2

Statement

Dear Customer!

We would like to congratulate you on your new Greenhouse purchase.

We hope that by following the detailed assembly instructions you will find as much pleasure in assembly process

same as the time you will spend in your greenhouse in the future.

The assembly instructions mainly consist of detailed illustrations and no specific technical knowledge is required

for the assembly of the greenhouse.

Depending on the model & accessories package you purchased you may have received multiple packages. The

main ClimaPod house (not counting in accessories or extended models) has three main master packages:

- Straight Frame & Base

- Panels

- Curved Frame

7’ Extension Set also come in three different packages.

The aluminum base, straight frame profiles, as well as supporting hardware are packed in one carton. The

greenhouse curved frames or “arches”are packed in a curved shape package.

All the polycarbonate panels are packed in one carton.

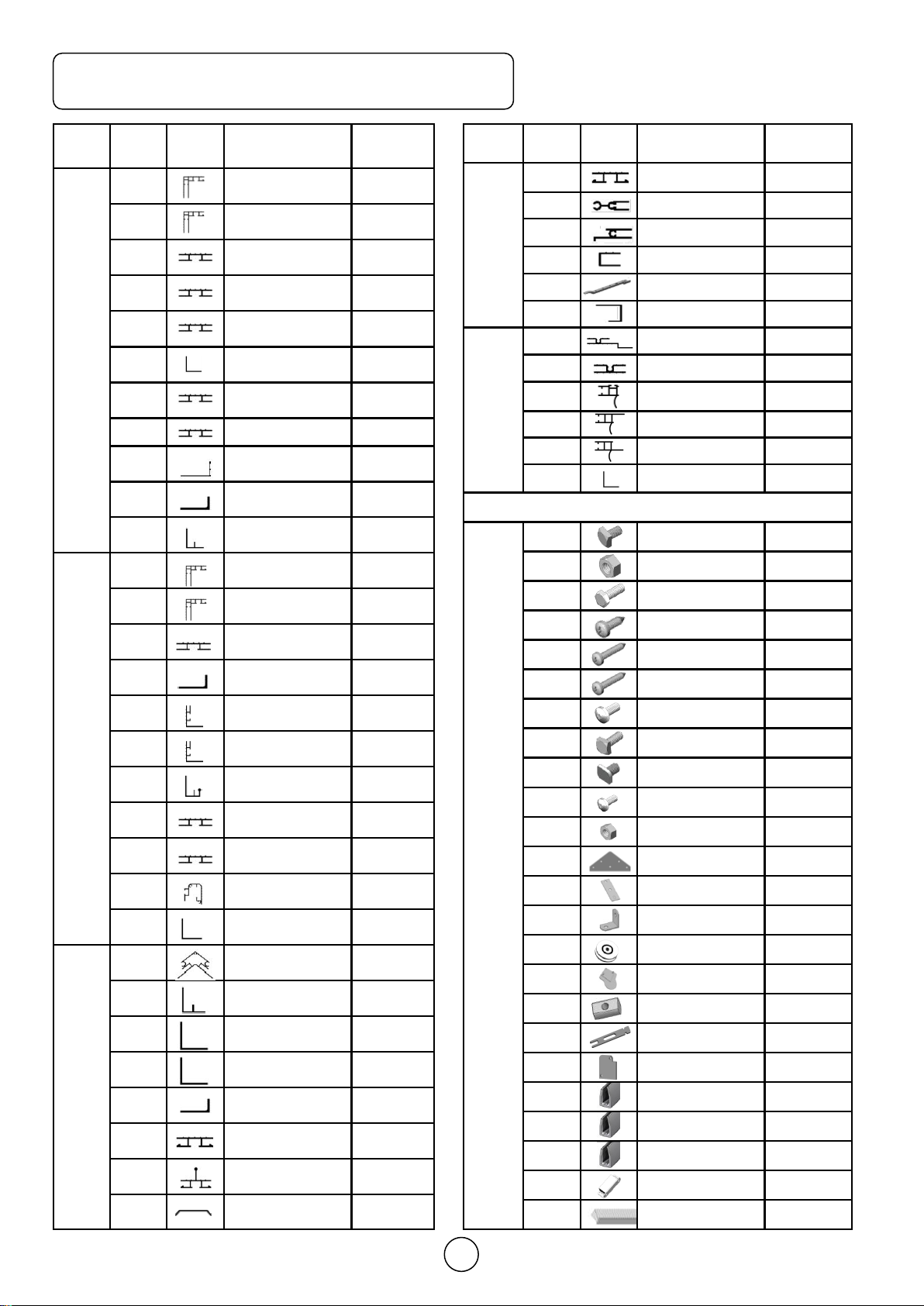

All of the aluminum profiles are marked with a part number corresponding to the numbers given on the draw-

ings and listed on the parts list. Nuts, bolts, and fittings will be found in the relevant package.

