Clipper NORTON JUMBO 651 HONDA User manual

JUMBO 651 HONDA

OPERATING INSTRUCTIONS

2

3

The undersigned manufacturer:

SAINT - GOBAIN ABRASIVES S.A.

190, BD J.F. KENNEDY

L- 4930 BASCHARAGE

Declares that this product:

Masonry Saws:

Jumbo 651 P5.5 Honda

Code:

70184610073

is in conformity with the following Directives:

•European Machinery Directive 2006/42/EC

•Electromagnetic Compatibility Directive 2004/108/EC

and European standard:

•EN 12418 – Masonry and stone cutting-off machines – Safety

Pierre Mersch

Business Manager Machines Europe

Declaration of conformity

4

5

JUMBO 651 HONDA

OPERATING INSTRUCTIONS AND SPARE PARTS LIST

1

Basic Safety Instructions 6

1.1

Symbols 6

1.2 Machine plate 7

1.3 Safety instructions for particular operating phases 7

2

Machine description 8

2.1

Short description 8

2.2

Purpose of use 8

2.3

Layout 8

2.4

Technical Data 10

3

Assembly and commissioning 11

3.1

Tool assembly 11

3.2

Starting the machine 11

3.3

Water cooling system 12

4

Transport and storing 13

4.1

Securing for transport 13

4.2

Transport procedure 13

4.3

Long period of inactivity 13

5

Operating the machine 14

5.1

Site of work 14

5.2

Cutting methods 14

6

Maintenance and servicing 16

6.1

Maintenance of the machine 16

6.2

Maintenance of the engine 17

7

Faults: causes and cures 20

7.1

Fault-finding procedures 20

7.2

Trouble-shooting guide 20

7.3

Customer service 20

6

1 Basic Safety Instructions

The Jumbo 651 is exclusively designed for the cutting of construction products mainly on

construction sites.

Uses other than the manufacturer's instructions shall be considered as contravening the regulations.

The manufacturer shall not be held responsible for any resulting damage. Any risk shall be borne

entirely by the user. Observing the operating instructions and compliance with inspection and

servicing requirements shall also be considered as included under use in accordance with the

regulations.

1.1 Symbols

Important warnings and pieces of advice are indicated on the machine using symbols. The following

symbols are used on the machine:

Read operator’s instructions Ear protection must be worn

Hand protection must be worn Eye protection shall be worn

Rotation direction of the blade

Danger: risk of cut Never move the machine with the blade running

idle.

7

1.2 Machine plate

Important data can be found on the following plate located on the machine:

1.3 Safety instructions for particular operating phases

Before commencing work

•Before commencing work, make yourself familiar with the working environment at the place of

use. The working environment includes: obstacles in the area of work and manoeuvre, the

firmness of the floor, necessary protection at the site relating to public thoroughfares and the

availability of help in the event of accidents.

•Site the machine on an even, firm and stable base!

•During work, apply the brakes located on two of the four wheels.

•Check for correct mounting of the blade regularly.

•Immediately remove damaged or badly worn blades, as they endanger the operator whilst

rotating.

•The material to be cut must be held securely in place on the conveyor cart to allow no

movement during cutting operation.

•Always cut with the blade guard in position.

•Only fit NORTON diamond blades to the machine! The use of other tools can damage the

machine!

•Read the blades’ specifications carefully to choose the correct tool for your application.

•Attention is drawn to the use of BS2092 safety goggles in conformity with specified Processes

No.8 of the Protection of Eyes Regulation 1974, Regulation 2(2) Part 1.

Petrol powered machines:

•Always use the fuel advised.

•In confined areas, exhaust gases should be evacuated and the job site properly aerated.

•Petrol and diesel machines, which by their nature emit toxic exhaust gases, must not be used in

places prohibited by the Health at Work etc. Act 1974 or which are prohibited by Factory

Inspectors or Safety Officers.

•Fuel is flammable. Before filling the tank, shut down the engine, extinguish all open flames and

do not smoke. Take care that no petrol is spilled on any motor part. Always wipe up spilled fuel.

•In case of danger, use the emergency stop button just in front of the machine.

Machine Model Machine Code Weight Year of production Maximum blade diameter

Machine type Serial number Power Safety standard Blade speed

Bore

diameter

8

2 Machine description

Any modification, which could lead to a change in the original characteristics of the machine, may

be done only by Saint-Gobain Abrasives who shall confirm that the machine is still in conformity with

the safety regulations.

2.1 Short description

The JUMBO 651 block saw is designed for durability and high performance for onsite wet and dry

cutting operations of a wide range of masonry, refractory and natural stone products.

As with all other NORTON products, the operator will immediately appreciate the attention given to

detail and quality of materials used in construction. The machine and its component parts are

assembled to high standards assuring long life and minimum maintenance.

2.2 Purpose of use

The machine is designed for cutting a large range of building and refractory materials. It is not

designed for cutting wood or metals.

2.3 Layout

9

Frame (1)

Jig-welded, reinforced and all-steel construction ensures perfect rigidity. The frame includes a large

capacity water tray with drain plug. Frame has built-in lift brackets for easy transportation and is

mounted on 4 wheels, 2 of which have a locking device to secure the machine during cutting.

Cutting head (2)

Jig-welded steel console equipped with pivot bar fixed to frame upright and housed in heavy-duty

bearings. Console supports the motor, the belt drive with its guard and the blade shaft assembly.

Bearings are machined for perfect fit and alignment.

Blade shaft

Precision-machined blade shaft, held in ballbearings and is driven by three heavy-duty V-section

drive belts. The blade shaft assembly is completely enclosed in a cutting head console, accessible

for inspection by way of a removable plate. The removable blade flange is tightened by means of a

hexagonal nut.

Blade guard (3)

Jig-welded steel construction with 650mm-diameter blade capacity, which offers maximum operator

protection and increased visibility of the work piece. Incorporated in the blade guard is an outer

detachable metal cover, which permits easy access to shaft for inspection and blade replacement

when motor is switched off, while fully protecting the blade when in operation.

