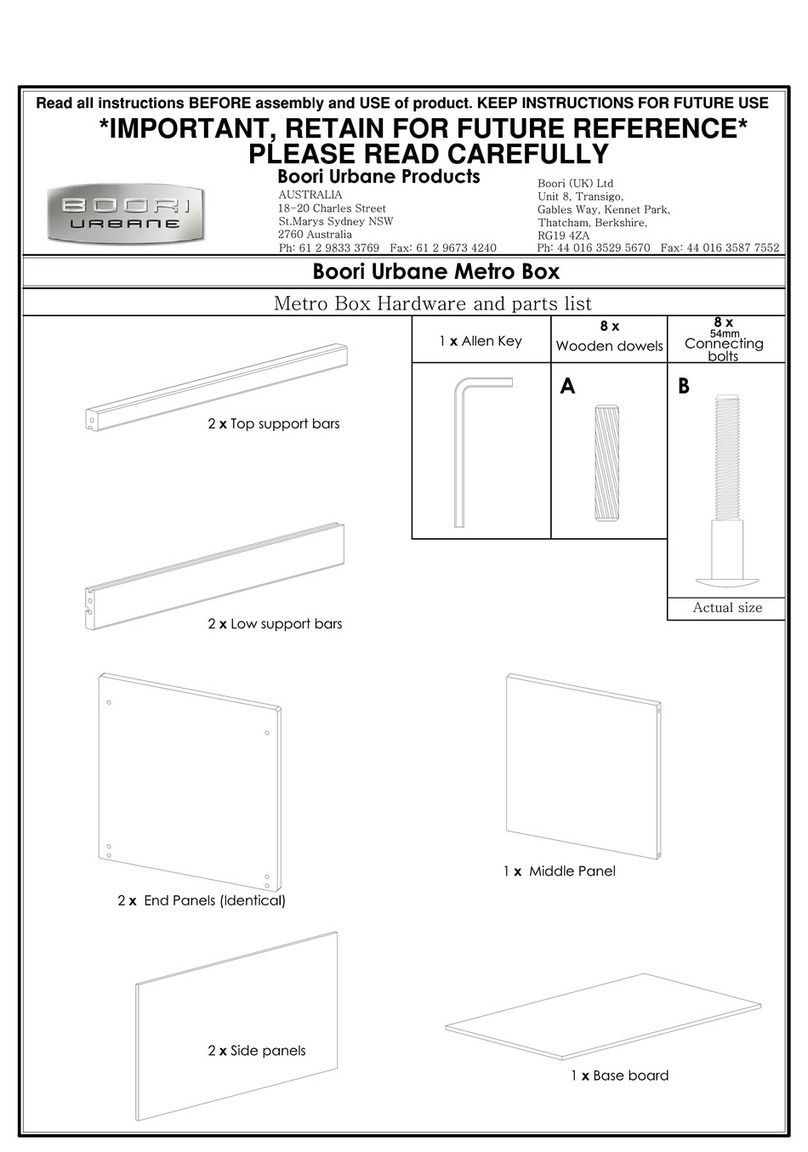

boori

boori Urbanе Metro Box BU-MTBX Assembly instructions

IKEA

IKEA LÖNSET 002.787.19 manual

Carena

Carena UTÖ manual

Levira

Levira CÉOU 10116.05 Assembly instructions

Raynor

Raynor eurotech ADAPT-HI Assembly instructions/Operating instructions

Naomi Home

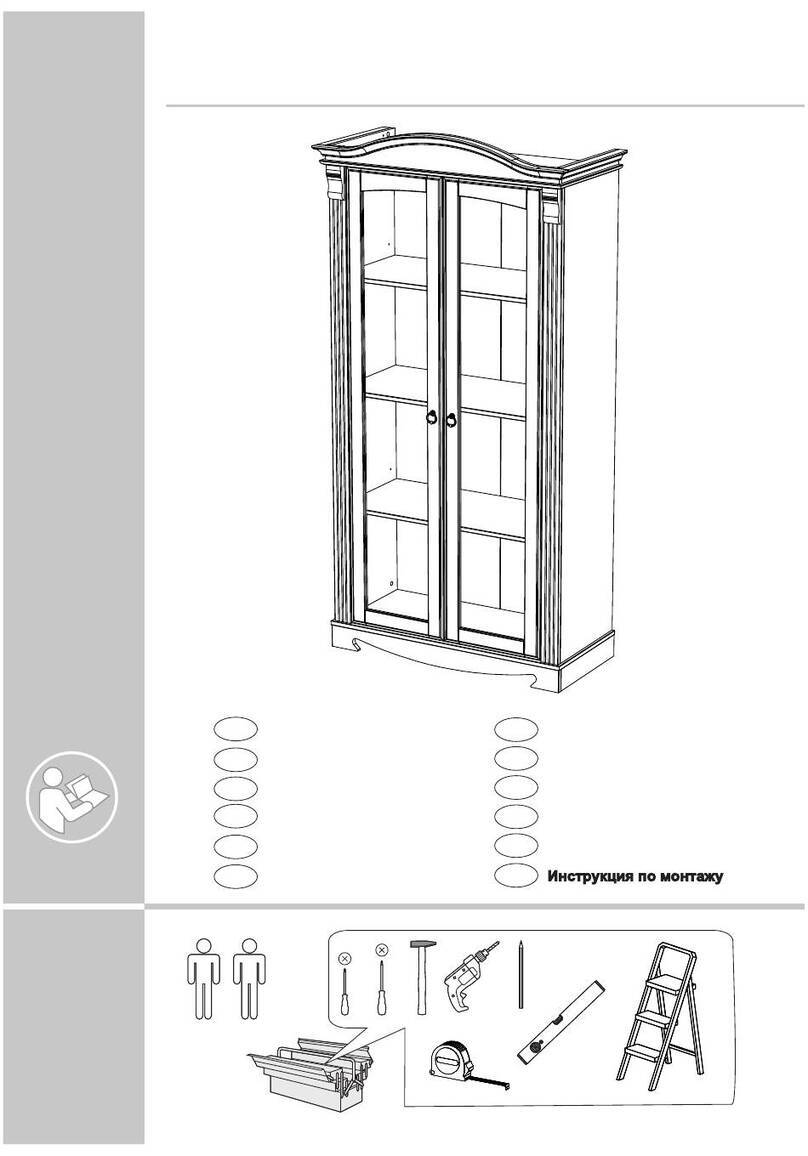

Naomi Home Bianca Office Cabinet Assembly instructions

Home Decorators Collection

Home Decorators Collection 15101-VS24C-WT Assembly instructions

DURAVIT

DURAVIT LM 7874 Mounting instructions

Friant

Friant Tiles installation manual