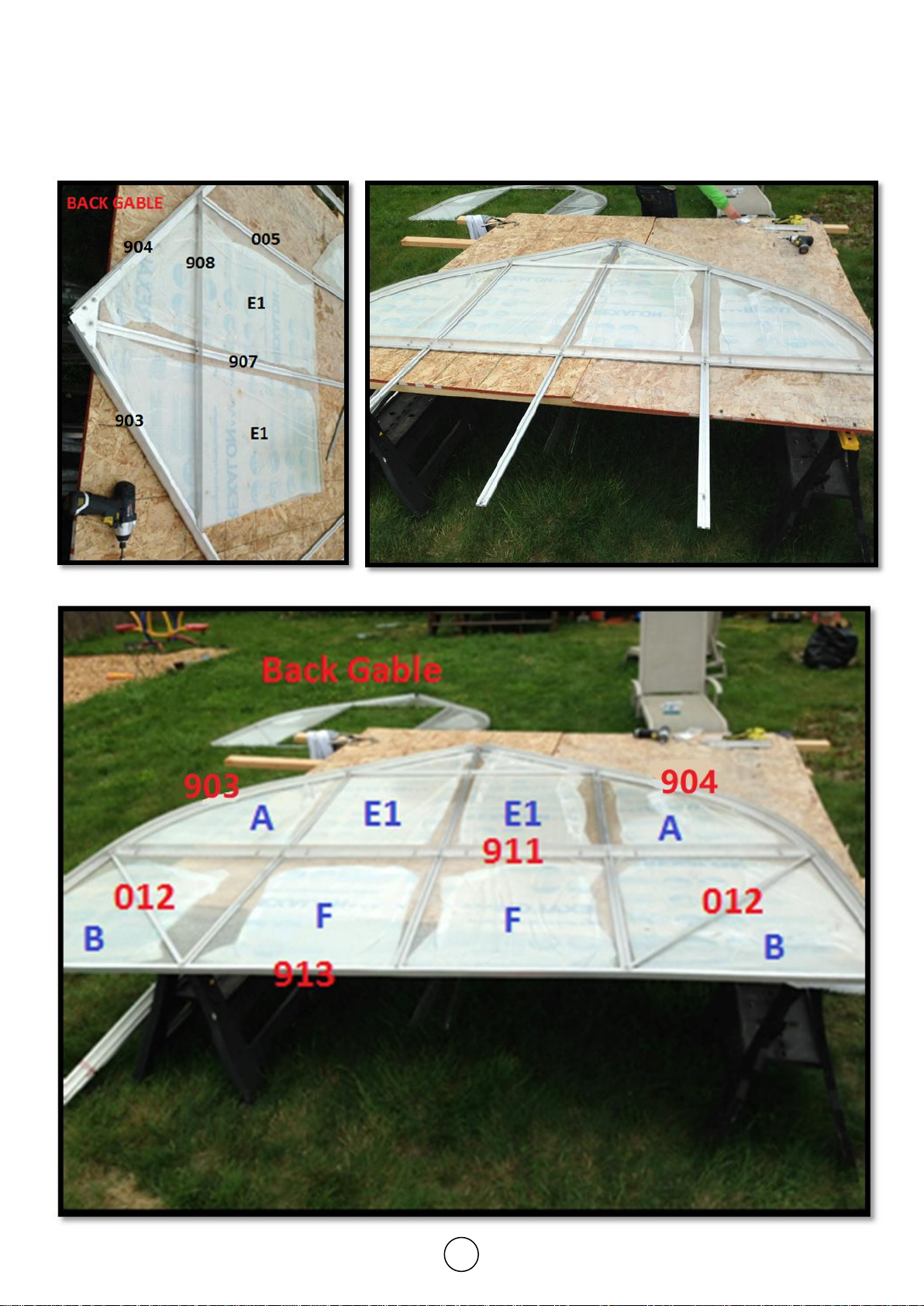

All of the rear gable section straight frames are in package No.1

All of the front gable section straight frames are in package No.2

All of the roof/side wall section straight frames are in package No.3

All of the frames and components for the window are in package No.4

All of the frames and components for the door are in package No.5

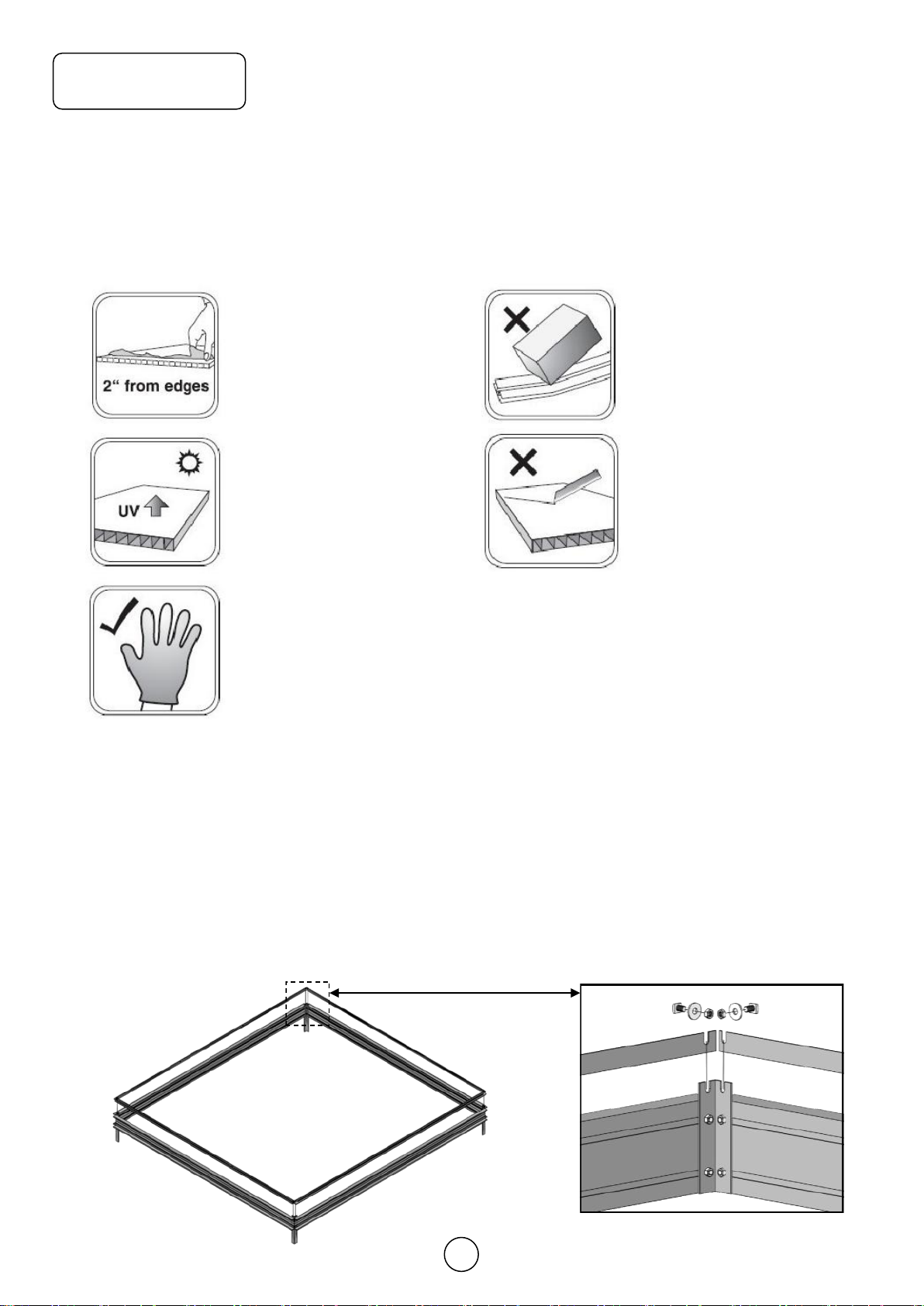

Each of the polycarbonate panels have are labeled with item number corresponding to the instructions. You

may also differentiate them by their size and shape. Note: once you get to insert the polycarbonate panels,

make sure to have the side with opal white film facing outside.

Accessories

Modular Organics LCC (ClimaPod) offers a wide range of accessories which contribute to a better yield and

make life easier for the gardener. A selection of the range is shown in the supplements to these instructions. Upon

the request, your local dealer mayprovide you with more information about available accessories. You mayalso

refer to our main website www.ClimaPod.com for more information.

Winter Protection

In areas where snow might be expected we recommend the following in order to protect your green- house:

1. Support the ridge at the center of the greenhouse.

2. Remove larger snow loads by sliding them down the sides.

3. Take precautions against snow falling down.

Complaints

Weput severe demands on quality to secure that you get a faultless product. However, should a problem occur,

we kindly ask you to contact the dealer from whom you have bought the greenhouse. For a quick service, you

should specify the extent of the defect by means of the parts list in the assembly instructions. Please

also note to mention the model number which is marked on the front page of these instructions.

Guarantee

Wegrant a 10 year comprehensive guarantee which covers replacement or repairs of defective parts due to ma-

terial or manufacturing defect. The guarantee does not cover polycarbonate, transport, erection. The guarantee

is invalid if the greenhouse is not assembled according to these instructions.

Insurance

Not all insurance companies automatically cover greenhouses.We strongly recommend you contact your insur-

ance agent to ensure that your greenhouse is added to the coverage once assembled.