Down feed and cutting depth adjustment (4)

The spring-loaded cutting head, activated by hand with the grip on the blade guard ensures smooth

lowering of the cutting head for shock-free penetration of the work piece and improved control of the

cutting pressure. A depth-locking device fixed to cutting head and frame enables the operator to set

the cutting head to desired or to maximum cutting depth.

Conveyor cart (5)

Large, heavy-duty and galvanised conveyor cart fitted with water flow-control vents, mounted on 2

locating rollers and 2 flat rollers to give maximum stability and smooth movement. The conveyor cart

is equipped with graduated scale on the backstop and with a guide-a-cut device.

Water cooling system (6)

The coolant system comprises:

•A powerful, submersible water pump

•Plastic suction pipe delivering the water from the water pan to the cutting head

•A large capacity water pan (pan is galvanised) supplied with drain plug

•A water-tap, fitted to the blade guard, permitting controlled water flow

•Two water nozzles located on the blade guard ensure adequate flow of water to both sides of

the cutting blade

•3 water curtains, fixed to frame and blade guard to restrict water spray and to minimise water

loss

Petrol Motor

The Honda GX160 motor is fitted out with an emergency stop button to ensure the safety of the

operator while using the machine.

10

2.4 Technical Data

Motor Honda GX200 4,8kW (6,5HP)

Fuel Automotive unleaded gasoline

Oil

Honda 4-Stroke, or equivalent high detergent, premium quality

motor oil certified to meet or exceed U.S. automobile

manufacturer’s requirement for service classification SG, SF.

(SG, SF designated on the oil container).

SAE 10W-30 recommended

Max. blade diameter 650 mm

Bore 25,4 mm

Cutting length mm 500 mm

Cutting depth mm 265 mm

Table dimension 600x500 mm

Flange diameter 118 mm

Blade shaft speed 1350 min

-1

Machine dimensions 1700x800x1480 mm

Weight 212 kg

Max. operating weight 262 kg

Sound pressure level 93 dB (A) (following ISO EN 11201)

Sound energy level 105 dB (A) (following ISO EN 3744)

11

3 Assembly and commissioning

The machine is delivered fully equipped and assembled (although without diamond blade) and is

ready for operation after connection to the appropriate power supply.

3.1 Tool assembly

Only NORTON blades with a maximum diameter of 650 mm can be used with the Jumbo 651.

All tools used must be selected with regard to their maximum permitted cutting speed for the

machine’s maximum permitted rotation speed.

Before mounting a new blade into the machine, switch off the machine.

To mount a new blade, follow these steps:

•Retract outside cover of blade guard.

•Loosen the hexagonal nut on the blade shaft, which holds the removable outer flange.

•Remove the outer flange.

•Clean the flanges and blade shaft and inspect for wear.

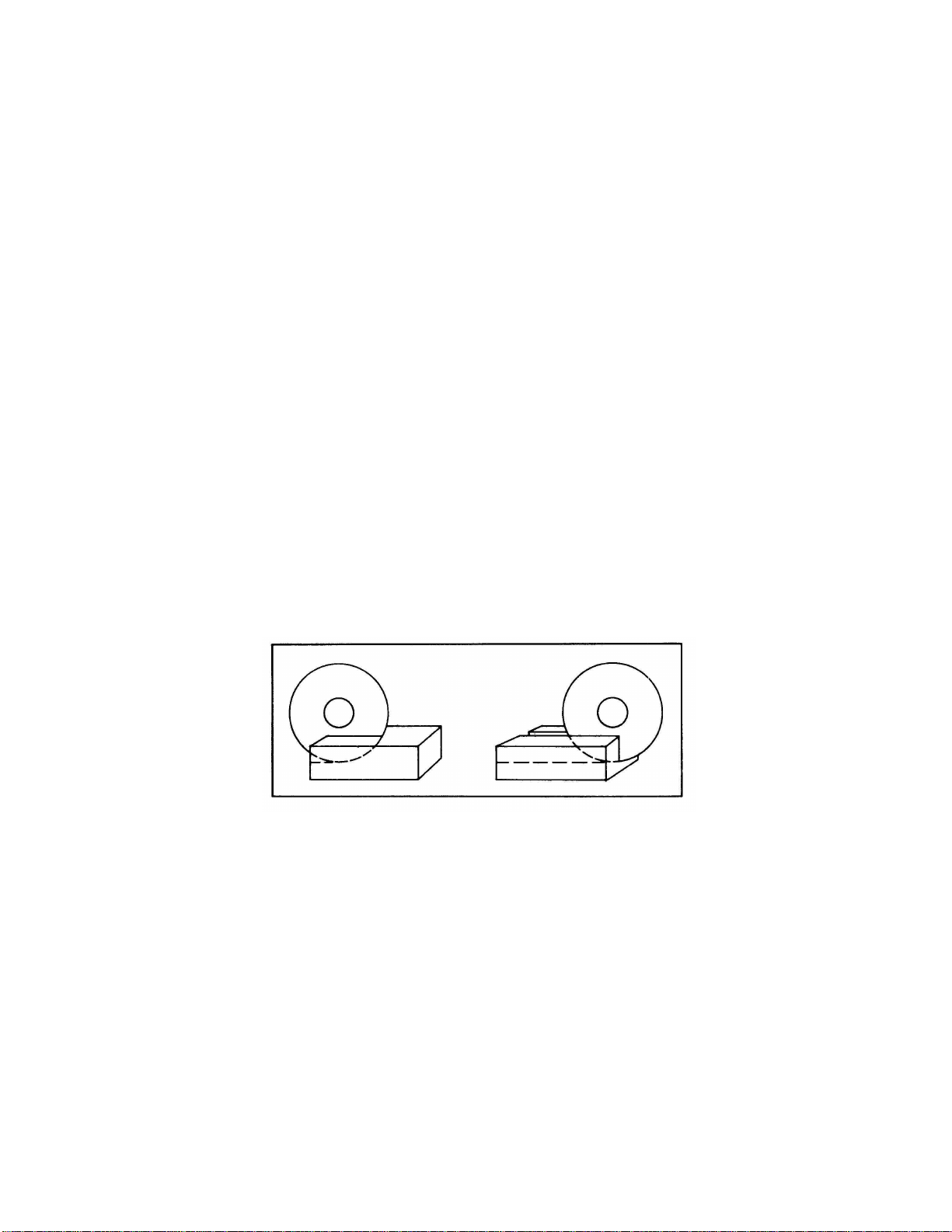

•Mount the blade on arbor ensuring that direction of rotation is correct. Wrong direction of rotation

blunts the blade quickly.

•Replace outer blade flange.

•Tighten hexagonal nut with spanner supplied for this purpose.

•Shut retractable blade guard cover.

The blade bore must correspond exactly to the diameter of the blade shaft. Cracked or damaged

bore is dangerous for the operator and for the machine.

3.2 Starting the machine

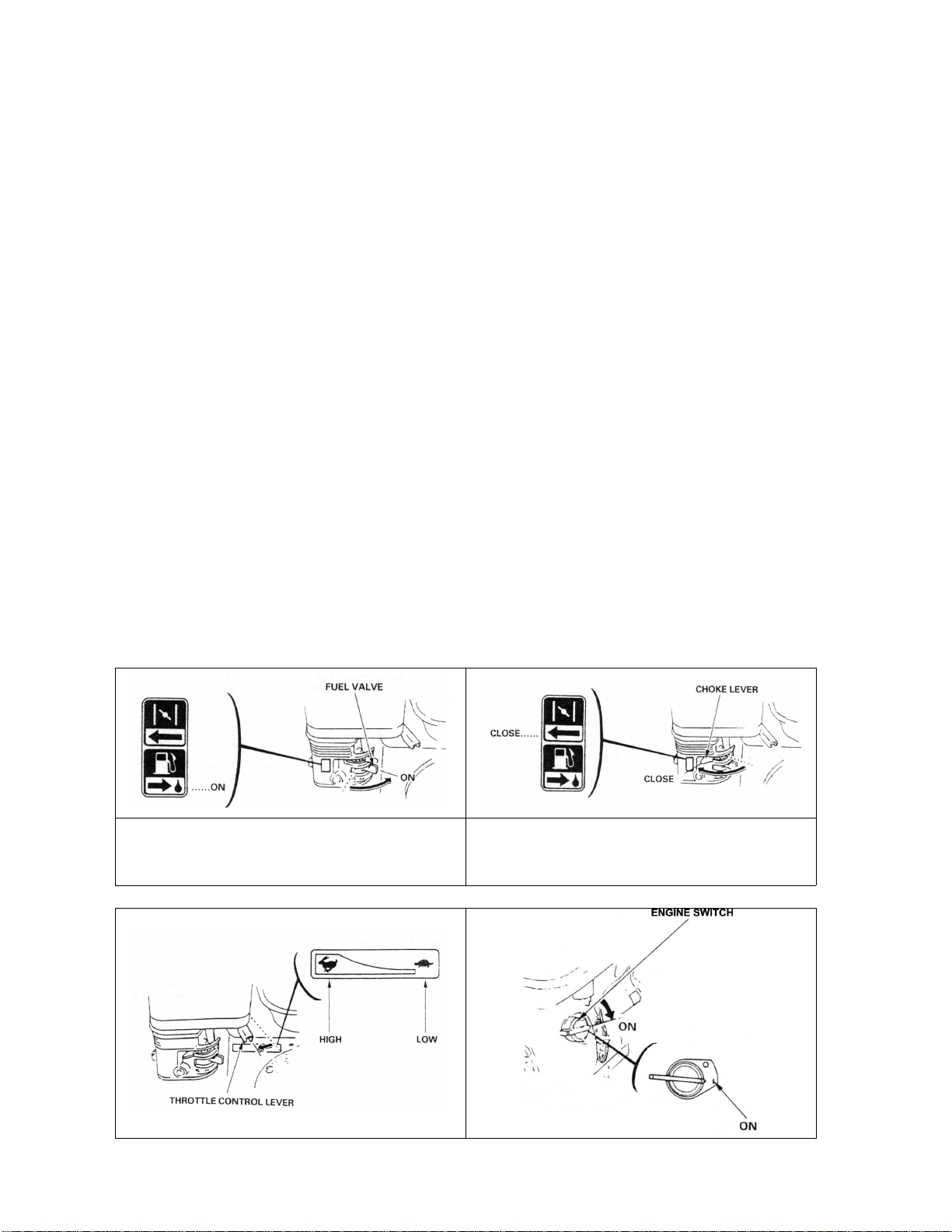

Turn the fuel valve to the ON position. Move the choke lever to the CLOSED position.

NOTE: do not use the choke if the engine is

warm or the air temperature is high.

12

Move the throttle control lever slightly to the

left. Put the engine switch on ON, and make sure

the emergency switch on the board of the

machine is in the correct position.

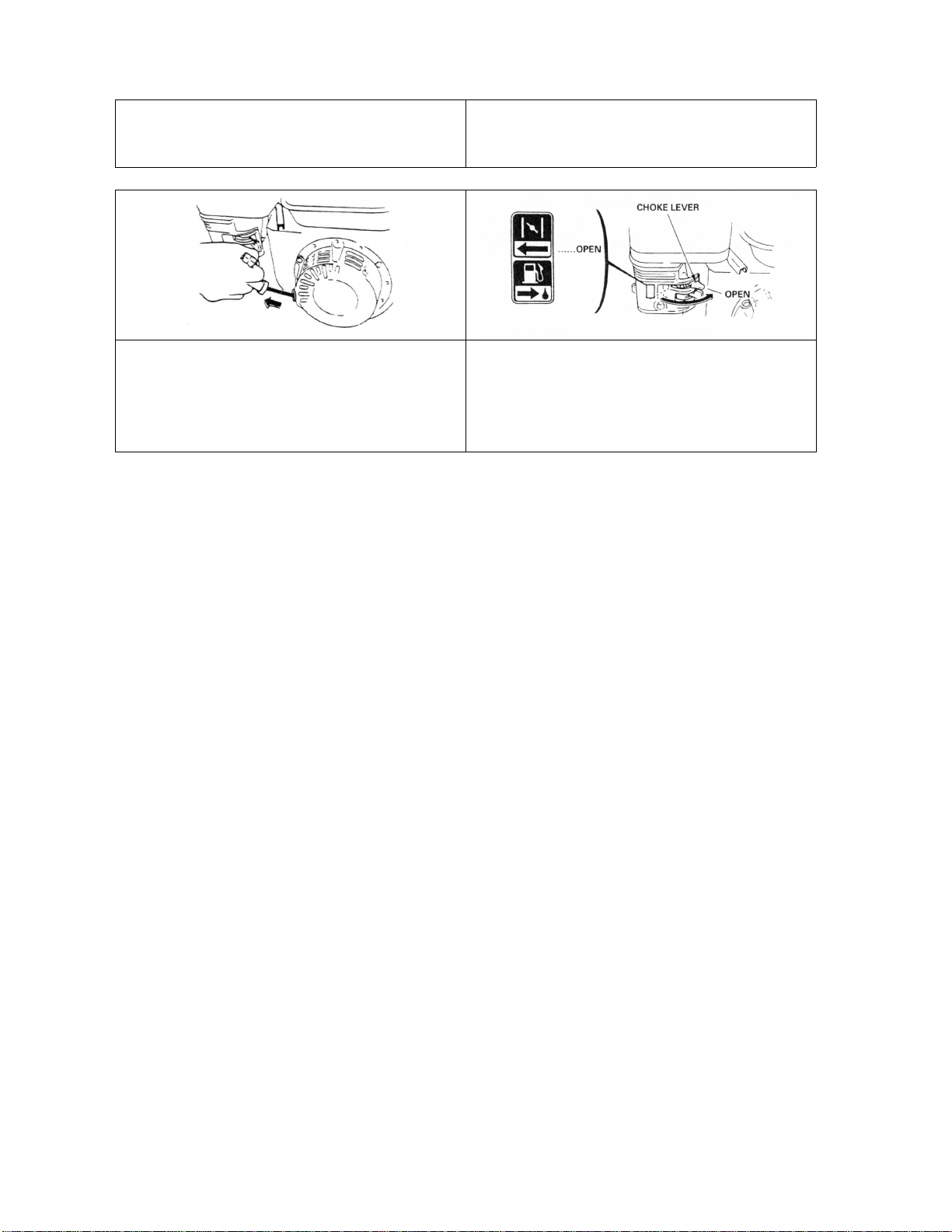

Pull the starter grip lightly until you feel

resistance, then pull briskly.

CAUTION: Do not allow the starter grip to snap

back against the engine. Return it gently to

prevent damage to the starter.

As the engine warms up, gradually move the

choke lever to the OPEN position.

Position the throttle control lever for the

maximum engine speed.

To stop the engine, move the throttle control lever fully to the right, then turn the engine switch to

the OFF position. Turn the fuel valve to the OFF position.

3.3 Water cooling system

Fill the water pan with clean water to approximately 2,5cm from top (ensure that bottom of pump is

fully immersed in water).

Open water-tap at blade guard (note that handle on water-tap should be in line with water-flow).

Ensure that water is flowing freely in the circuit and is delivered adequately to both sides of the

blade, as insufficient water supply may result in premature failure of the diamond blade.

The water pump must never run without water. Always make sure that there is enough water in the

pan and refill if necessary. In case of frost, empty the water cooling system.

13

4 Transport and storing

Take the following measures in order to transport the Jumbo 651 securely.

4.1 Securing for transport

Before transporting or lifting the machine, always remove the blade and empty the water pan.

The conveyor cart must be secured:

•move the conveyor cart to the end of the machine

•fix it using the pin on the rear right post and the eye screw on the conveyor cart.

4.2 Transport procedure

The machine can be moved on a flat surface using its wheels. Only use the lift brackets to lift the

machine, as other parts of the machine are not designed for this purpose.

4.3 Long period of inactivity

If the machine is not going to be used for a long period, please take the following measures:

•Completely clean the machine

•Loosen the drive belts

•Empty the water system

•Take the water pump out of the slurry and clean it thoroughly.

The storage site must be clean, dry and at a constant temperature.

14

5 Operating the machine

5.1 Site of work

5.1.1 Siting the machine

•Remove from the site anything, which might hinder the working procedure!

•Make sure the site is sufficiently well lit!

•Observe manufacturer's conditions for connecting to power supplies!

•Make sure you have a continual adequate view of the working area so you can intervene in the

working process at any time!

•Keep other staff out of the area, so you can work securely.

5.1.2 Space required for operation and maintenance

Leave 2 m in front of the machine and 1,5 m around it for usage and maintenance of the Jumbo

651.

5.2 Cutting methods

To use the machine correctly, you must face it with one hand on the handle of the cutting head, and

the other on the handle of the conveyor cart. Always keep your hands away from the moving blade.

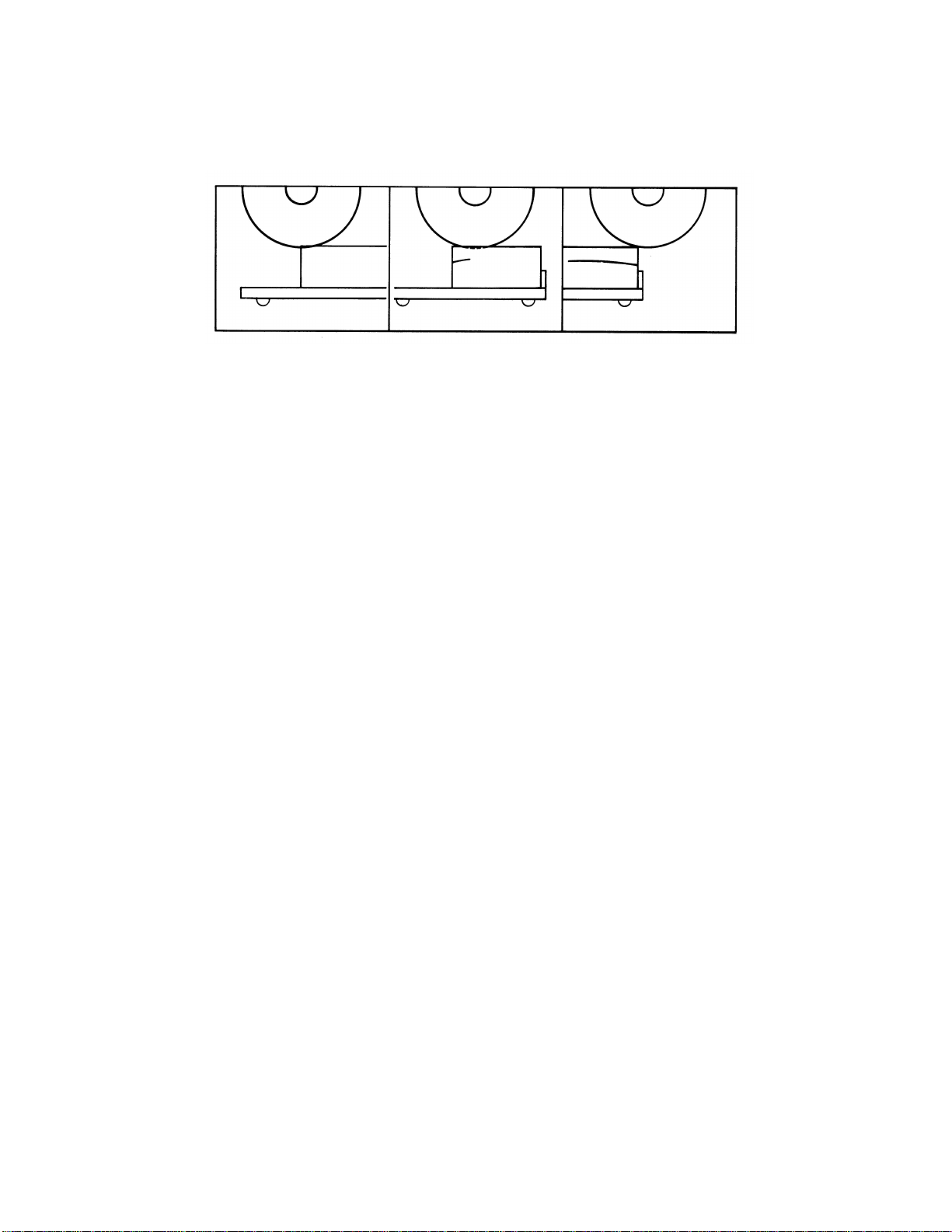

5.2.1 Jam or fixed cutting

In jam or fixed cutting, the cutting head is locked in a fixed position and the material is pushed into it

as shown.

•Lower the cutting head to the desired cutting depth (in “through cutting”, lower cutting head until

blade periphery reaches max. 3-5mm under the surface of the conveyor cart) by means of the

handle on the blade guard

•Fix position by tightening the clamping device

•Put material on conveyor cart

•Push the conveyor cart slowly and without undue pressure towards the rotating blade and cut

the material.

NOTE: While recommended, it is not absolutely necessary to lock the cutting head into a given

depth position when jam cutting. The desired cutting depth can be maintained by holding firmly the

depth feed handle on the blade guard.

If the full depth of cut requires excessive pressure (on very dense material e.g.) make 2 or 3 shallow

cuts.

15

5.2.2 Multiple step cutting

Multiple step cutting consists of moving the conveyor cart with the material to be cut back and

forward under the rotating blade,

•Place the material to be cut on the conveyor cart firmly against the guide-a-cut and the

backstop, keeping the hands well away from the blade.

•Move conveyor cart forward near the blade and pull down the cutting head until blade is lowered

to a point where it will lightly contact the surface of the material.

•Then pass the material beneath with rapid full length strokes, taking a shallow cut

(approximately 3 mm deep) on the forward. On the backward stroke, lift the blade just clear over

the cutting line.

•Complete each rapid stroke backward and forward by passing the material beyond the centre of

the blade before starting the reverse movement of the conveyor cart.

NOTE: the harder the material, the more rapid should be the forward and backward strokes.

Step cutting lessens the area of the blade circumference in contact with the material, keeping the

blade cool, running free and cutting at peak efficiency.

5.2.3 General advice for the cutting

•Material weighing under 50 kg and having dimensions smaller than 600x500x265mm can be cut

with the Jumbo 651.

•Before commencing work make sure tools are firmly seated!

•Select the right tools as recommended by the manufacturer depending on the material to be

worked, the working procedure (dry or wet cut) to be carried out and the required efficiency.

•Apply cooling water continuously whilst cutting and in good time!

•When dry cutting, ensure sufficient dust extraction!

•When cutting work is finished, close the water-tap so you can remove the cut pieces from the

conveyor cart without getting wet.

16

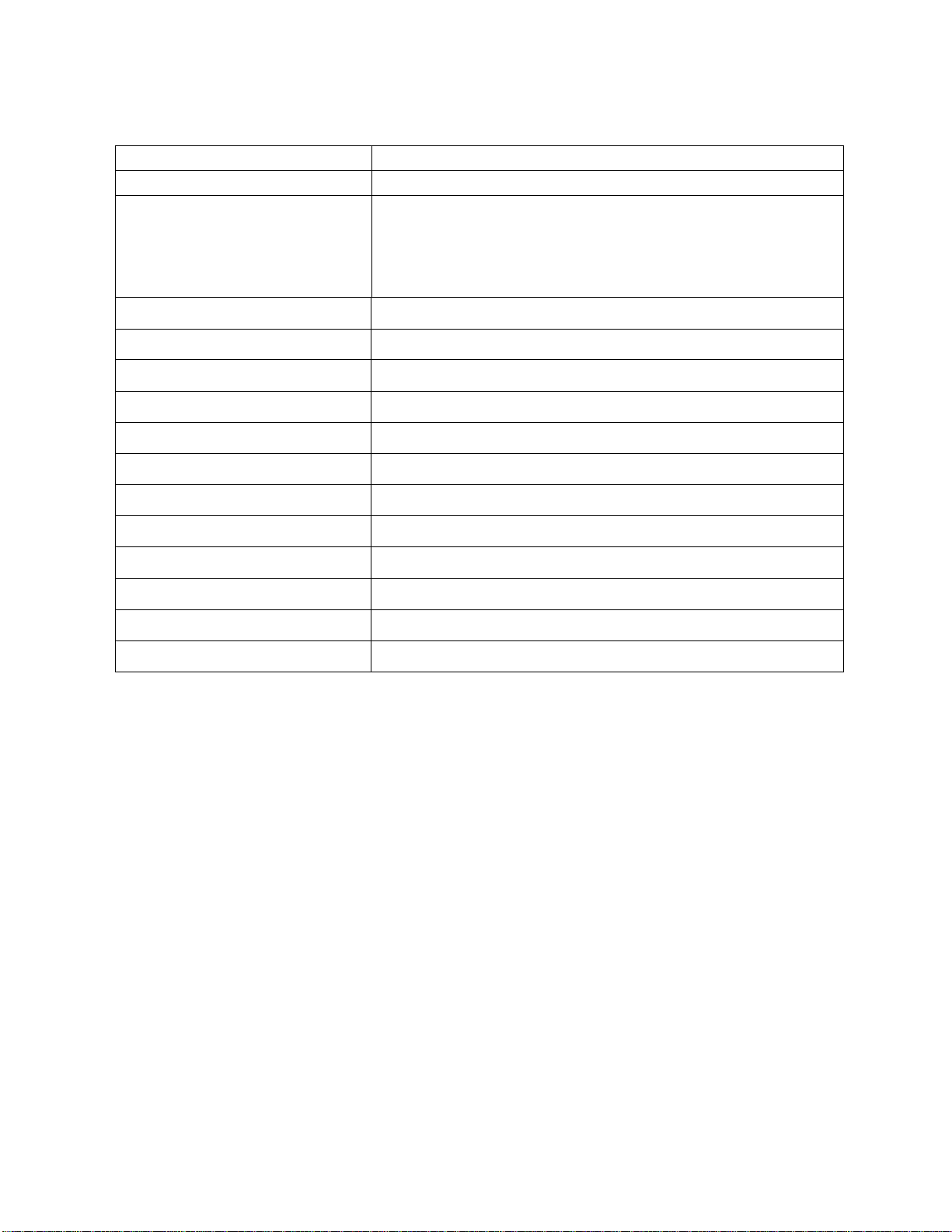

6 Maintenance and servicing

6.1 Maintenance of the machine

To ensure a long-term quality from the cutting with the Jumbo 651, please follow the maintenance

plan below:

Begin of the day

During the changing of the

tool

End of the day

Every week

After a fault

After a damage

Visual control (general

aspect, watertightness)

Whole machine

Clean

Flange and blade fixing devices Clean

Belts tension Check tension and adjust

Water pan Clean

Water pump Clean

Water hoses and nozzles Clean

Water pump filter Clean

Cart guiding bars Clean

Engine housing Clean

Reachable nuts and screws Tighten up

Maintenance of the engine

Always perform the maintenance of the motor with the machine switched off.

Adjustment and replacement of the belts

To adjust the belts, firstly remove the belt guard by unscrewing the 6 nuts. Loose the 4 engine bolts

and shift the engine by using the two screws on the side.

To replace the belts, move the engine completely to the left. Adjust the belts and retighten them by

shifting the motor to the left.

Always use a matched set of belts. Do not replace single belts.

Lubrication

The Jumbo 651 uses life-lubricated bearings. Therefore, you don’t need to lubricate the machine at

all.

Cleaning of the machine

Your machine will last longer if you clean it thoroughly after each day of work, especially water

pump, water pan, motor and blade flange.

17

6.2 Maintenance of the engine

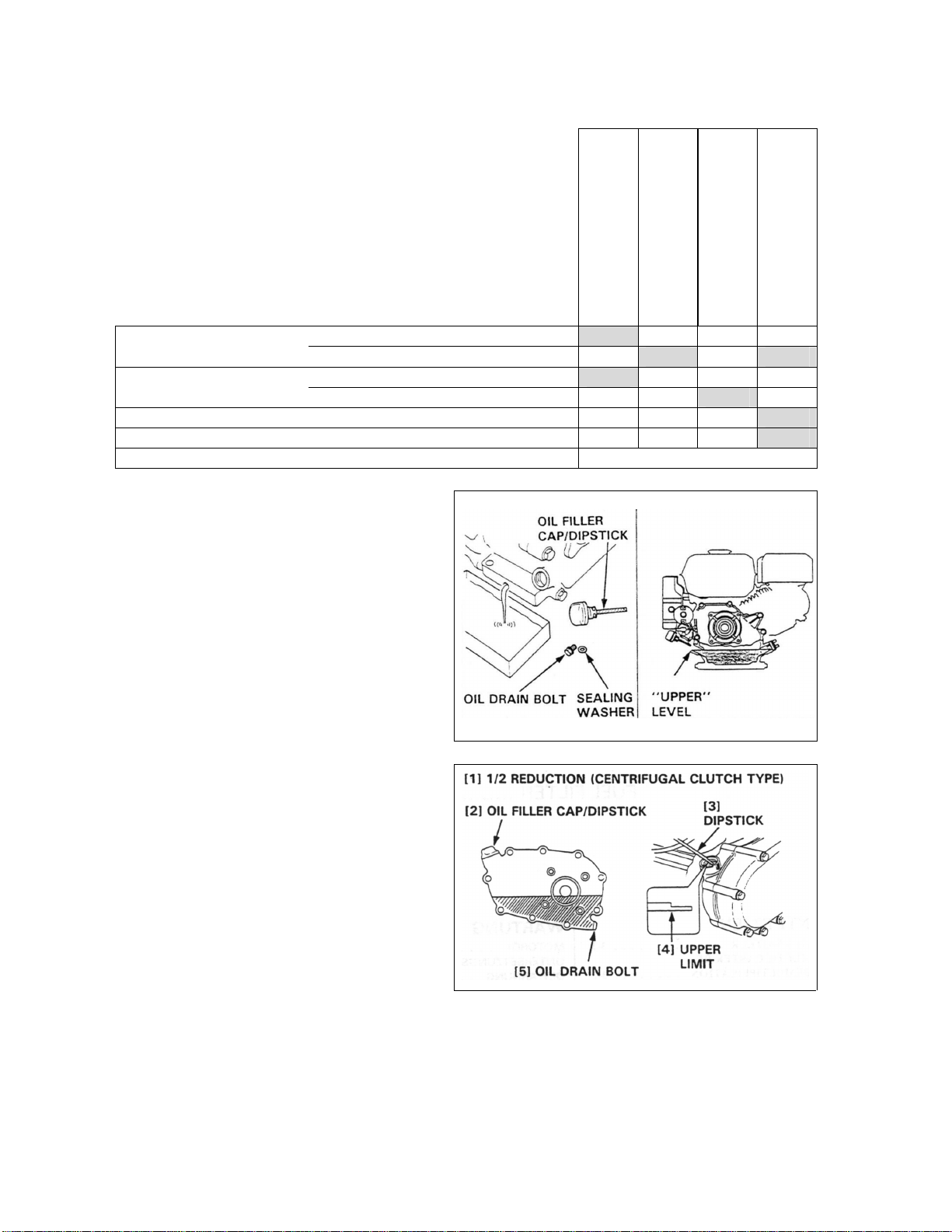

Regular service period

Perform at every indicated month or

operating hour interval, whichever comes

first

Each use

First month or 20 hours

Every 3 months or 50 hours

Every 6 months or 100 hours

Check level

Engine oil Change

Check

Air cleaner filter Clean

Fuel strainer cup Clean

Spark plug Check-Clean

Fuel line Check (Replace if necessary) Every 2 years

Engine oil

To change the oil,

•Remove the oil filler cap/dipstick and

drain bolt.

•Allow the oil to drain completely.

•Reinstall the drain bolt, and tighten it

to 18 N.m.

•Fill the crankcase with the engine oil to

the outer edge of the oil filler neck.

•Reinstall the filler cap/dipstick.

Reduction case oil

•Remove the oil filler cap/dipstick and

drain bolt.

•Allow the oil to drain completely.

•Reinstall the drain bolt, and tighten it

to 18 N.m.

•Fill the reduction case with the same

oil that is recommended for the

engine. Fill to the upper limit mark on

the dipstick.

18

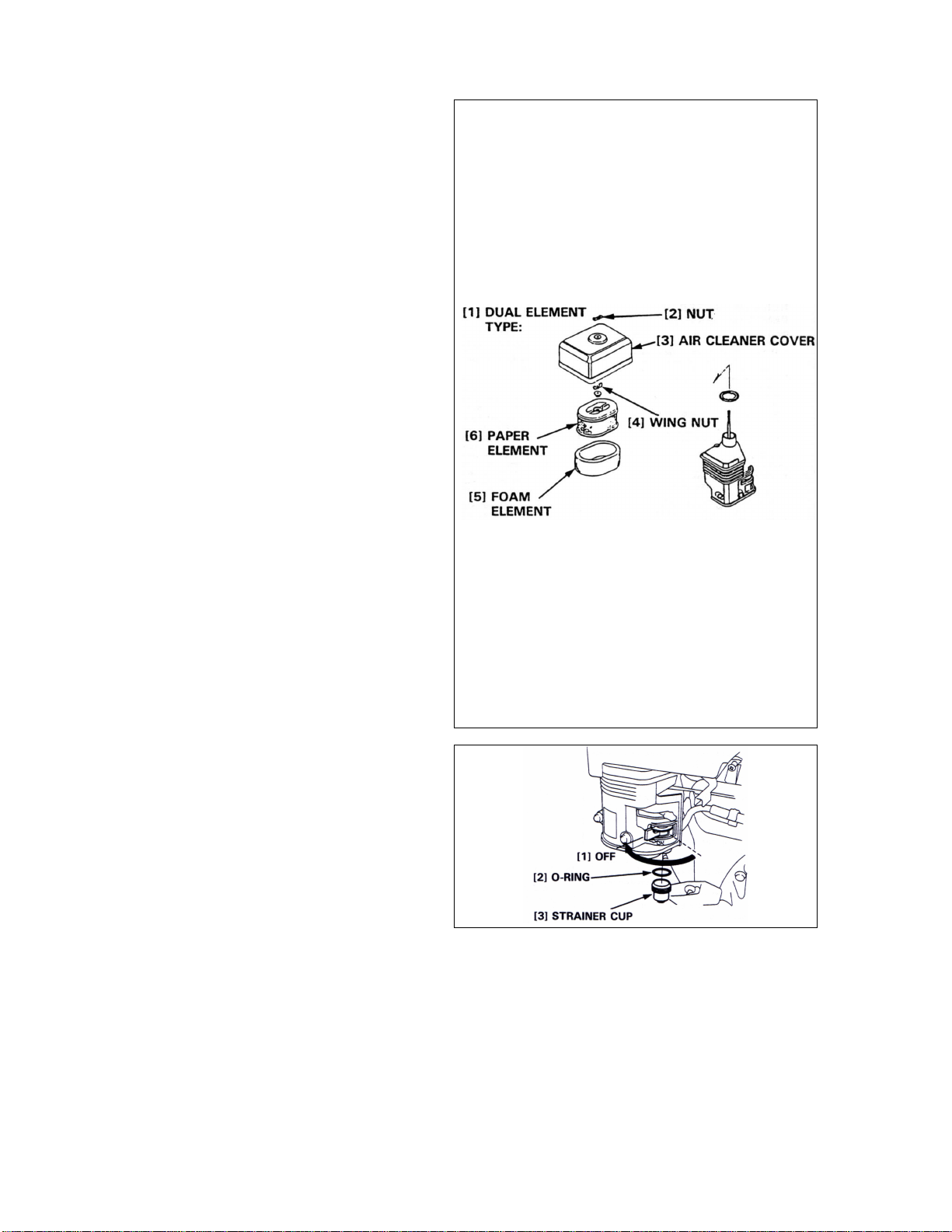

Air cleaner

The Jumbo 651 has a dual type filter.

To service the air cleaner filter, follow

these instructions:

•Remove the nut, air cleaner cover and

wing nut.

•Remove the pre air cleaner elements

and separate them.

•Carefully check both elements for

holes or tears and replace if damaged.

•Paper element: tap element lightly

several times on a hard surface to

remove excess dirt or blow

compressed air lightly through the filter

from the inside out. Never brush the

dirt off; brushing will force dirt into the

fibres.

•Foam element: clean in warm soapy

water, rinse and allow to dry

thoroughly. Dip the element in clean

engine oil and squeeze out all the

excess. The engine will smoke during

initial start-up if too much oil is left in

the foam.

•Shine a light through the elements,

and inspect them carefully. Reinstall

the elements if they are free of holes

and tears.

Fuel strainer cup

To service fuel strainer cup, follow these

instructions:

•Turn off the fuel valve and remove the

strainer cup.

•Clean the strainer cup with solvent.

•Install the O-ring and strainer cup.

•Tighten the strainer cup to 4N.m.

19

Spark plug

To service the spark plug, follow these

instructions:

•Visually inspect the spark plug.

Discard the plug if the insulator is

cracked or chipped.

•Remove carbon or other deposits with

a stiff wire brush.

•Measure the plug gap with a wire-type

feeler gauge. If necessary, adjust the

gap by bending the side electrode.

•Make sure the sealing washer is in

good condition; replace the plug if

necessary.

•Install the plug fingertight to seat the

washer, then tighten with a plug

wrench (an additional ½ turn if a new

plug) to compress the sealing washer.

If you are reusing a plug, tighten 1/8-

1/4 turn after the plug seats.

Fuel line

To service the fuel line, follow these

instructions:

•Drain the fuel into a suitable container,

and remove the fuel tank.

•Disconnect the fuel line, and unscrew

the fuel filter from the tank.

•Clean the filter with solvent, and

check, that the filter screen is

undamaged.

•Place the O-ring on the filter and

reinstall. Tighten the filter to 2N.m.

After reassembly, check for fuel leaks.

Further maintenance

For further maintenance, please contact the nearest engine maintenance centre.

20

7 Faults: causes and cures

7.1 Fault-finding procedures

Should any fault occur during the use of the machine, turn it off.

7.2 Trouble-shooting guide

Trouble Possible source Resolution

Not enough fuel Fill fuel tank

Fuel filter clogged Clean fuel filter

Spark plug faulty Inspect spark plug

Hard starting

Stronger fault Contact nearest engine

maintenance centre

Blade is not turning Belts not tightened or defective Check the belts tension and

change them if needed

Air filter restricted Clean or replace air filterEngine lacks power Stronger fault Contact nearest engine

maintenance centre

Not enough water in the pan Refill the water pan

Water tap is closed Open tap on blade guard

Water supply system is blocked up Clean water supply system

No water on the blade

Water pump is not working •Check if pump pulley is driven

by the belts

•Change the pump

7.3 Customer service

When ordering spare parts, please mention:

•The serial number (7 digits).

•The code of the part.

•The exact denomination.

•The number of parts required.

•The delivery address.

•Please indicate clearly the means of transportation required such as "express" or "by air".

Without specific instructions, we will forward the parts through the means which seem

appropriate to us --- but which is not always the quickest way.

Clear instructions will avoid problems and faulty deliveries. If not sure, please send us the defective

part. In the case of a warranty claim, the part must always be returned for evaluation. Spare parts

for the motor can be ordered with the manufacturer of the motor or with their dealer, which is often

quicker and cheaper.

This machine has been manufactured by Saint-Gobain Abrasives S.A.

190, Bd. J.F. Kennedy

L- 4930 BASCHARAGE

Grand-Duché de Luxembourg.

Tel. : 00352-50401-1

Fax : 00352- 50 16 33

http://www.construction.norton.eu

e-mail: sales.nlx@saint-gobain.com

Table of contents

Other Clipper Saw manuals

Clipper

Clipper GC25E UP User manual

Clipper

Clipper TT 180 BM User manual

Clipper

Clipper BBH455 User manual

Clipper

Clipper C13SPM User manual

Clipper

Clipper CTC701 User manual

Clipper

Clipper C65B User manual

Clipper

Clipper C13E User manual

Clipper

Clipper BBM307 User manual

Clipper

Clipper C1316SS User manual

Clipper

Clipper Jumbo 1000 P13 User manual